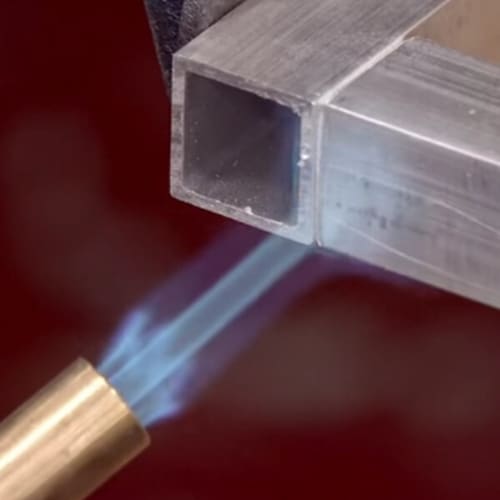

Best Brazing Techniques . Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Brazing flux protects and cleans the surfaces to be brazed. An average brazing alloy depth of.010” seems to work the best. Explore our best brazing practices for successful projects. Master the art of brazing with cup alloys. There are four main types of brazing heating methods: Torch or manual brazing, induction brazing, resistance brazing, and vacuum.

from weldingtroop.com

Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Explore our best brazing practices for successful projects. Brazing flux protects and cleans the surfaces to be brazed. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. There are four main types of brazing heating methods: Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Master the art of brazing with cup alloys. An average brazing alloy depth of.010” seems to work the best.

Aluminum Brazing Complete Guide Advantages Over Welding

Best Brazing Techniques Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux protects and cleans the surfaces to be brazed. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Explore our best brazing practices for successful projects. Master the art of brazing with cup alloys. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. There are four main types of brazing heating methods: An average brazing alloy depth of.010” seems to work the best.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques Best Brazing Techniques Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. There are four main types of brazing heating methods: An average brazing alloy depth of.010” seems to work the best. Explore our best brazing practices for successful projects. Master the art of. Best Brazing Techniques.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Best Brazing Techniques Explore our best brazing practices for successful projects. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. An average brazing alloy depth of.010” seems to work the best. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. There are four main types of brazing heating methods: Brazing flux protects and. Best Brazing Techniques.

From www.scribd.com

Brazing Brazing is a metaljoining process in which two or more metal Best Brazing Techniques Explore our best brazing practices for successful projects. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux protects and cleans the surfaces to be brazed. An average brazing alloy depth of.010” seems to work the best. There are four main types of brazing heating methods: Master the art of brazing with cup alloys. Learn essential techniques, joint. Best Brazing Techniques.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Best Brazing Techniques There are four main types of brazing heating methods: Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Brazing flux protects and cleans the surfaces to be brazed. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. An. Best Brazing Techniques.

From www.youtube.com

Metal Joining Processes Welding, Riveting, Bolting, Brazing, Soldering Best Brazing Techniques Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux protects and cleans the surfaces to be brazed. Explore our best brazing practices for successful projects. Master the art of brazing with cup alloys. Brazing is a fascinating process that connects metals using a filler material. Best Brazing Techniques.

From www.acrjournal.uk

Top tips on brazing ACR Journal Best Brazing Techniques Brazing flux protects and cleans the surfaces to be brazed. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. An average brazing alloy depth of.010” seems to work the best. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. There are four main types of brazing heating methods:. Best Brazing Techniques.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages Best Brazing Techniques Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Explore our best brazing practices for successful projects. There are four main types of brazing heating methods: Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Brazing flux protects and cleans the surfaces to be brazed. Master the art of brazing with cup alloys. An average brazing. Best Brazing Techniques.

From twobabox.com

“Casting Iron with Braze A HowTo Guide” Best Brazing Techniques Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Explore our best brazing practices for successful projects. An average brazing alloy depth of.010” seems to work the best. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Master. Best Brazing Techniques.

From www.harrisproductsgroup.com.au

How Brazing Works Capillary Action Harris Products Group Best Brazing Techniques Master the art of brazing with cup alloys. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. An average brazing alloy depth of.010” seems to work the best. Brazing flux protects and cleans the surfaces to be brazed. There are four main types of brazing heating methods: Learn essential techniques, joint. Best Brazing Techniques.

From beststudwelders.com

Guide to Metal Brazing Techniques and Processes best stud welders Best Brazing Techniques Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux protects and cleans the surfaces to be brazed. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. There are four main types of brazing heating methods: Master. Best Brazing Techniques.

From www.nttinc.com

Brazing Copper Tips and Tricks for the Novice NTT Training Best Brazing Techniques Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. There are four main types of brazing heating methods: Master the art of brazing with cup alloys. Explore our best brazing practices for successful projects. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. An average brazing alloy depth. Best Brazing Techniques.

From www.acrjournal.uk

Top tips on brazing ACR Journal Best Brazing Techniques Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. An average brazing alloy depth of.010” seems to work the best. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux protects and cleans the surfaces to be brazed. Master the art of brazing with cup alloys. There are four main types of brazing heating methods:. Best Brazing Techniques.

From www.youtube.com

Fundamentals of Brazing 5 Brazing the Assembly YouTube Best Brazing Techniques There are four main types of brazing heating methods: Master the art of brazing with cup alloys. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. An average brazing alloy depth of.010” seems to work the best. Brazing flux protects and. Best Brazing Techniques.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. Brazing flux protects and cleans the surfaces to be brazed. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Master the art of brazing with cup alloys. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. There are four. Best Brazing Techniques.

From www.youtube.com

🔥 Gas Brazing Technique YouTube Best Brazing Techniques Explore our best brazing practices for successful projects. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. There are four main types of brazing heating methods: Master the art of brazing with cup alloys. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Learn essential techniques, joint design, fluxing, and. Best Brazing Techniques.

From engtrainingcentre.com

Brazing Engineering Trainng Centre Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. There are four main types of brazing heating methods: Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Explore our best brazing practices for successful projects. Brazing flux protects and cleans the surfaces to be brazed. Torch or manual brazing,. Best Brazing Techniques.

From www.bernzomatic.com

Bernzomatic How To Braze Metal Together Brazing Metal Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Explore our best brazing practices for successful projects. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Master the art of brazing with cup alloys. Brazing flux protects and cleans. Best Brazing Techniques.

From www.pipsisland.com

10 Simple Steps to Braze Copper Pipe (Extended Tips) Best Brazing Techniques Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Master the art of brazing with cup alloys. There are four main types of brazing heating methods: Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Explore our best brazing practices for successful projects. Torch or manual brazing, induction. Best Brazing Techniques.

From www.cpvmfg.com

Joining Metals Your Frequently Asked Questions About Brazing, Answered Best Brazing Techniques Master the art of brazing with cup alloys. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Explore our best brazing practices for successful projects. An average brazing alloy depth of.010” seems to work the best. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is a fascinating process that connects metals using a filler. Best Brazing Techniques.

From hlqinductionheating.wordpress.com

Induction Aluminum Brazing Techniques and Benefits Explained HLQ Best Brazing Techniques Master the art of brazing with cup alloys. Brazing flux protects and cleans the surfaces to be brazed. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. There are four main types of brazing heating methods: Explore our best. Best Brazing Techniques.

From weldingpros.net

Silver brazing Overview HowTo Guide, Brazing Tips, Techniques, And Best Brazing Techniques There are four main types of brazing heating methods: An average brazing alloy depth of.010” seems to work the best. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Master the art of brazing with cup alloys. Explore our best brazing practices for successful projects. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux. Best Brazing Techniques.

From weldingintro.com

What Is Brazing Welding & How It Works (Basic) Best Brazing Techniques Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Brazing flux protects and cleans the surfaces to be brazed. There are four main types of brazing heating methods: Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Explore our best brazing practices for successful projects. Brazing is a fascinating process that connects metals using a filler. Best Brazing Techniques.

From www.youtube.com

Field Brazing Tips & Techniques YouTube Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. Explore our best brazing practices for successful projects. There are four main types of brazing heating methods: Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Master the art of brazing with cup alloys. Brazing is a fascinating process that connects metals using a filler material heated to. Best Brazing Techniques.

From www.youtube.com

How to Braze Aluminum to Copper YouTube Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. Explore our best brazing practices for successful projects. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux protects and cleans the surfaces to be brazed. There are four main types of brazing heating methods: Brazing is a fascinating process that connects metals using a filler material. Best Brazing Techniques.

From www.youtube.com

TIG Welding & TIG Brazing YouTube Best Brazing Techniques Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Master the art of brazing with cup alloys. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. An average brazing alloy depth of.010” seems to work the best. Explore our best brazing practices for successful projects. Brazing flux protects. Best Brazing Techniques.

From www.youtube.com

Brazing Tips MTF5 vs. Single Flame YouTube Best Brazing Techniques Explore our best brazing practices for successful projects. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Master the art of brazing with cup alloys. There are four main types of brazing heating methods: Brazing flux protects and cleans the surfaces. Best Brazing Techniques.

From midsouthsupply.com

Guide to Aluminum Brazing Mid South Supply Best Brazing Techniques Explore our best brazing practices for successful projects. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Master the art of brazing with cup alloys. An average brazing alloy depth of.010” seems to work the best. There are four main types of brazing heating methods: Brazing is. Best Brazing Techniques.

From www.pinterest.com

What Are The Types Of Brazing? "7 Brazing Types Explained" Brazing Best Brazing Techniques Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Master the art of brazing with cup alloys. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. An average brazing alloy depth of.010” seems to work the best. There. Best Brazing Techniques.

From www.twi-global.com

What are the different methods of brazing? TWI Best Brazing Techniques Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. An average brazing alloy depth of.010” seems to work the best. Master the art of brazing with cup alloys. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Brazing. Best Brazing Techniques.

From weldersadvice.com

How to Braze Aluminum to Steel Steps, Techniques & Advantages Best Brazing Techniques Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. An average brazing alloy depth of.010” seems to work the best. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing flux protects and cleans the surfaces to be brazed. There are four main types of brazing heating methods: Learn essential. Best Brazing Techniques.

From www.youtube.com

Brazing Techniques YouTube Best Brazing Techniques Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. An average brazing alloy depth of.010” seems to work the best. Brazing flux protects and cleans the surfaces to be brazed. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Master the art of brazing with cup alloys. There are four main types of brazing heating methods:. Best Brazing Techniques.

From www.diydoctor.org.uk

Brazing a Joint Using a Blow Torch and How to use a Brazing Rod DIY Best Brazing Techniques Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. There are four main types of brazing heating methods: Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Explore our best brazing practices for successful projects. An average brazing. Best Brazing Techniques.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Explore our best brazing practices for successful projects. Master the art of brazing with cup alloys. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Brazing flux protects. Best Brazing Techniques.

From www.youtube.com

Induction Brazing Carbide to Steel on a Form Tool YouTube Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. There are four main types of brazing heating methods: Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Master the art of brazing with cup alloys. Brazing flux protects and cleans the surfaces to be brazed. Explore our best brazing practices for successful projects. Torch or. Best Brazing Techniques.

From www.indiamart.com

Metal Brazing Tips And Advice at best price in Kanpur ID 21125893091 Best Brazing Techniques An average brazing alloy depth of.010” seems to work the best. Explore our best brazing practices for successful projects. Master the art of brazing with cup alloys. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Learn essential techniques, joint design, fluxing, and heating for strong, durable joints. Torch or manual. Best Brazing Techniques.