Standard Gold Plating Thickness Pcb . Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the application and. Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. What is hard gold surface finish on pcbs? Aggressive gold baths and high gold thickness can. Different materials allow varying board sizes. Knowledge base / hard gold surface finish. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Discover the world of gold plating for pcbs with elepcb. Explore types, thickness, and learn about industry standards of gold plating in pcb. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. This finish provides a robust surface against depreciation.

from www.oneseine.com

Aggressive gold baths and high gold thickness can. This finish provides a robust surface against depreciation. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the application and. What is hard gold surface finish on pcbs? 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Different materials allow varying board sizes. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. Discover the world of gold plating for pcbs with elepcb. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate.

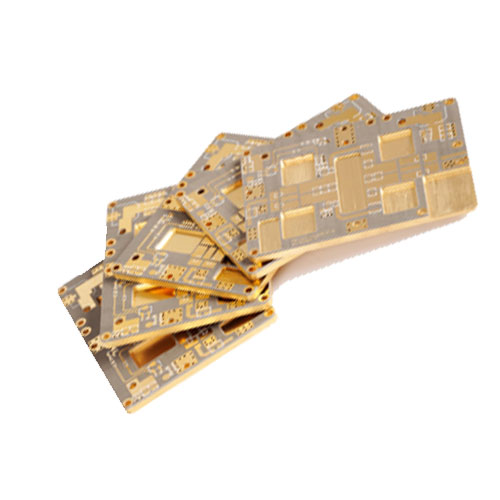

Rogers 3003 Gold Plated PCB

Standard Gold Plating Thickness Pcb When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the application and. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Explore types, thickness, and learn about industry standards of gold plating in pcb. Knowledge base / hard gold surface finish. What is hard gold surface finish on pcbs? This finish provides a robust surface against depreciation. Different materials allow varying board sizes. Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Aggressive gold baths and high gold thickness can. Discover the world of gold plating for pcbs with elepcb.

From hillmancurtis.com

Top 6 Benefits Of Using Gold Plating PCB Hillman Curtis Printed Standard Gold Plating Thickness Pcb Knowledge base / hard gold surface finish. This finish provides a robust surface against depreciation. Explore types, thickness, and learn about industry standards of gold plating in pcb. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold). Standard Gold Plating Thickness Pcb.

From www.fujitsu.com

Process Fujitsu UK Standard Gold Plating Thickness Pcb 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. What is hard gold surface finish on pcbs? Aggressive gold baths and high gold thickness can. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Explore types,. Standard Gold Plating Thickness Pcb.

From wiringharnessnews.com

Detailed Discussion of MILSTD1353 (Part 2) Gold and Nickel Plating Standard Gold Plating Thickness Pcb Explore types, thickness, and learn about industry standards of gold plating in pcb. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Aggressive gold baths and high gold thickness can. What is hard gold surface finish on pcbs? 1.1 scope this specification sets the requirements. Standard Gold Plating Thickness Pcb.

From absolutepcbassembly.com

Standard PCB Thickness Everything you need to know about Standard Gold Plating Thickness Pcb This finish provides a robust surface against depreciation. Different materials allow varying board sizes. Discover the world of gold plating for pcbs with elepcb. Aggressive gold baths and high gold thickness can. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches. Standard Gold Plating Thickness Pcb.

From www.venture-mfg.com

Your Trusted Hard Gold Plating PCB ManufacturerVenture Electronic Standard Gold Plating Thickness Pcb For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Explore types, thickness, and learn about industry standards of gold plating in pcb. Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. When gold is plated during the enig process, it depends. Standard Gold Plating Thickness Pcb.

From www.oneseine.com

Rogers 3003 Gold Plated PCB Standard Gold Plating Thickness Pcb Different materials allow varying board sizes. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the application and. This finish provides a robust surface against depreciation. Aggressive gold baths and high gold thickness can. Discover the world of gold plating for pcbs with elepcb. Hard gold is a type of. Standard Gold Plating Thickness Pcb.

From www.eftfastqualityservices.com

Surface Finishes EFT Plating Standard Gold Plating Thickness Pcb Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. Aggressive gold baths and high gold thickness can. Explore types, thickness, and learn about industry standards of gold plating in pcb. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Gold plating. Standard Gold Plating Thickness Pcb.

From www.researchgate.net

(a) Setup for gold plating with two electrodes; (b) different samples Standard Gold Plating Thickness Pcb For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Explore types, thickness, and learn about industry standards of gold plating in pcb. Discover the world of gold plating for pcbs with elepcb. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Aggressive gold baths and high. Standard Gold Plating Thickness Pcb.

From sfxpcb.com

Explore Excellence with Leading Gold Fingers PCB Manufacturer Services Standard Gold Plating Thickness Pcb When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Explore types, thickness, and learn about industry standards of gold plating in pcb. Discover the world of gold plating for pcbs with. Standard Gold Plating Thickness Pcb.

From quickjewelryrepairs.com

Gold Plating Jewelry Thickness What You Need To Know Standard Gold Plating Thickness Pcb Discover the world of gold plating for pcbs with elepcb. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. This finish provides a robust surface against depreciation.. Standard Gold Plating Thickness Pcb.

From www.ipcb.com

Enig Immersion Gold PCB Standard PCB Standard Gold Plating Thickness Pcb Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the application and. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate.. Standard Gold Plating Thickness Pcb.

From hillmancurtis.com

PCB Gold Plating Hard Gold PCB, PCB Gold Plating Thickness and More Standard Gold Plating Thickness Pcb Explore types, thickness, and learn about industry standards of gold plating in pcb. Aggressive gold baths and high gold thickness can. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the application and. This finish provides a robust surface against depreciation. Hard gold is a type of surface finish applied. Standard Gold Plating Thickness Pcb.

From www.silvexinc.com

How Thick is Gold Plating for Electronics? Silvex Inc. Standard Gold Plating Thickness Pcb Different materials allow varying board sizes. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the application and. Hard gold is a type of surface finish applied to high wear areas, such. Standard Gold Plating Thickness Pcb.

From www.wellpcb.com

PCB Plating The Complete Guide of Plating Techniques in PCB Standard Gold Plating Thickness Pcb Explore types, thickness, and learn about industry standards of gold plating in pcb. Discover the world of gold plating for pcbs with elepcb. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. This finish provides a robust surface against depreciation. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig). Standard Gold Plating Thickness Pcb.

From hillmancurtis.com

PCB Gold Plating Hard Gold PCB, PCB Gold Plating Thickness and More Standard Gold Plating Thickness Pcb Discover the world of gold plating for pcbs with elepcb. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Aggressive gold baths and high gold thickness can.. Standard Gold Plating Thickness Pcb.

From www.solder.net

Six Benefits of a Gold Plating for PCBs Standard Gold Plating Thickness Pcb Explore types, thickness, and learn about industry standards of gold plating in pcb. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Gold plating typically results in. Standard Gold Plating Thickness Pcb.

From advancedplatingtech.com

Gold Plating Thickness of Connectors Advanced Plating Tech Blog Standard Gold Plating Thickness Pcb When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. What is hard gold surface finish on pcbs? Aggressive gold baths and high gold thickness can. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin) or more, depending on the. Standard Gold Plating Thickness Pcb.

From www.ourpcb.com

Gold PCB Protective Immersion or Electroplating Finishing for Circuit Standard Gold Plating Thickness Pcb Discover the world of gold plating for pcbs with elepcb. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Different materials allow varying board sizes. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Explore types,. Standard Gold Plating Thickness Pcb.

From mavink.com

Standard Pcb Thickness Chart Standard Gold Plating Thickness Pcb 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Knowledge base / hard gold surface finish. This finish provides a robust surface against depreciation. Discover the world of gold plating for pcbs with elepcb. Explore types, thickness, and learn about industry standards of gold plating in pcb. Aggressive gold baths and. Standard Gold Plating Thickness Pcb.

From www.raypcb.com

What’s the Difference Between PCB Immersion Gold and Gold Plating PCB Standard Gold Plating Thickness Pcb 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. This finish provides a robust surface against depreciation. Explore types, thickness, and learn about industry standards of gold plating in pcb. What is hard gold surface finish on pcbs? For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6. Standard Gold Plating Thickness Pcb.

From hillmancurtis.com

PCB Gold Plating Hard Gold PCB, PCB Gold Plating Thickness and More Standard Gold Plating Thickness Pcb Knowledge base / hard gold surface finish. What is hard gold surface finish on pcbs? Aggressive gold baths and high gold thickness can. Different materials allow varying board sizes. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. This finish provides a robust surface against. Standard Gold Plating Thickness Pcb.

From www.hiquality-pcb.com

bonding PCB, ENEPIG pcb, gold plating pcb Immersion gold PCB Standard Gold Plating Thickness Pcb What is hard gold surface finish on pcbs? Different materials allow varying board sizes. Explore types, thickness, and learn about industry standards of gold plating in pcb. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. This finish provides a robust surface against depreciation. Knowledge base / hard gold surface finish. Gold plating typically results. Standard Gold Plating Thickness Pcb.

From padpcb.com

Complete Guide for PCB Plating Process PadPCB Standard Gold Plating Thickness Pcb For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Discover the world of gold plating for pcbs with elepcb. Explore types, thickness, and learn about industry standards of gold plating in pcb. Aggressive gold baths and high gold thickness can. Gold plating typically results in a thicker coating, ranging from 3 to 50 microinches (µin). Standard Gold Plating Thickness Pcb.

From www.allaboutcircuits.com

PCB Copper Trace Finish Materials and Plating Methods Technical Articles Standard Gold Plating Thickness Pcb What is hard gold surface finish on pcbs? Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Explore types, thickness, and learn about industry standards of gold plating. Standard Gold Plating Thickness Pcb.

From goldplatedhiphoppendantsninpatsu.blogspot.com

Gold Plated Hip Hop Pendants Pcb Plating Types Standard Gold Plating Thickness Pcb 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Aggressive gold baths and high gold thickness can. What is hard gold surface finish on pcbs? Hard gold. Standard Gold Plating Thickness Pcb.

From ar.inspiredpencil.com

Gold Plating Process Standard Gold Plating Thickness Pcb Explore types, thickness, and learn about industry standards of gold plating in pcb. What is hard gold surface finish on pcbs? When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig). Standard Gold Plating Thickness Pcb.

From goldschoices.blogspot.com

Pcb Gold Plating Gold Choices Standard Gold Plating Thickness Pcb Knowledge base / hard gold surface finish. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Aggressive gold baths and high gold thickness can. Discover the world of gold plating for pcbs with elepcb. Different materials allow varying board sizes. This finish provides a robust. Standard Gold Plating Thickness Pcb.

From bayareacircuits.com

Standard PCB Thickness PCB Layer Bay Area Circuits Standard Gold Plating Thickness Pcb When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. Aggressive gold baths and high gold thickness can. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Hard gold is a type of surface finish applied to. Standard Gold Plating Thickness Pcb.

From www.raypcb.com

What’s the Difference Between PCB Immersion Gold and Gold Plating PCB Standard Gold Plating Thickness Pcb When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Aggressive gold baths and high gold thickness can. For instance, the standard fr4 pcb thickness lies between 0.4. Standard Gold Plating Thickness Pcb.

From www.raypcb.com

How Thick is Gold Finger PCB Plating and its Cost RAYPCB Standard Gold Plating Thickness Pcb What is hard gold surface finish on pcbs? 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. For instance, the standard fr4 pcb thickness lies between 0.4 mm. Standard Gold Plating Thickness Pcb.

From hillmancurtis.com

Top 6 Benefits Of Using Gold Plating PCB Hillman Curtis Printed Standard Gold Plating Thickness Pcb Knowledge base / hard gold surface finish. Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. This finish provides a robust surface against depreciation. Different materials allow varying board sizes. Discover the world of gold plating for pcbs with elepcb. Explore types, thickness, and learn about. Standard Gold Plating Thickness Pcb.

From www.ourpcb.com

Gold PCB Protective Immersion or Electroplating Finishing for Circuit Standard Gold Plating Thickness Pcb Explore types, thickness, and learn about industry standards of gold plating in pcb. Discover the world of gold plating for pcbs with elepcb. For instance, the standard fr4 pcb thickness lies between 0.4 mm and 1.6 mm. Knowledge base / hard gold surface finish. Aggressive gold baths and high gold thickness can. Different materials allow varying board sizes. Gold plating. Standard Gold Plating Thickness Pcb.

From thesparklane.com

Gold Plating 101 Sparklane Standard Gold Plating Thickness Pcb Different materials allow varying board sizes. Aggressive gold baths and high gold thickness can. When gold is plated during the enig process, it depends on a corrosion reaction to place itself (gold) on top of the nickel substrate. What is hard gold surface finish on pcbs? This finish provides a robust surface against depreciation. Explore types, thickness, and learn about. Standard Gold Plating Thickness Pcb.

From www.jigsawcad.com

Let the experts talk about What is PCB gold plating [Pictures] Standard Gold Plating Thickness Pcb Aggressive gold baths and high gold thickness can. Discover the world of gold plating for pcbs with elepcb. Different materials allow varying board sizes. 1.1 scope this specification sets the requirements for the use of electroless nickel/immersion gold (enig) as a surface. Knowledge base / hard gold surface finish. Explore types, thickness, and learn about industry standards of gold plating. Standard Gold Plating Thickness Pcb.

From www.protoexpress.com

Hard Gold Surface Finish Sierra Circuits Standard Gold Plating Thickness Pcb Different materials allow varying board sizes. Knowledge base / hard gold surface finish. Hard gold is a type of surface finish applied to high wear areas, such as edge connectors, keyboards, or gold/edge fingers on pcbs. What is hard gold surface finish on pcbs? This finish provides a robust surface against depreciation. Gold plating typically results in a thicker coating,. Standard Gold Plating Thickness Pcb.