Dial Indicator For Rear End . See schematics, examples, and patterns for different gear tooth surfaces. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Timken bearing adjustment dial indicators stronger value: Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify wheel end play after. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio.

from www.ianpaterson.org

See schematics, examples, and patterns for different gear tooth surfaces. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Timken bearing adjustment dial indicators stronger value: Easily and accurately verify wheel end play after. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure.

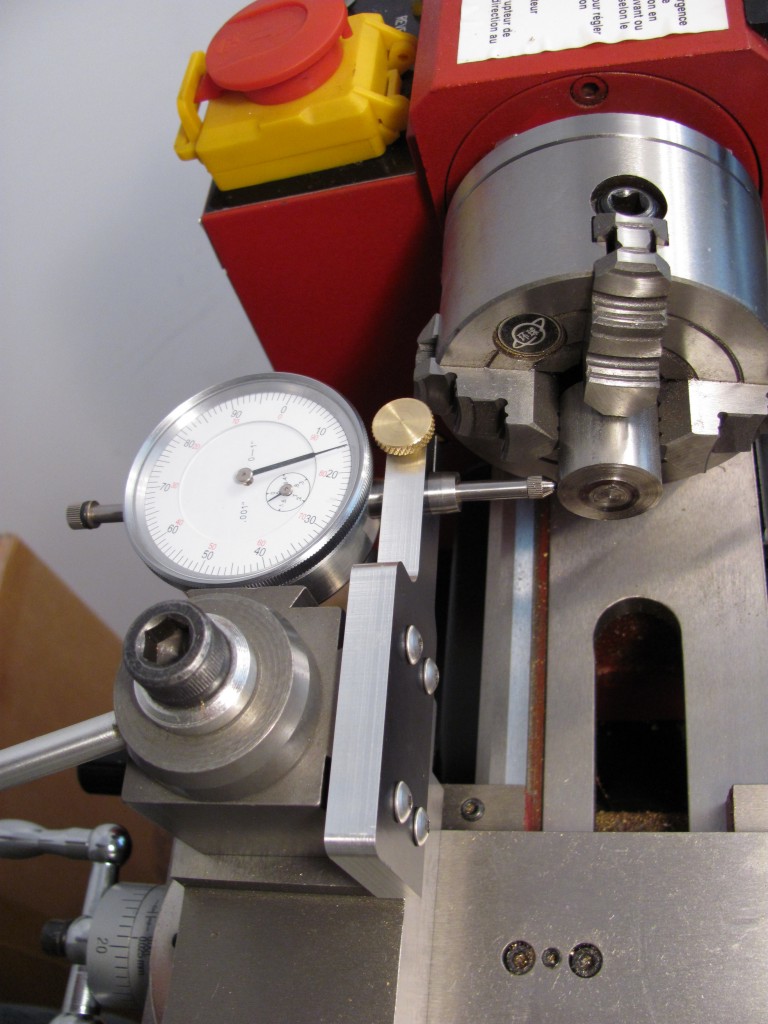

Dial Indicator Holder for Mini Lathe Quick Change Toolpost

Dial Indicator For Rear End Easily and accurately verify wheel end play after. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. See schematics, examples, and patterns for different gear tooth surfaces. Easily and accurately verify wheel end play after. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Timken bearing adjustment dial indicators stronger value: Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators.

From monacotool.com

Dial Indicator Monaco Tool, Inc. Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. See schematics, examples, and. Dial Indicator For Rear End.

From www.indiamart.com

Stainless Steel Analog Mitutoyo 2046S Dial Indicator, For Measurement Dial Indicator For Rear End They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Timken bearing adjustment dial indicators stronger value: Learn how. Dial Indicator For Rear End.

From www.used.forsale

Starrett Dial Indicator for sale Only 4 left at 70 Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Timken bearing adjustment dial indicators stronger. Dial Indicator For Rear End.

From www.grainger.com

INSIZE Back Plunger Dial Indicator, Range 0 in to 0.2 in, Back Type Dial Indicator For Rear End Using a magnetic base, mount the dial indicator on the spindle end, making sure the. See schematics, examples, and patterns for different gear tooth surfaces. Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component. Dial Indicator For Rear End.

From www.leevalley.com

Dial Indicator Lee Valley Tools Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Timken bearing adjustment dial indicators stronger value: Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. They're also used to measure distances and to check flat surfaces like. Dial Indicator For Rear End.

From www.penntoolco.com

Precise Metric Dial Indicator with Range 020mm DCI008 Penn Tool Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify wheel end play after. Using a magnetic base, mount the dial indicator on the spindle end, making. Dial Indicator For Rear End.

From pixshark.com

Dial Indicator Images Galleries With A Bite! Dial Indicator For Rear End Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Use a dial indicator to. Dial Indicator For Rear End.

From www.amazon.com.au

Anytime Tools COAX Coaxial Centering Indicator Milling Machine Dial Indicator For Rear End They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. See schematics, examples, and patterns for different gear tooth surfaces. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Use a dial indicator to check ring gear backlash in a. Dial Indicator For Rear End.

From www.ianpaterson.org

Dial Indicator Holder for Mini Lathe Quick Change Toolpost Dial Indicator For Rear End Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Easily and accurately verify wheel end play after. Timken bearing adjustment dial indicators stronger value: Using a magnetic base, mount the. Dial Indicator For Rear End.

From tillescenter.org

Indicator Back Dial Indicator Flat tillescenter Test, Measure & Inspect Dial Indicator For Rear End Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. See schematics, examples, and. Dial Indicator For Rear End.

From www.sborse.com

Federal Dial Indicator Model 12I Dial Indicator For Rear End Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. See schematics, examples, and patterns for different. Dial Indicator For Rear End.

From hupshenghardware.com

Insize 230950 Dial Indicator, Range 50mm, 0.01mm, Accuracy 40μm Dial Indicator For Rear End Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. See schematics, examples, and patterns for different gear tooth surfaces. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Timken bearing adjustment dial indicators stronger value: They're also. Dial Indicator For Rear End.

From www.rawze.com

Hub bearing adjustment w/dial indicator Dial Indicator For Rear End Timken bearing adjustment dial indicators stronger value: Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential. Dial Indicator For Rear End.

From eastcoastgearsupply.com

DIAL INDICATOR BASE DIFFERENTIAL, REAREND TOOL Dial Indicator For Rear End Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Timken bearing adjustment dial indicators stronger value: Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a. Dial Indicator For Rear End.

From www.ianpaterson.org

Dial Indicator Holder for Mini Lathe Quick Change Toolpost Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Timken bearing adjustment dial indicators stronger value: Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims. Dial Indicator For Rear End.

From thetoolsfactory.com

Dial Indicator thetoolsfactory Dial Indicator For Rear End Easily and accurately verify wheel end play after. Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. They're also used to measure distances and to check flat surfaces like the engine's flywheel for. Dial Indicator For Rear End.

From www.ebay.ie

50/100mm DTI Indicator Probe/ Metric Dial Indicator for Height Depth Dial Indicator For Rear End Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Learn how to use a pinion depth. Dial Indicator For Rear End.

From www.amazon.com

Test Equipment, Accurate Precision Dial Indicator Dial Indicator Gauge Dial Indicator For Rear End They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify wheel end play after. Timken bearing adjustment dial indicators stronger value: Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Our dial indicator assembly kit allows. Dial Indicator For Rear End.

From www.randysworldwide.com

How To Use A Dial Indicator RANDYS Worldwide Dial Indicator For Rear End Timken bearing adjustment dial indicators stronger value: They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. See schematics,. Dial Indicator For Rear End.

From knowhow.napaonline.com

How To Rebuild A GM 8.5” 10Bolt Rear Differential Dial Indicator For Rear End Timken bearing adjustment dial indicators stronger value: Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators.. Dial Indicator For Rear End.

From www.chronos.ltd.uk

Metric Dial Test Indicator with Adjustable Holder SORRY OUT OF STOCK Dial Indicator For Rear End Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Timken bearing adjustment dial indicators stronger value: Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set.. Dial Indicator For Rear End.

From testequipmentusa.com

Starrett 25431J WCSC DIAL INDICATOR WITH CASE STEM CAP 0 .500 Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. See schematics, examples, and patterns for different gear tooth surfaces. Timken bearing adjustment dial indicators stronger value: They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify. Dial Indicator For Rear End.

From www.mbauction.com

Snap On Rear End Dial Indicator Musser Bros. Inc. Dial Indicator For Rear End Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Timken bearing adjustment dial indicators stronger value: Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear. Dial Indicator For Rear End.

From eastcoastgearsupply.com

DIAL INDICATOR BASE DIFFERENTIAL, REAREND TOOL Dial Indicator For Rear End Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify wheel end play after. Timken bearing adjustment dial indicators stronger value: Learn how to adjust backlash, pinion depth, and carrier bearing preload. Dial Indicator For Rear End.

From www.amstedseals.com

Dial Indicators Amsted Seals Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Easily and accurately verify wheel end. Dial Indicator For Rear End.

From www.printables.com

CenTech (Harbor Freight) Dial Indicator Flat Rear Cover by Maxim7745 Dial Indicator For Rear End Timken bearing adjustment dial indicators stronger value: Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Learn how to adjust backlash, pinion depth, and carrier bearing preload in. Dial Indicator For Rear End.

From www.amazon.com

Dial Indicator with Base Holder, Dial Indicator Set with Point Dial Indicator For Rear End Easily and accurately verify wheel end play after. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Timken bearing adjustment dial indicators stronger value: Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Using a magnetic base, mount the dial indicator on. Dial Indicator For Rear End.

From www.yukongear.com

12 Tech Tips For Differential Assembly & Setup Dial Indicator For Rear End Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Easily and accurately verify wheel end play after. See schematics, examples, and patterns for different gear tooth surfaces. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Using. Dial Indicator For Rear End.

From hupshenghardware.com

Insize 23115 Compact Dial Indicator, 5mm, 0.01mm, Accuracy 14μm Dial Indicator For Rear End Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. They're also used to measure distances and. Dial Indicator For Rear End.

From www.desertcart.in

Buy Dial Indicator 025mm 0.01mm Dial Indicator with Lug Back dial Dial Indicator For Rear End Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify wheel end play after. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Use. Dial Indicator For Rear End.

From www.accud.com

DIAL INDICATOR ACCUD Dial Indicator For Rear End Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear set. Easily and accurately verify wheel end play after. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure. Timken bearing adjustment dial indicators stronger value: Using a magnetic base, mount the dial indicator on. Dial Indicator For Rear End.

From www.shahemeasuring.com

5304 Mini Dial indicator Wenzhou Sanhe Measuring Instrument Co.,LTD Dial Indicator For Rear End See schematics, examples, and patterns for different gear tooth surfaces. Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Easily and accurately verify wheel end play after. Using. Dial Indicator For Rear End.

From www.racingjunk.com

How to Set up Your Rear Gear Correctly RacingJunk News Dial Indicator For Rear End Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify wheel end play after. Using a magnetic base, mount the dial indicator on the spindle end, making sure the. Timken. Dial Indicator For Rear End.

From www.mmsonline.com

Reading What the Dial Indicator Is Saying Modern Machine Shop Dial Indicator For Rear End Learn how to use a pinion depth tool to adjust the pinion depth of a rear differential with a 3.70 gear ratio. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Our dial indicator assembly kit allows fleets to precisely verify end play to prevent premature wheel end component failure.. Dial Indicator For Rear End.

From www.aliexpress.com

Dial Indicator For Rear End They're also used to measure distances and to check flat surfaces like the engine's flywheel for runout. Easily and accurately verify wheel end play after. Learn how to adjust backlash, pinion depth, and carrier bearing preload in a differential with shims and dial indicators. Use a dial indicator to check ring gear backlash in a differential's ring and pinion gear. Dial Indicator For Rear End.