O-Ring Sealing Surface Roughness . After standing 10 days, the. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange.

from www.ouhongseal.com

Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. After standing 10 days, the. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control.

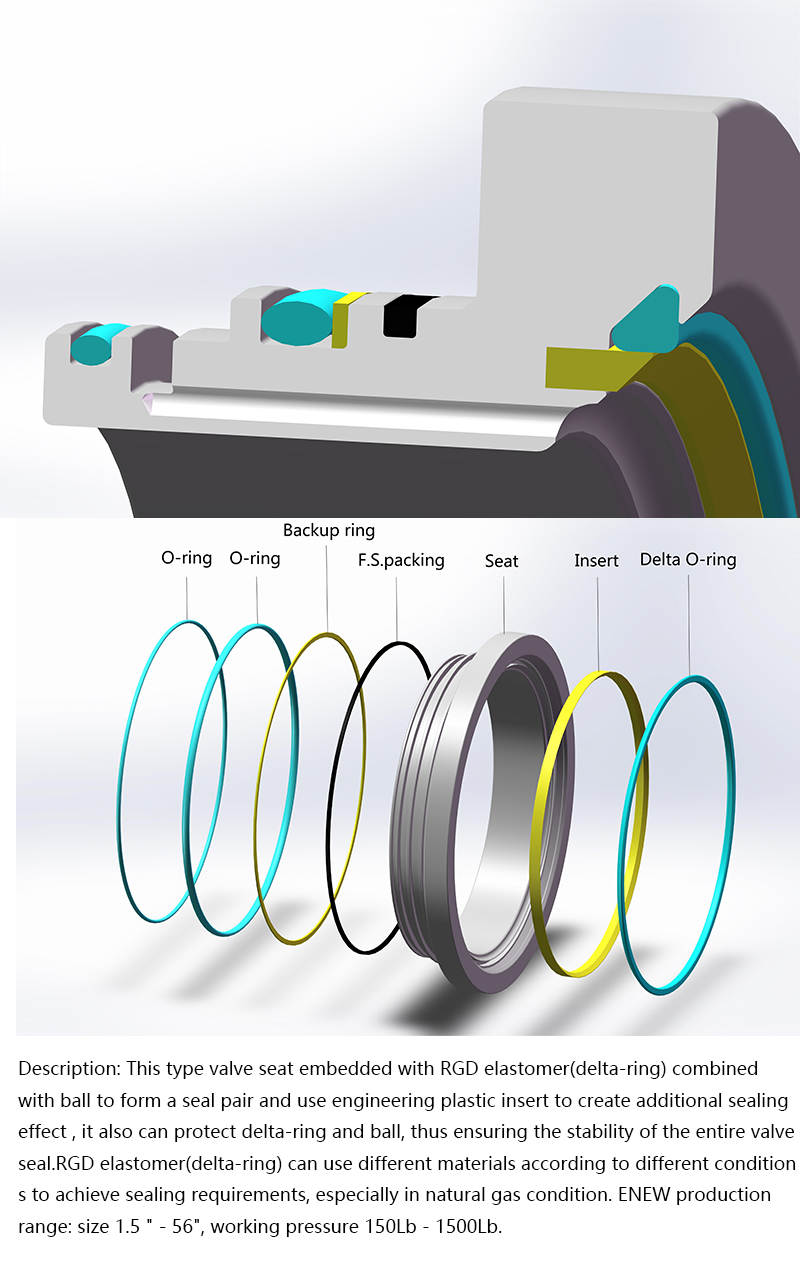

DELTARING & PROTECTIVE RING STRUCTUREOUHONG SEALING

O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control.

From www.machinemfg.com

ORing Sealing Principles and Features MachineMFG O-Ring Sealing Surface Roughness Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with. O-Ring Sealing Surface Roughness.

From www.awimach.com

Basic Knowledge [Sealing Business] AIR WATER MACH INC. O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar. O-Ring Sealing Surface Roughness.

From www.researchgate.net

Contact between Oring and sealing surfaces Download Scientific Diagram O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Usually, for common purposes, the surface roughness grade of the orings is not important, but there. O-Ring Sealing Surface Roughness.

From www.researchgate.net

The 1D surface roughness power spectra of the sandblasted Orings O-Ring Sealing Surface Roughness Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to. O-Ring Sealing Surface Roughness.

From caeuniversity.com

Oring seal simulation subjected to pressure of a fluid. O-Ring Sealing Surface Roughness Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to. O-Ring Sealing Surface Roughness.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those. O-Ring Sealing Surface Roughness.

From www.prosealsusa.com

PROSEALS provides orings and engineered sealing products, including O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar. O-Ring Sealing Surface Roughness.

From ecosealthailand.com

Fundamental of ORing O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.edmdept.com

3D Roughness Inspection of Complex Surface ORing Groove O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Usually, for common purposes, the surface roughness grade of the orings is not important, but there. O-Ring Sealing Surface Roughness.

From sealingaustralia.com.au

O’ring Groove Design Sealing Australia O-Ring Sealing Surface Roughness Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to. O-Ring Sealing Surface Roughness.

From www.sealingaustralia.com.au

O’ring Groove Design « Sealing Australia O-Ring Sealing Surface Roughness Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.researchgate.net

The 1D surface roughness power spectra of the sandblasted Orings O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. After standing 10 days, the. Usually, for common purposes, the surface roughness grade of the orings. O-Ring Sealing Surface Roughness.

From www.globaloring.com

A Complete Overview of Elastomers Global ORing and Seal O-Ring Sealing Surface Roughness Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. After standing 10 days, the. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.jiayuanfitting.com

Surface finish acceptance criteria for ORFS fittings Knowledge O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. After standing 10 days, the. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of. O-Ring Sealing Surface Roughness.

From www.inventortales.com

Gland Schematic from Parker ORing Handbook O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those. O-Ring Sealing Surface Roughness.

From www.researchgate.net

Schematic of a common Oring sealing design in DOPCs. Download O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.youtube.com

ORing Groove Surface Finishes YouTube O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Simply understanding a mating surface’s r a, or roughness average value, is not enough to. O-Ring Sealing Surface Roughness.

From www.tpsearchtool.com

Surface Finish Surface Roughness Its Indications Symbols Images O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those. O-Ring Sealing Surface Roughness.

From mavink.com

Surface Roughness Symbols And Meanings O-Ring Sealing Surface Roughness After standing 10 days, the. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.alliedmetrics.com

ORing Groove Design Guide Allied Metrics ORings & Seals, Inc. O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Usually, for common purposes, the surface roughness grade of the orings is not important, but there. O-Ring Sealing Surface Roughness.

From www.submarineboat.com

Hull O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those. O-Ring Sealing Surface Roughness.

From harrymoto.com

Countershaft seal issues O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From caeuniversity.com

oring seal simulation CAE University O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. After standing 10 days, the. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of. O-Ring Sealing Surface Roughness.

From ahpseals.com

Seal design Viton seal American High Performance Seals O-Ring Sealing Surface Roughness After standing 10 days, the. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.researchgate.net

Schematic of sealing mechanism of elastomer Orings (a) free condition O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Usually, for common purposes, the surface roughness grade of the orings is not important, but there. O-Ring Sealing Surface Roughness.

From studylib.net

Static ORing Sealing Sealing Devices Inc. O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate. O-Ring Sealing Surface Roughness.

From edmontonrealestateinvestmentblog.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. After standing 10 days, the. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.ouhongseal.com

DELTARING & PROTECTIVE RING STRUCTUREOUHONG SEALING O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. After standing 10 days, the. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of. O-Ring Sealing Surface Roughness.

From www.sealingaustralia.com.au

O’ring Groove Design « Sealing Australia O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Usually, for common purposes, the surface roughness grade of the orings is not important, but there. O-Ring Sealing Surface Roughness.

From www.researchgate.net

Surface roughness of ring sample and counterpart after test Download O-Ring Sealing Surface Roughness After standing 10 days, the. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Usually, for common purposes, the surface roughness grade of the orings is not important, but there are cases in which the roughness control. Simply understanding a mating surface’s r a, or roughness average. O-Ring Sealing Surface Roughness.

From www.researchgate.net

Effect of the ring coating layer on the surface roughness and its O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate. O-Ring Sealing Surface Roughness.

From shop.eriks.nl

Engineering Basics Guide to ORings ERIKS shop NL O-Ring Sealing Surface Roughness After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Usually, for common purposes, the surface roughness grade of the orings. O-Ring Sealing Surface Roughness.

From mavink.com

Surface Roughness Symbols And Meanings O-Ring Sealing Surface Roughness Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those. O-Ring Sealing Surface Roughness.

From www.youtube.com

Surface Finish ORings Gaskets Oil Seals PTFE O-Ring Sealing Surface Roughness After standing 10 days, the. Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Usually, for common purposes, the surface roughness grade of the orings. O-Ring Sealing Surface Roughness.

From shop.maagtechnic.ch

Grundlagen im Engineering ORingLeitfaden MAAGTECHNIC shop CH O-Ring Sealing Surface Roughness Simply understanding a mating surface’s r a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very different surface textures with similar r a values, and those variances can greatly affect seal performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate. O-Ring Sealing Surface Roughness.