Safety Factor Heat Exchanger . fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. Fouling fouling factors are based on shell. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. safety factor for fouling, but in a phe, it actually increases the potential for fouling. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical.

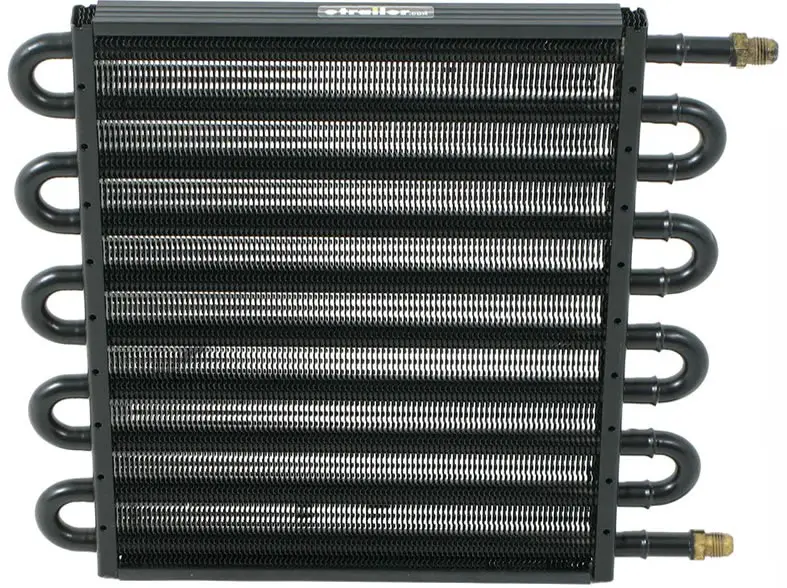

from www.mechanicalbooster.com

Fouling fouling factors are based on shell. safety factor for fouling, but in a phe, it actually increases the potential for fouling. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger.

What is Heat Exchanger? Complete Explanation Mechanical Booster

Safety Factor Heat Exchanger the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. safety factor for fouling, but in a phe, it actually increases the potential for fouling. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. Fouling fouling factors are based on shell. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch.

From idronics.caleffi.com

4 THERMAL CHARACTERISTICS OF HEAT EXCHANGERS Caleffi Idronics Safety Factor Heat Exchanger Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. safety factor for fouling, but in a phe, it actually increases the potential for fouling. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard. Safety Factor Heat Exchanger.

From www.numerade.com

SOLVED subject process safety and loss prevention FIGURE Q3 shows the Safety Factor Heat Exchanger the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. to introduce and apply basic heat exchanger design concepts to the solution of. Safety Factor Heat Exchanger.

From www.youtube.com

Introduction to Heat Exchanger Network Design Pinch Analysis Safety Factor Heat Exchanger to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. Fouling fouling factors are based on shell. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. the colburn method is based on a correlation of industrial data for a. Safety Factor Heat Exchanger.

From www.youtube.com

Fouling Factor in Heat Exchanger YouTube Safety Factor Heat Exchanger Fouling fouling factors are based on shell. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. this design guideline covers the selection,. Safety Factor Heat Exchanger.

From www.youtube.com

Fouling Factor Heat Exchanger Heat Transfer YouTube Safety Factor Heat Exchanger to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. safety factor for fouling, but in a phe, it actually increases the potential for fouling. this design guideline covers. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Heat Exchanger Design PowerPoint Presentation, free download ID Safety Factor Heat Exchanger the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. the purpose of this article was to discuss the existing methods to cope. Safety Factor Heat Exchanger.

From www.researchgate.net

Fig. LMTD correction factor for heat exchanger, with one shell pass and Safety Factor Heat Exchanger Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. safety factor for fouling, but in a phe, it actually increases the potential for fouling. fouling. Safety Factor Heat Exchanger.

From www.alaquainc.com

Safety Considerations While Cleaning Heat Exchanger Safety Factor Heat Exchanger fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. Fouling fouling factors are based on shell. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Chapter 3.2 Heat Exchanger Analysis Using NTU method Safety Factor Heat Exchanger the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. Fouling fouling factors are based on shell. safety factor for fouling, but in. Safety Factor Heat Exchanger.

From www.mechanicalbooster.com

What is Heat Exchanger? Complete Explanation Mechanical Booster Safety Factor Heat Exchanger Fouling fouling factors are based on shell. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. safety factor for fouling, but in a phe, it actually increases the potential for. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Heat Exchangers PowerPoint Presentation, free download ID4204370 Safety Factor Heat Exchanger Fouling fouling factors are based on shell. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to. Safety Factor Heat Exchanger.

From www.researchgate.net

Heat exchanger simulation SSStatic AnalysisFactor of safety1 Safety Factor Heat Exchanger fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. Fouling fouling factors are based on shell. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. this design guideline covers the selection, sizing methods and troubleshooting. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Heat Exchanger Design PowerPoint Presentation, free download ID Safety Factor Heat Exchanger safety factor for fouling, but in a phe, it actually increases the potential for fouling. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. the colburn. Safety Factor Heat Exchanger.

From www.researchgate.net

(a) Simplified flow schematic of platefin heat exchanger and example Safety Factor Heat Exchanger fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. safety factor for fouling, but in a phe, it actually increases the potential for fouling. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. this. Safety Factor Heat Exchanger.

From www.nuclear-power.com

Heat Exchanger Analysis Performance Calculation Safety Factor Heat Exchanger safety factor for fouling, but in a phe, it actually increases the potential for fouling. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in. Safety Factor Heat Exchanger.

From www.slideshare.net

Thermodynamics Chapter 3 Heat Transfer Safety Factor Heat Exchanger fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. Fouling fouling factors are based on shell. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. to introduce and apply basic heat exchanger design concepts to the solution of industrial. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Chapter 3.2 Heat Exchanger Analysis Using NTU method Safety Factor Heat Exchanger this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe. Safety Factor Heat Exchanger.

From www.youtube.com

Analysis Of Heat Exchanger By Lmtd Method Cross Flow Heat Exchanger Safety Factor Heat Exchanger to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. . Safety Factor Heat Exchanger.

From www.youtube.com

Heat Exchanger Analysis YouTube Safety Factor Heat Exchanger safety factor for fouling, but in a phe, it actually increases the potential for fouling. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. the. Safety Factor Heat Exchanger.

From www.youtube.com

Correction factor concept of heat exchanger and its significance Safety Factor Heat Exchanger this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. Fouling fouling factors are based on shell. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT HEAT EXCHANGERS PowerPoint Presentation, free download ID1905891 Safety Factor Heat Exchanger the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. safety factor for fouling, but in a phe, it actually increases the potential for fouling. the. Safety Factor Heat Exchanger.

From www.youtube.com

ANSYS Training Shell and Tube Heat Exchangers Thermal Analysis Safety Factor Heat Exchanger this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. safety factor for fouling, but in a phe, it actually increases the potential for fouling. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. the purpose of this article was. Safety Factor Heat Exchanger.

From chempedia.info

Heat exchangers correction factor Big Chemical Encyclopedia Safety Factor Heat Exchanger Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. safety factor for fouling, but in a phe, it actually increases the potential for fouling. to introduce and apply basic. Safety Factor Heat Exchanger.

From idronics.caleffi.com

4 THERMAL CHARACTERISTICS OF HEAT EXCHANGERS Caleffi Idronics Safety Factor Heat Exchanger fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using. Safety Factor Heat Exchanger.

From liliequipment.en.made-in-china.com

Multifunctional and High Safety Mixing Heat Exchanger China Heat Safety Factor Heat Exchanger Fouling fouling factors are based on shell. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. safety factor for fouling, but in a phe, it actually increases the potential for. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Chapter 3.2 Heat Exchanger Analysis Using NTU method Safety Factor Heat Exchanger safety factor for fouling, but in a phe, it actually increases the potential for fouling. Fouling fouling factors are based on shell. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in. Safety Factor Heat Exchanger.

From www.youtube.com

Types of Heat Exchanger YouTube Safety Factor Heat Exchanger Fouling fouling factors are based on shell. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used. Safety Factor Heat Exchanger.

From www.semanticscholar.org

Table 1 from Heat exchanger fouling model and preventive maintenance Safety Factor Heat Exchanger fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. . Safety Factor Heat Exchanger.

From slidetodoc.com

PDT 202 HEAT TRANSFER CHAPTER 7 HEAT EXCHANGERS Safety Factor Heat Exchanger the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. safety factor for fouling, but in a phe, it actually increases the potential for fouling. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Heat Exchangers PowerPoint Presentation, free download ID4204370 Safety Factor Heat Exchanger the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. this design guideline. Safety Factor Heat Exchanger.

From www.nuclear-power.com

Heat Exchanger Analysis Performance Calculation Safety Factor Heat Exchanger Fouling fouling factors are based on shell. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. safety factor for fouling, but in a phe, it actually increases the potential for fouling. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat. Safety Factor Heat Exchanger.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Safety Factor Heat Exchanger the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe. Safety Factor Heat Exchanger.

From www.slideserve.com

PPT Heat Exchanger Design PowerPoint Presentation, free download ID Safety Factor Heat Exchanger Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. this design guideline covers the selection, sizing methods and troubleshooting for heat exchangers which are commonly used in typical. the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and. Safety Factor Heat Exchanger.

From www.youtube.com

Correction Factor Heat Exchanger Basics explained Heat Transfer Safety Factor Heat Exchanger the purpose of this article was to discuss the existing methods to cope with uncertainty in shell and tube heat. to introduce and apply basic heat exchanger design concepts to the solution of industrial heat exchanger problems. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger.. Safety Factor Heat Exchanger.

From www.europages.co.uk

safety heat exchanger products Safety Factor Heat Exchanger Fouling fouling factors are based on shell. the colburn method is based on a correlation of industrial data for a wide range of fluids in heat exchangers using standard tube pitch. fouling resistances are selected from independent sources such as the tema standards [2007], plant data, company. to introduce and apply basic heat exchanger design concepts to. Safety Factor Heat Exchanger.