Drive Shaft Operating Angles Should Be Within . Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Driveline angles should be equal to or within 1° of each other. Select the number of shafts in your. Park the vehicle on the surface. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. These two angles are formed between the centerline of the shaft and the.

from schematicdegauss.z21.web.core.windows.net

Driveline angles should be equal to or within 1° of each other. Select the number of shafts in your. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. These two angles are formed between the centerline of the shaft and the. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Park the vehicle on the surface.

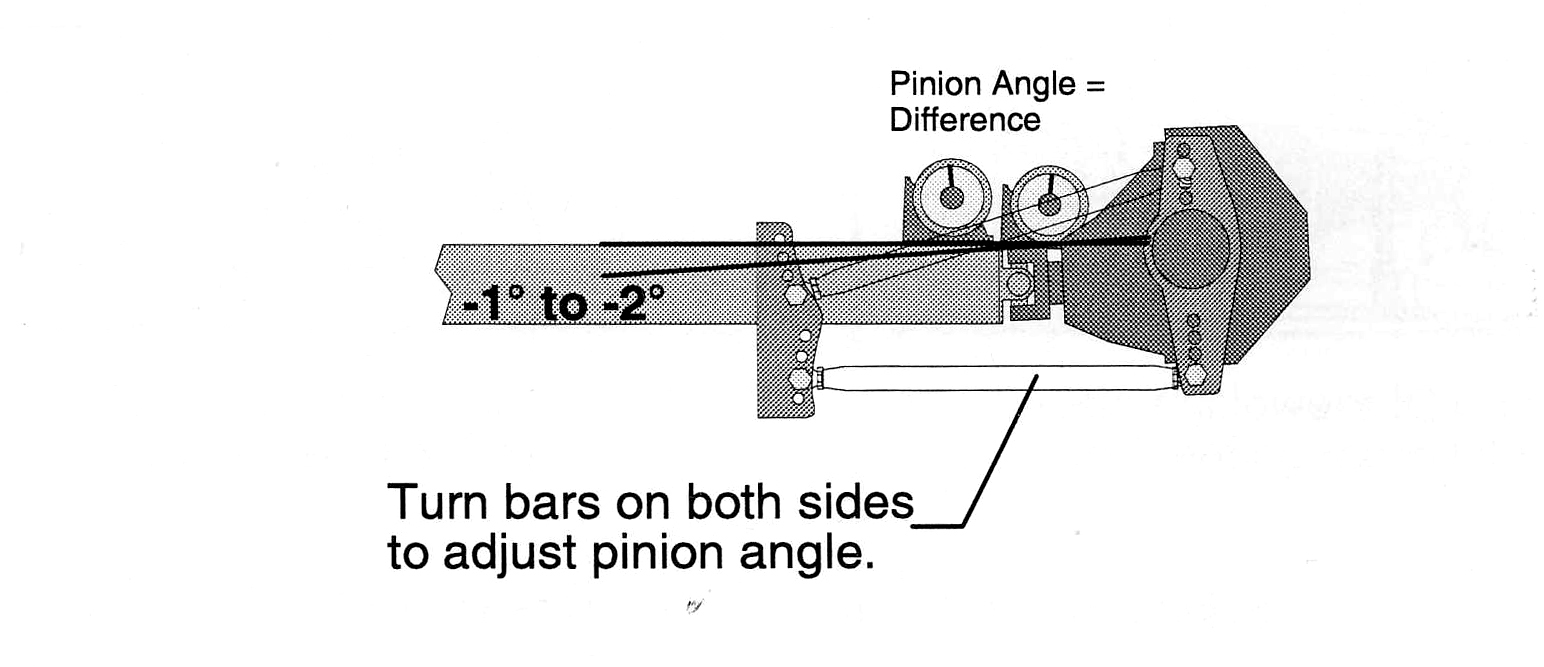

Drive Shaft Pinion Angle Setting

Drive Shaft Operating Angles Should Be Within Driveline angles should be equal to or within 1° of each other. Driveline angles should be equal to or within 1° of each other. Select the number of shafts in your. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Park the vehicle on the surface. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. These two angles are formed between the centerline of the shaft and the. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Correct operating angles are those angles at which the manufacture has designed the driveline to operate.

From www.truckowners.com

Truck Owners Drive Line Phasing And Universal Joint Angles Drive Shaft Operating Angles Should Be Within Driveline angles should be equal to or within 1° of each other. Park the vehicle on the surface. These two angles are formed between the centerline of the shaft and the. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Select the number of shafts in your. Correct. Drive Shaft Operating Angles Should Be Within.

From www.pinterest.com

Pin on Motor Drive Shaft Operating Angles Should Be Within Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. These two angles are formed between the centerline of the shaft and the. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other,. Drive Shaft Operating Angles Should Be Within.

From oldschool.co.nz

2piece driveshaft angles Tech Talk oldschool.co.nz Drive Shaft Operating Angles Should Be Within Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Select the number of shafts in your. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. These two angles are formed between. Drive Shaft Operating Angles Should Be Within.

From teamcpp.com

Driveshaft How To The Basics Everyone Should Know Team CPP Drive Shaft Operating Angles Should Be Within Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Driveline angles should be equal to or within 1° of each other. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. These. Drive Shaft Operating Angles Should Be Within.

From www.youtube.com

Drive shaft angles measuring setting up YouTube Drive Shaft Operating Angles Should Be Within Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Park the vehicle on the surface. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. These two angles are formed between the. Drive Shaft Operating Angles Should Be Within.

From www.youtube.com

How To Perfectly Set Up Your Drive Shaft Angles! YouTube Drive Shaft Operating Angles Should Be Within Correct operating angles are those angles at which the manufacture has designed the driveline to operate. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Park the vehicle. Drive Shaft Operating Angles Should Be Within.

From www.vintage-mustang.com

Driveline angle help. Vintage Mustang Forums Drive Shaft Operating Angles Should Be Within Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Driveline angles should be equal to or within 1° of each other. Select the number of shafts in your. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Ideally the operating angles. Drive Shaft Operating Angles Should Be Within.

From garo-design.blogspot.com

Double Cardan Driveshaft Angle 3D Mockup PSD Mockups Drive Shaft Operating Angles Should Be Within These two angles are formed between the centerline of the shaft and the. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Measure the angles of each. Drive Shaft Operating Angles Should Be Within.

From www.youtube.com

Driveshaft Angles YouTube Drive Shaft Operating Angles Should Be Within Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. These two angles are formed between the centerline of the shaft and the. Select the number of shafts in your. Park the vehicle on the surface. When checking driveshaft angles, be sure all tires. Drive Shaft Operating Angles Should Be Within.

From www.moderndriveline.com

Driveshaft QuickTech Modern Driveline Drive Shaft Operating Angles Should Be Within These two angles are formed between the centerline of the shaft and the. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Select the number of shafts in. Drive Shaft Operating Angles Should Be Within.

From exomkbevz.blob.core.windows.net

Components Of A Driveshaft at Wendy Craig blog Drive Shaft Operating Angles Should Be Within Driveline angles should be equal to or within 1° of each other. These two angles are formed between the centerline of the shaft and the. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Ideally the operating angles. Drive Shaft Operating Angles Should Be Within.

From exoqpwoaw.blob.core.windows.net

Purpose Of A Drive Shaft Working Angle And Can Excessive Angle Create Drive Shaft Operating Angles Should Be Within Select the number of shafts in your. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Park the vehicle on the surface. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate.. Drive Shaft Operating Angles Should Be Within.

From gtsparkplugs.com

Drive Shaft Angles GTSparkplugs Drive Shaft Operating Angles Should Be Within Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. When checking driveshaft angles, be sure all tires are inflated to their normal. Drive Shaft Operating Angles Should Be Within.

From unsealed4x4.com.au

Lift kit? Make sure you get your driveline angles right Unsealed 4X4 Drive Shaft Operating Angles Should Be Within Select the number of shafts in your. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Park the vehicle on the surface. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Driveline angles should be equal to or within 1° of each other. Ideally, the operating angles. Drive Shaft Operating Angles Should Be Within.

From www.hellcat.org

Factory driveshaft not straight SRT Hellcat Forum Drive Shaft Operating Angles Should Be Within Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of. Drive Shaft Operating Angles Should Be Within.

From www.westerndiff.com

Drive Shafts Western Differential & Driveline Drive Shaft Operating Angles Should Be Within When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. These two angles are formed between the centerline of the shaft and the. Park the vehicle on the surface. Driveline angles should be equal to or within 1° of each other. Correct operating angles are those angles at which the manufacture has designed the driveline. Drive Shaft Operating Angles Should Be Within.

From www.racingjunk.com

What You Need To Know About Street & Strip Driveshafts Part 3 Drive Shaft Operating Angles Should Be Within Driveline angles should be equal to or within 1° of each other. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Park the vehicle on the surface. Correct operating angles are those angles at which the manufacture has designed the driveline to operate.. Drive Shaft Operating Angles Should Be Within.

From www.drive-lines.com

Drive Line Service Drive Shaft Operating Angles Should Be Within Park the vehicle on the surface. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Select the number of shafts in your. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. When checking driveshaft angles, be. Drive Shaft Operating Angles Should Be Within.

From karolrust.blogspot.com

double cardan joint diagram Karol Rust Drive Shaft Operating Angles Should Be Within Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. These two angles are formed between the centerline of the shaft and the. Park the vehicle on the surface. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member),. Drive Shaft Operating Angles Should Be Within.

From www.chevyhardcore.com

Driveshaft Angles Why They Matter And How Keep Them In Check Drive Shaft Operating Angles Should Be Within Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Select the number of shafts in your. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Ideally the operating angles on each end of the drive shaft should be equal or within. Drive Shaft Operating Angles Should Be Within.

From www.myxxgirl.com

Driveshaft Angle Chart My XXX Hot Girl Drive Shaft Operating Angles Should Be Within When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator. Drive Shaft Operating Angles Should Be Within.

From gtsparkplugs.com

Drive Shaft Angles GTSparkplugs Drive Shaft Operating Angles Should Be Within Driveline angles should be equal to or within 1° of each other. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Select the number of shafts in your. Park the vehicle on the surface. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. These two angles are. Drive Shaft Operating Angles Should Be Within.

From www.chevyhardcore.com

Driveshaft Angles Why They Matter And How Keep Them In Check Drive Shaft Operating Angles Should Be Within These two angles are formed between the centerline of the shaft and the. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Driveline angles should be equal to or within 1° of each other. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of. Drive Shaft Operating Angles Should Be Within.

From www.powerperformancenews.com

Critical Speed Drive Shaft Operating Angles Should Be Within When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Park the vehicle on the surface. These two angles are formed between the centerline of the shaft and the. Select the number of shafts in your. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of. Drive Shaft Operating Angles Should Be Within.

From teamcpp.com

Driveshaft How To The Basics Everyone Should Know Team CPP Drive Shaft Operating Angles Should Be Within Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Select the number of shafts in your. Driveline angles should be equal to or within 1° of each other. These two angles are formed between the centerline of the shaft and the. Park the vehicle on the surface. Correct. Drive Shaft Operating Angles Should Be Within.

From www.youtube.com

Driveline Angles YouTube Drive Shaft Operating Angles Should Be Within Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Park the vehicle on the surface. These two angles are formed between the centerline of the shaft and the. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Measure the angles of each component in your drivetrain (driving. Drive Shaft Operating Angles Should Be Within.

From schematicdegauss.z21.web.core.windows.net

Drive Shaft Pinion Angle Setting Drive Shaft Operating Angles Should Be Within Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. These two angles are formed between the centerline of the shaft and the. Measure the angles of each. Drive Shaft Operating Angles Should Be Within.

From www.dreferenz.com

Drive Shaft Angle On Lifted Trucks dReferenz Blog Drive Shaft Operating Angles Should Be Within Select the number of shafts in your. Correct operating angles are those angles at which the manufacture has designed the driveline to operate. Park the vehicle on the surface. Driveline angles should be equal to or within 1° of each other. These two angles are formed between the centerline of the shaft and the. When checking driveshaft angles, be sure. Drive Shaft Operating Angles Should Be Within.

From gtsparkplugs.com

Drive Shaft Angles GTSparkplugs Drive Shaft Operating Angles Should Be Within Select the number of shafts in your. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. Park the vehicle on the surface. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate.. Drive Shaft Operating Angles Should Be Within.

From www.jalopyjournal.com

Technical Driveline angles The H.A.M.B. Drive Shaft Operating Angles Should Be Within These two angles are formed between the centerline of the shaft and the. Driveline angles should be equal to or within 1° of each other. Park the vehicle on the surface. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. When checking driveshaft. Drive Shaft Operating Angles Should Be Within.

From www.facebook.com

How to Use the Driveline Operating Angle Calculator You can measure Drive Shaft Operating Angles Should Be Within Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. Select the number of shafts in your. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Correct. Drive Shaft Operating Angles Should Be Within.

From www.youtube.com

Drive shaft angle measurement YouTube Drive Shaft Operating Angles Should Be Within Correct operating angles are those angles at which the manufacture has designed the driveline to operate. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Select the number of shafts in your. Park. Drive Shaft Operating Angles Should Be Within.

From www.ford-trucks.com

Correct drive shaft angles Ford Truck Enthusiasts Forums Drive Shaft Operating Angles Should Be Within Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3. Drive Shaft Operating Angles Should Be Within.

From hxegchtao.blob.core.windows.net

Transmission Vibration Under Load at Christopher Ortiz blog Drive Shaft Operating Angles Should Be Within Driveline angles should be equal to or within 1° of each other. These two angles are formed between the centerline of the shaft and the. Select the number of shafts in your. Ideally, the operating angles on each end of the driveshaft should be equal to or within 1 degree of each other, have a 3 degree maximum. Correct operating. Drive Shaft Operating Angles Should Be Within.

From www.chevyhardcore.com

Video Custom Basics Driveshaft UJoints, Angles, and Velocity Drive Shaft Operating Angles Should Be Within Measure the angles of each component in your drivetrain (driving member, driveshaft (s), driven member), then use this calculator to calculate. Ideally the operating angles on each end of the drive shaft should be equal or within one degree of each other, have a three degree maximum. Park the vehicle on the surface. These two angles are formed between the. Drive Shaft Operating Angles Should Be Within.