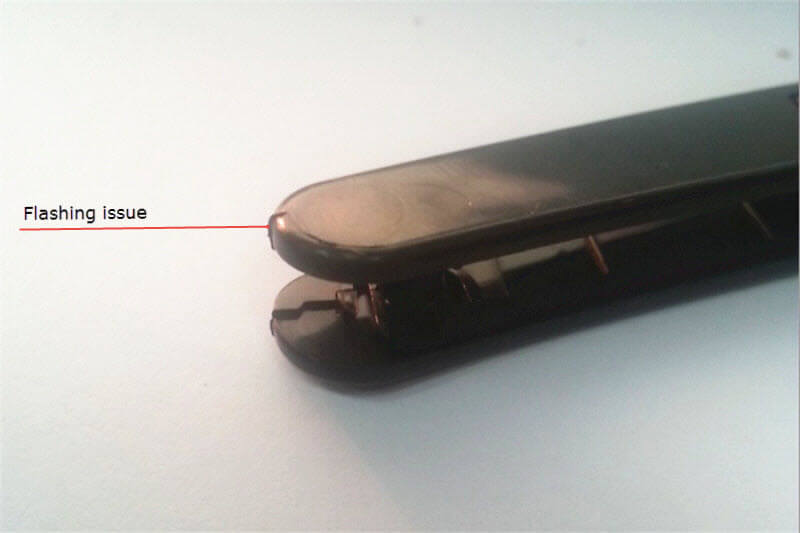

What Is Flash In Molding . This flaw can damage molds and. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. What is injection molding flash? This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. What is flash in injection molding? The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. Flashing is often the most common occurrence on the separating line of plastic molding.

from www.plastopialtd.com

It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. Flashing is often the most common occurrence on the separating line of plastic molding. This flaw can damage molds and. What is injection molding flash? What is flash in injection molding? An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down.

Flash Injection Molding Plastopia

What Is Flash In Molding Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. Flashing is often the most common occurrence on the separating line of plastic molding. This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: What is flash in injection molding? Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. What is injection molding flash? This flaw can damage molds and. If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer What Is Flash In Molding Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. What is flash in injection molding? Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during. What Is Flash In Molding.

From prototool.com

Injection Molding Flash Causes & Solutions And How To Avoid Prototool What Is Flash In Molding This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions. What Is Flash In Molding.

From www.dgmfmoldclamps.com

What Is Flash Injection Molding? Mould Clamps Manufacturer What Is Flash In Molding Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. This flaw can damage molds and. The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet. Flash in injection molding refers to the unwanted. What Is Flash In Molding.

From www.midstatemold.com

Flash Archives Midstate Mold & Engineering What Is Flash In Molding The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet. What is flash in injection molding? This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash”. What Is Flash In Molding.

From www.vem-tooling.com

Flash What Is Flash In Molding Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. What is injection molding flash? This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown. What Is Flash In Molding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits What Is Flash In Molding An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. This flaw can damage molds and. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. The defect known. What Is Flash In Molding.

From www.plastopialtd.com

Flash Injection Molding Plastopia What Is Flash In Molding If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. Flashing is often the most common occurrence on the separating line of plastic molding. The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or. What Is Flash In Molding.

From empslc.com

Injection Molding Terminology Flash And Various Processes EnviroTech What Is Flash In Molding An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. This flaw can damage molds and. This extra material is usually located. What Is Flash In Molding.

From www.zdcpu.com

Dealing with Injection Molding Flash Causes, Prevention, and Removal What Is Flash In Molding This flaw can damage molds and. Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as. What Is Flash In Molding.

From www.optimim.com

Flash and Witness Lines Metal Injection Molding OptiMIM What Is Flash In Molding Flashing is often the most common occurrence on the separating line of plastic molding. If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. Flash, a common defect,. What Is Flash In Molding.

From www.rapiddirect.com

Injection Molding Flash Top 9 Causes and How to Fix Them What Is Flash In Molding If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: What is injection molding flash? Flash, a. What Is Flash In Molding.

From www.cnclathing.com

How to Avoid Flash in TPE Plastic Injection Molding Flash Defect What Is Flash In Molding Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. The defect known as injection molding flash happens when a component has. What Is Flash In Molding.

From info.crescentind.com

How to Avoid Plastic Injection Molding Flash What Is Flash In Molding An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: What is injection molding flash? What is flash in injection molding? It appears. What Is Flash In Molding.

From www.all-plastics.com

Flash In Injection Molding AllPlastics What Is Flash In Molding It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. What is injection molding flash? Flashing is often the most common occurrence on the separating line of plastic molding. The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at. What Is Flash In Molding.

From www.longshengmfg.com

How to Avoid Flash in Injection molding LONGSHENG What Is Flash In Molding This flaw can damage molds and. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. What is flash in injection molding? Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the. What Is Flash In Molding.

From plasticinjectionresources.com

What is Flashing Plastic Injection Molding Explained Plastic Injection What Is Flash In Molding The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet. What is injection molding flash? Flashing is often the most common occurrence on the separating line of plastic molding. It appears as thin, often sharp edges of plastic. What Is Flash In Molding.

From www.longshengmfg.com

How to Avoid Flash in Injection molding LONGSHENG What Is Flash In Molding Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. What is injection molding flash? The defect known as injection molding flash happens when a component has excess plastic on the parting line,. What Is Flash In Molding.

From www.vem-tooling.com

Flash What Is Flash In Molding This flaw can damage molds and. This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters. What Is Flash In Molding.

From www.dgmfmoldclamps.com

What Causes The Injection Molding Flash? Mould Clamps Manufacturer What Is Flash In Molding Flashing is often the most common occurrence on the separating line of plastic molding. It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing. What Is Flash In Molding.

From www.optimim.com

Flash and Witness Lines Metal Injection Molding OptiMIM What Is Flash In Molding What is flash in injection molding? Flashing is often the most common occurrence on the separating line of plastic molding. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when. What Is Flash In Molding.

From www.alpine-mold.com

How to Prevent Flash in Injection MoldingAlpineMold What Is Flash In Molding The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet. What is injection molding flash? Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. Flashing is often the most common occurrence on the. What Is Flash In Molding.

From www.vem-tooling.com

Flash What Is Flash In Molding This flaw can damage molds and. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. If plastic injection molding were like painting a living room, flash would be the traces of burnished. What Is Flash In Molding.

From www.scribd.com

What Is Flash in Injection Molding Download Free PDF Industrial What Is Flash In Molding What is injection molding flash? What is flash in injection molding? An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. Flashing is often the most common occurrence on the separating line of plastic molding. If plastic injection molding were like painting a living room, flash would be the traces of burnished. What Is Flash In Molding.

From tdlmould.com

Flash in Injection Molding Causes, Effects, and Solutions TDL What Is Flash In Molding If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. This flaw can damage molds and. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. Flashing is often the most common occurrence on the separating line. What Is Flash In Molding.

From www.seaskymedical.com

What Causes Molding Flash and How to Avoid it Seaskymedical What Is Flash In Molding Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. This extra material is usually located on the edge or surface of. What Is Flash In Molding.

From www.vem-tooling.com

Flash What Is Flash In Molding Flashing is often the most common occurrence on the separating line of plastic molding. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of. What Is Flash In Molding.

From www.plastopialtd.com

Injection Molding Glossary & Basics Plastopia What Is Flash In Molding It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. Flashing is often the most common occurrence on the separating line of plastic molding. Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. The defect known as injection molding flash happens when a component has excess plastic. What Is Flash In Molding.

From www.seaskymedical.com

What Causes Molding Flash and How to Avoid it Seaskymedical What Is Flash In Molding Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. This flaw can damage molds and. The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet. If plastic injection. What Is Flash In Molding.

From lmcindustries.com

What is Flash in Plastic Molding? Contract Manufacturing LMC Industries What Is Flash In Molding Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. What is flash in injection molding? Flashing is often the most common occurrence on the separating line of plastic molding. This flaw can damage molds and. The defect known as injection molding flash happens when a component has excess plastic on. What Is Flash In Molding.

From plasticinjectionresources.com

What is Flashing Plastic Injection Molding Explained Plastic Injection What Is Flash In Molding Flash on plastic parts, also known as burrs or spews, refers to the extra material produced during the molding process when the plastic melt enters the gap of the mold. This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: What. What Is Flash In Molding.

From dienamics.com.au

Trial and Error Flashing Dienamics What Is Flash In Molding This flaw can damage molds and. What is flash in injection molding? An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. The defect known as injection molding. What Is Flash In Molding.

From inspectapedia.com

Roof Drip Edge Flashing Installation FAQs Q&A on the right way to What Is Flash In Molding Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. What is injection molding flash? Flashing is often the most common occurrence on the separating line of plastic molding. Flash in injection molding refers to the unwanted excess plastic that forms on a part during the molding process. This flaw can damage molds and. Flash on. What Is Flash In Molding.

From www.vem-tooling.com

Flash What Is Flash In Molding This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: What is injection molding flash? If plastic injection molding were like painting a living room, flash would be the traces of burnished clay or hague blue that seep around. This flaw. What Is Flash In Molding.

From www.slideshare.net

What is flash injection molding? What Is Flash In Molding This extra material is usually located on the edge or surface of the plastic part and appears sharp, hence the name “flash” — as shown in the image below: This flaw can damage molds and. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. Flash in injection molding refers to the. What Is Flash In Molding.

From www.kemalmfg.com

9 Common Causes of Injection Molding Flash and How to Fix Them What Is Flash In Molding This flaw can damage molds and. Flashing is often the most common occurrence on the separating line of plastic molding. An injection molding cycle involves injecting molten plastic into a mold cavity and allowing it to cool down. It appears as thin, often sharp edges of plastic that extend beyond the desired shape of the product. The defect known as. What Is Flash In Molding.