Plastic Extrusion Is Basically . It involves heating, shaping, cooling,. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Learn how this manufacturing process shapes industries. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusion is a vital process in the manufacturing industry.

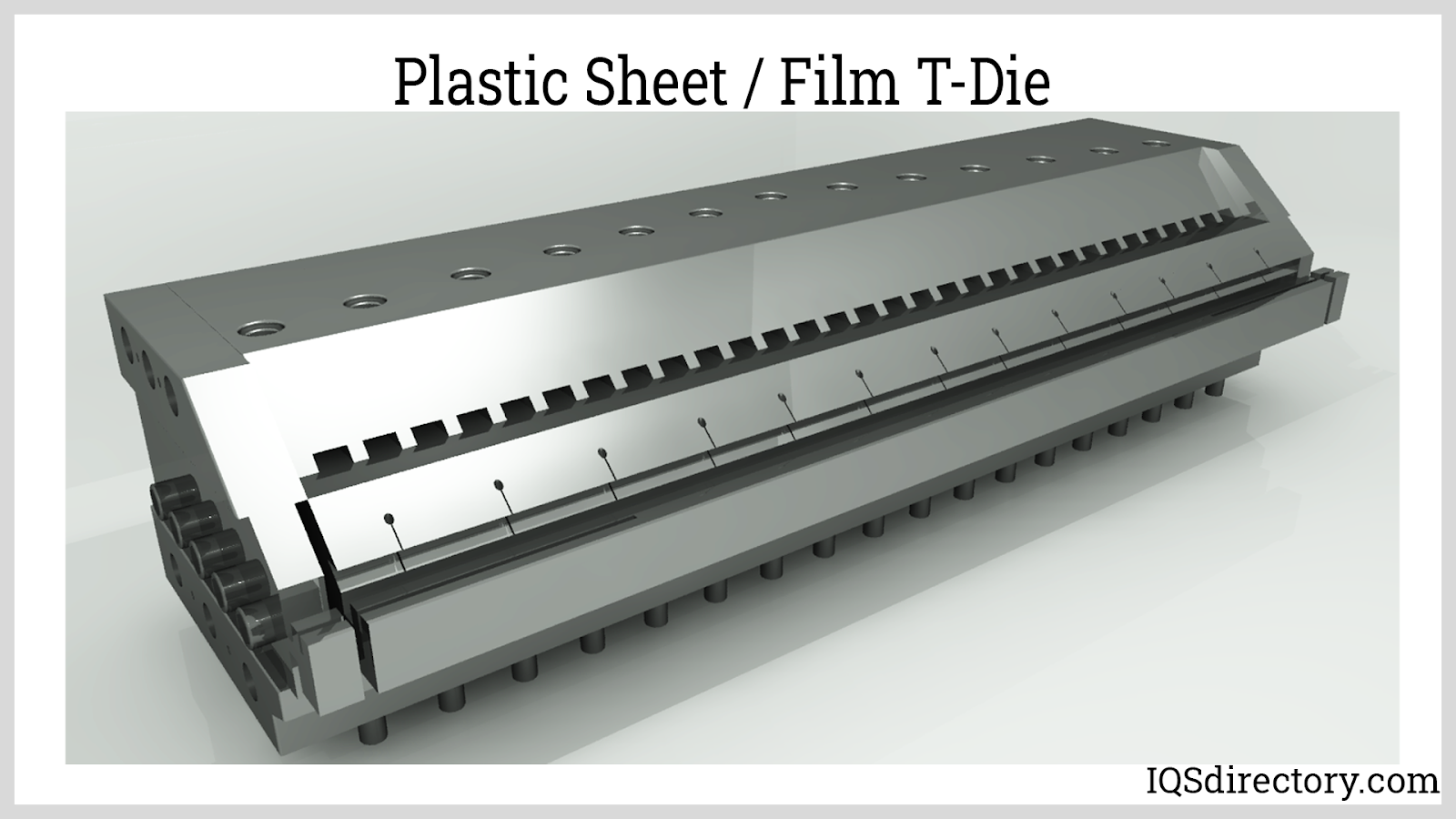

from www.iqsdirectory.com

The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Learn how this manufacturing process shapes industries. It involves heating, shaping, cooling,. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a.

Plastic Extrusion What Is It? How Does It Work? Process

Plastic Extrusion Is Basically It involves heating, shaping, cooling,. Learn how this manufacturing process shapes industries. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion is a vital process in the manufacturing industry. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. It involves heating, shaping, cooling,. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a.

From rpmindinc.com

Plastic Extrusions Basic Principles and Processes Plastic Extrusion Is Basically Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Learn how this manufacturing process shapes industries. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a.. Plastic Extrusion Is Basically.

From industrialplastics.com.au

Plastic Extrusion Welding Explained Industrial Plastics Plastic Extrusion Is Basically Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusion is a vital process in the manufacturing industry. Learn how this manufacturing process shapes industries. Plastic extrusion is a remarkable manufacturing. Plastic Extrusion Is Basically.

From www.newprocess.com

Plastic Extrusion Guide New Process Fibre Company, Inc. Plastic Extrusion Is Basically The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. It involves heating, shaping, cooling,. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Learn how this manufacturing process shapes industries. Explore the world of plastic extrusion — its definition,. Plastic Extrusion Is Basically.

From www.iqsdirectory.com

Plastic Trim Types, Extrusion Methods, Applications, and Benefits Plastic Extrusion Is Basically Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. It involves heating, shaping, cooling,. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Plastic extrusion is a process where granular. Plastic Extrusion Is Basically.

From www.iqsdirectory.com

Nylon Tubing Types, Materials, Applications, and Benefits Plastic Extrusion Is Basically Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion is a vital process in the manufacturing industry. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion, also known as plasticating extrusion,. Plastic Extrusion Is Basically.

From www.opusplastics.com

What is Plastic Extrusion? Process Guide Opus Plastics Plastic Extrusion Is Basically Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion is a process where granular pieces of plastics go through. Plastic Extrusion Is Basically.

From www.essaii.com

What is a plastic extrusion process in a stepbystep guide? Plastic Extrusion Is Basically Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Learn how this manufacturing process shapes industries. Explore the world of. Plastic Extrusion Is Basically.

From www.bausano.com

Plastic Extrusion Process What it is and Function Bausano Plastic Extrusion Is Basically Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Learn how this manufacturing process shapes industries. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Explore the world of plastic extrusion — its definition, purpose,. Plastic Extrusion Is Basically.

From engineeringlearn.com

Types of Extrusion Process Working, Advantages & Disadvantages Plastic Extrusion Is Basically Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusion is a vital process in the manufacturing industry. It involves heating, shaping, cooling,. Learn how this manufacturing process shapes industries. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting. Plastic Extrusion Is Basically.

From www.youtube.com

What is Plastic Extrusion? YouTube Plastic Extrusion Is Basically It involves heating, shaping, cooling,. Learn how this manufacturing process shapes industries. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion. Plastic Extrusion Is Basically.

From jada.com.co

EXTRUSIÓN DE PVC RÍGIDO • JADA INDUSTRY Plastic Extrusion Is Basically Learn how this manufacturing process shapes industries. It involves heating, shaping, cooling,. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide. Plastic Extrusion Is Basically.

From www.calpexplastics.com

Plastic Extrusions Calpex Plastics Inc. Plastic Extrusion Is Basically Learn how this manufacturing process shapes industries. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications.. Plastic Extrusion Is Basically.

From proleantech.com

Extrusions de plastique un guide complet Plastic Extrusion Is Basically Plastic extrusion is a vital process in the manufacturing industry. Learn how this manufacturing process shapes industries. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Plastic extrusion is a remarkable manufacturing process that plays a pivotal. Plastic Extrusion Is Basically.

From mavink.com

Plastic Extrusion Diagram Plastic Extrusion Is Basically Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a.. Plastic Extrusion Is Basically.

From www.rocalextrusions.co.uk

How do Plastic Extrusion Machines Work? Rocal Extrusions Plastic Extrusion Is Basically Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. It involves heating, shaping, cooling,. The. Plastic Extrusion Is Basically.

From www.ipfinc.net

Plastic Extrusion Integrated Packaging Film Inc. Plastic Extrusion Is Basically The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. It involves heating, shaping, cooling,. Explore the. Plastic Extrusion Is Basically.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Plastic Extrusion Is Basically Learn how this manufacturing process shapes industries. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion, also known as plasticating extrusion, is a continuous. Plastic Extrusion Is Basically.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Is Basically Plastic extrusion is a vital process in the manufacturing industry. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Learn how this manufacturing process shapes industries. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in. Plastic Extrusion Is Basically.

From www.microscopio.pro

Cuáles Son Las Principales Aplicaciones De La Técnica De Extrusión Del Plastic Extrusion Is Basically Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. It involves heating, shaping, cooling,. Learn how this manufacturing process shapes industries. Explore the world of plastic extrusion — its definition,. Plastic Extrusion Is Basically.

From hitechextrusions.com

Understanding the Extrusion Process A StepbyStep Guide Plastic Extrusion Is Basically Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. It involves heating, shaping, cooling,. Explore the world of plastic extrusion. Plastic Extrusion Is Basically.

From www.kemalmfg.com

Plastic Extrusion Guide Plastic Extrusion Is Basically Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Learn how this manufacturing process shapes industries. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. It involves heating, shaping, cooling,. The process involves taking a thermoplastic material — such. Plastic Extrusion Is Basically.

From www.prmmold.com

How Does Plastic Extrusion Work? Plastic Extrusion Is Basically It involves heating, shaping, cooling,. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Learn how this manufacturing process shapes industries. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting. Plastic Extrusion Is Basically.

From www.fukuvi-usa.com

EXTRUSION 101 Fukuvi USA, manufacturer of highquality extruded Plastic Extrusion Is Basically Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusion. Plastic Extrusion Is Basically.

From www.3erp.com

The basics of plastic extrusion process, materials, applications Plastic Extrusion Is Basically Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. It involves heating, shaping, cooling,. Plastic extrusion is a vital process in the manufacturing industry. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. The process involves taking a thermoplastic material — such. Plastic Extrusion Is Basically.

From www.hardwareinterviews.fyi

Basics of Plastic Extrusion Consumer Hardware Guide Hardware FYI Plastic Extrusion Is Basically Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Learn how this manufacturing process shapes industries. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. It involves heating, shaping, cooling,. Explore the world of plastic extrusion — its definition,. Plastic Extrusion Is Basically.

From plasticextrusiontech.net

What is Plastic Extruding? Plastic Extrusion Tech Plastic Extrusion Is Basically Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a vital process in the manufacturing industry. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in. Plastic Extrusion Is Basically.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics Plastic Extrusion Is Basically Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Learn how this manufacturing process shapes industries. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. The process involves taking a thermoplastic material — such as powder,. Plastic Extrusion Is Basically.

From cbmplasticsusa.com

Plastic Extrusion Process, Materials, Applications CBM Plastics Plastic Extrusion Is Basically Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Learn how this manufacturing process shapes industries. Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. Plastic extrusion is a process. Plastic Extrusion Is Basically.

From mechanicstips.blogspot.com

Plastic Extrusion MechanicsTips Plastic Extrusion Is Basically The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion,. Plastic Extrusion Is Basically.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Is Basically Learn how this manufacturing process shapes industries. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the. Plastic Extrusion Is Basically.

From www.wanhan-plastic.com

Proceso de enfriamiento del proceso de moldeo por extrusión. Plastic Extrusion Is Basically Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion, also known as plasticating extrusion,. Plastic Extrusion Is Basically.

From www.dwplastics.co.uk

Why is plastic useful D W Plastics Plastic Extrusion Is Basically Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Learn how this manufacturing process shapes industries. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which. Plastic Extrusion Is Basically.

From ramextrusion.co.uk

Plastic Extrusion Process Explained Thoroughly By RAM Extrusion Plastic Extrusion Is Basically The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Learn how this manufacturing process shapes industries. Plastic extrusion is a remarkable manufacturing process that plays a pivotal role in producing a wide array of plastic products we. Plastic extrusion is a vital process in the manufacturing industry.. Plastic Extrusion Is Basically.

From xometry.pro

Plastic Extrusion Technology Overview Xometry Pro Plastic Extrusion Is Basically Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the molten. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in. Plastic Extrusion Is Basically.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Is Basically Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a. The process involves taking a thermoplastic material — such as powder, pellets, or granules — melting it uniformly, then pushing the. Plastic Extrusion Is Basically.