Chip Resistor Manufacturing Process . Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. In actuality the entire alumina substrate is processed at one time, but for illustrative. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Provide basic explanation of how the chip resistors are made. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Introduction to their thin and thick film product offering. Chip resistors are general passive components which are primarily used to create. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal.

from www.nanowerk.com

The following illustrates the manufacturing flow of a typical smd resistor (mcr series). In actuality the entire alumina substrate is processed at one time, but for illustrative. Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. Introduction to their thin and thick film product offering. Provide basic explanation of how the chip resistors are made. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Chip resistors are general passive components which are primarily used to create.

Transistors explained what they are and what they do

Chip Resistor Manufacturing Process In actuality the entire alumina substrate is processed at one time, but for illustrative. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Introduction to their thin and thick film product offering. Chip resistors are general passive components which are primarily used to create. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Provide basic explanation of how the chip resistors are made. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. In actuality the entire alumina substrate is processed at one time, but for illustrative.

From www.researchgate.net

Typical process flow for chip resistor fabrication [courtesy TT Chip Resistor Manufacturing Process The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on. Chip Resistor Manufacturing Process.

From akronic.com

ASIC Turnkey Solutions Akronic Chip Resistor Manufacturing Process Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Thin film chip resistor manufacturing typically starts with screen printing. Chip Resistor Manufacturing Process.

From www.slideserve.com

PPT RChip Introduction PowerPoint Presentation, free download ID Chip Resistor Manufacturing Process Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Chip resistors are general passive components which are primarily used to create. Introduction to their thin and thick film product offering. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). The general resistor manufacturing process involves designing the. Chip Resistor Manufacturing Process.

From www.wfxg.com

Thick Film and Thin Film Chip Resistors WFXG Chip Resistor Manufacturing Process The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Chip resistors are general passive components which are primarily used to create. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Provide basic explanation. Chip Resistor Manufacturing Process.

From www.ganjingworld.com

YAGEO Chip Resistors manufacturing process Chip Resistor Manufacturing Process Chip resistors are general passive components which are primarily used to create. In actuality the entire alumina substrate is processed at one time, but for illustrative. Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Provide basic explanation. Chip Resistor Manufacturing Process.

From www.researchgate.net

(a) Fabrication process of the metal structure for the resistor and Chip Resistor Manufacturing Process A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Chip resistors are general passive components which are primarily used. Chip Resistor Manufacturing Process.

From mavink.com

Semiconductor Chip Manufacturing Process Chip Resistor Manufacturing Process The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Chip resistors are general passive components which are primarily used. Chip Resistor Manufacturing Process.

From www.globalspec.com

Chip Capacitors Information Engineering360 Chip Resistor Manufacturing Process A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. In actuality the entire alumina substrate is processed at one. Chip Resistor Manufacturing Process.

From passive-components.eu

Resistor Types, Construction and Features Chip Resistor Manufacturing Process The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Provide basic explanation of how the chip resistors are made. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. Chip resistor array (common terminal circuit). Chip Resistor Manufacturing Process.

From www.researchgate.net

A resistor manufacturing process [DuPont February 1998] Download Chip Resistor Manufacturing Process A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. The following illustrates the manufacturing flow of a typical smd. Chip Resistor Manufacturing Process.

From anal-13gb75.blogspot.com

☑ Explain Integrated Circuit Fabrication Process Chip Resistor Manufacturing Process Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Introduction to their thin and thick film product offering. In actuality the entire alumina substrate is processed at one time, but for illustrative. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Thin film chip resistor manufacturing typically. Chip Resistor Manufacturing Process.

From mungfali.com

Semiconductor Manufacturing Process Flow Chart Chip Resistor Manufacturing Process In actuality the entire alumina substrate is processed at one time, but for illustrative. Provide basic explanation of how the chip resistors are made. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. The following illustrates the. Chip Resistor Manufacturing Process.

From passive-components.eu

Chip resistors manufacturing process Chip Resistor Manufacturing Process Chip resistors are general passive components which are primarily used to create. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of. Chip Resistor Manufacturing Process.

From passive-components.eu

Vishay Video Introducing TNPW Thin Film Chip Resistors Construction and Chip Resistor Manufacturing Process Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. Introduction to their thin and thick film product offering. Provide basic explanation of how the chip resistors are made. In actuality the entire alumina substrate is processed at one time, but for illustrative. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). A. Chip Resistor Manufacturing Process.

From www.jakelectronics.com

What Is A Chip Fixed Resistor? Chip Resistor Manufacturing Process In actuality the entire alumina substrate is processed at one time, but for illustrative. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Introduction to their thin and thick film product offering. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes (. Chip Resistor Manufacturing Process.

From www.youtube.com

Chip Resistor Automatic Screen Printing Line Aurel Automation YouTube Chip Resistor Manufacturing Process Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Provide basic explanation of how the chip resistors are made. Chip resistors are general passive components which are primarily used to create. In actuality the entire alumina substrate is processed at one time, but for illustrative. The general resistor manufacturing process involves. Chip Resistor Manufacturing Process.

From riedon.com

Thick Film and Thin Film Chip Resistors Riedon Company Blog Chip Resistor Manufacturing Process Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the. Chip Resistor Manufacturing Process.

From www.slideserve.com

PPT RChip Introduction PowerPoint Presentation, free download ID Chip Resistor Manufacturing Process The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Introduction to their thin and thick film product offering. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Provide. Chip Resistor Manufacturing Process.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Electronics Tutorial The Best Chip Resistor Manufacturing Process Chip resistors are general passive components which are primarily used to create. Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. In actuality the entire alumina substrate is processed at one time, but for illustrative. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4. Chip Resistor Manufacturing Process.

From risunsemi.com

Parameters and Selection Principles of Chip Resistors Risun Semiconductor Chip Resistor Manufacturing Process In actuality the entire alumina substrate is processed at one time, but for illustrative. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of. Chip Resistor Manufacturing Process.

From www.nanowerk.com

Transistors explained what they are and what they do Chip Resistor Manufacturing Process A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Introduction to their thin and thick film product offering. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Provide. Chip Resistor Manufacturing Process.

From www.researchgate.net

͑ a ͒ ͑ d ͒ Fabrication process for building silicon resistors and Chip Resistor Manufacturing Process Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Introduction to their thin and thick film product offering. Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. A chip. Chip Resistor Manufacturing Process.

From aboutwhatever-a.blogspot.com

Yageo Chip Resistors Instruction Chip Resistor Manufacturing Process In actuality the entire alumina substrate is processed at one time, but for illustrative. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually. Chip Resistor Manufacturing Process.

From www.epectec.com

Embedded Resistors in PCBs HiSpeed Printed Circuit Boards Chip Resistor Manufacturing Process Chip resistors are general passive components which are primarily used to create. In actuality the entire alumina substrate is processed at one time, but for illustrative. Provide basic explanation of how the chip resistors are made. Introduction to their thin and thick film product offering. Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. A chip. Chip Resistor Manufacturing Process.

From microchipusa.com

A StepbyStep Guide to Semiconductor Manufacturing Microchip USA Chip Resistor Manufacturing Process Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. In actuality the entire alumina substrate is processed at one time, but for illustrative. Chip resistor array (common terminal circuit) or chip resistor network (isolated circuit) (4) select the shape of surface. Introduction to their thin and thick film product offering. The general resistor manufacturing process involves. Chip Resistor Manufacturing Process.

From www.edubisnis.com

Steps of Resistor Manufacturing Chip Resistor Manufacturing Process The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Introduction to their thin and thick film product offering. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. Chip. Chip Resistor Manufacturing Process.

From www.researchgate.net

Schematic diagrams of (a) dimensions of the 0603 chip resistor and Cu Chip Resistor Manufacturing Process Chip resistors are general passive components which are primarily used to create. Provide basic explanation of how the chip resistors are made. Introduction to their thin and thick film product offering. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. A chip resistor. Chip Resistor Manufacturing Process.

From mavink.com

Semiconductor Chip Manufacturing Process Chip Resistor Manufacturing Process The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Chip resistors are general passive components which are primarily used to create. Introduction to their thin and thick film product offering. Provide basic explanation of how the chip resistors are made. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated. Chip Resistor Manufacturing Process.

From epci.eu

the Challenges of Using SubMilliohm SMD Chip Resistors Chip Resistor Manufacturing Process A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. The general. Chip Resistor Manufacturing Process.

From passive-components.eu

MELF, SMD Resistors and Resistor Network Chip Resistor Manufacturing Process Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. Provide basic explanation of how the chip resistors are made. In actuality the entire alumina substrate is processed at one time, but for illustrative. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Introduction to their thin and thick film product offering. Chip. Chip Resistor Manufacturing Process.

From comingwallpaper.blogspot.com

A Brief Introduction To Ceramic Capacitors Semantic Scholar Chip Resistor Manufacturing Process Chip resistors are general passive components which are primarily used to create. The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal. Chip Resistor Manufacturing Process.

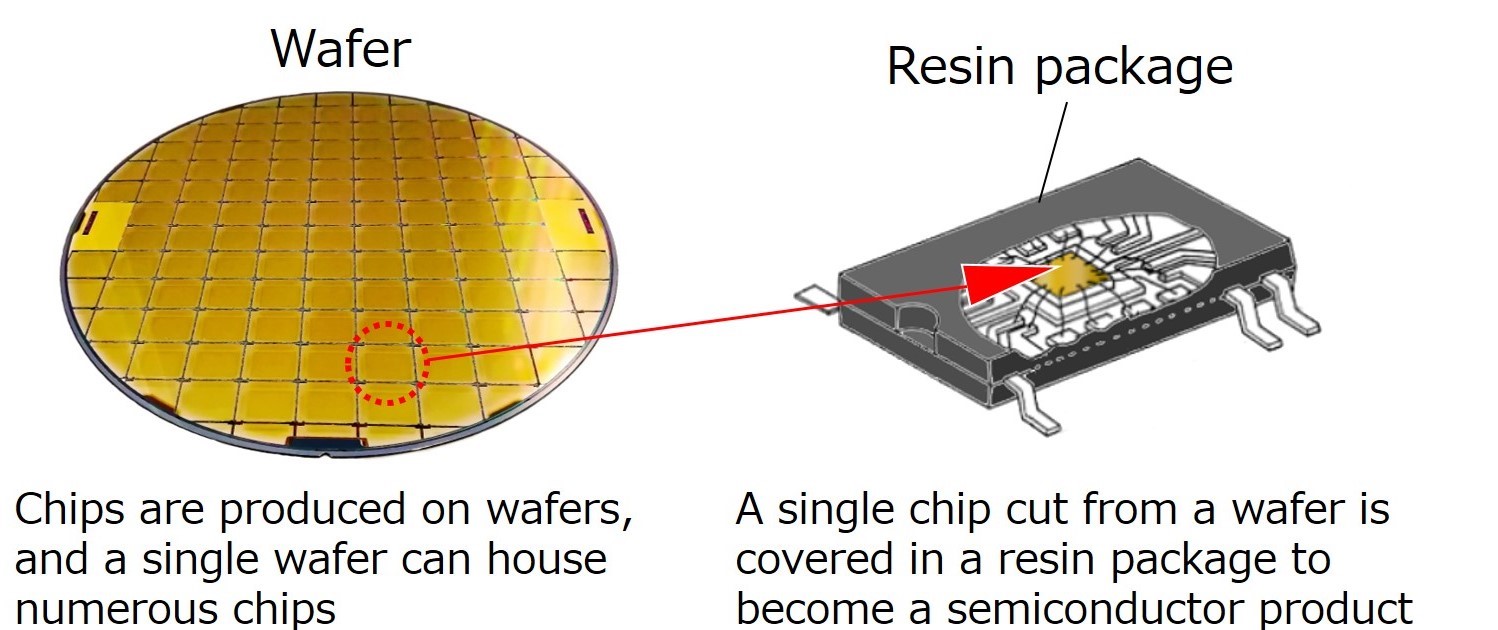

From news.samsung.com

Eight Major Steps to Semiconductor Fabrication, Part 1 Creating the Chip Resistor Manufacturing Process The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Provide basic explanation of how the chip resistors are made. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). Thin film chip resistor manufacturing typically starts with screen printing the inner conductors. Introduction to their thin and thick. Chip Resistor Manufacturing Process.

From risunsemi.com

Production Process and Failure Analysis of Chip Resistor Risun Chip Resistor Manufacturing Process The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Chip resistors are general passive components which are primarily used to create. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate. Chip Resistor Manufacturing Process.

From www.slideserve.com

PPT RChip Introduction PowerPoint Presentation, free download ID Chip Resistor Manufacturing Process Chip resistors are general passive components which are primarily used to create. Introduction to their thin and thick film product offering. A chip resistor ( 1 ) includes a chip substrate ( 2 ) a mutually separated terminal electrodes ( 3, 4 ) formed on the upper surface of the substrate ( 2. The following illustrates the manufacturing flow of. Chip Resistor Manufacturing Process.

From www.slideserve.com

PPT RChip Introduction PowerPoint Presentation, free download ID Chip Resistor Manufacturing Process In actuality the entire alumina substrate is processed at one time, but for illustrative. The following illustrates the manufacturing flow of a typical smd resistor (mcr series). The general resistor manufacturing process involves designing the device to achieve a specified range around the resistance nominal. Chip resistors are general passive components which are primarily used to create. Thin film chip. Chip Resistor Manufacturing Process.