Babbitt In Oil . Corrosion can be eliminated by replacing the lubricating oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Any kind of light weight spindle oil between. These are based on the shaft speed and stability,. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. Dte is still a valid designation, and it is a. Corrosion can be eliminated by replacing the lubricating oil.

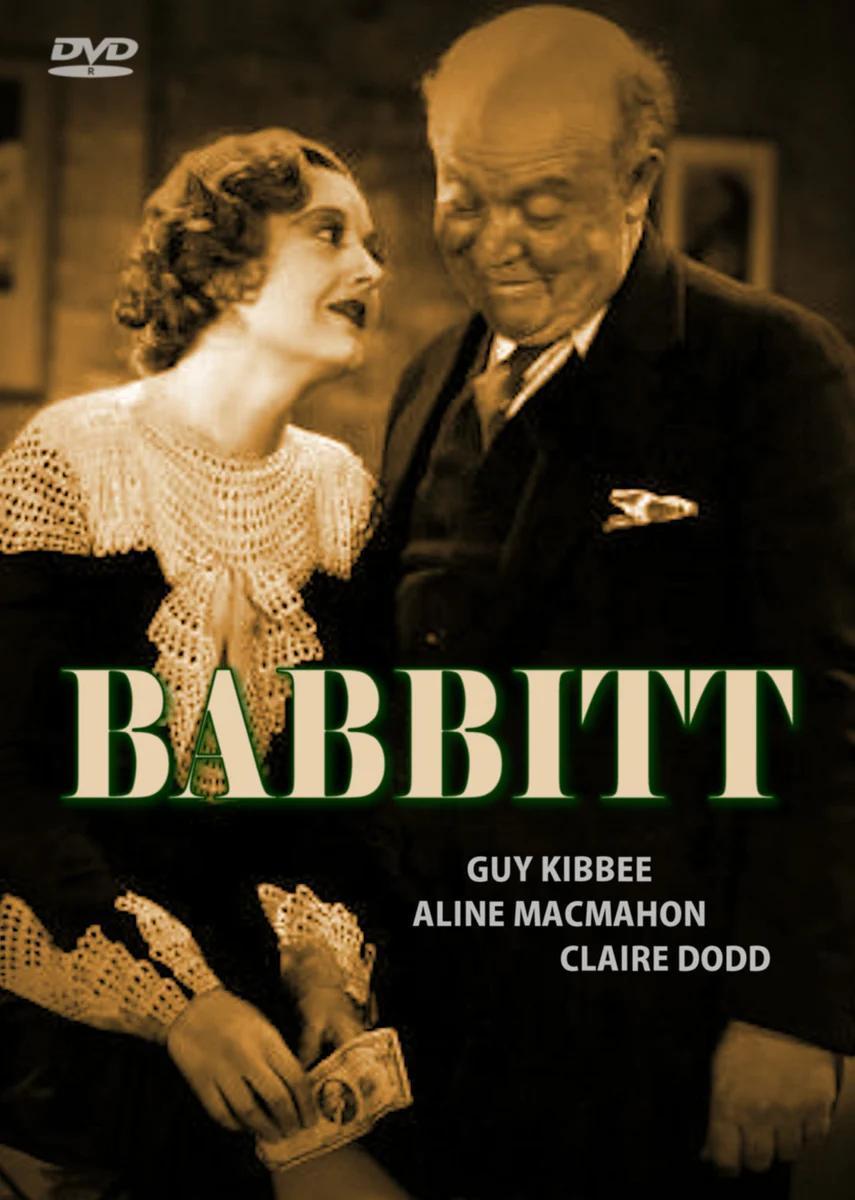

from www.filmaffinity.com

Dte is still a valid designation, and it is a. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Any kind of light weight spindle oil between. Corrosion can be eliminated by replacing the lubricating oil. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Most old literature suggest that babbitt bearings be oiled with a light machine oil. These are based on the shaft speed and stability,.

Image gallery for Babbitt FilmAffinity

Babbitt In Oil The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Corrosion can be eliminated by replacing the lubricating oil. These are based on the shaft speed and stability,. Most old literature suggest that babbitt bearings be oiled with a light machine oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Dte is still a valid designation, and it is a. Any kind of light weight spindle oil between. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. Corrosion can be eliminated by replacing the lubricating oil. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Corrosion can be eliminated by replacing the lubricating oil. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. These are based on the shaft speed and stability,. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Another friend used to work at a paper mill which had a. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Any kind of light weight spindle oil between. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. Corrosion can be eliminated by replacing the lubricating oil. The. Babbitt In Oil.

From pmebabbittbearings.com

Oil Deflectors PME Babbitt Bearings Babbitt In Oil Dte is still a valid designation, and it is a. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. The cause of corrosion is best detected by. Babbitt In Oil.

From www.wikihow.com

How to Pour Babbitt Bearings 10 Steps (with Pictures) wikiHow Babbitt In Oil Dte is still a valid designation, and it is a. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. These are based on the shaft speed and stability,. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in. Babbitt In Oil.

From www.youtube.com

RF Point Level Switch for Oil/Water Interface Detection Babbitt Babbitt In Oil In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Corrosion can be eliminated by replacing the lubricating oil. Any kind of light weight spindle oil between. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Most old literature suggest that babbitt bearings be oiled with a light machine. Babbitt In Oil.

From www.mdpi.com

Lubricants Free FullText Survey of Damage Investigation of Babbitt In Oil These are based on the shaft speed and stability,. Corrosion can be eliminated by replacing the lubricating oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Any kind of light weight spindle oil between. Corrosion can be eliminated by replacing the lubricating oil. In addition, the entire bearing assembly, oil reservoir. Babbitt In Oil.

From forums.aaca.org

Babbitt Bearings and modern oils General Discussion Antique Babbitt In Oil In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. These are based on the shaft speed and stability,. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Any kind of light weight spindle oil between. The cause of corrosion is best detected by knowledge of the babbitt composition and. Babbitt In Oil.

From folsomindustrial.com

Folsom Industrial Babbitt Bearings Repair Babbitt In Oil The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Corrosion can be eliminated by replacing the lubricating oil. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. In addition,. Babbitt In Oil.

From www.practicalmachinist.com

A Fascinating Tale of Babbitting How it was Done the the Repair Shop Babbitt In Oil Most old literature suggest that babbitt bearings be oiled with a light machine oil. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. These are based on the shaft speed and stability,. Corrosion can be eliminated by replacing the lubricating oil. Corrosion can be eliminated by replacing the lubricating oil. In addition, the entire. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Dte is still a valid designation, and it is a. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. Corrosion can be eliminated by replacing the lubricating oil. Any kind. Babbitt In Oil.

From www.mtfca.com

Model T Ford Forum Oil grooves in Babbitt Bearings. Babbitt In Oil Most old literature suggest that babbitt bearings be oiled with a light machine oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. These are based on the shaft speed and stability,. Corrosion can be eliminated by replacing the lubricating oil. Corrosion can be eliminated by replacing the lubricating oil. In addition,. Babbitt In Oil.

From www.youtube.com

KC Engineering Oil Film / Whitemetal / Babbitt Bearings Manufacture Babbitt In Oil These are based on the shaft speed and stability,. Dte is still a valid designation, and it is a. Most old literature suggest that babbitt bearings be oiled with a light machine oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Any kind of light weight spindle oil between. The traditional. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Dte is still a valid designation, and it is a. These are based on the shaft speed and stability,. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The traditional oil for this type of bearing was. Babbitt In Oil.

From www.youtube.com

The difference between Babbitt and Insert Bearings & modern oil filters Babbitt In Oil These are based on the shaft speed and stability,. Corrosion can be eliminated by replacing the lubricating oil. Corrosion can be eliminated by replacing the lubricating oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Any. Babbitt In Oil.

From www.filmaffinity.com

Image gallery for Babbitt FilmAffinity Babbitt In Oil The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. Dte is still. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Most old literature suggest that babbitt bearings be oiled with a light machine oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Another friend used to work at a paper mill which had a line shaft. Babbitt In Oil.

From www.jensenmachine.com

Split Turbine Babbitt Bearing with Thrust Face Jensen Machine Company Babbitt In Oil In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Corrosion can be eliminated by replacing the lubricating oil. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Corrosion can be eliminated by replacing the. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil These are based on the shaft speed and stability,. Any kind of light weight spindle oil between. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. In. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Corrosion can be eliminated by replacing the lubricating oil. Dte is still a valid designation, and it is a. Any kind of light weight spindle oil between. Corrosion can. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Dte is still a valid designation, and it is a. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Corrosion can be eliminated by replacing the lubricating oil. Any kind of light weight spindle oil between. These. Babbitt In Oil.

From www.babbittsonline.com

01 Suspension Oil Babbitts Online Babbitt In Oil In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Any kind of light weight spindle oil between. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Corrosion can be eliminated by replacing the lubricating oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Most old. Babbitt In Oil.

From www.wikihow.com

How to Pour Babbitt Bearings 10 Steps (with Pictures) wikiHow Babbitt In Oil The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Any kind of light weight spindle oil between. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said. Babbitt In Oil.

From www.babbittsonline.com

PS4 EXTREME OW50 4Cycle Oil Babbitts Online Babbitt In Oil The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Corrosion can be eliminated by replacing the lubricating oil. Another friend used to. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Corrosion can be eliminated by replacing the lubricating oil. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Corrosion can be eliminated by replacing the lubricating oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Another friend used to work at a paper mill which had. Babbitt In Oil.

From www.youtube.com

Pouring A Babbitt Rod Bearing Cletrac Crawler YouTube Babbitt In Oil Dte is still a valid designation, and it is a. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Corrosion can be eliminated by replacing. Babbitt In Oil.

From fusionbabbitting.com

Understanding the Babbitting Process From Start to Finish Fusion Babbitt In Oil The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Dte is still a valid designation, and it is a. Corrosion can be eliminated by replacing the lubricating oil. Any kind of light weight spindle oil between. The cause of corrosion. Babbitt In Oil.

From www.homemodelenginemachinist.com

Babbitt material for Howell V4 oil bushing Home Model Engine Babbitt In Oil In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Corrosion can be eliminated by replacing the lubricating oil. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. These are based on. Babbitt In Oil.

From www.mdpi.com

Lubricants Free FullText Survey of Damage Investigation of Babbitt In Oil Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he said they all ran in oil. Any kind of light weight spindle oil between. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Most old literature suggest that babbitt bearings be oiled with. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Corrosion can be eliminated by replacing the lubricating oil. These are based on the shaft speed and stability,. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Corrosion can be eliminated by replacing the lubricating oil. Dte is still a valid designation, and it is a. The cause of corrosion is best detected by knowledge. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil Most old literature suggest that babbitt bearings be oiled with a light machine oil. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Corrosion can be eliminated by replacing the lubricating oil. Dte is still a valid designation, and. Babbitt In Oil.

From hibond.com

Babbitt Bearing Types, Characteristics & Applications Babbitt In Oil In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Most old literature suggest that babbitt bearings be oiled with a light machine oil. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. The cause of corrosion is best detected by knowledge of the babbitt composition and. Babbitt In Oil.

From autowise.com

What is a Babbitt Bearing? (And 10 Steps to Pour Your Own) Autowise Babbitt In Oil The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Corrosion can be eliminated by replacing the lubricating oil. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Another friend used to work at a paper mill which had a line shaft with babbitt bearings, and he. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil The traditional oil for this type of bearing was a dte (dynamo, turbine, engine) oil. Most old literature suggest that babbitt bearings be oiled with a light machine oil. Any kind of light weight spindle oil between. Corrosion can be eliminated by replacing the lubricating oil. The cause of corrosion is best detected by knowledge of the babbitt composition and. Babbitt In Oil.

From www.avservicestech.com

Babbitt Bearings Oil Lubricated AV Servicees Tech Babbitt In Oil These are based on the shaft speed and stability,. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Corrosion can be eliminated by replacing the lubricating oil. Dte is still a valid designation, and it is a.. Babbitt In Oil.