Belt Grinder Vs Wheel . For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. Uncooled belt sharpening stands a very good chance of overheating the edge. Grinders can also be designed. While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. Belt grinders are expensive, but the quality is worth it. I'd say it's close to a guarantee. 95% of all professional knife makers use. Dressing the wheels are a p i t a. I'd probably use the grinder more if i get a cbn wheel. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Mostly i use the sorby belt sander. Key differences between a bench grinder vs belt sander.

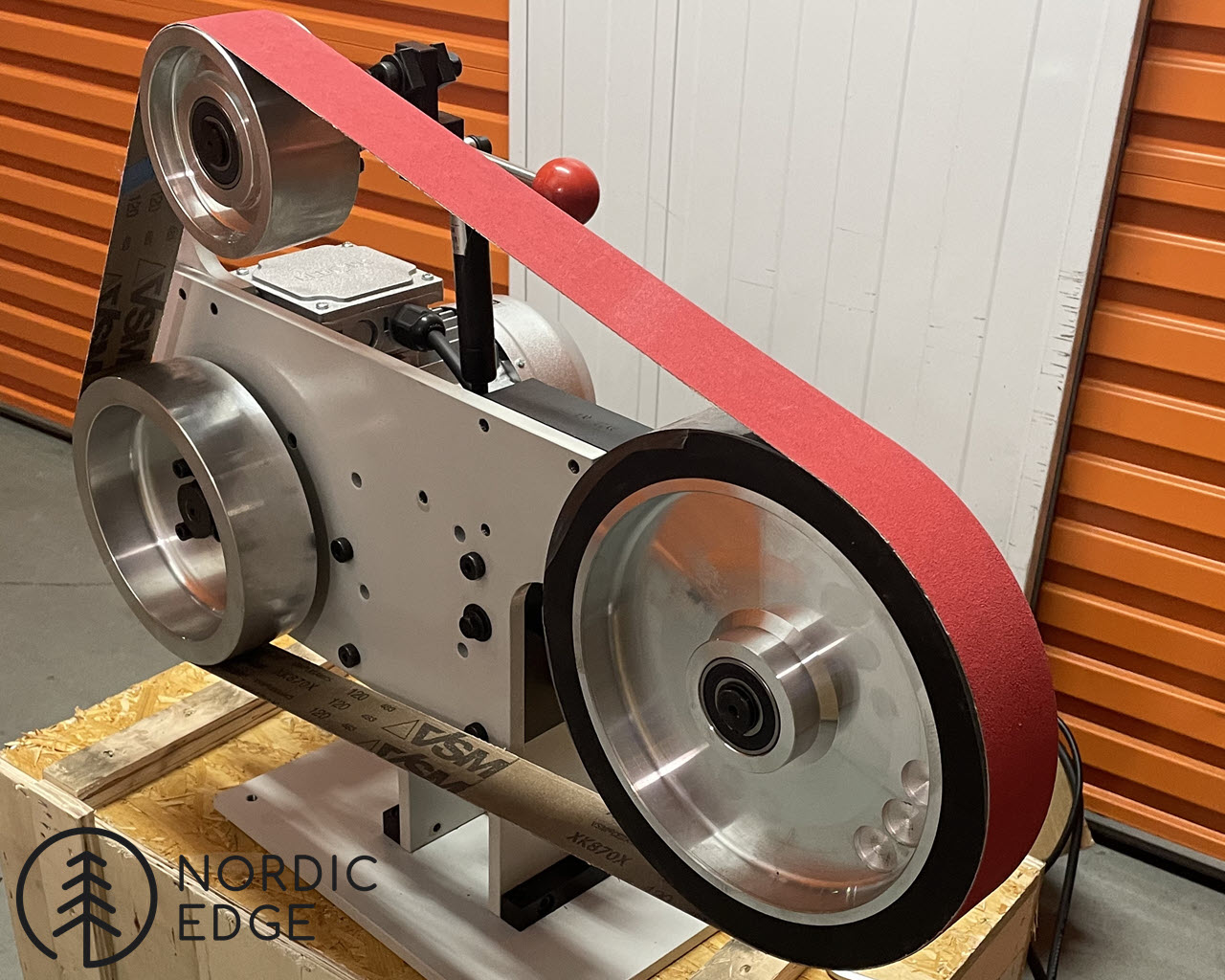

from nordicedge.com.au

95% of all professional knife makers use. Uncooled belt sharpening stands a very good chance of overheating the edge. While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. I'd probably use the grinder more if i get a cbn wheel. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Dressing the wheels are a p i t a. Grinders can also be designed. Mostly i use the sorby belt sander. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. I'd say it's close to a guarantee.

Belt Grinder 2 x 72" Package Nordic Edge

Belt Grinder Vs Wheel Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. Dressing the wheels are a p i t a. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Uncooled belt sharpening stands a very good chance of overheating the edge. Grinders can also be designed. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. Key differences between a bench grinder vs belt sander. Mostly i use the sorby belt sander. While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. I'd probably use the grinder more if i get a cbn wheel. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. I'd say it's close to a guarantee. Belt grinders are expensive, but the quality is worth it. 95% of all professional knife makers use.

From www.redmondmachinery.com

Jet SWG272VS, 2" x 72" Square Wheel Belt Grinder, 6200 SFPM, 1Ph 115/230V Belt Grinder Vs Wheel For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. I'd probably use the grinder more if i get a cbn wheel. Belt grinders may all look similar, but specs vary from grinder to grinder, which. Belt Grinder Vs Wheel.

From aboutsanders.com

Belt Grinder vs. Belt Sander The Ultimate Showdown Belt Grinder Vs Wheel Dressing the wheels are a p i t a. 95% of all professional knife makers use. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. I'd probably use the grinder more if i get a cbn wheel. Mostly i use the sorby belt sander. I'd say it's close to a. Belt Grinder Vs Wheel.

From www.pinterest.com

DIY Making A 2x72" / Belt Grinder with buffing wheel in 2020 Knife grinder, Belt grinder Belt Grinder Vs Wheel Uncooled belt sharpening stands a very good chance of overheating the edge. Dressing the wheels are a p i t a. Mostly i use the sorby belt sander. I'd say it's close to a guarantee. Grinders can also be designed. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Belt. Belt Grinder Vs Wheel.

From www.jbtools.com

Jet 577405 SWG272VS , 2 x 72 Variable Speed Square Wheel Belt Grinder 115V 1Ph JB Tools Belt Grinder Vs Wheel Grinders can also be designed. 95% of all professional knife makers use. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. I'd say it's close to a guarantee. Uncooled belt sharpening stands a very good chance of overheating the edge. Belt grinders may all look similar, but specs. Belt Grinder Vs Wheel.

From www.vevor.ca

VEVOR Belt Grinder 2" x 72" Wheel Set, Complete Belt Knife Grinder Wheel Set, Aluminum Belt Belt Grinder Vs Wheel Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. 95% of all professional knife makers use. Uncooled belt sharpening stands a very good chance of overheating the edge. Dressing the wheels are. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder Drive Wheel 7" Diameter, 2"x72" Knife Grinder Drive Wheel 0.94" Bore/Shaft Belt Grinder Vs Wheel Dressing the wheels are a p i t a. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. I'd say it's close to a guarantee. 95% of all professional knife makers use. Key differences between a bench grinder vs belt sander. Grinders can also be designed. Uncooled belt. Belt Grinder Vs Wheel.

From originblademaker.com

Belt Grinder Wheels Origin Blade Maker Belt Grinder Vs Wheel I'd probably use the grinder more if i get a cbn wheel. While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. Belt grinders are expensive, but the quality is worth it. Key differences between a bench grinder vs belt sander. Uncooled belt sharpening stands a very good chance of overheating the edge. I'd. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder 2"x72" Wheel Set, Complete Belt Knife Grinder Wheel Set, Aluminum Belt Belt Grinder Vs Wheel Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. Grinders can also be designed. 95% of all professional knife makers use. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Uncooled belt sharpening stands a very good chance. Belt Grinder Vs Wheel.

From www.desertcart.no

Buy (6" 19) Belt Grinder Drive Wheel CNC Machined Belt Grinder Drive Wheel for Grinders 160 mm Belt Grinder Vs Wheel Belt grinders are expensive, but the quality is worth it. Grinders can also be designed. I'd say it's close to a guarantee. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt. Belt Grinder Vs Wheel.

From www.youtube.com

2X48 Homemade belt grinder YouTube Belt Grinder Vs Wheel Key differences between a bench grinder vs belt sander. Belt grinders are expensive, but the quality is worth it. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Grinders can also be designed. Belt grinders. Belt Grinder Vs Wheel.

From nordicedge.com.au

Belt Grinder 2 x 72" Package Nordic Edge Belt Grinder Vs Wheel While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. Dressing the wheels are a p i t a. Mostly i use the sorby belt sander. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. Grinders can also be designed. For best. Belt Grinder Vs Wheel.

From aboutsanders.com

Belt Grinder vs. Belt Sander The Ultimate Showdown Belt Grinder Vs Wheel I'd probably use the grinder more if i get a cbn wheel. Uncooled belt sharpening stands a very good chance of overheating the edge. Mostly i use the sorby belt sander. Grinders can also be designed. Key differences between a bench grinder vs belt sander. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder Drive Wheel 7" Diameter, 2"x72" Knife Grinder Drive Wheel 0.94" Bore/Shaft Belt Grinder Vs Wheel For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Uncooled belt sharpening stands a very good chance of overheating the edge. Grinders can also be designed. Key differences between a bench grinder vs belt sander.. Belt Grinder Vs Wheel.

From nordicedge.com.au

Belt Grinder 2 x 72" Package Nordic Edge Belt Grinder Vs Wheel Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. Key differences between a bench grinder vs belt sander. I'd probably use the grinder more if i get a cbn wheel. While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. Belt grinders. Belt Grinder Vs Wheel.

From www.youtube.com

How to Setup a Contact Wheel on a 2x72 Belt Grinder YouTube Belt Grinder Vs Wheel I'd probably use the grinder more if i get a cbn wheel. Mostly i use the sorby belt sander. Dressing the wheels are a p i t a. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. 95% of all professional knife makers use. Uncooled belt sharpening stands a very. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder 2" x 72" Wheel Set, Complete Belt Knife Grinder Wheel Set, Aluminum Belt Belt Grinder Vs Wheel Grinders can also be designed. 95% of all professional knife makers use. Dressing the wheels are a p i t a. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Belt grinders may all look. Belt Grinder Vs Wheel.

From www.instructables.com

Bolt Together 2 X 72 Belt Grinder 12 Steps (with Pictures) Instructables Belt Grinder Vs Wheel Belt grinders are expensive, but the quality is worth it. Key differences between a bench grinder vs belt sander. I'd say it's close to a guarantee. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one.. Belt Grinder Vs Wheel.

From hxeidmcjj.blob.core.windows.net

Grinding Wheel Vs Belt Sander at Ellen Lopes blog Belt Grinder Vs Wheel Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. I'd say it's close to a guarantee. Key differences between a bench grinder vs belt sander. Dressing the wheels are a p i t a. Belt grinders are expensive, but the quality is worth it. While these workshop tools. Belt Grinder Vs Wheel.

From www.desertcart.ae

Happybuy Belt Grinder Rubber Wheel 12 x2 inch,Serrated Rubber Contact Wheel 6206, Bearing Belt Belt Grinder Vs Wheel Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. I'd probably use the grinder more if i get a cbn wheel. Mostly i use the sorby belt sander. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Dressing. Belt Grinder Vs Wheel.

From www.northerntool.com

JET Square Wheel Belt Grinder — 2in. x 72in., 115 Volt, 1PH, Model J4103 Northern Tool Belt Grinder Vs Wheel Belt grinders are expensive, but the quality is worth it. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Dressing the wheels are a p i t a. Mostly i use the sorby belt sander.. Belt Grinder Vs Wheel.

From landmarktools.com

Baileigh BG2482; 110V 1.5HP Two Wheel Belt Grinder 2" Belt Width 48" Belt Grinder Vs Wheel Key differences between a bench grinder vs belt sander. I'd say it's close to a guarantee. 95% of all professional knife makers use. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Dressing the wheels are a p i t a. I'd probably use the grinder more if i get. Belt Grinder Vs Wheel.

From www.youtube.com

Multitool Belt Grinder Attachment Installation Guide YouTube Belt Grinder Vs Wheel 95% of all professional knife makers use. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Grinders can also be designed. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. I'd say it's close to a guarantee. Belt. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder 2" x 72" Wheel Set, Complete Belt Knife Grinder Wheel Set, Aluminum Belt Belt Grinder Vs Wheel Belt grinders are expensive, but the quality is worth it. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. I'd say it's close to a guarantee. Dressing the wheels are a p i t a.. Belt Grinder Vs Wheel.

From www.youtube.com

2 x 72 belt sander/grinder with contact wheel YouTube Belt Grinder Vs Wheel 95% of all professional knife makers use. Key differences between a bench grinder vs belt sander. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Metal grinding is a crucial process in various industries, using. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder 2" x 72" Wheel Set, Complete Belt Knife Grinder Wheel Set, Aluminum Belt Belt Grinder Vs Wheel For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Belt grinders are expensive, but the quality is worth it. Dressing the wheels are a p i t a. Grinders can also be designed. Mostly i. Belt Grinder Vs Wheel.

From handymansworld.net

Belt Grinder vs. Bench Grinder Which to Use? Handyman's World Belt Grinder Vs Wheel While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. 95% of all professional knife makers use. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. Uncooled belt sharpening stands a very good chance of overheating the edge. For best results, it’s essential to. Belt Grinder Vs Wheel.

From amktactical.com

AMK77 2X72 Belt Grinder, 2hp, Variable Speed VFD, 12" wheel Belt Grinder Vs Wheel For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. Grinders can also be designed.. Belt Grinder Vs Wheel.

From www.sears.com

VEVOR Belt Grinder 3in1 Belt Sander 2" X 82" Complete Chassis 2hp Motor & Vfd Combo Belt Grinder Vs Wheel For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Dressing the wheels are a p i t a. I'd say it's close to a guarantee. 95% of all professional knife makers use. Grinders can also. Belt Grinder Vs Wheel.

From www.trick-tools.com

482 Burr King Belt Grinder, Variable Speed, 2x48 belt size Belt Grinder Vs Wheel Belt grinders are expensive, but the quality is worth it. Uncooled belt sharpening stands a very good chance of overheating the edge. I'd say it's close to a guarantee. I'd probably use the grinder more if i get a cbn wheel. Dressing the wheels are a p i t a. Belt grinders may all look similar, but specs vary from. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder Drive Wheel 5" Diameter, 2"x72" Knife Grinder Drive Wheel 5/8" Bore/Shaft Belt Grinder Vs Wheel Uncooled belt sharpening stands a very good chance of overheating the edge. I'd say it's close to a guarantee. Mostly i use the sorby belt sander. Grinders can also be designed. Key differences between a bench grinder vs belt sander. While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. Belt grinders may all. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder 2"x72" Wheel Set, Complete Belt Knife Grinder Wheel Set, Aluminum Belt Belt Grinder Vs Wheel For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Belt grinders are expensive, but the quality is worth it. Grinders can also be designed. Mostly i use the sorby belt sander. Belt grinders may all. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder Drive Wheel 6" Diameter, 2"x72" Knife Grinder Drive Wheel 5/8" Bore/Shaft Belt Grinder Vs Wheel I'd say it's close to a guarantee. Dressing the wheels are a p i t a. Key differences between a bench grinder vs belt sander. Uncooled belt sharpening stands a very good chance of overheating the edge. Belt grinders may all look similar, but specs vary from grinder to grinder, which can cause variations in performance. 95% of all professional. Belt Grinder Vs Wheel.

From www.vevor.com

VEVOR Belt Grinder 2" x 72" Wheel Set, Complete Belt Knife Grinder Wheel Set, Aluminum Belt Belt Grinder Vs Wheel Mostly i use the sorby belt sander. Belt grinders are expensive, but the quality is worth it. Grinders can also be designed. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as well as the correct abrasive for each one. Belt grinders may all. Belt Grinder Vs Wheel.

From homeassistpoint.com

Best 2X72 Belt Grinder Wheels Your Smart Home Belt Grinder Vs Wheel While these workshop tools are known to horn dull surfaces, they have varying applications for smoothing. Dressing the wheels are a p i t a. Belt grinders are expensive, but the quality is worth it. I'd probably use the grinder more if i get a cbn wheel. Metal grinding is a crucial process in various industries, using abrasive wheels or. Belt Grinder Vs Wheel.

From www.amazon.com

Belt Grinder 2.6inch Wheel Set,Aluminum Belt Grinder Wheel with Bolt Belt Grinder Tracking Wheel Belt Grinder Vs Wheel Belt grinders are expensive, but the quality is worth it. Uncooled belt sharpening stands a very good chance of overheating the edge. I'd say it's close to a guarantee. Dressing the wheels are a p i t a. Key differences between a bench grinder vs belt sander. Belt grinders may all look similar, but specs vary from grinder to grinder,. Belt Grinder Vs Wheel.