Braze Material Temperature . Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Flux is completely clear and active, looks like water. Test the temperature by touching brazing filler metal to base metal. Bright metal surface is visible underneath.

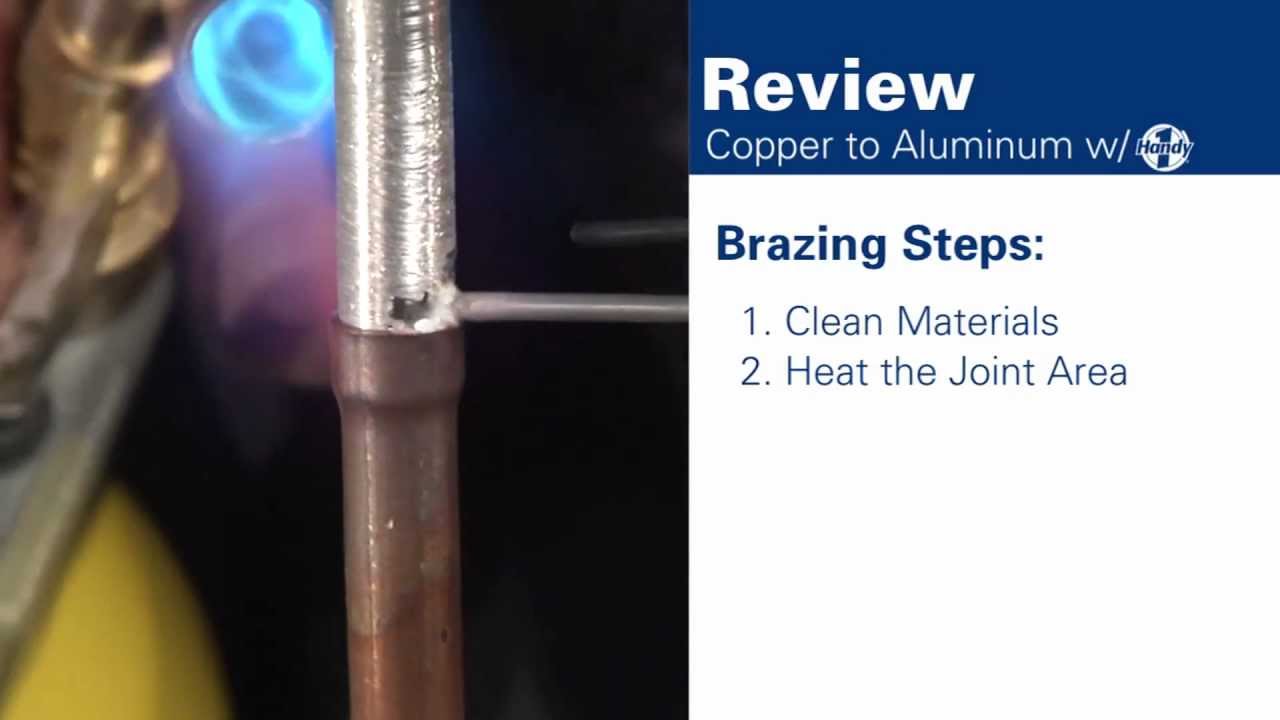

from www.youtube.com

Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. Bright metal surface is visible underneath. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals.

How to Braze Aluminum to Copper YouTube

Braze Material Temperature Flux is completely clear and active, looks like water. Bright metal surface is visible underneath. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Flux is completely clear and active, looks like water. Test the temperature by touching brazing filler metal to base metal.

From www.researchgate.net

Schematic view of the brazing assembly appropriate to the tensile Braze Material Temperature Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. 33 rows brazing differs from. Braze Material Temperature.

From www.youtube.com

Fundamentals of Brazing 5 Brazing the Assembly YouTube Braze Material Temperature 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing. Braze Material Temperature.

From www.aluminium-brazing.com

Fixture for braze assembly during brazing Aluminium Brazing Braze Material Temperature Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. Bright metal surface is visible underneath. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Braze Material Temperature.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Bright metal surface is visible underneath. Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Braze Material Temperature.

From www.slideserve.com

PPT Soldering, Brazing and Braze Welding PowerPoint Presentation Braze Material Temperature Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Test the temperature by touching brazing filler metal to base metal. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Bright metal surface is visible underneath. Flux is completely clear and active, looks like. Braze Material Temperature.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Braze Material Temperature Bright metal surface is visible underneath. Test the temperature by touching brazing filler metal to base metal. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Flux is completely clear and active, looks. Braze Material Temperature.

From 4handbook.blogspot.com

4Handbook Brazing Handbook Copper alloys for CuproBraze Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Test the temperature by touching brazing. Braze Material Temperature.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy Braze Material Temperature Test the temperature by touching brazing filler metal to base metal. Bright metal surface is visible underneath. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Flux is completely clear and active, looks like. Braze Material Temperature.

From www.mdpi.com

Materials Free FullText Characterization of SiC Ceramic Joints Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Bright metal surface is. Braze Material Temperature.

From www.researchgate.net

Nitrogen contents in the braze metal and in the base material as a Braze Material Temperature Flux is completely clear and active, looks like water. Bright metal surface is visible underneath. Test the temperature by touching brazing filler metal to base metal. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is typically performed at temperatures above 450°c but below the melting point of the. Braze Material Temperature.

From youtube.com

Joining Brass to Copper with Braze™ YouTube Braze Material Temperature 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Flux is completely clear and active, looks like water. Test the temperature by touching brazing filler metal to base metal. Brazing is a group. Braze Material Temperature.

From blog.thepipingmart.com

How to Braze Mild Steel A Complete Guide Braze Material Temperature Test the temperature by touching brazing filler metal to base metal. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Bright metal surface is visible underneath. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Flux is completely clear and active, looks. Braze Material Temperature.

From www.bernzomatic.com

Bernzomatic How To Braze Metal Together Brazing Metal Braze Material Temperature Flux is completely clear and active, looks like water. Bright metal surface is visible underneath. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing filler metal to base. Braze Material Temperature.

From heater.heat-tech.biz

About Brazing HEATTECH Braze Material Temperature Flux is completely clear and active, looks like water. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group of welding processes which produces coalescence of materials by heating to. Braze Material Temperature.

From eureka.patsnap.com

Ironbased braze filler metal for hightemperature applications Braze Material Temperature Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Test the temperature by touching brazing filler metal to base metal. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. 33 rows brazing differs from soldering through the use of a higher temperature and. Braze Material Temperature.

From www.researchgate.net

6 Filler metals for brazing titaniumbase alloys Download Table Braze Material Temperature Bright metal surface is visible underneath. Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. 33 rows brazing differs from soldering through the use of a higher temperature and much more. Braze Material Temperature.

From www.globalspec.com

Braze and Brazing Alloys Selection Guide Types, Features, Applications Braze Material Temperature Bright metal surface is visible underneath. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Test the temperature by touching brazing filler metal to base metal. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures. Braze Material Temperature.

From www.slideserve.com

PPT Mechanical Fastening Processes Brazing PowerPoint Presentation Braze Material Temperature Bright metal surface is visible underneath. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like. Braze Material Temperature.

From vacaero.com

Partial Pressure Brazing Braze Material Temperature Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Flux is completely clear and active, looks like water. Test the temperature by touching brazing filler metal to base metal. 33 rows brazing differs from. Braze Material Temperature.

From ultraflexpower.com

brazing silver to copper Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Bright metal surface is visible. Braze Material Temperature.

From www.homeplumbing.com

Braze Process How Does Brazing Work HomePlumbing Braze Material Temperature 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Flux is completely clear and active, looks like water. Bright metal surface is visible underneath. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c. Braze Material Temperature.

From www.globalspec.com

Braze and Brazing Alloys Information Engineering360 Braze Material Temperature Test the temperature by touching brazing filler metal to base metal. Bright metal surface is visible underneath. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Flux is completely clear and active,. Braze Material Temperature.

From www.scribd.com

HighTemperature Braze Applications Ready To Meet Your Needs PDF Braze Material Temperature 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Test the temperature by touching brazing filler metal to base metal. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Bright metal surface is visible underneath. Flux is completely clear and active, looks. Braze Material Temperature.

From www.youtube.com

Brazing 101 How to Braze Copper to Copper Using Silver Solder YouTube Braze Material Temperature Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Bright metal surface is visible underneath. Flux is completely clear and active, looks like water. Brazing is typically performed at temperatures above 450°c. Braze Material Temperature.

From www.slideserve.com

PPT Joining Processes Welding, Brazing, Soldering Brazing and Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Bright metal surface is visible underneath. Flux is completely clear and active, looks like water. Test the temperature by touching brazing filler metal to base metal. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Braze Material Temperature.

From informacionpublica.svet.gob.gt

How To Braze Copper Welding Headquarters Braze Material Temperature Bright metal surface is visible underneath. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Test the temperature by touching brazing filler metal to base metal. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group of welding processes. Braze Material Temperature.

From blog.thepipingmart.com

Brazing vs Silver Soldering What's the Difference Braze Material Temperature Test the temperature by touching brazing filler metal to base metal. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Flux is completely clear and active, looks like water. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group. Braze Material Temperature.

From maque832.blogspot.com

List 15 Difference Between Welding Soldering And Brazing Braze Material Temperature Flux is completely clear and active, looks like water. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing filler metal to base metal. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is a group. Braze Material Temperature.

From www.youtube.com

How to Braze Aluminum to Copper YouTube Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Flux is completely clear and active, looks like water. Bright metal surface is visible underneath. Test the temperature by touching brazing filler metal to base. Braze Material Temperature.

From www.alibaba.com

Nickel Based Solder Metal Superalloys Melting Temperature Material Bni Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Flux is completely clear and active, looks like water. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is a group of welding processes which produces coalescence of materials by heating to. Braze Material Temperature.

From studylib.net

DSMB0009.2 Amdry 105 High Temperature Braze Filler Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Test the temperature by touching brazing filler metal to base metal. 33 rows brazing differs from soldering through the use of a higher temperature and. Braze Material Temperature.

From www.researchgate.net

Cooling profile of braze material measured by IRT from the bottom of Braze Material Temperature Bright metal surface is visible underneath. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing filler metal to base metal. 33 rows brazing differs from soldering through the. Braze Material Temperature.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Braze Material Temperature Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Test the temperature by touching brazing filler metal to base metal. Flux is completely clear and active, looks like water. Brazing is a group. Braze Material Temperature.

From www.google.com

WO2003045619A1 Alloy composition and method for low temperature Braze Material Temperature 33 rows brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable temperature. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Test the temperature by touching brazing. Braze Material Temperature.

From www.diydoctor.org.uk

Brazing a Joint Using a Blow Torch and How to use a Brazing Rod DIY Braze Material Temperature Flux is completely clear and active, looks like water. Brazing is typically performed at temperatures above 450°c but below the melting point of the base metals. Bright metal surface is visible underneath. Test the temperature by touching brazing filler metal to base metal. Brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Braze Material Temperature.