Lead Apron Inspection . Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. When to inspect your lead apron? Learn how to inspect lead aprons for cracks and holes. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. Read on to learn exactly when and how to inspect your lead apron. To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process.

from mavig.com

By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Learn how to inspect lead aprons for cracks and holes. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Read on to learn exactly when and how to inspect your lead apron. When to inspect your lead apron? Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods.

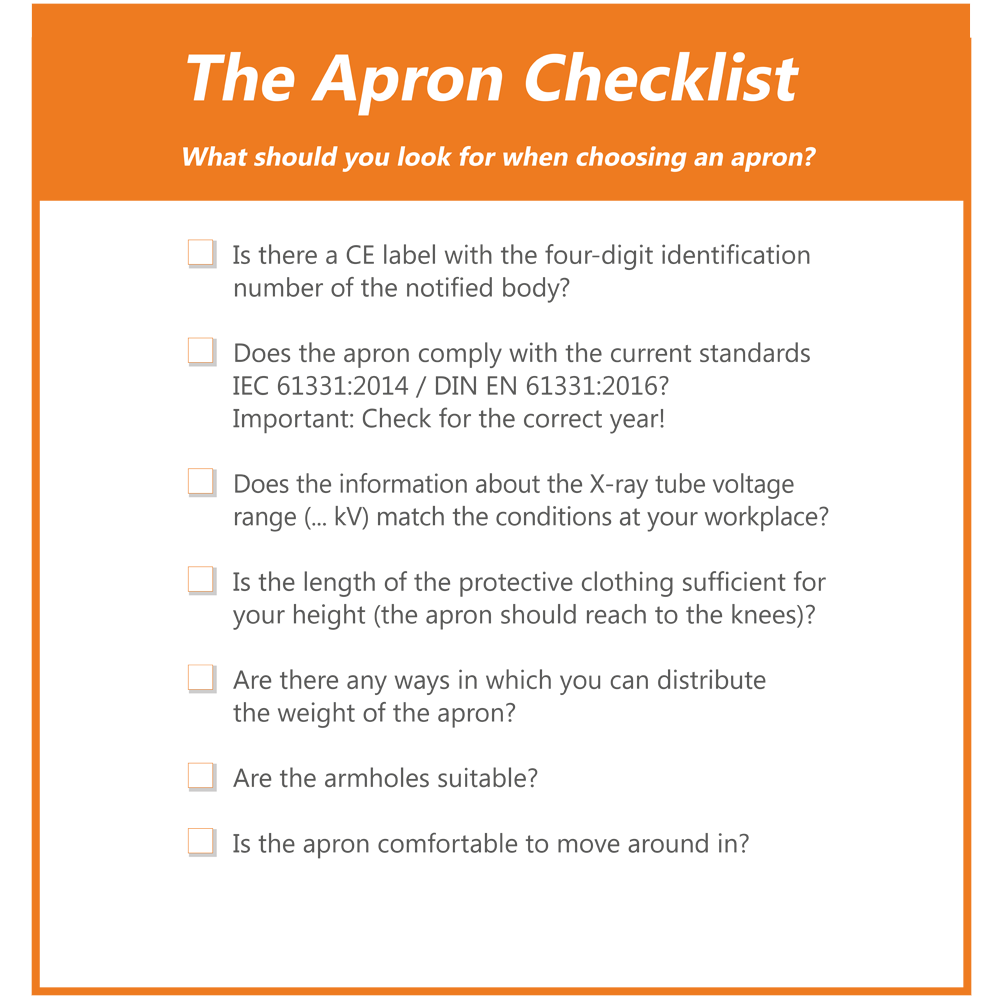

How To Buy An XRay Apron Detailed Explanation & Checklist

Lead Apron Inspection To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. When to inspect your lead apron? By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Read on to learn exactly when and how to inspect your lead apron. Learn how to inspect lead aprons for cracks and holes. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring.

From www.templateroller.com

DHEC Form 3185 Download Printable PDF or Fill Online Walkthrough Lead Apron Inspection When to inspect your lead apron? By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. Regularly implementing a lead apron inspection checklist,. Lead Apron Inspection.

From www.pinterest.com

Radiation free lead aprons Hospital design, Radiation exposure Lead Apron Inspection By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Ensure safety in radiology by. Lead Apron Inspection.

From eljayxray.com

Shielding Dental Tech Apron Eljay XRay, Inc. Lead Apron Inspection When to inspect your lead apron? By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. To ensure that lead aprons provide the. Lead Apron Inspection.

From www.indiamart.com

Radiation protection Lead Apron at Rs 7500/piece Patel Nagar New Lead Apron Inspection When to inspect your lead apron? To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. By following the steps outlined in this guide, you can confidently inspect your lead. Lead Apron Inspection.

From xenashield.blogspot.com

xenashield Efficiency of lead aprons in blocking radiation Lead Apron Inspection To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair. Lead Apron Inspection.

From in.pinterest.com

Inspection and Quality Work Checklist for Concrete Placement lceted Lead Apron Inspection By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Read on to learn exactly when and how to inspect your lead apron. Learn how to inspect lead aprons for cracks and holes. To ensure that. Lead Apron Inspection.

From www.hmpgloballearningnetwork.com

Your Lead is Cracked? Radiation Safety Revisited Lead Apron Inspection By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. Read on to learn exactly when and how to. Lead Apron Inspection.

From www.vumc.org

Annual Inspection of Lead Shielding PPE for Protection from XRays at Lead Apron Inspection For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. By following the steps outlined in this. Lead Apron Inspection.

From nap.nationalacademies.org

Reading Preventive Maintenance at General Aviation Airports Volume 2 Lead Apron Inspection When to inspect your lead apron? For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Learn how to inspect lead aprons for cracks and holes. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. By following the steps outlined in. Lead Apron Inspection.

From www.youtube.com

How to INSPECT Lead APRONS YouTube Lead Apron Inspection To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take. Lead Apron Inspection.

From cashier.mijndomein.nl

Home Inspection Checklist Template Lead Apron Inspection Read on to learn exactly when and how to inspect your lead apron. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Learn how to inspect lead aprons for cracks and holes. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. When to inspect. Lead Apron Inspection.

From petronelearningacademy.com

Lead Apron Testing Lead Apron Inspection To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. When to inspect your lead apron? Read. Lead Apron Inspection.

From www.vrogue.co

Printable Heavy Equipment Daily Inspection Checklist Template Prior To Lead Apron Inspection Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. When to inspect your lead apron? Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. Read on to learn exactly when and how to inspect your lead apron. By following the steps outlined in this guide, you can confidently. Lead Apron Inspection.

From printableformsfree.com

Printable Lead Apron Inspection Form Printable Forms Free Online Lead Apron Inspection Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. By following the steps outlined in this guide, you. Lead Apron Inspection.

From www.etsy.com

Workplace Inspection Schedule Health and Safety Template Excel Template Lead Apron Inspection To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. When to inspect your lead apron? Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is. Lead Apron Inspection.

From www.vumc.org

Annual Inspection of Lead Shielding PPE for Protection from XRays Lead Apron Inspection Learn how to inspect lead aprons for cracks and holes. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. Read on to learn exactly when and how to inspect your lead apron. To ensure that. Lead Apron Inspection.

From www.scribd.com

046 Form Maintenance Check List Rev01 Ok PDF Lead Apron Inspection Learn how to inspect lead aprons for cracks and holes. When to inspect your lead apron? For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to. Lead Apron Inspection.

From www.trivitron.com

How To Inspect Your Lead Radiation Protection Aprons? Lead Apron Inspection When to inspect your lead apron? To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. Read on to learn exactly. Lead Apron Inspection.

From academy.almss.com

Radiation and Laser Safety Document Collection Lead Apron Inspection When to inspect your lead apron? To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Read on to learn exactly when and how to inspect your lead apron. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Learn. Lead Apron Inspection.

From www.aadcomed.com

Lead Apron Racks Shop Lead Apron Storage Online AADCO Medical, Inc. Lead Apron Inspection Read on to learn exactly when and how to inspect your lead apron. Learn how to inspect lead aprons for cracks and holes. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. To ensure that. Lead Apron Inspection.

From mavig.com

How To Buy An XRay Apron Detailed Explanation & Checklist Lead Apron Inspection Learn how to inspect lead aprons for cracks and holes. Read on to learn exactly when and how to inspect your lead apron. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify. Lead Apron Inspection.

From www.attenutech.com

Lead Apron Year Inspection Stickers Attenutech Lead Apron Inspection To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. When to inspect your lead apron? By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Read. Lead Apron Inspection.

From www.jacr.org

Lead Apron Inspection Using Infrared Light A Model Validation Study Lead Apron Inspection Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. Read on to learn exactly when and how to inspect your. Lead Apron Inspection.

From www.kennedyradiology.us

Essential Guide to Lead Apron Inspection for Radiologists and Surgeons Lead Apron Inspection Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Read on to learn exactly when and how to inspect your lead apron. Learn how to inspect lead aprons for cracks and. Lead Apron Inspection.

From www.dochub.com

Lead apron inspection checklist Fill out & sign online DocHub Lead Apron Inspection Read on to learn exactly when and how to inspect your lead apron. When to inspect your lead apron? To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action. Lead Apron Inspection.

From studylib.net

Northern Health Centers, Inc. Inspection Form Instructions Checklist Lead Apron Inspection When to inspect your lead apron? To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. Learn how to inspect lead aprons for cracks and holes. Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic. Lead Apron Inspection.

From www.inpaspages.com

PPE Inspection form Lead Apron Inspection Learn how to inspect lead aprons for cracks and holes. When to inspect your lead apron? To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. By following the steps. Lead Apron Inspection.

From www.alamy.com

Nurse wearing a lead apron in an operating theater, France Stock Photo Lead Apron Inspection Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. When to inspect your lead apron? Read on to learn exactly when and how to inspect your lead apron. To ensure that lead aprons provide the. Lead Apron Inspection.

From burmed.com

How to Inspect Your Lead Apron from Burlington Medical Lead Apron Inspection By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. Read on to learn exactly when and how to inspect your lead apron. For a single apron with a 0.50 lead/lead equivalency, tears of more than. Lead Apron Inspection.

From www.hmpgloballearningnetwork.com

What is the Life Expectancy for Your Lead Apron? Are Your Lab Teams Lead Apron Inspection Regularly implementing a lead apron inspection checklist, including visual, palpation, and radiographic checks, is crucial for ensuring. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. By following the steps outlined in this guide, you. Lead Apron Inspection.

From excel2excel123.blogspot.com

EXCEL TEMPLATES Inspection Template Excel Lead Apron Inspection To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. When to inspect your lead apron? Read on to learn exactly when and how to inspect your lead apron. Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. Learn how to inspect lead aprons for cracks and. Lead Apron Inspection.

From www.aadcomed.com

Lead Apron Racks Shop Lead Apron Storage Online AADCO Medical, Inc. Lead Apron Inspection When to inspect your lead apron? Learn how to inspect lead aprons for cracks and holes. By following the steps outlined in this guide, you can confidently inspect your lead aprons, identify any issues, and take appropriate action to repair or replace them, ultimately ensuring the safety of everyone involved. For a single apron with a 0.50 lead/lead equivalency, tears. Lead Apron Inspection.

From www.researchgate.net

(PDF) Integrity test of lead apron and its effect on personnel and carer Lead Apron Inspection Ensure safety in radiology by following these visual, tactile, and radiographic inspection methods. To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Learn how to inspect lead aprons for cracks and holes. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are. Lead Apron Inspection.

From www.expresscdlpracticetest.com

The Importance of Prior to Trip Inspections Lead Apron Inspection For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Learn how to inspect lead aprons for cracks and holes. When to inspect your lead apron? Ensure safety in radiology. Lead Apron Inspection.

From www.youtube.com

Lead apron testing YouTube Lead Apron Inspection Read on to learn exactly when and how to inspect your lead apron. For a single apron with a 0.50 lead/lead equivalency, tears of more than 5.4 cm in length are cause for rejection. When to inspect your lead apron? To ensure that lead aprons provide the highest level of protection, it’s essential to follow a systematic inspection process. Learn. Lead Apron Inspection.