Minimum Splice Length Reinforcing Steel . Camber of beams and slabs structural steel: 18, and in 20 to 40 ft lengths for smaller bar sizes. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Development lengths and lap splices scale. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Bars may be spaced apart or in contact. But not less than 12 inches (305 mm). For this reason, and because it is often more. A lap splice is the predominant method used for splicing reinforcing bars. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices.

from www.formsbank.com

Camber of beams and slabs structural steel: The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. A lap splice is the predominant method used for splicing reinforcing bars. But not less than 12 inches (305 mm). 18, and in 20 to 40 ft lengths for smaller bar sizes. The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. Development lengths and lap splices scale. For this reason, and because it is often more. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate.

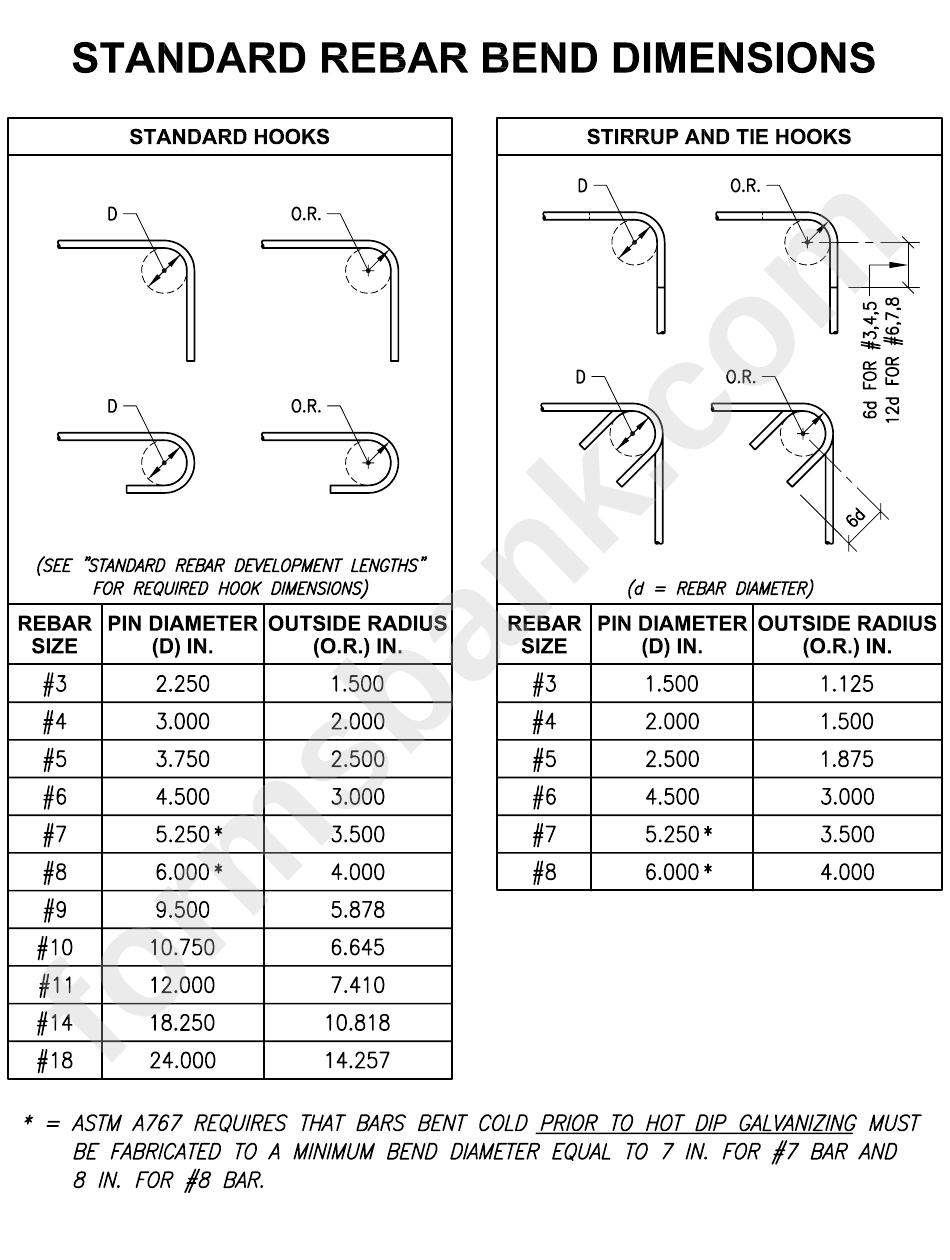

Standard Rebar Bend Dimensions Chart printable pdf download

Minimum Splice Length Reinforcing Steel Development lengths and lap splices scale. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. Bars may be spaced apart or in contact. For this reason, and because it is often more. A lap splice is the predominant method used for splicing reinforcing bars. Camber of beams and slabs structural steel: In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: 18, and in 20 to 40 ft lengths for smaller bar sizes. Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. But not less than 12 inches (305 mm). Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Development lengths and lap splices scale.

From www.youtube.com

Rebar Splice Length Design Example Part 7 learnengineering YouTube Minimum Splice Length Reinforcing Steel Development lengths and lap splices scale. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. 18, and in 20 to 40 ft lengths for smaller bar sizes. Bars may be. Minimum Splice Length Reinforcing Steel.

From www.aboutcivil.org

Steel Reinforcement for Walls Horizontal Rebars, Vertical and Splicing Minimum Splice Length Reinforcing Steel The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. Camber of beams and slabs structural steel: The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: A lap splice is the predominant method used for splicing reinforcing bars. 18, and in. Minimum Splice Length Reinforcing Steel.

From mungfali.com

Rebar Splice Length Chart Minimum Splice Length Reinforcing Steel Bars may be spaced apart or in contact. But not less than 12 inches (305 mm). For this reason, and because it is often more. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Camber of beams and slabs structural steel: The development length of a. Minimum Splice Length Reinforcing Steel.

From kuudesign.com

28+ Aci Rebar Lap Splice Chart Home Design Minimum Splice Length Reinforcing Steel For this reason, and because it is often more. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: Development lengths and lap splices scale. Building codes include requirements for minimum reinforcement development lengths and splice lengths,. Minimum Splice Length Reinforcing Steel.

From www.scribd.com

Minimum Rebar Development and Splice Lengths (MM) PDF Minimum Splice Length Reinforcing Steel The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. Bars may be spaced apart or in contact. A lap splice is the predominant method used for splicing reinforcing bars. Camber of beams and slabs structural steel: In general reinforcing bars are stocked by suppliers in lengths of. Minimum Splice Length Reinforcing Steel.

From pdfslide.net

(PDF) REINFORCING STEEL LAP SPLICES AND EMBEDMENTS · 2018. 5. 24. · reinforcing steel lap Minimum Splice Length Reinforcing Steel For this reason, and because it is often more. Development lengths and lap splices scale. Camber of beams and slabs structural steel: Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for. Minimum Splice Length Reinforcing Steel.

From civilmint.com

What Is Splicing Of Reinforcement Bars? Minimum Splice Length Reinforcing Steel Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Development lengths and lap splices scale. But not less than 12 inches (305 mm). 18, and in 20 to 40 ft lengths for smaller bar sizes. A lap splice is the predominant method used for splicing reinforcing. Minimum Splice Length Reinforcing Steel.

From dat.perueduca.edu.pe

Rebar Splice Length Chart Printable Templates Free Minimum Splice Length Reinforcing Steel 18, and in 20 to 40 ft lengths for smaller bar sizes. But not less than 12 inches (305 mm). A lap splice is the predominant method used for splicing reinforcing bars. For this reason, and because it is often more. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Camber of. Minimum Splice Length Reinforcing Steel.

From www.eng-tips.com

What is the minimum length for a member piece in splice connection? Structural engineering Minimum Splice Length Reinforcing Steel The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. But not less than 12 inches (305 mm). 18, and in 20 to 40 ft lengths for smaller bar sizes. Camber of beams and slabs structural steel: Building codes include requirements for minimum reinforcement development lengths and splice. Minimum Splice Length Reinforcing Steel.

From mungfali.com

Rebar Splice Length Chart Minimum Splice Length Reinforcing Steel In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. But not less than 12 inches (305 mm). The minimum length of lap splices for reinforcing bars in tension. Minimum Splice Length Reinforcing Steel.

From structuralcalc.com

Rebar Development Length Calculator to ACI 318 (US) — Structural Calc Minimum Splice Length Reinforcing Steel Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Bars may be spaced apart or in contact. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. But not less than 12 inches (305. Minimum Splice Length Reinforcing Steel.

From www.youtube.com

NSCP 2015 Reinforcement Detailing p1 Intro and Development Length of Tension Bars YouTube Minimum Splice Length Reinforcing Steel Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full. Minimum Splice Length Reinforcing Steel.

From studylibmueller.z1.web.core.windows.net

Lap Splice Length For Rebar Chart Minimum Splice Length Reinforcing Steel For this reason, and because it is often more. Camber of beams and slabs structural steel: Bars may be spaced apart or in contact. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Development lengths and lap splices scale. The minimum length of lap splices for. Minimum Splice Length Reinforcing Steel.

From ar.inspiredpencil.com

Aci Rebar Splice Length Minimum Splice Length Reinforcing Steel Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. The development length of a rebar is the shortest embedment length required for. Minimum Splice Length Reinforcing Steel.

From www.monolithic.org

Rebar Splicing and Rebar Sizing Minimum Splice Length Reinforcing Steel 18, and in 20 to 40 ft lengths for smaller bar sizes. The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: Development lengths and lap splices scale. For this reason, and because it is often more. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for. Minimum Splice Length Reinforcing Steel.

From learninglibschuhmancher.z13.web.core.windows.net

Aci Rebar Lap Splice Length Chart Minimum Splice Length Reinforcing Steel A lap splice is the predominant method used for splicing reinforcing bars. Camber of beams and slabs structural steel: Bars may be spaced apart or in contact. The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: But not less than 12 inches (305 mm). In general reinforcing bars are stocked by suppliers in. Minimum Splice Length Reinforcing Steel.

From www.lceted.com

What is Lap Length Lap length of Beams Lap Length of Slabs Lap Length of Columns Lap Minimum Splice Length Reinforcing Steel In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Camber of beams and slabs structural steel: Bars may be spaced apart or in contact. 18, and in 20 to 40 ft lengths for smaller bar sizes. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements. Minimum Splice Length Reinforcing Steel.

From constrofacilitator.com

Different methods for splicing reinforced bars Minimum Splice Length Reinforcing Steel Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. A lap splice is the predominant method used for splicing reinforcing bars. Development. Minimum Splice Length Reinforcing Steel.

From georgiabaker.z21.web.core.windows.net

Aci Rebar Lap Splice Length Chart Minimum Splice Length Reinforcing Steel Camber of beams and slabs structural steel: 18, and in 20 to 40 ft lengths for smaller bar sizes. A lap splice is the predominant method used for splicing reinforcing bars. Bars may be spaced apart or in contact. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure. Minimum Splice Length Reinforcing Steel.

From constrofacilitator.com

Different methods for splicing reinforced bars Minimum Splice Length Reinforcing Steel 18, and in 20 to 40 ft lengths for smaller bar sizes. Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. But. Minimum Splice Length Reinforcing Steel.

From structuralcalc.com

Rebar Development Length Calculator to ACI 318 — Structural Calc Minimum Splice Length Reinforcing Steel Bars may be spaced apart or in contact. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Camber of beams and slabs structural steel: The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: In general reinforcing bars are stocked. Minimum Splice Length Reinforcing Steel.

From www.monolithic.org

Rebar Splicing and Rebar Sizing Minimum Splice Length Reinforcing Steel In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. But not less than 12 inches (305 mm). Bars may be spaced apart or in contact. For this reason, and because it is often more. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop. Minimum Splice Length Reinforcing Steel.

From dailycivil.com

What Is Lap Length Of Reinforcement Bars Lapping Length of Steel Bars Minimum Splice Length Reinforcing Steel Development lengths and lap splices scale. Bars may be spaced apart or in contact. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Camber of beams and slabs structural steel: The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be:. Minimum Splice Length Reinforcing Steel.

From www.researchgate.net

Overlap in steel bar by splicing by wire Download Table Minimum Splice Length Reinforcing Steel Bars may be spaced apart or in contact. A lap splice is the predominant method used for splicing reinforcing bars. But not less than 12 inches (305 mm). Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. The minimum length of lap splices for reinforcing bars. Minimum Splice Length Reinforcing Steel.

From theconstructor.org

How to Properly Splice Column Reinforcement as per Indian Standards? The Constructor Minimum Splice Length Reinforcing Steel In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. 18, and in 20 to 40 ft lengths for smaller bar sizes. But not less than 12 inches (305 mm). A lap splice is the predominant method used for splicing reinforcing bars. Development lengths and lap splices scale. Bars may be spaced apart. Minimum Splice Length Reinforcing Steel.

From www.formsbank.com

Standard Rebar Bend Dimensions Chart printable pdf download Minimum Splice Length Reinforcing Steel 18, and in 20 to 40 ft lengths for smaller bar sizes. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. Camber of beams and slabs structural steel: In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. But not. Minimum Splice Length Reinforcing Steel.

From mavink.com

Crsi Rebar Lap Splice Chart Minimum Splice Length Reinforcing Steel Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. Bars may be spaced apart or in contact. The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. In general reinforcing bars are stocked. Minimum Splice Length Reinforcing Steel.

From ar.inspiredpencil.com

Lap Splice Reinforcement Minimum Splice Length Reinforcing Steel Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. Development lengths and lap splices scale. A lap splice is the predominant method used for splicing reinforcing bars. But not less than 12 inches (305 mm). For this reason, and because it is often more. The. Minimum Splice Length Reinforcing Steel.

From ar.inspiredpencil.com

Aci Rebar Splice Length Minimum Splice Length Reinforcing Steel A lap splice is the predominant method used for splicing reinforcing bars. But not less than 12 inches (305 mm). 18, and in 20 to 40 ft lengths for smaller bar sizes. Bars may be spaced apart or in contact. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to. Minimum Splice Length Reinforcing Steel.

From ar.inspiredpencil.com

Aci Rebar Splice Length Minimum Splice Length Reinforcing Steel A lap splice is the predominant method used for splicing reinforcing bars. Camber of beams and slabs structural steel: The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. Bars may be spaced apart or in contact. Lap splices of bundled bars should be based on the lap. Minimum Splice Length Reinforcing Steel.

From www.vrogue.co

Understanding Lap Splices In Reinforcing Bars vrogue.co Minimum Splice Length Reinforcing Steel The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: Lap splices of bundled bars should be based on the lap splice length recommended for individual bars of the same size, and individual splices. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to. Minimum Splice Length Reinforcing Steel.

From www.scribd.com

Minimum Development and Splice Length Requirements for Reinforcing Bars According to ACI318M08 Minimum Splice Length Reinforcing Steel A lap splice is the predominant method used for splicing reinforcing bars. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. Bars may be spaced apart or in contact. The development length of a rebar is the shortest embedment length required for a reinforcing bar to. Minimum Splice Length Reinforcing Steel.

From www.youtube.com

Development Length and Lapping Length for Reinforcement Civil Engineering Videos YouTube Minimum Splice Length Reinforcing Steel A lap splice is the predominant method used for splicing reinforcing bars. The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: Bars may be spaced apart or in contact. 18, and in 20 to 40 ft lengths for smaller bar sizes. Development lengths and lap splices scale. Camber of beams and slabs structural. Minimum Splice Length Reinforcing Steel.

From robertmurray.z21.web.core.windows.net

Lap Splice Length For Rebar Chart Minimum Splice Length Reinforcing Steel The minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: The development length of a rebar is the shortest embedment length required for a reinforcing bar to develop its full yield strength. For this reason, and because it is often more. Development lengths and lap splices scale. A lap splice is the predominant method. Minimum Splice Length Reinforcing Steel.

From www.youtube.com

What is Overlap Length in Reinforcement Structure Member What is Splice length Overlapping Minimum Splice Length Reinforcing Steel Bars may be spaced apart or in contact. Development lengths and lap splices scale. A lap splice is the predominant method used for splicing reinforcing bars. Building codes include requirements for minimum reinforcement development lengths and splice lengths, as well as requirements for standard hooks, to ensure the adequate. The development length of a rebar is the shortest embedment length. Minimum Splice Length Reinforcing Steel.