Best Paint For Heavy Equipment . Due to water and chemical intervention,. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. industrial machinery and heavy equipment demand better treatment.

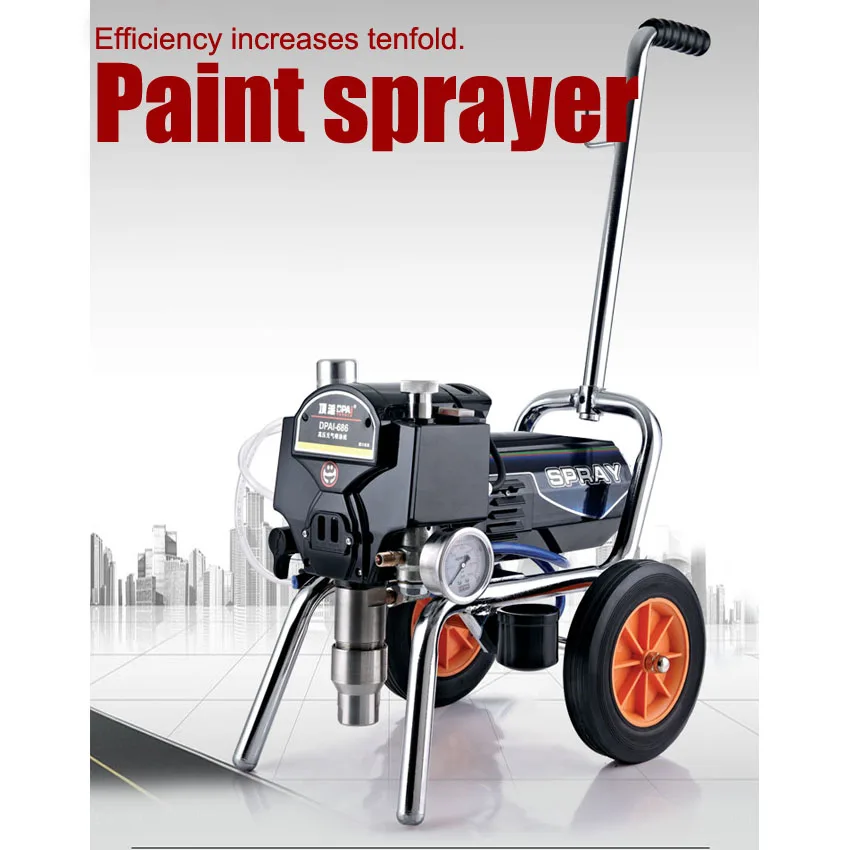

from www.aliexpress.com

heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. industrial machinery and heavy equipment demand better treatment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. Due to water and chemical intervention,.

1PC Professional airless electric piston paint sprayer with spray gun

Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. industrial machinery and heavy equipment demand better treatment. Due to water and chemical intervention,. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance.

From interstateheavyequipment.com

Importance of Painting Heavy Equipment Interstate Heavy Equipment Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. Due to water and chemical intervention,. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. color consistency, edge coverage,. Best Paint For Heavy Equipment.

From proallusarefurbish.wordpress.com

Painting Heavy Equipment Provides a Value Addition ProAll Equipment Best Paint For Heavy Equipment heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. industrial machinery and heavy equipment demand better treatment. when choosing an enamel paint for your industrial needs,. Best Paint For Heavy Equipment.

From paintingvalley.com

Heavy Equipment Painting at Explore collection of Best Paint For Heavy Equipment heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. Due to water and chemical intervention,. industrial machinery and heavy equipment demand better treatment. color consistency, edge. Best Paint For Heavy Equipment.

From paintingvalley.com

Heavy Equipment Painting at Explore collection of Best Paint For Heavy Equipment heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. industrial machinery and heavy equipment demand better treatment. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. Due to. Best Paint For Heavy Equipment.

From www.indiamart.com

JAGUAR C781 Heavy Duty Airless Spray Painting Machine, Max Flow 9 Lpm Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. heavy industrial equipment painting isn’t. Best Paint For Heavy Equipment.

From paintingvalley.com

Heavy Equipment Painting at Explore collection of Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. Due to water and chemical intervention,. industrial machinery and heavy equipment demand better treatment. for 20 years, our services have included painting of oem parts, metal cleaning. Best Paint For Heavy Equipment.

From exopqgsjg.blob.core.windows.net

Airless Paint Sprayer Painting Machine at Christy Fisher blog Best Paint For Heavy Equipment color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. Due to water and chemical intervention,. industrial machinery and heavy equipment demand better. Best Paint For Heavy Equipment.

From mobilepaintguy.com

Heavy Equipment Painting INDUSTRIAL,HEAVY EQUIPMENT,MACHINERY Best Paint For Heavy Equipment for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. industrial machinery and heavy equipment. Best Paint For Heavy Equipment.

From www.amazon.com

Home Right C800769 Pro 6.8 Heavy Duty Paint Sprayer Power Paint Best Paint For Heavy Equipment Due to water and chemical intervention,. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance.. Best Paint For Heavy Equipment.

From www.jaguarequipments.in

Spray Painting Equipment,Spray Paint Hose,Airless Spray Painting Equipment Best Paint For Heavy Equipment Due to water and chemical intervention,. industrial machinery and heavy equipment demand better treatment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. when choosing an. Best Paint For Heavy Equipment.

From www.newmantractor.com

Heavy Equipment Painting Newman Tractor Best Paint For Heavy Equipment Due to water and chemical intervention,. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. industrial machinery and heavy equipment demand better treatment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. when choosing an. Best Paint For Heavy Equipment.

From paintingvalley.com

Heavy Equipment Painting at Explore collection of Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. Due to water and chemical intervention,.. Best Paint For Heavy Equipment.

From proallusarefurbish.wordpress.com

Painting Heavy Equipment Provides a Value Addition ProAll Equipment Best Paint For Heavy Equipment color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. heavy industrial equipment painting isn’t. Best Paint For Heavy Equipment.

From www.newmantractor.com

Heavy Equipment Painting Newman Tractor Best Paint For Heavy Equipment industrial machinery and heavy equipment demand better treatment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact. Best Paint For Heavy Equipment.

From www.heavytruckpainting.com

We Paint Heavy Equipment Best Paint For Heavy Equipment industrial machinery and heavy equipment demand better treatment. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact. Best Paint For Heavy Equipment.

From www.homedepot.com

HomeRight Titanium Series Heavy Duty Airless Paint SprayerC800917.M Best Paint For Heavy Equipment heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. color consistency, edge coverage, and corrosion resistance are the reasons. Best Paint For Heavy Equipment.

From www.aliexpress.com

1PC Professional airless electric piston paint sprayer with spray gun Best Paint For Heavy Equipment industrial machinery and heavy equipment demand better treatment. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. for 20 years, our services have included painting of. Best Paint For Heavy Equipment.

From dcifleet.com

Sandblasting and Paint Heavy Equipment, Trucks and Trailers DCI Best Paint For Heavy Equipment industrial machinery and heavy equipment demand better treatment. Due to water and chemical intervention,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. color consistency, edge coverage, and corrosion resistance are the reasons why leading global. Best Paint For Heavy Equipment.

From paintingvalley.com

Heavy Equipment Painting at Explore collection of Best Paint For Heavy Equipment industrial machinery and heavy equipment demand better treatment. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact. Best Paint For Heavy Equipment.

From www.heavytruckpainting.com

We Paint Heavy Equipment Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. industrial machinery and heavy equipment. Best Paint For Heavy Equipment.

From interstateheavyequipment.com

Importance of Painting Heavy Equipment Interstate Heavy Equipment Best Paint For Heavy Equipment for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. industrial machinery and heavy equipment demand better treatment. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. when choosing an enamel paint for your industrial needs,. Best Paint For Heavy Equipment.

From paintingvalley.com

Heavy Equipment Painting at Explore collection of Best Paint For Heavy Equipment Due to water and chemical intervention,. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. heavy industrial equipment painting isn’t as easy. Best Paint For Heavy Equipment.

From www.jamestowncoatings.com

Heavy Equipment Metal Coatings Industrial Paint Jamestown Coating Best Paint For Heavy Equipment industrial machinery and heavy equipment demand better treatment. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact. Best Paint For Heavy Equipment.

From www.youtube.com

Heavy Equipment Painting YouTube Best Paint For Heavy Equipment color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. Due to water and chemical intervention,. industrial machinery and heavy equipment demand better treatment. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. for 20 years,. Best Paint For Heavy Equipment.

From wikimachine.com

10 Best Paint Sprayer For in 2021 Wiki Machine Best Paint For Heavy Equipment Due to water and chemical intervention,. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. industrial machinery and heavy equipment demand better. Best Paint For Heavy Equipment.

From paintingvalley.com

Painting Construction Equipment at Explore Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. industrial machinery and heavy equipment demand better treatment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose. Best Paint For Heavy Equipment.

From www.aliexpress.com

Professional airless electric piston paint sprayer with spray gun heavy Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. industrial machinery and heavy equipment demand better treatment. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic. Best Paint For Heavy Equipment.

From paintingvalley.com

Heavy Equipment Painting at Explore collection of Best Paint For Heavy Equipment heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. industrial machinery and heavy equipment demand better treatment. Due to water and chemical intervention,. when choosing an. Best Paint For Heavy Equipment.

From www.indiamart.com

Portable Airless Spray Painting Machine, Max Flow 9 LPM, ID 21823706988 Best Paint For Heavy Equipment industrial machinery and heavy equipment demand better treatment. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. Due to. Best Paint For Heavy Equipment.

From www.youtube.com

How to paint heavy equipment backhoe YouTube Best Paint For Heavy Equipment Due to water and chemical intervention,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder.. Best Paint For Heavy Equipment.

From proallusarefurbish.wordpress.com

Painting Heavy Equipment Provides a Value Addition ProAll Equipment Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. heavy industrial equipment painting isn’t. Best Paint For Heavy Equipment.

From www.youtube.com

Our industrial painter gives how to tips for painting heavy equipment Best Paint For Heavy Equipment for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. industrial machinery and heavy equipment demand better treatment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. Due to water and chemical. Best Paint For Heavy Equipment.

From www.newmantractor.com

Heavy Equipment Painting Newman Tractor Best Paint For Heavy Equipment Due to water and chemical intervention,. industrial machinery and heavy equipment demand better treatment. color consistency, edge coverage, and corrosion resistance are the reasons why leading global oems and their tier suppliers choose to specify powder. heavy industrial equipment painting isn’t as easy as taking up a brush and prettying up your equipment. when choosing an. Best Paint For Heavy Equipment.

From www.slideserve.com

PPT Value Addition on Painting Heavy Equipment PowerPoint Best Paint For Heavy Equipment when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance. Due to water and chemical intervention,. industrial machinery and heavy equipment demand better treatment. for 20 years, our services have included painting of oem parts, metal cleaning. Best Paint For Heavy Equipment.

From www.thedrive.com

Best Airless Paint Sprayers (Review & Buying Guide) in 2021 Best Paint For Heavy Equipment for 20 years, our services have included painting of oem parts, metal cleaning with glass beads, walnut shells, ceramic media, metal finishing,. Due to water and chemical intervention,. when choosing an enamel paint for your industrial needs, consider the surface that needs painting, the level of durability required, and the environmental factors that may impact the paint’s performance.. Best Paint For Heavy Equipment.