What Grit Hone For Cast Rings . For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. These hones are commonly available in everything from 180 grit to 800. So, the higher the number, the finer the grit. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. What grit ball hone should i use. How do you determine which is the correct one (or combination. The most commonly used grits for. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. Whether it was a fresh or a used cylinder?

from www.grainger.com

It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. So, the higher the number, the finer the grit. How do you determine which is the correct one (or combination. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. These hones are commonly available in everything from 180 grit to 800. Whether it was a fresh or a used cylinder? The most commonly used grits for. What grit ball hone should i use. The key to a successful break in is that you must lap or seat the piston rings to get the maximum.

FLEXHONE TOOL Silicon Carbide Flexible Cylinder Hone, Medium Grade

What Grit Hone For Cast Rings A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. Whether it was a fresh or a used cylinder? What grit ball hone should i use. How do you determine which is the correct one (or combination. So, the higher the number, the finer the grit. For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. The most commonly used grits for. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. These hones are commonly available in everything from 180 grit to 800.

From www.cobaltss.net

Cylinder hone/deglazewhat gritflexhone Cobalt SS Network What Grit Hone For Cast Rings It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. How do you determine which is the correct one (or combination. Hones with 180 to 240 grits are good. What Grit Hone For Cast Rings.

From tridon.com.au

301062 Cylinder Hone Stones Toledo What Grit Hone For Cast Rings So, the higher the number, the finer the grit. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. The most commonly used grits for. For plain cast iron or chrome rings in a stock, street performance. What Grit Hone For Cast Rings.

From www.stainless-steelballs.com

304 430 Stainless Steel Grit , Wire Casting Steel Shot And Grit 0.5mm 1.0mm What Grit Hone For Cast Rings Whether it was a fresh or a used cylinder? How do you determine which is the correct one (or combination. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. What grit ball hone should i use.. What Grit Hone For Cast Rings.

From goodson.com

HN200S 150 Grit Goodson Honing Stones Goodson Tools & Supplies What Grit Hone For Cast Rings The key to a successful break in is that you must lap or seat the piston rings to get the maximum. For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. A 320 grit, and even sometimes as fine as 400 grit are often used in. What Grit Hone For Cast Rings.

From www.jewelrytools.com

G01525B GRS Diamond Power Hone, 600 Grit Diamond Wheel What Grit Hone For Cast Rings What grit ball hone should i use. These hones are commonly available in everything from 180 grit to 800. So, the higher the number, the finer the grit. The most commonly used grits for. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. For plain cast. What Grit Hone For Cast Rings.

From www.grainger.com

FLEXHONE TOOL Flexible Cylinder Hone 4 1/4 in Bore Dia., Silicon What Grit Hone For Cast Rings The most commonly used grits for. It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. So, the higher the number, the finer the grit. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. What grit. What Grit Hone For Cast Rings.

From www.kbctools.com

FLEXHONE,BC 5/8 IN. 120 GRIT FLEXHONE,1610FH013,KBC Tools & Machinery What Grit Hone For Cast Rings How do you determine which is the correct one (or combination. Whether it was a fresh or a used cylinder? The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. The key to a successful break in. What Grit Hone For Cast Rings.

From www.youtube.com

Cylinder Bore Finish and Piston Ring Relationship Explained YouTube What Grit Hone For Cast Rings It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. What grit ball hone should i use. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance.. What Grit Hone For Cast Rings.

From dannysengineportal.com

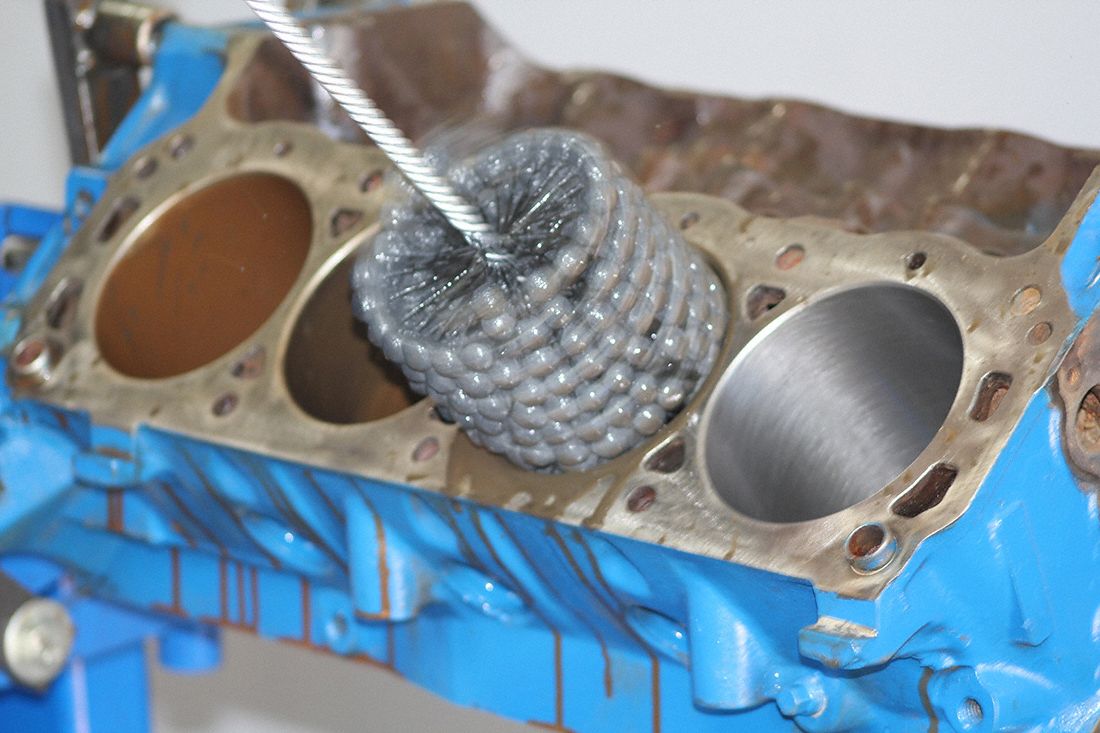

Ball Hone How To Get The Perfect Finish, For Piston Ring Sealing What Grit Hone For Cast Rings So, the higher the number, the finer the grit. For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. The most typical grits. What Grit Hone For Cast Rings.

From chevelles.com

3 stone hone or ball hone?????????? Chevelle Tech What Grit Hone For Cast Rings These hones are commonly available in everything from 180 grit to 800. It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. The most typical grits. What Grit Hone For Cast Rings.

From www.yotashop.com

FlexHone 9095mm Cylinder Ball Hone 180 Grit (Silicon Carbide) What Grit Hone For Cast Rings How do you determine which is the correct one (or combination. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. What grit ball hone should i use. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with. What Grit Hone For Cast Rings.

From www.classicbritishspares.com

Selecting The Correct Hone Grit What Grit Hone For Cast Rings These hones are commonly available in everything from 180 grit to 800. It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. How do you determine which is the. What Grit Hone For Cast Rings.

From tillescenter.org

Range 3.55.5 280 Grit Cylinder Hone Stone Set for Sunnen AN Style Hone What Grit Hone For Cast Rings It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. Whether it was a fresh or a used cylinder? The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some. What Grit Hone For Cast Rings.

From triaticinc.com

Diamond Tapered Hone 3/8" Diameter, 3" Overall Length with 12° Angle What Grit Hone For Cast Rings Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. So, the higher the number, the finer the grit. The most commonly used grits for. For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide. What Grit Hone For Cast Rings.

From www.ebay.com

70 Grit Cylinder Hone Stone Set for AN111 Sunnen Hone Range 3.5 5.5 What Grit Hone For Cast Rings Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. Whether it was a fresh or a used cylinder? What grit ball hone should i use. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance. What Grit Hone For Cast Rings.

From www.stainless-steelballs.com

304 430 Stainless Steel Grit , Wire Casting Steel Shot And Grit 0.5mm 1.0mm What Grit Hone For Cast Rings What grit ball hone should i use. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. So, the higher the number, the finer the grit. The most commonly used grits for. For plain cast iron or chrome rings in a stock, street performance or dirt track. What Grit Hone For Cast Rings.

From www.bladehq.com

Lansky Diamond Sharpening Hone (Fine Grit) LDHFN Blade HQ What Grit Hone For Cast Rings The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. How do you determine which is. What Grit Hone For Cast Rings.

From cekneagn.blob.core.windows.net

What Grit Ball Hone For Moly Rings at Charles Soto blog What Grit Hone For Cast Rings Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. A 320 grit, and. What Grit Hone For Cast Rings.

From cekneagn.blob.core.windows.net

What Grit Ball Hone For Moly Rings at Charles Soto blog What Grit Hone For Cast Rings These hones are commonly available in everything from 180 grit to 800. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. The most typical grits we. What Grit Hone For Cast Rings.

From goodson.com

JN100 Sunnen 70 grit Hone Stone 2.0 2.20" Range GOODSON What Grit Hone For Cast Rings These hones are commonly available in everything from 180 grit to 800. So, the higher the number, the finer the grit. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. The most typical grits we see used for deglazing applications are 180 and 240 grit, but. What Grit Hone For Cast Rings.

From www.grainger.com

FLEXHONE TOOL Silicon Carbide Flexible Cylinder Hone, Medium Grade What Grit Hone For Cast Rings How do you determine which is the correct one (or combination. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. So, the higher the number, the finer the grit. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the. What Grit Hone For Cast Rings.

From www.amazon.ca

Brush Research FlexHone Cylinder Hone, GBD Series, Silicon Carbide What Grit Hone For Cast Rings The most commonly used grits for. What grit ball hone should i use. For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. These hones are commonly available in everything from 180 grit to 800. The key to a successful break in is that you must. What Grit Hone For Cast Rings.

From www.competitionproducts.com

BRM, Flex Hone, 41/2" (114mm), 320 Grit, Sold as Each Competition What Grit Hone For Cast Rings For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. Whether it was a fresh or a used cylinder? It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. A 320 grit, and even sometimes as. What Grit Hone For Cast Rings.

From www.ubuy.cl

Flex Hone 4 To 4.125 SBC SBF Ball Hone For Cast Chile Ubuy What Grit Hone For Cast Rings For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. What grit ball hone should i use. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. So, the higher the number, the. What Grit Hone For Cast Rings.

From gritrings.bandcamp.com

Grit Rings Grit Rings What Grit Hone For Cast Rings How do you determine which is the correct one (or combination. Whether it was a fresh or a used cylinder? The key to a successful break in is that you must lap or seat the piston rings to get the maximum. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used. What Grit Hone For Cast Rings.

From www.dragzine.com

Honing At Home Chucking Up A Ball Hone And Testing The Results What Grit Hone For Cast Rings These hones are commonly available in everything from 180 grit to 800. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. The most commonly used. What Grit Hone For Cast Rings.

From www.stainless-steelballs.com

304 430 Stainless Steel Grit , Wire Casting Steel Shot And Grit 0.5mm 1.0mm What Grit Hone For Cast Rings The key to a successful break in is that you must lap or seat the piston rings to get the maximum. What grit ball hone should i use. So, the higher the number, the finer the grit. Whether it was a fresh or a used cylinder? The most commonly used grits for. The most typical grits we see used for. What Grit Hone For Cast Rings.

From www.kroger.com

Weiler Cylinder Hone,Coarse Grade,Grit 120 34294, 1 Kroger What Grit Hone For Cast Rings These hones are commonly available in everything from 180 grit to 800. How do you determine which is the correct one (or combination. The most commonly used grits for. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some. What Grit Hone For Cast Rings.

From www.esslinger.com

Diamond Hone File Fine Grit 600 Bench and Accessories Esslinger & Co What Grit Hone For Cast Rings The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. These hones are commonly available in everything from 180 grit to 800. It is highly recommended, unless the cylinders are rebored, to use a power hone or. What Grit Hone For Cast Rings.

From www.grainger.com

FLEXHONE TOOL Silicon Carbide Flexible Cylinder Hone, Extra Fine Grade What Grit Hone For Cast Rings How do you determine which is the correct one (or combination. These hones are commonly available in everything from 180 grit to 800. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. The most typical grits we see used for deglazing applications are 180 and 240 grit, but. What Grit Hone For Cast Rings.

From www.gingermeekallen.com

Grit Ring Ginger Meek Allen Metalsmith & Custom Studio Jeweler What Grit Hone For Cast Rings The most commonly used grits for. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. These hones are commonly available in everything from 180 grit to 800. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with. What Grit Hone For Cast Rings.

From shot-blasting-china.en.made-in-china.com

Chilled Iron Grit Casting Shot and Casting What Grit Hone For Cast Rings How do you determine which is the correct one (or combination. These hones are commonly available in everything from 180 grit to 800. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. What grit ball hone. What Grit Hone For Cast Rings.

From donnaweaverdesign.com

Silver Grit Ring What Grit Hone For Cast Rings It is highly recommended, unless the cylinders are rebored, to use a power hone or rigid hone for moly rings. The key to a successful break in is that you must lap or seat the piston rings to get the maximum. The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used. What Grit Hone For Cast Rings.

From www.gingermeekallen.com

Grit Ring Ginger Meek Allen Metalsmith & Custom Studio Jeweler What Grit Hone For Cast Rings The most typical grits we see used for deglazing applications are 180 and 240 grit, but the range used is 120 all the way up to 400 (we’ve even seen some extreme performance. The most commonly used grits for. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance. What Grit Hone For Cast Rings.

From www.rideapart.com

How To Hone Your Cylinders At Home With A FlexHone What Grit Hone For Cast Rings For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or. What grit ball hone should i use. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. The most commonly used grits for.. What Grit Hone For Cast Rings.