Mig Wire Size For Roll Cage . I prefer.025 or.028 mig wire to weld cages. The correct size tubing for building a roll cage depends on the race class you will be participating in. Mild steel roll cage material is usually.134. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. On a side note, even a weak. I want to learn to properly weld a roll cage into a production based racecar. If you have the skill, you can create a sound roll cage using a mig welder. What size tubing for roll cage? Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. It lets me work the puddle better for. The cage would be contructed of 1.5 od x.095 wall.

from app.aws.org

What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. What size tubing for roll cage? If you have the skill, you can create a sound roll cage using a mig welder. I prefer.025 or.028 mig wire to weld cages. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. The correct size tubing for building a roll cage depends on the race class you will be participating in. Mild steel roll cage material is usually.134. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. The cage would be contructed of 1.5 od x.095 wall. It lets me work the puddle better for.

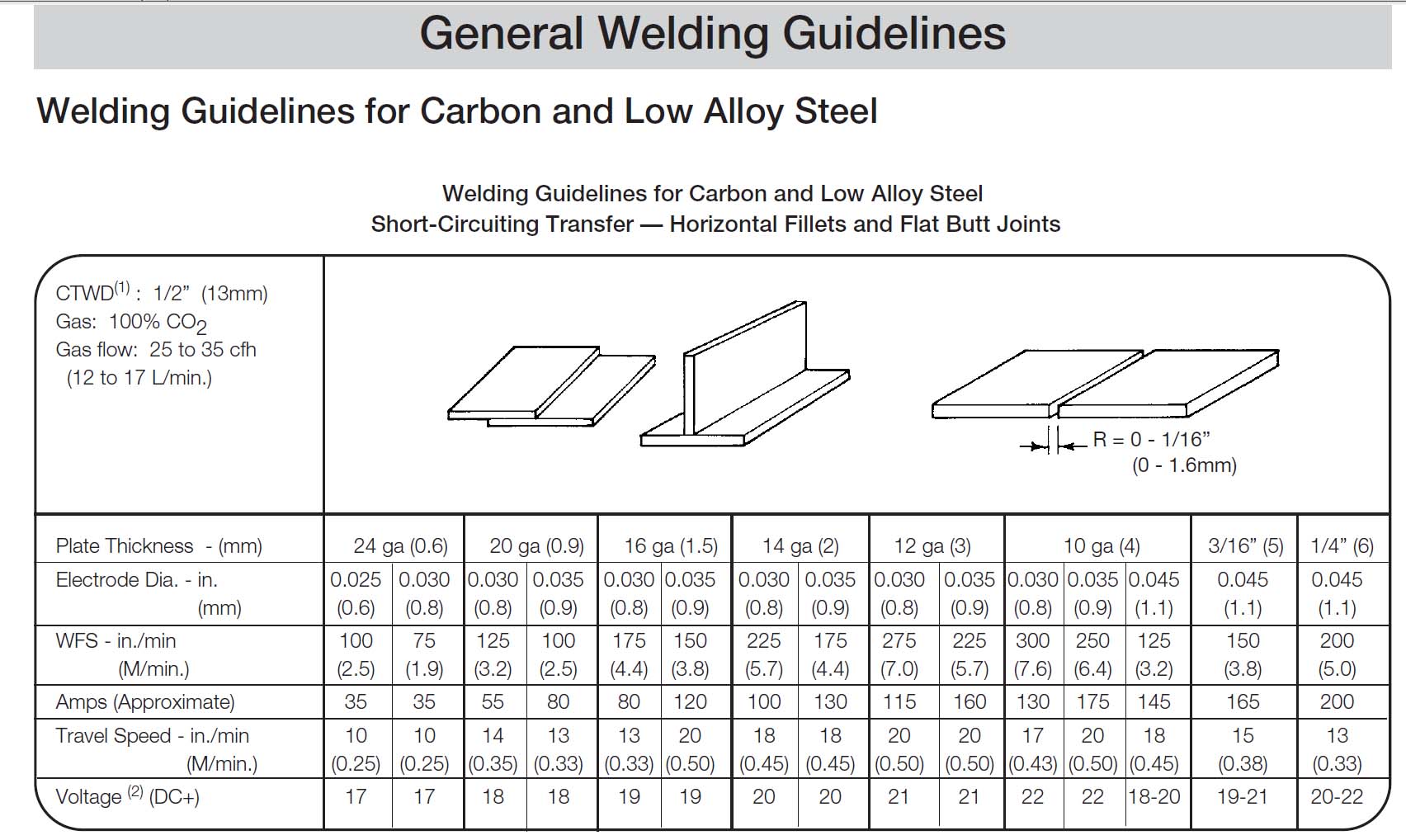

MIG settings for welding different thickness mild steel

Mig Wire Size For Roll Cage I want to learn to properly weld a roll cage into a production based racecar. On a side note, even a weak. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. I prefer.025 or.028 mig wire to weld cages. If you have the skill, you can create a sound roll cage using a mig welder. The cage would be contructed of 1.5 od x.095 wall. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. What size tubing for roll cage? In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. Mild steel roll cage material is usually.134. What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. I want to learn to properly weld a roll cage into a production based racecar. It lets me work the puddle better for. The correct size tubing for building a roll cage depends on the race class you will be participating in.

From www.youtube.com

MIG Setup Part 3 Wire roll setup and drive rolls YouTube Mig Wire Size For Roll Cage On a side note, even a weak. The cage would be contructed of 1.5 od x.095 wall. I prefer.025 or.028 mig wire to weld cages. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. If you have the skill, you can create a sound roll cage using a mig welder. The. Mig Wire Size For Roll Cage.

From hxersorvj.blob.core.windows.net

Mig Wire Size at Tina Wildman blog Mig Wire Size For Roll Cage The correct size tubing for building a roll cage depends on the race class you will be participating in. What size tubing for roll cage? The cage would be contructed of 1.5 od x.095 wall. If you have the skill, you can create a sound roll cage using a mig welder. What is great about it is the fact that. Mig Wire Size For Roll Cage.

From www.kinderboerderijdebuiktuin.com

Welding Equipment & Accessories Duty MIG Wire Feeder Assembly Roll Wire Mig Wire Size For Roll Cage The cage would be contructed of 1.5 od x.095 wall. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. On a side note, even a weak. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll. Mig Wire Size For Roll Cage.

From simplifybuying.com

MIG WELDING WIRE 0.8MM, 15KG/ROLL, GOLDEN BRIDGE ER70S6 Mig Wire Size For Roll Cage The correct size tubing for building a roll cage depends on the race class you will be participating in. The cage would be contructed of 1.5 od x.095 wall. I prefer.025 or.028 mig wire to weld cages. If you have the skill, you can create a sound roll cage using a mig welder. What size tubing for roll cage? In. Mig Wire Size For Roll Cage.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Mig Wire Size For Roll Cage What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. On a side note, even a weak. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. If you don't absolutely. Mig Wire Size For Roll Cage.

From weldguru.com

How To MIG Weld Aluminum Beginners Guide (with Chart) Mig Wire Size For Roll Cage What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. The cage would be contructed of 1.5 od x.095 wall. If. Mig Wire Size For Roll Cage.

From demiwalton.z13.web.core.windows.net

Mig Weld Settings For Aluminum Mig Wire Size For Roll Cage Mild steel roll cage material is usually.134. On a side note, even a weak. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. The correct size tubing for building a roll cage depends on the race class you will be participating in. I. Mig Wire Size For Roll Cage.

From www.homedepot.com

Forney 0.030 Flux Core Mild Steel MIG Welding Wire 2 lbs. Spool 42300 Mig Wire Size For Roll Cage If you have the skill, you can create a sound roll cage using a mig welder. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. Mild steel roll cage material is usually.134. In these videos he’s got some great tips and trick and methods on how to weld. Mig Wire Size For Roll Cage.

From www.aliexpress.com

Buy 1 Roll 1kg 0.8mm Gasless Mig Welding Wire Flux Mig Wire Size For Roll Cage Mild steel roll cage material is usually.134. If you have the skill, you can create a sound roll cage using a mig welder. The correct size tubing for building a roll cage depends on the race class you will be participating in. It lets me work the puddle better for. What size tubing for roll cage? The cage would be. Mig Wire Size For Roll Cage.

From garage.grumpysperformance.com

mig wire selection Grumpys Performance Garage Mig Wire Size For Roll Cage The correct size tubing for building a roll cage depends on the race class you will be participating in. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. What size tubing for roll cage? If you have the skill, you can create a. Mig Wire Size For Roll Cage.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Mig Wire Size For Roll Cage In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. Mild steel roll cage material is usually.134. On a side note, even a weak. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll. Mig Wire Size For Roll Cage.

From weldsmartly.com

The Basics Of Mig Welding [With Detailed Steps & Guide] Mig Wire Size For Roll Cage In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. It lets me work the puddle better for. If you have the skill, you can create a sound roll cage using a mig welder. What size tubing for roll cage? Roll cage fabrication is. Mig Wire Size For Roll Cage.

From www.welspring.com

MIG Wire — Welspring Universal Mig Wire Size For Roll Cage What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. Mild steel roll cage material is usually.134. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. If. Mig Wire Size For Roll Cage.

From www.indiamart.com

Mig Wire Roll, Thickness 1.2 mm at Rs 84/kilogram in Ludhiana ID Mig Wire Size For Roll Cage Mild steel roll cage material is usually.134. It lets me work the puddle better for. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. In these videos he’s got some. Mig Wire Size For Roll Cage.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Mig Wire Size For Roll Cage In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. The cage would be contructed of 1.5 od x.095 wall. The correct size tubing for building a roll cage depends on the race class you will be participating in. If you have the skill,. Mig Wire Size For Roll Cage.

From app.aws.org

MIG settings for welding different thickness mild steel Mig Wire Size For Roll Cage Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. On a side note, even a weak. What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. In these videos he’s. Mig Wire Size For Roll Cage.

From www.thewelderswarehouse.com

3 Easy to follow Steps for Perfect Mig Wire Feed Speed Mig Wire Size For Roll Cage Mild steel roll cage material is usually.134. I prefer.025 or.028 mig wire to weld cages. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. It lets me work the puddle better for. On a side note, even a weak. Roll cage fabrication is a critical part of driver. Mig Wire Size For Roll Cage.

From garage.grumpysperformance.com

mig wire selection Grumpys Performance Garage Mig Wire Size For Roll Cage I want to learn to properly weld a roll cage into a production based racecar. What size tubing for roll cage? What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. The correct size tubing for building a roll. Mig Wire Size For Roll Cage.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses Mig Wire Size For Roll Cage I prefer.025 or.028 mig wire to weld cages. The cage would be contructed of 1.5 od x.095 wall. On a side note, even a weak. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. Mild steel roll cage material is usually.134. What is great about it is the. Mig Wire Size For Roll Cage.

From www.machineryhouse.com.au

W252 UNIMIG 390 Compact Industrial MIG Welder Hare & Forbes Mig Wire Size For Roll Cage If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. The cage would be contructed of 1.5 od x.095 wall. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. What size tubing for roll cage? I prefer.025 or.028 mig wire. Mig Wire Size For Roll Cage.

From weldingireland.ie

WELDMIG HF350 1.2MM Solid Hardfacing Mig Wire 15kg Welding and Safety Mig Wire Size For Roll Cage Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. If you have the skill, you can create a sound roll cage using a mig welder. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar.. Mig Wire Size For Roll Cage.

From fyowfbcvs.blob.core.windows.net

Mig Wire Gauge at Doris Mantooth blog Mig Wire Size For Roll Cage I want to learn to properly weld a roll cage into a production based racecar. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. Mild steel roll cage material is usually.134. On a side note, even a weak. The cage would be contructed of 1.5 od x.095 wall. If you don't. Mig Wire Size For Roll Cage.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses Mig Wire Size For Roll Cage What size tubing for roll cage? If you have the skill, you can create a sound roll cage using a mig welder. I prefer.025 or.028 mig wire to weld cages. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. I want to learn to properly weld a roll cage into a. Mig Wire Size For Roll Cage.

From vycodeshita.blogspot.com

Mig Wire Size Chart Metric Mig Wire Size For Roll Cage On a side note, even a weak. I prefer.025 or.028 mig wire to weld cages. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. The correct size tubing for building a roll cage depends on the race class you will be participating in. The cage would be contructed of 1.5 od. Mig Wire Size For Roll Cage.

From www.kimhingleong.com

MIG Welding Wire 0.8mm x 5kg/ Roll Mig Wire Size For Roll Cage I prefer.025 or.028 mig wire to weld cages. If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. What size tubing for roll cage? I want to learn to properly weld a roll cage into a production based racecar. Roll cage fabrication is a critical part of driver safety. Mig Wire Size For Roll Cage.

From www.vector-welding.com

MIG MAG welding wire / wire roll buy now VECTOR WELDING Mig Wire Size For Roll Cage What size tubing for roll cage? If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. The correct size tubing for building a roll cage depends on the race class you will be participating in. Roll cage fabrication is a critical part of driver safety in building a race. Mig Wire Size For Roll Cage.

From www.collisionblast.com

MIG Welding Basics Parts of a MIG Welder Video Tutorial Automotive Mig Wire Size For Roll Cage The correct size tubing for building a roll cage depends on the race class you will be participating in. The cage would be contructed of 1.5 od x.095 wall. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. I want to learn to. Mig Wire Size For Roll Cage.

From www.arccaptain.com

MIG Wire Sizes A Comprehensive Guide Mig Wire Size For Roll Cage If you don't absolutely need a tig then a mig will suit your needs just fine for welding a roll cage. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. What size tubing for roll cage? On a side note, even a weak. I prefer.025 or.028 mig wire to weld cages.. Mig Wire Size For Roll Cage.

From weldingdirect.com

MIG Welding Wire Output Amperage & Selection Chart Mig Wire Size For Roll Cage I prefer.025 or.028 mig wire to weld cages. What size tubing for roll cage? On a side note, even a weak. In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. What is great about it is the fact that he’s showing you what. Mig Wire Size For Roll Cage.

From maker-hub.georgefox.edu

MIG Welder makerhub Mig Wire Size For Roll Cage I want to learn to properly weld a roll cage into a production based racecar. What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. Mild steel roll cage material is usually.134. If you don't absolutely need a tig. Mig Wire Size For Roll Cage.

From hxersorvj.blob.core.windows.net

Mig Wire Size at Tina Wildman blog Mig Wire Size For Roll Cage What size tubing for roll cage? In these videos he’s got some great tips and trick and methods on how to weld your tubing together for a roll cage or roll bar. If you have the skill, you can create a sound roll cage using a mig welder. Mild steel roll cage material is usually.134. It lets me work the. Mig Wire Size For Roll Cage.

From vycodeshita.blogspot.com

Mig Wire Size Chart Metric Mig Wire Size For Roll Cage It lets me work the puddle better for. The correct size tubing for building a roll cage depends on the race class you will be participating in. Roll cage fabrication is a critical part of driver safety in building a race car chassis, and one. Mild steel roll cage material is usually.134. The cage would be contructed of 1.5 od. Mig Wire Size For Roll Cage.

From www.youtube.com

MIG Welding What Size Wire Should I Use? YouTube Mig Wire Size For Roll Cage I want to learn to properly weld a roll cage into a production based racecar. What is great about it is the fact that he’s showing you what you need to know to weld inside the car, not in some perfect position on a work bench. Mild steel roll cage material is usually.134. In these videos he’s got some great. Mig Wire Size For Roll Cage.

From www.indiamart.com

Stainless Steel MIG Wire 308l 0.80mm, For Industrial, Quantity Per Roll Mig Wire Size For Roll Cage The cage would be contructed of 1.5 od x.095 wall. What size tubing for roll cage? If you have the skill, you can create a sound roll cage using a mig welder. I want to learn to properly weld a roll cage into a production based racecar. In these videos he’s got some great tips and trick and methods on. Mig Wire Size For Roll Cage.

From vycodeshita.blogspot.com

Mig Wire Size Chart Metric Mig Wire Size For Roll Cage If you have the skill, you can create a sound roll cage using a mig welder. I want to learn to properly weld a roll cage into a production based racecar. The correct size tubing for building a roll cage depends on the race class you will be participating in. It lets me work the puddle better for. The cage. Mig Wire Size For Roll Cage.