Fabrication Process Of Transistor . Construction of an npn bipolar transistor. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: Lithography process has been the mainstream chip manufacturing. 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Cmos transistors are fabricated on silicon wafers.

from medium.com

Lithography process has been the mainstream chip manufacturing. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Deposition, photoresist, lithography, etch, ionization and packaging. 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Let’s discuss six critical semiconductor manufacturing steps: Cmos transistors are fabricated on silicon wafers. Construction of an npn bipolar transistor.

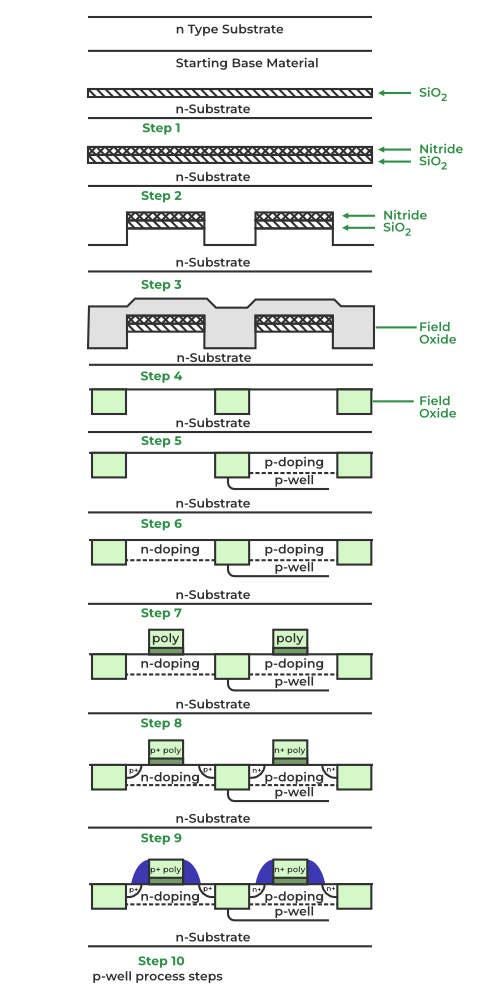

CMOS FABRICATION (PWELL PROCESS) by Agnathavasi Medium

Fabrication Process Of Transistor Deposition, photoresist, lithography, etch, ionization and packaging. Lithography process has been the mainstream chip manufacturing. Construction of an npn bipolar transistor. 600 nm) is deposited on top. Cmos transistors are fabricated on silicon wafers. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Let’s discuss six critical semiconductor manufacturing steps:

From stock.adobe.com

FinFET transistors for 14nm, 10nm, 7 nm, 5nm technology node of chip manufacturing process. 3D Fabrication Process Of Transistor Construction of an npn bipolar transistor. 600 nm) is deposited on top. Cmos transistors are fabricated on silicon wafers. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion. Fabrication Process Of Transistor.

From www.vrogue.co

A Schematics Of Top Gate Transistor Fabrication Proce vrogue.co Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Lithography process has been the mainstream chip manufacturing. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors.. Fabrication Process Of Transistor.

From www.newport.com.cn

Semiconductor Manufacturing Fabrication Process Of Transistor Construction of an npn bipolar transistor. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Cmos transistors are fabricated on silicon wafers. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: 600 nm) is deposited on top. The. Fabrication Process Of Transistor.

From www.youtube.com

pMOS Fabrication process, pmos fabrication steps, VLSI Design, pMOS Transistor design YouTube Fabrication Process Of Transistor The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. 600 nm) is deposited on top. Construction of an npn bipolar transistor. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. Lithography process has been the mainstream chip manufacturing. This step is where all of the. Fabrication Process Of Transistor.

From mungfali.com

SiC MOSFET Process Flow Fabrication Process Of Transistor Deposition, photoresist, lithography, etch, ionization and packaging. 600 nm) is deposited on top. Cmos transistors are fabricated on silicon wafers. Construction of an npn bipolar transistor. Lithography process has been the mainstream chip manufacturing. Let’s discuss six critical semiconductor manufacturing steps: The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp.. Fabrication Process Of Transistor.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Fabrication Process Of Transistor Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: 600 nm) is deposited on top. Construction of an npn bipolar transistor. Cmos transistors are fabricated on silicon wafers. Lithography process has been the mainstream chip manufacturing. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp.. Fabrication Process Of Transistor.

From slidetodoc.com

Standard Bipolar Transistor Fabrication Process In this lecture Fabrication Process Of Transistor Lithography process has been the mainstream chip manufacturing. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Construction of an npn bipolar transistor. 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer. Fabrication Process Of Transistor.

From www.researchgate.net

Fabrication process flow for the IIIV 4D transistors w and lateral... Download Scientific Diagram Fabrication Process Of Transistor Let’s discuss six critical semiconductor manufacturing steps: This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Construction of an npn bipolar transistor. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Deposition, photoresist,. Fabrication Process Of Transistor.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Let’s discuss six critical semiconductor manufacturing steps: Lithography process has been the mainstream chip manufacturing. Deposition, photoresist, lithography, etch, ionization and packaging. This step is where all of the transistors are wired together, along. Fabrication Process Of Transistor.

From medium.com

CMOS FABRICATION (PWELL PROCESS) by Agnathavasi Medium Fabrication Process Of Transistor This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: Construction of an npn bipolar transistor. Cmos transistors are fabricated on silicon wafers. The semiconductor manufacturing process involves multiple steps,. Fabrication Process Of Transistor.

From www.researchgate.net

Representation of the working principle of a pMOS transistor. The... Download Scientific Diagram Fabrication Process Of Transistor Lithography process has been the mainstream chip manufacturing. Construction of an npn bipolar transistor. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation,. Fabrication Process Of Transistor.

From www.nanowerk.com

Transistors explained what they are and what they do Fabrication Process Of Transistor Construction of an npn bipolar transistor. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Let’s discuss six critical semiconductor manufacturing steps: This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. 600 nm). Fabrication Process Of Transistor.

From www.researchgate.net

Operation Process for 3D Transistor in Fabrication of Semiconductor Device Download Scientific Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. 600 nm) is deposited on top. Lithography process has been the mainstream chip manufacturing. Construction of an npn bipolar transistor. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. This step is where all of the. Fabrication Process Of Transistor.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Fabrication Process Of Transistor This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Let’s discuss six critical semiconductor manufacturing steps: 600 nm) is deposited on top. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Construction of. Fabrication Process Of Transistor.

From siliconupdates.blogspot.com

World's first 5nm chip with Gateallaround transistors from IBM Silicon Updates Fabrication Process Of Transistor Construction of an npn bipolar transistor. Let’s discuss six critical semiconductor manufacturing steps: The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. 600 nm) is deposited on top. Lithography process has been the mainstream chip manufacturing. Cmos transistors are fabricated on silicon wafers. This step is where all of the. Fabrication Process Of Transistor.

From www.researchgate.net

Thin film transistor fabrication process. a) Printing the precursors,... Download Scientific Fabrication Process Of Transistor The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Cmos transistors are fabricated on silicon wafers. Construction of an npn bipolar transistor. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Lithography process. Fabrication Process Of Transistor.

From www.researchgate.net

(a) Schematic of graphene transistors fabricated. Transistors had a... Download Scientific Diagram Fabrication Process Of Transistor The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Cmos transistors are fabricated on silicon wafers. Lithography process has been the mainstream chip manufacturing. Let’s discuss six critical semiconductor manufacturing steps: Construction of an npn bipolar transistor. This step is where all of the transistors are wired together, along with. Fabrication Process Of Transistor.

From anal-13gb75.blogspot.com

☑ Explain Integrated Circuit Fabrication Process Fabrication Process Of Transistor 600 nm) is deposited on top. Lithography process has been the mainstream chip manufacturing. Cmos transistors are fabricated on silicon wafers. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Fabrication Process Of Transistor.

From www.researchgate.net

Evolution of the Field Effect Transistor (FET) Architecture. The single... Download Scientific Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. Construction of an npn bipolar transistor. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. 600 nm). Fabrication Process Of Transistor.

From www.scribd.com

Fabrication of NMOS Transistor PDF Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. Let’s discuss six critical semiconductor manufacturing steps: This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Lithography process has been the mainstream chip manufacturing. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves. Fabrication Process Of Transistor.

From www.researchgate.net

Transistor manufacture al, Fabrication process flow of the nFET/pFET... Download Scientific Fabrication Process Of Transistor Deposition, photoresist, lithography, etch, ionization and packaging. Construction of an npn bipolar transistor. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. 600 nm). Fabrication Process Of Transistor.

From www.mdpi.com

Fabrication and Evaluation of NChannel GaN MetalOxideSemiconductor FieldEffect Transistors Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. Lithography process has been the mainstream chip manufacturing. Construction of an npn bipolar transistor. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. 600 nm) is deposited on top. Let’s discuss six critical semiconductor manufacturing steps: This step is where all of the. Fabrication Process Of Transistor.

From www.researchgate.net

The semiconductor manufacturing process. Download Scientific Diagram Fabrication Process Of Transistor Deposition, photoresist, lithography, etch, ionization and packaging. 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Construction of an npn bipolar transistor. Lithography process has been the mainstream chip manufacturing. Cmos transistors are fabricated on silicon wafers.. Fabrication Process Of Transistor.

From www.gallagherseals.com

Basic Semiconductor Manufacturing Process Fabrication Process Of Transistor Let’s discuss six critical semiconductor manufacturing steps: Construction of an npn bipolar transistor. Cmos transistors are fabricated on silicon wafers. 600 nm) is deposited on top. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Lithography process has been the mainstream chip manufacturing. This step is where all of the. Fabrication Process Of Transistor.

From news.skhynix.com

Semiconductor FrontEnd Process Episode 6 Metallization Fabrication Process Of Transistor This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Construction of an npn bipolar transistor. Let’s discuss six critical semiconductor manufacturing steps: Lithography process has been the mainstream chip manufacturing. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Fabrication Process Of Transistor.

From www.researchgate.net

Schematic for (a) fabrication process of (b) the rSWCNT transistor... Download Scientific Diagram Fabrication Process Of Transistor Lithography process has been the mainstream chip manufacturing. Let’s discuss six critical semiconductor manufacturing steps: This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Deposition, photoresist, lithography, etch, ionization and packaging. Cmos transistors are fabricated on silicon wafers. The semiconductor manufacturing process involves. Fabrication Process Of Transistor.

From www.researchgate.net

21 Schéma des principales étapes de fabrication d'un transistor FDSOI... Download Scientific Fabrication Process Of Transistor Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: Cmos transistors are fabricated on silicon wafers. Lithography process has been the mainstream chip manufacturing. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. 600 nm) is deposited on top. Construction of an npn bipolar transistor.. Fabrication Process Of Transistor.

From www.researchgate.net

Fabrication process flow of a SiNTFET. Download Scientific Diagram Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. Construction of an npn bipolar transistor. The. Fabrication Process Of Transistor.

From www.researchgate.net

The proposed fabrication process of the SGJLMOS transistor. Download Scientific Diagram Fabrication Process Of Transistor 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Cmos transistors are fabricated on silicon wafers. Let’s discuss six critical semiconductor manufacturing steps: Lithography process has been the mainstream chip manufacturing. The semiconductor manufacturing process involves multiple. Fabrication Process Of Transistor.

From www.researchgate.net

Fabrication and testing of metal oxide HJ transistors. A) Schematic of... Download Scientific Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Let’s discuss six critical semiconductor manufacturing steps: Lithography process has been the mainstream chip manufacturing. Deposition, photoresist, lithography, etch, ionization and packaging. Construction of an npn bipolar. Fabrication Process Of Transistor.

From www.vrogue.co

A Schematics Of Top Gate Transistor Fabrication Proce vrogue.co Fabrication Process Of Transistor Let’s discuss six critical semiconductor manufacturing steps: Construction of an npn bipolar transistor. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Lithography process has been the mainstream chip manufacturing. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric. Fabrication Process Of Transistor.

From www.researchgate.net

Fabrication process of fieldeffect transistor (FET) devices.... Download Scientific Diagram Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. Construction of an npn bipolar transistor. Lithography process has been the mainstream chip manufacturing. 600 nm) is deposited on top. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Deposition, photoresist, lithography, etch, ionization and packaging.. Fabrication Process Of Transistor.

From www.researchgate.net

(a) Schematics of topgate transistor fabrication process. (b) Optical Download Scientific Diagram Fabrication Process Of Transistor The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Cmos transistors are fabricated on silicon wafers. Deposition, photoresist, lithography, etch, ionization and packaging. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Lithography. Fabrication Process Of Transistor.

From microchipusa.com

A StepbyStep Guide to Semiconductor Manufacturing Microchip USA Fabrication Process Of Transistor Cmos transistors are fabricated on silicon wafers. Construction of an npn bipolar transistor. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Lithography process. Fabrication Process Of Transistor.

From www.semanticscholar.org

Figure 4 from BRIEF FABRICATION PROCESSES OF SILICONON INSULATOR AND LATERAL BIPOLAR Fabrication Process Of Transistor Lithography process has been the mainstream chip manufacturing. This step is where all of the transistors are wired together, along with interlayer connections (vias), capacitors (in dram), dielectric isolation, and chip to package connectors. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp.. Fabrication Process Of Transistor.