Rotary Airlock Valve Temperature . How to calculate the capacity of an airlock rotary valve ? Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. Pressure differentials to 20psi and temperatures to 750°f. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. We have made specials to handle temperatures covering 2190°f and pressures to. As the airlock is exposed to. A key player in these systems is the rotary airlock. How does a rotary airlock valve work ? What is a rotary airlock valve ? The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature.

from www.gre.ac.uk

Pressure differentials to 20psi and temperatures to 750°f. As the airlock is exposed to. A key player in these systems is the rotary airlock. How to calculate the capacity of an airlock rotary valve ? What is a rotary airlock valve ? We have made specials to handle temperatures covering 2190°f and pressures to. How does a rotary airlock valve work ? The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,.

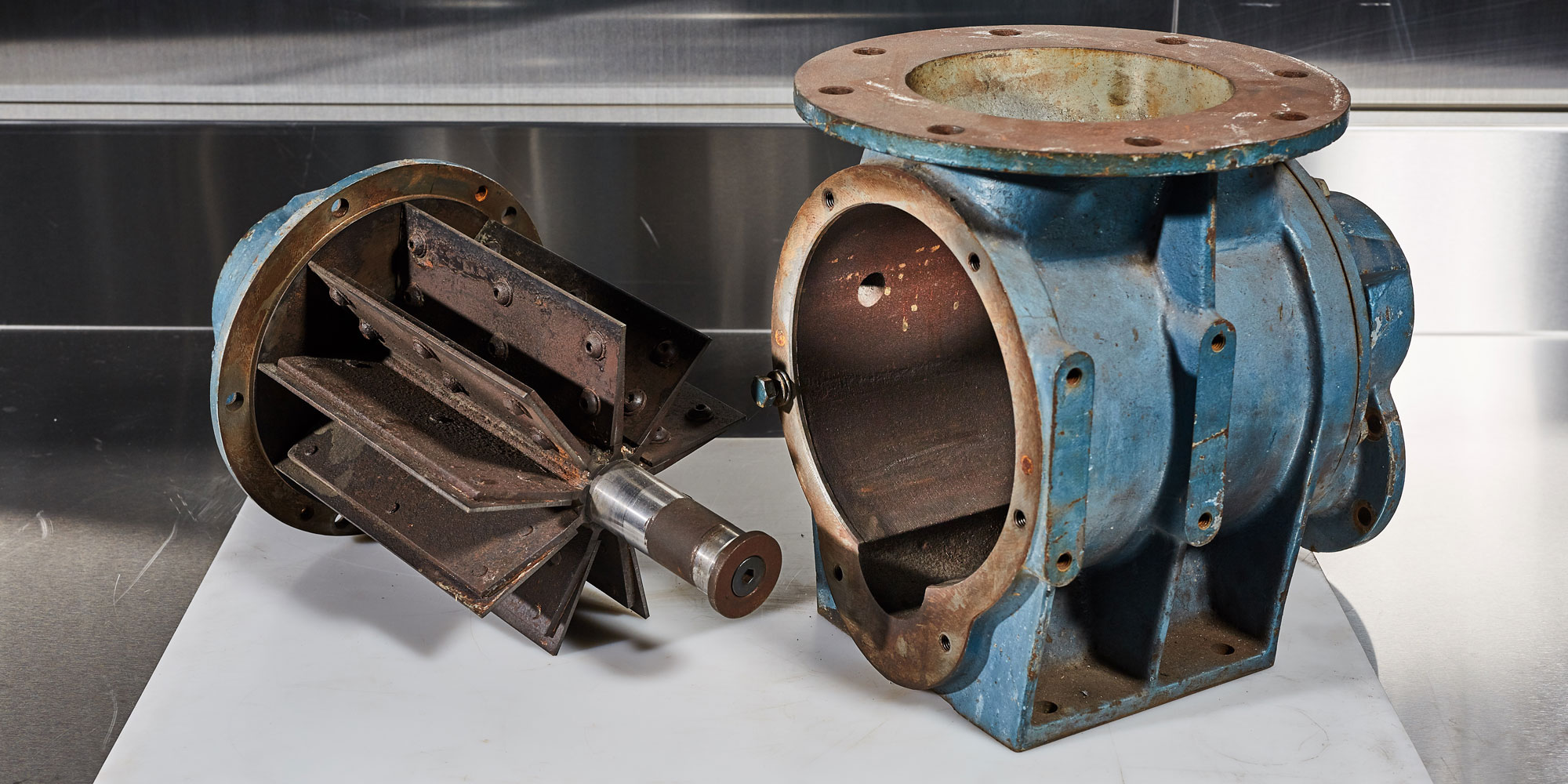

Rotary Valves Design, Selection and Operational Issues Wolfson

Rotary Airlock Valve Temperature The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. What is a rotary airlock valve ? The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. How to calculate the capacity of an airlock rotary valve ? As the airlock is exposed to. A key player in these systems is the rotary airlock. We have made specials to handle temperatures covering 2190°f and pressures to. Pressure differentials to 20psi and temperatures to 750°f. How does a rotary airlock valve work ? Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries.

From everluckymachinery.en.made-in-china.com

WaterCooled Dust Airlock Rotary Valve for High Temperature Conveying Rotary Airlock Valve Temperature As the airlock is exposed to. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. Pressure differentials to 20psi and temperatures to 750°f. A key player in these systems is the rotary airlock. We have made specials to handle temperatures covering 2190°f and pressures to. How to calculate the capacity of an. Rotary Airlock Valve Temperature.

From dir.indiamart.com

Rotary Airlock Valves in Faridabad, रोटरी एयरलाक वाल्व, फरीदाबाद Rotary Airlock Valve Temperature The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. We have made specials to handle temperatures covering 2190°f and pressures to. How to calculate the capacity of an airlock rotary valve ? In bulk and specialty material handling systems, rotary airlock valve specifications and designs. Rotary Airlock Valve Temperature.

From carolinaconveying.com

Best Standard Duty Rotary Airlock Valves Manufacturer & Supplier Rotary Airlock Valve Temperature The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. Processes with hot material or heated process air or conveying air can affect an. Rotary Airlock Valve Temperature.

From www.vortexglobal.com

Applying Gate Valves with Rotary Airlocks in Pneumatic Conveying Vortex Rotary Airlock Valve Temperature As the airlock is exposed to. What is a rotary airlock valve ? Pressure differentials to 20psi and temperatures to 750°f. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. How does a rotary airlock valve work ? Processes with hot material or heated process air or. Rotary Airlock Valve Temperature.

From carolinaconveying.com

DropThru Rotary Airlock Valves Carloina Conveying Rotary Airlock Valve Temperature In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. Pressure differentials to 20psi and temperatures to 750°f. We have made specials to handle temperatures covering 2190°f and pressures to. What is a rotary airlock valve ? Pneumatic conveying systems play a vital role in efficiently transporting materials. Rotary Airlock Valve Temperature.

From www.alibaba.com

Rotary Valve High Temperature Rotary Airlock Valve Rotary Valve For Rotary Airlock Valve Temperature How to calculate the capacity of an airlock rotary valve ? Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. What is a rotary airlock valve ? A key player in these systems is the rotary airlock. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. As. Rotary Airlock Valve Temperature.

From www.indiamart.com

Mild Steel Round Rotary Airlock Valve, Diameter 250 mm, Size 200 Nb Rotary Airlock Valve Temperature A key player in these systems is the rotary airlock. We have made specials to handle temperatures covering 2190°f and pressures to. Pressure differentials to 20psi and temperatures to 750°f. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. What is a rotary airlock valve ? Pneumatic. Rotary Airlock Valve Temperature.

From carolinaconveying.com

DropThru Rotary Airlock Valves Carolina Conveying Rotary Airlock Valve Temperature Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. How does a rotary airlock valve work ? How to calculate the capacity of an airlock rotary valve ? Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. A key player in these systems is the rotary airlock.. Rotary Airlock Valve Temperature.

From www.alibaba.com

Rotary Valve High Temperature Rotary Airlock Valve Rotary Valve For Rotary Airlock Valve Temperature Pressure differentials to 20psi and temperatures to 750°f. We have made specials to handle temperatures covering 2190°f and pressures to. How does a rotary airlock valve work ? In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. A key player in these systems is the rotary airlock.. Rotary Airlock Valve Temperature.

From www.sultan.com.tr

Rotary Valve AIRLOCK Rotary Valves Blow Through Rotary Valve Rotary Airlock Valve Temperature Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop.. Rotary Airlock Valve Temperature.

From dir.indiamart.com

Rotary Air Lock Rotary Airlocks Latest Price, Manufacturers & Suppliers Rotary Airlock Valve Temperature A key player in these systems is the rotary airlock. Pressure differentials to 20psi and temperatures to 750°f. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. How does a rotary airlock valve work ? The precision casting, cnc machining, and tight final assembly tolerances of acs. Rotary Airlock Valve Temperature.

From www.isystemsweb.com

Rotary Airlock Valves for Dust Collectors Imperial Systems, Inc. Rotary Airlock Valve Temperature Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. How does a rotary airlock valve work ? Pressure differentials to 20psi and temperatures to 750°f. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. As the airlock is exposed to. How to calculate the capacity of an. Rotary Airlock Valve Temperature.

From www.indiamart.com

Rotary Airlock Valve Wholesale Trader from Kolkata Rotary Airlock Valve Temperature The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. We have made specials to handle temperatures covering 2190°f and pressures to. Pressure differentials to 20psi and temperatures to 750°f. How does a rotary airlock valve work ? What is a rotary airlock valve ? In. Rotary Airlock Valve Temperature.

From www.indiamart.com

Water Mild Steel High Temperature Rotary Airlock, Size 5 Inch at Rs Rotary Airlock Valve Temperature The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. Pressure differentials to 20psi and temperatures to 750°f. How does a rotary airlock valve work ? What is a rotary airlock valve ? As the airlock is exposed to. A key player in these systems is. Rotary Airlock Valve Temperature.

From www.gre.ac.uk

Rotary Valves Design, Selection and Operational Issues Wolfson Rotary Airlock Valve Temperature How to calculate the capacity of an airlock rotary valve ? As the airlock is exposed to. We have made specials to handle temperatures covering 2190°f and pressures to. Pressure differentials to 20psi and temperatures to 750°f. A key player in these systems is the rotary airlock. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary. Rotary Airlock Valve Temperature.

From www.sczili.com

China factory customized High Temperature Rotary Airlock Negative Rotary Airlock Valve Temperature We have made specials to handle temperatures covering 2190°f and pressures to. How does a rotary airlock valve work ? As the airlock is exposed to. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. A key player in these systems is the rotary airlock.. Rotary Airlock Valve Temperature.

From www.shreetechnoeng.com

Rotary Valves High Temperature Rotary Airlock Valves Manufacturer Rotary Airlock Valve Temperature What is a rotary airlock valve ? As the airlock is exposed to. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. How does a rotary airlock valve work ?. Rotary Airlock Valve Temperature.

From www.alibaba.com

Rotary Valve High Temperature Rotary Airlock Valve Rotary Valve For Rotary Airlock Valve Temperature In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. What is a rotary airlock valve ? Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature.. Rotary Airlock Valve Temperature.

From cheegers.en.made-in-china.com

Rotary Valve High Temperature Low Price Rotary Airlock Valve China Rotary Airlock Valve Temperature How does a rotary airlock valve work ? What is a rotary airlock valve ? We have made specials to handle temperatures covering 2190°f and pressures to. How to calculate the capacity of an airlock rotary valve ? Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. As the airlock is exposed. Rotary Airlock Valve Temperature.

From carolinaconveying.com

Drop Thru Rotary Airlock Valves Manufacturer Carolina Conveying Rotary Airlock Valve Temperature What is a rotary airlock valve ? In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. We have made specials to handle temperatures covering 2190°f and pressures to. Pressure differentials to 20psi and temperatures to 750°f. How to calculate the capacity of an airlock rotary valve ?. Rotary Airlock Valve Temperature.

From www.dk-engineers.com

Rotary Airlock Valve Manufacturer in Ahmedabad Rotary Airlock Valve Temperature As the airlock is exposed to. Pressure differentials to 20psi and temperatures to 750°f. A key player in these systems is the rotary airlock. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. How to calculate the capacity of an airlock rotary valve ? What is a rotary airlock valve ? We. Rotary Airlock Valve Temperature.

From www.alibaba.com

Super Quality Chain Type Rotary Airlock Valve High Temperature Price Rotary Airlock Valve Temperature As the airlock is exposed to. How to calculate the capacity of an airlock rotary valve ? Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. A key player in these systems is the rotary airlock. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage. Rotary Airlock Valve Temperature.

From blog.progressiveproductsinc.com

Impact of Temperature & Pressure on Rotary Airlock Valves Rotary Airlock Valve Temperature Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. As the airlock is exposed to. A key player in these systems is the rotary airlock. We have made specials to handle temperatures covering 2190°f and pressures to. How does a rotary airlock valve work ? Pneumatic conveying systems play a vital role. Rotary Airlock Valve Temperature.

From www.indiamart.com

Industrial Rotary Airlock Valve, Size 10"NB, Lifting Capacity 1000kg Rotary Airlock Valve Temperature In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. Pressure differentials to 20psi and temperatures to 750°f. A key player in these systems is the rotary airlock. As the airlock. Rotary Airlock Valve Temperature.

From www.alibaba.com

Rotary Feeder Rotary Airlock Valve Stainless Steel Gas Electric Control Rotary Airlock Valve Temperature Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. How to calculate the capacity of an airlock rotary valve ? The precision casting, cnc machining, and tight final assembly tolerances. Rotary Airlock Valve Temperature.

From www.indiamart.com

Rav Cast Iron Very High Temperature Rotary Airlock Valves, Size 4 Inch Rotary Airlock Valve Temperature How to calculate the capacity of an airlock rotary valve ? Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. Pressure differentials to 20psi and temperatures to 750°f. We have made specials to handle temperatures covering 2190°f and pressures to. What is a rotary airlock valve ? In bulk and specialty material. Rotary Airlock Valve Temperature.

From www.alibaba.com

Rotary Feeder Rotary Airlock Valve Stainless Steel Gas Electric Control Rotary Airlock Valve Temperature We have made specials to handle temperatures covering 2190°f and pressures to. A key player in these systems is the rotary airlock. How to calculate the capacity of an airlock rotary valve ? How does a rotary airlock valve work ? In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as. Rotary Airlock Valve Temperature.

From everluckymachinery.en.made-in-china.com

High Temperature Stainless Steel Rotary Airlock Valve Airlock Feeder Rotary Airlock Valve Temperature How does a rotary airlock valve work ? Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. As the airlock is exposed to. Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves. Rotary Airlock Valve Temperature.

From edu.svet.gob.gt

Rotary Airlock Valve Catalog edu.svet.gob.gt Rotary Airlock Valve Temperature How does a rotary airlock valve work ? Pneumatic conveying systems play a vital role in efficiently transporting materials across various industries. As the airlock is exposed to. Pressure differentials to 20psi and temperatures to 750°f. We have made specials to handle temperatures covering 2190°f and pressures to. A key player in these systems is the rotary airlock. The precision. Rotary Airlock Valve Temperature.

From www.airlockcorp.co.th

Airlock Valves AIRLOCK CORPORATION LTD. Rotary Airlock Valve Temperature Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low. Rotary Airlock Valve Temperature.

From www.airlockintl.com.ph

Airlock Valves Airlock INC Rotary Airlock Valve Temperature As the airlock is exposed to. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. How does a rotary airlock valve work ? We have made specials to handle temperatures covering 2190°f and pressures to. What is a rotary airlock valve ? Pneumatic conveying systems play a. Rotary Airlock Valve Temperature.

From plattco.com

Plattco Double Flap Airlock Valve Vs. Rotary Valves Rotary Airlock Valve Temperature Pressure differentials to 20psi and temperatures to 750°f. As the airlock is exposed to. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. How to calculate the capacity of an airlock rotary valve ? What is a rotary airlock valve ? A key player in. Rotary Airlock Valve Temperature.

From www.rotolok.com.au

Rotary Valve Rotolok Australia Rotary Airlock Valve Temperature Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. What is a rotary airlock valve ? A key player in these systems is the rotary airlock. In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. Pressure differentials to 20psi. Rotary Airlock Valve Temperature.

From bossproductsamerica.com

Rotary Valve HT Series Boss Products America Rotary Airlock Valve Temperature How does a rotary airlock valve work ? Processes with hot material or heated process air or conveying air can affect an airlock’s operating temperature. What is a rotary airlock valve ? How to calculate the capacity of an airlock rotary valve ? The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal. Rotary Airlock Valve Temperature.

From everluckymachinery.en.made-in-china.com

Stainless Steel High Temperature Resistant Rotary Airlock Valves with Rotary Airlock Valve Temperature How to calculate the capacity of an airlock rotary valve ? In bulk and specialty material handling systems, rotary airlock valve specifications and designs are influenced by such factors as pressure, size, temperature,. The precision casting, cnc machining, and tight final assembly tolerances of acs rotary airlock valves ensure minimal air leakage and low effective pressure drop. Pneumatic conveying systems. Rotary Airlock Valve Temperature.