Tooling Abrasive Flow Machining . Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. It offers brilliant surface finish, economy and. Abrasive flow machining is a relatively new process in field of manufacturing. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6).

from www.researchgate.net

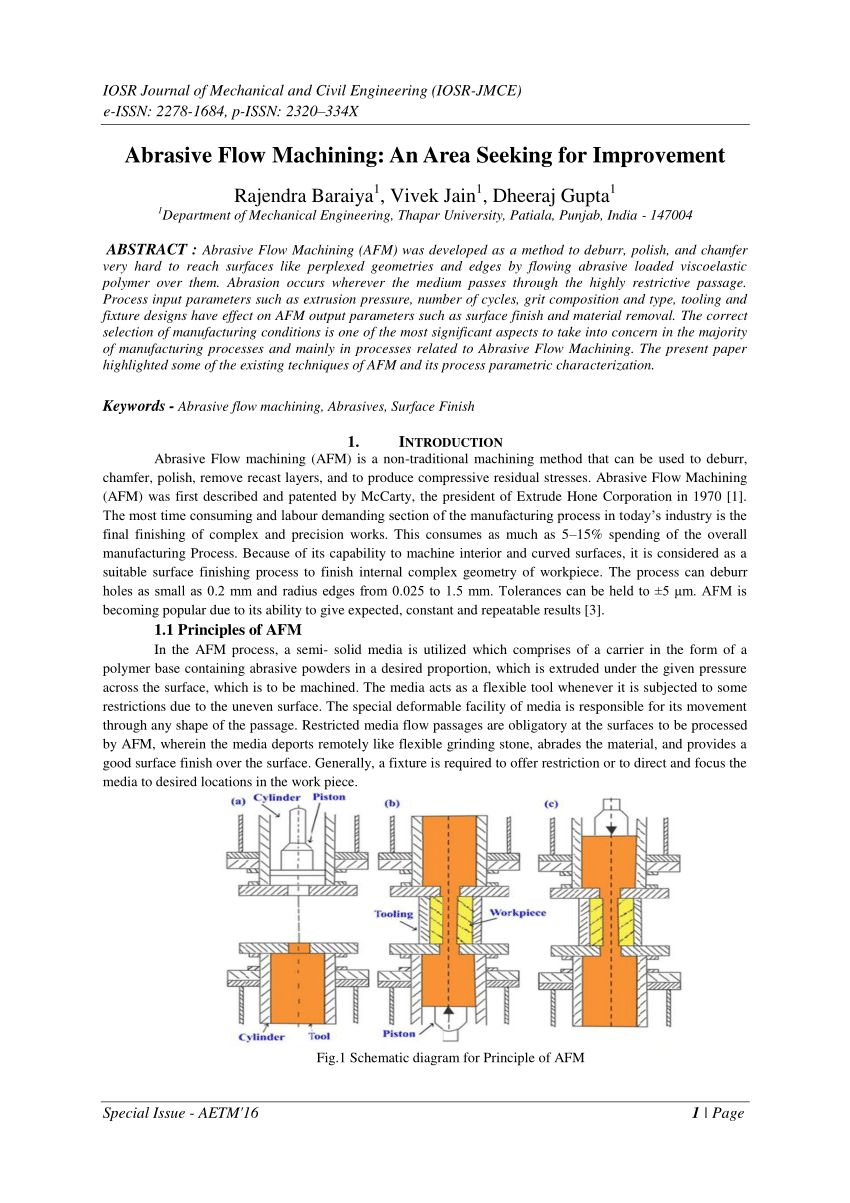

Abrasive flow machining is a relatively new process in field of manufacturing. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). It offers brilliant surface finish, economy and. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be.

(PDF) Abrasive Flow Machining An Area Seeking for Improvement

Tooling Abrasive Flow Machining Abrasive flow machining is a relatively new process in field of manufacturing. Abrasive flow machining is a relatively new process in field of manufacturing. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). It offers brilliant surface finish, economy and.

From www.youtube.com

Abrasive Flow Machining/Extrude Hone Video 2 Engineered Finishing Tooling Abrasive Flow Machining Abrasive flow machining is a relatively new process in field of manufacturing. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. It offers brilliant surface finish, economy and. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and. Tooling Abrasive Flow Machining.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow machining is a relatively new process in field of manufacturing.. Tooling Abrasive Flow Machining.

From www.researchgate.net

(PDF) Abrasive Flow Machining An Area Seeking for Improvement Tooling Abrasive Flow Machining It offers brilliant surface finish, economy and. Abrasive flow machining is a relatively new process in field of manufacturing. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially. Tooling Abrasive Flow Machining.

From www.mdpi.com

Study on Elucidation of the Roundness Improvement Mechanism of the Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Abrasive flow machining is a relatively new process in field of manufacturing. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. External edges or surfaces,. Tooling Abrasive Flow Machining.

From www.researchgate.net

Schematic diagram of abrasive flow machining Download Scientific Diagram Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. It offers brilliant surface finish, economy and. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining is a relatively new process in. Tooling Abrasive Flow Machining.

From optimas.com

Selecting Industrial Abrasives for Manufacturing Optimas Tooling Abrasive Flow Machining Abrasive flow machining is a relatively new process in field of manufacturing. It offers brilliant surface finish, economy and. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive. Tooling Abrasive Flow Machining.

From www.alu.com.cn

Multicut Flowgrind Media for Abrasive Flow MachineAluminium products Tooling Abrasive Flow Machining External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. It offers brilliant surface finish, economy and. Abrasive flow machining is a. Tooling Abrasive Flow Machining.

From www.flowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. It offers brilliant surface finish, economy and. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. External edges or surfaces, tooling is used to restrict. Tooling Abrasive Flow Machining.

From www.flowgrinding.com

Aerospace Winbro Flow Grinding Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. It offers brilliant surface finish, economy and. Abrasive flow machining is a relatively new process in field of manufacturing. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes. Tooling Abrasive Flow Machining.

From www.youtube.com

Stress Risers, Meet Abrasive Flow Machining YouTube Tooling Abrasive Flow Machining Abrasive flow machining is a relatively new process in field of manufacturing. It offers brilliant surface finish, economy and. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound. Tooling Abrasive Flow Machining.

From www.extrudehone.com.cn

Abrasive Flow Machining solutions for 3D printed componentsParis Air Show Tooling Abrasive Flow Machining It offers brilliant surface finish, economy and. Abrasive flow machining is a relatively new process in field of manufacturing. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially. Tooling Abrasive Flow Machining.

From www.flowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Tooling Abrasive Flow Machining External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow machining is a relatively new process in field of manufacturing. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface.. Tooling Abrasive Flow Machining.

From www.slideserve.com

PPT ABRASIVE FLOW MACHINING PowerPoint Presentation, free Tooling Abrasive Flow Machining It offers brilliant surface finish, economy and. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. External. Tooling Abrasive Flow Machining.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining is a relatively new process in field of manufacturing. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow. Tooling Abrasive Flow Machining.

From www.researchgate.net

Schematic diagram of the precision machining of abrasive flow Tooling Abrasive Flow Machining External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow machining is a relatively new process in field of manufacturing. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow. Tooling Abrasive Flow Machining.

From www.youtube.com

Look at what this Abrasive flow machining can do! Amazing industrial Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. It offers brilliant surface finish, economy and. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow machining is a relatively new. Tooling Abrasive Flow Machining.

From enggkatta.com

Ultrasonic Machining Working Principle, Setup, Applications EnggKatta Tooling Abrasive Flow Machining External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). It offers brilliant surface finish, economy and. Abrasive flow machining is a relatively new process in field of manufacturing. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden,. Tooling Abrasive Flow Machining.

From electricalworkbook.com

What is Abrasive Flow Finishing (AFF)? Process, Diagram, Working Tooling Abrasive Flow Machining It offers brilliant surface finish, economy and. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted. Tooling Abrasive Flow Machining.

From www.researchgate.net

(PDF) Modeling and Energy Efficiency of Abrasive Flow Machining on Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining is a relatively new process in field of manufacturing. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over. Tooling Abrasive Flow Machining.

From www.extrudehone.com

FGP testimonial, VECTOR Abrasive Flow Machining (AFM) machine Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. It offers brilliant surface finish, economy and. Abrasive flow machining is a relatively new process in field of manufacturing. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside. Tooling Abrasive Flow Machining.

From www.youtube.com

Diamond Turn Machining Abrasive Flow Machining Abrasive Tooling Abrasive Flow Machining Abrasive flow machining is a relatively new process in field of manufacturing. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. External edges or surfaces,. Tooling Abrasive Flow Machining.

From www.researchgate.net

27 Schematic illustration of one abrasive flow machining setup. The Tooling Abrasive Flow Machining Abrasive flow machining is a relatively new process in field of manufacturing. It offers brilliant surface finish, economy and. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive. Tooling Abrasive Flow Machining.

From www.locatoronline.com

For Sale Extrude Hone Vector 8/6 Abrasive Flow Honing Machine Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. It offers brilliant surface finish, economy and. Abrasive flow machining is a relatively new process in field of manufacturing. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes. Tooling Abrasive Flow Machining.

From www.extrudehoneafm.com

Improve Surface Finishes of Precision Dies, Molds & Gears with Abrasive Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining is a relatively new process in field of manufacturing. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over. Tooling Abrasive Flow Machining.

From www.researchgate.net

(PDF) Latest Trends in Abrasive Flow Machining Process Tooling Abrasive Flow Machining Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. The abrasive flow machining / extrude honing (afm). Tooling Abrasive Flow Machining.

From www.researchgate.net

(PDF) A Review on Abrasive Flow Machining (AFM) Tooling Abrasive Flow Machining Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. External edges or surfaces, tooling is used to. Tooling Abrasive Flow Machining.

From www.youtube.com

(주)혼텍 Abrasive Flow Machining YouTube Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. External edges or surfaces, tooling is. Tooling Abrasive Flow Machining.

From www.directindustry.com

AFM polishing machine ONE WAY FLOW Extrude Hone® for metals Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow machining works by the back and forth flow under pressure. Tooling Abrasive Flow Machining.

From www.pinterest.com

Abrasive flow polishing machine or extrude honing machine using soft Tooling Abrasive Flow Machining It offers brilliant surface finish, economy and. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow machining is a relatively new process in field of manufacturing. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow. Tooling Abrasive Flow Machining.

From gcfd.blogspot.com

MY RESEARCH PROJECTS Design of fixtures used in Abrasive Flow Tooling Abrasive Flow Machining External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. Abrasive flow machining works by the back and forth flow under pressure of an. Tooling Abrasive Flow Machining.

From www.microsurfaces.de

Abrasive Flow Machine Performance Line Micro Surfaces GmbH Tooling Abrasive Flow Machining Abrasive flow machining is a relatively new process in field of manufacturing. It offers brilliant surface finish, economy and. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside. Tooling Abrasive Flow Machining.

From www.researchgate.net

Top panel initial setup of the microscopic abrasive flow machining Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Abrasive flow machining is a relatively new process in field of manufacturing. Tooling holds workpiece in position and directs the abrasive media to the appropriate areas, restricts flow at areas where abrasion is. It offers brilliant surface. Tooling Abrasive Flow Machining.

From www.machinesused.com

Machines Used Dynaflow Process AFM Abrasive Flow Model HL20 Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. External edges or surfaces, tooling is used to restrict the flow between the outside of the part and the inside of the fixture (figure 6). Abrasive flow machining works by the back and forth flow under pressure. Tooling Abrasive Flow Machining.

From www.flowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Tooling Abrasive Flow Machining The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be. It offers brilliant surface finish, economy. Tooling Abrasive Flow Machining.

From www.youtube.com

Working principle of Abrasive Flow Machining (AFM) YouTube Tooling Abrasive Flow Machining It offers brilliant surface finish, economy and. The abrasive flow machining / extrude honing (afm) process is ideal for polishing and deburring, especially for complex internal shapes and targeted surface. Abrasive flow machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to. Tooling Abrasive Flow Machining.