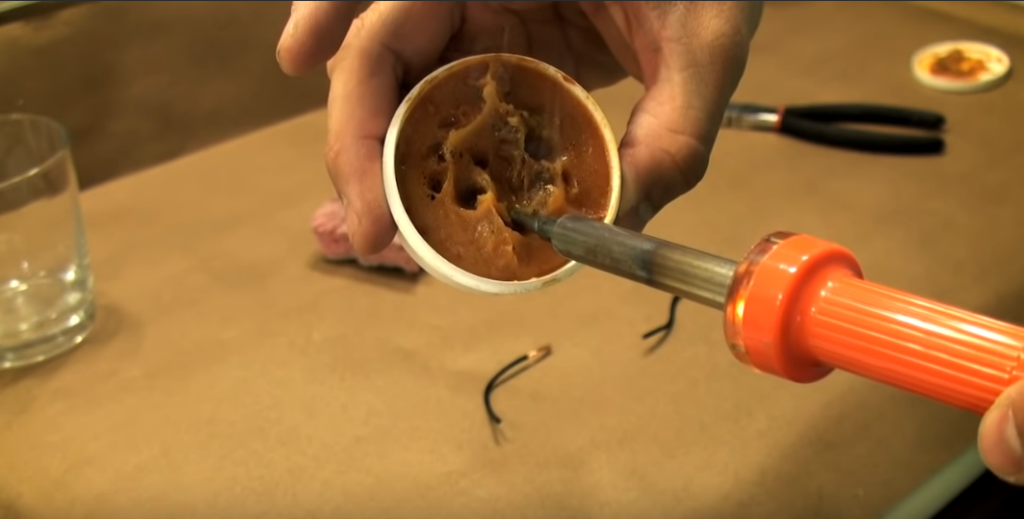

Soldering Flux Picture . Be cautious not to melt the solder too much, as you can When soldering, just remember to apply the flux directly to the soldered area; Its primary purpose is to remove oxidation,. Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. This article investigates types of flux commonly used in electronics. We all know that flux is critical to quality solder joints. Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Flux is a crucial ingredient in successfully soldering electronic components to a pcb.

from solderingironguide.com

Its primary purpose is to remove oxidation,. Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. This article investigates types of flux commonly used in electronics. But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. When soldering, just remember to apply the flux directly to the soldered area; Be cautious not to melt the solder too much, as you can In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world.

How to Use Flux When Soldering Electronics For Beginners

Soldering Flux Picture But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? Its primary purpose is to remove oxidation,. When soldering, just remember to apply the flux directly to the soldered area; Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Be cautious not to melt the solder too much, as you can But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. This article investigates types of flux commonly used in electronics. We all know that flux is critical to quality solder joints.

From www.amazon.in

Stainless Steel Soldering flux 20mL Amazon.in Home Improvement Soldering Flux Picture Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Be cautious not to melt the solder too much, as you can Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. When soldering, just remember to apply the flux directly to the soldered area; But what. Soldering Flux Picture.

From www.aliexpress.com

Kss S800 10cc Solder Paste Flux Soldering Paste Solder Paste Flux For Soldering Flux Picture This article investigates types of flux commonly used in electronics. Its primary purpose is to remove oxidation,. We all know that flux is critical to quality solder joints. Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Be cautious not to melt the solder too much, as you can In solder pastes, flux plays. Soldering Flux Picture.

From

Soldering Flux Picture But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? Flux is a crucial ingredient in successfully soldering electronic components to a pcb. This article investigates types of flux commonly used in electronics. Its primary purpose is to remove oxidation,. When soldering, just remember to apply the. Soldering Flux Picture.

From www.youtube.com

What Is Flux? Soldering YouTube Soldering Flux Picture When soldering, just remember to apply the flux directly to the soldered area; This article investigates types of flux commonly used in electronics. Be cautious not to melt the solder too much, as you can Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. But what exactly is flux and why. Soldering Flux Picture.

From

Soldering Flux Picture We all know that flux is critical to quality solder joints. When soldering, just remember to apply the flux directly to the soldered area; Be cautious not to melt the solder too much, as you can This article investigates types of flux commonly used in electronics. Soldering flux is a chemical compound that is applied to the metal surfaces before. Soldering Flux Picture.

From alexnld.com

KSS S800 10CC Solder Paste Flux Soldering Paste with Needle for Soldering Flux Picture In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Its primary purpose is to remove oxidation,. Be cautious not to melt the solder too much, as you can Flux is a chemical. Soldering Flux Picture.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners Soldering Flux Picture Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. When soldering, just remember to apply the flux directly to the soldered area; This article investigates types of flux commonly used. Soldering Flux Picture.

From

Soldering Flux Picture When soldering, just remember to apply the flux directly to the soldered area; In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Soldering flux is a chemical compound that is applied to the metal. Soldering Flux Picture.

From

Soldering Flux Picture Be cautious not to melt the solder too much, as you can Its primary purpose is to remove oxidation,. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung. Soldering Flux Picture.

From

Soldering Flux Picture We all know that flux is critical to quality solder joints. Be cautious not to melt the solder too much, as you can Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Its primary purpose is to remove oxidation,. Soldering flux is a chemical compound that is applied to the metal. Soldering Flux Picture.

From www.aliexpress.com

400g 60/40 Tin lead Solder Flux Wire Rosin Core Soldering Roll, 0.5Mm Soldering Flux Picture This article investigates types of flux commonly used in electronics. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. When soldering, just remember to apply the flux directly to the soldered area; Its primary purpose is to remove oxidation,. Be cautious not to melt the solder too. Soldering Flux Picture.

From www.grainger.com

LACO, 16 oz, Jar, Soldering Flux 31ME5722407 Grainger Soldering Flux Picture This article investigates types of flux commonly used in electronics. Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? Once it’s in place, you can then use the soldering iron to. Soldering Flux Picture.

From

Soldering Flux Picture When soldering, just remember to apply the flux directly to the soldered area; Be cautious not to melt the solder too much, as you can This article investigates types of flux commonly used in electronics. We all know that flux is critical to quality solder joints. But what exactly is flux and why do solder manufacturers go to the trouble. Soldering Flux Picture.

From

Soldering Flux Picture Flux is a crucial ingredient in successfully soldering electronic components to a pcb. When soldering, just remember to apply the flux directly to the soldered area; Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. This article investigates types of flux commonly used in electronics.. Soldering Flux Picture.

From

Soldering Flux Picture When soldering, just remember to apply the flux directly to the soldered area; Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. In solder pastes, flux plays a vital role. Soldering Flux Picture.

From

Soldering Flux Picture Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. We all know that flux is critical to quality solder joints. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Once it’s in place, you can then use the soldering iron to. Soldering Flux Picture.

From www.conro.com

What is soldering flux? ConRo Electronics Soldering Flux Picture We all know that flux is critical to quality solder joints. But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. In solder pastes, flux plays a vital role in ensuring strong,. Soldering Flux Picture.

From www.tilgear.info

LACO Soldering Flux 125g Flux Soldering Consumables Tilgear Soldering Flux Picture Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. This article investigates types of flux commonly used in electronics. When soldering, just remember to apply the flux directly to the soldered area; Be cautious not to. Soldering Flux Picture.

From

Soldering Flux Picture Be cautious not to melt the solder too much, as you can Its primary purpose is to remove oxidation,. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. This article. Soldering Flux Picture.

From

Soldering Flux Picture In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Its primary purpose is to remove oxidation,. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. This article investigates types of flux commonly. Soldering Flux Picture.

From

Soldering Flux Picture When soldering, just remember to apply the flux directly to the soldered area; Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Its primary purpose is to remove oxidation,. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Flux is a chemical compound that helps prepare the. Soldering Flux Picture.

From

Soldering Flux Picture This article investigates types of flux commonly used in electronics. When soldering, just remember to apply the flux directly to the soldered area; Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow. Soldering Flux Picture.

From

Soldering Flux Picture When soldering, just remember to apply the flux directly to the soldered area; Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. We all know that flux is critical to quality solder joints. But what exactly is flux and why do solder manufacturers go to. Soldering Flux Picture.

From

Soldering Flux Picture But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? This article investigates types of flux commonly used in electronics. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. Soldering flux is. Soldering Flux Picture.

From

Soldering Flux Picture Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Its primary purpose is to. Soldering Flux Picture.

From

Soldering Flux Picture This article investigates types of flux commonly used in electronics. When soldering, just remember to apply the flux directly to the soldered area; Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Its primary purpose is to remove oxidation,. Once it’s. Soldering Flux Picture.

From www.desertcart.ae

2 Jar Solder Flux, Flux for Soldering, Rosin Soldering Flux Paste for Soldering Flux Picture Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Once it’s in place, you can then use the soldering iron to melt the. Soldering Flux Picture.

From www.lowes.com

Soldering Flux at Soldering Flux Picture We all know that flux is critical to quality solder joints. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Be cautious not to melt the solder too much, as you can Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing. Soldering Flux Picture.

From

Soldering Flux Picture We all know that flux is critical to quality solder joints. This article investigates types of flux commonly used in electronics. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Be cautious not to melt the solder too much, as you can When soldering, just remember to apply the flux directly to the soldered area; In. Soldering Flux Picture.

From

Soldering Flux Picture When soldering, just remember to apply the flux directly to the soldered area; Flux is a crucial ingredient in successfully soldering electronic components to a pcb. This article investigates types of flux commonly used in electronics. Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Soldering flux is a chemical compound. Soldering Flux Picture.

From

Soldering Flux Picture But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Once it’s in place, you can then use the soldering iron to melt the solder. Soldering Flux Picture.

From

Soldering Flux Picture Flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of solder. We all know that flux is critical to quality solder joints. In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. Once it’s in. Soldering Flux Picture.

From

Soldering Flux Picture Be cautious not to melt the solder too much, as you can In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world. But what exactly is flux and why do solder manufacturers go to the trouble of stuffing it into the core of solder wire? Flux is a. Soldering Flux Picture.

From www.electronicsandyou.com

What is Solder Flux How to Use Flux in Soldering Soldering Flux Picture Be cautious not to melt the solder too much, as you can Flux is a crucial ingredient in successfully soldering electronic components to a pcb. When soldering, just remember to apply the flux directly to the soldered area; In solder pastes, flux plays a vital role in ensuring strong, reliable joints, making it the unsung hero of the soldering world.. Soldering Flux Picture.

From

Soldering Flux Picture Its primary purpose is to remove oxidation,. Once it’s in place, you can then use the soldering iron to melt the solder onto the surface. Flux is a crucial ingredient in successfully soldering electronic components to a pcb. Soldering flux is a chemical compound that is applied to the metal surfaces before soldering. This article investigates types of flux commonly. Soldering Flux Picture.