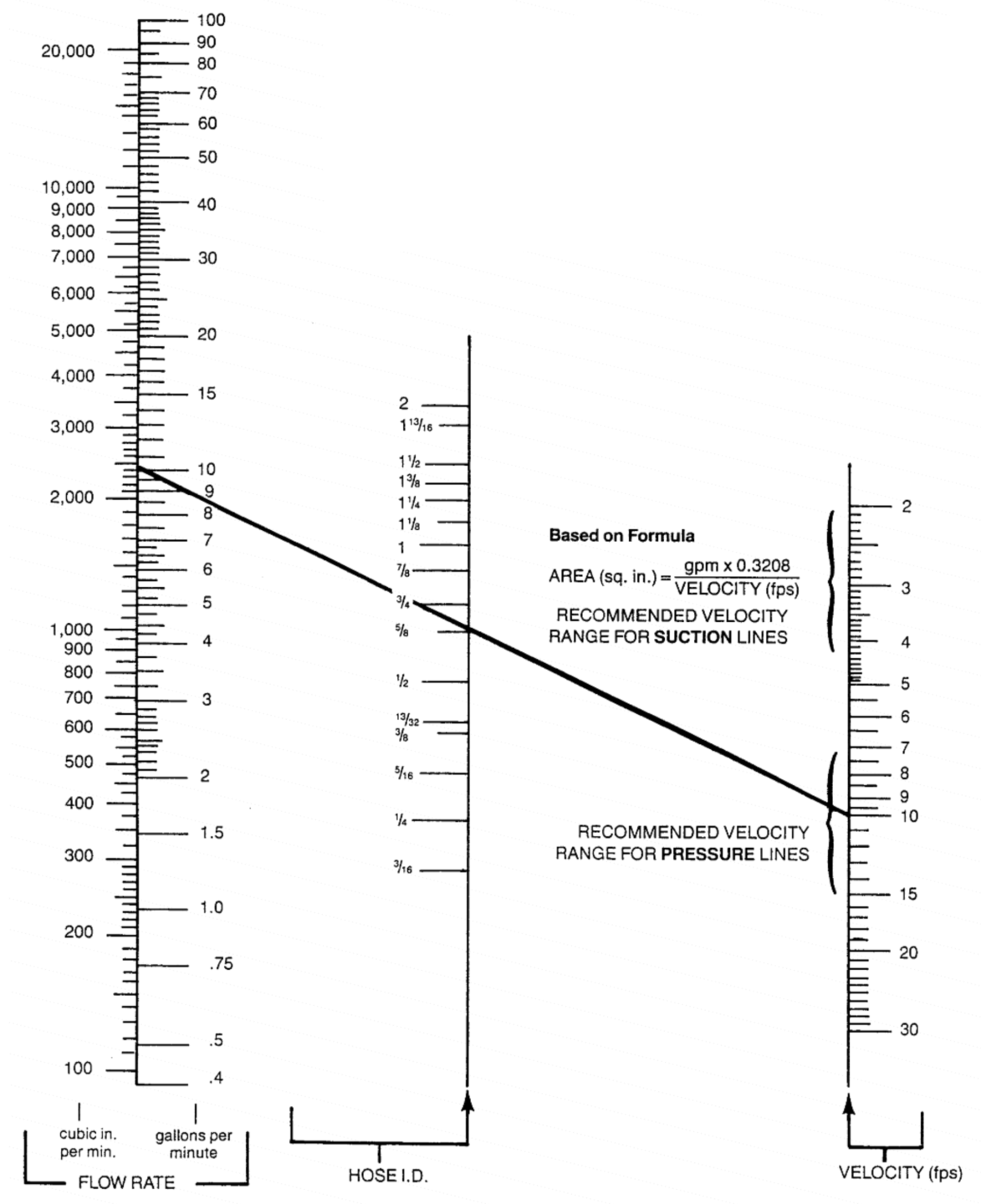

Hydraulic Tube Flow Chart . The table is based on the following. Tubing must meet two requirements: In order to choose the right hydraulic tube, you need to understand their basic specifications. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. The recommended flow diameter for the required flow rate and type of line can be determined by using. The first step in choosing the correct tube size is to determine required flow diameter. Straight pipe, curved pipe, and. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: Use the following “recommended flow diameters” table (table 1). And flow calculations 35 chapter 5: These include the inner diameter. Calculate hydraulic diameter for pipes and ducts. Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. Step 1 determine required flow diameter.

from www.kurthydraulics.com

Use the following “recommended flow diameters” table (table 1). In order to choose the right hydraulic tube, you need to understand their basic specifications. And flow calculations 35 chapter 5: Straight pipe, curved pipe, and. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: Step 1 determine required flow diameter. The table is based on the following. The recommended flow diameter for the required flow rate and type of line can be determined by using. The first step in choosing the correct tube size is to determine required flow diameter.

Flow and Velocity Kurt Hydraulics

Hydraulic Tube Flow Chart The recommended flow diameter for the required flow rate and type of line can be determined by using. And flow calculations 35 chapter 5: These include the inner diameter. Step 1 determine required flow diameter. The recommended flow diameter for the required flow rate and type of line can be determined by using. Use the following “recommended flow diameters” table (table 1). The first step in choosing the correct tube size is to determine required flow diameter. Calculate hydraulic diameter for pipes and ducts. In order to choose the right hydraulic tube, you need to understand their basic specifications. Straight pipe, curved pipe, and. Tubing must meet two requirements: The table is based on the following. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. Piping and pipeline pressure thickness integrity calculations 57 chapter 6:

From automationforum.co

Pitot tube flow velocity calculator Hydraulic Tube Flow Chart Calculate hydraulic diameter for pipes and ducts. The recommended flow diameter for the required flow rate and type of line can be determined by using. The table is based on the following. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. These include the inner diameter. In order to choose the. Hydraulic Tube Flow Chart.

From hydraulichosecrimpers.co.uk

Swage Charts Hydraulic Hose Crimpers Hydraulic Tube Flow Chart The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. The first step in choosing the correct tube size is to determine required flow diameter. These include the inner diameter. Straight pipe, curved pipe, and. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: Tubing must meet two requirements: The recommended. Hydraulic Tube Flow Chart.

From demonstrations.wolfram.com

Measuring Flow Rates with a Pitot Tube Wolfram Demonstrations Project Hydraulic Tube Flow Chart Step 1 determine required flow diameter. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. Calculate hydraulic diameter for pipes and ducts. The recommended flow diameter for the required flow rate and type of line can be determined by using. The. Hydraulic Tube Flow Chart.

From www.air-way.com

Steel Tubing Pressure Ratings AirWay Manufacturing Hydraulic Tube Flow Chart Use the following “recommended flow diameters” table (table 1). The recommended flow diameter for the required flow rate and type of line can be determined by using. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. And flow calculations 35 chapter 5: In order to choose the right hydraulic tube, you. Hydraulic Tube Flow Chart.

From books.gw-project.org

2.3 Components of Hydraulic Head Conceptual and Visual Understanding Hydraulic Tube Flow Chart The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. In order to choose the right hydraulic tube, you need to understand their basic specifications. The first step in choosing the correct tube size is to determine required flow diameter. These include the inner diameter. Calculate hydraulic diameter for pipes and ducts.. Hydraulic Tube Flow Chart.

From www.myxxgirl.com

Hydraulic Tubing Size Chart My XXX Hot Girl Hydraulic Tube Flow Chart And flow calculations 35 chapter 5: The first step in choosing the correct tube size is to determine required flow diameter. Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. These include the inner diameter. Straight pipe, curved pipe, and. Calculate hydraulic diameter for pipes and ducts. The recommended flow. Hydraulic Tube Flow Chart.

From www.eyc-tech.com

Pipe diameter (Round tube) / Flow velocity / Flow volume conversion table Hydraulic Tube Flow Chart These include the inner diameter. Straight pipe, curved pipe, and. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: And flow calculations 35 chapter 5: Use the following “recommended flow diameters” table (table 1). The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. The first step in choosing the correct. Hydraulic Tube Flow Chart.

From joigftjdd.blob.core.windows.net

Hvac Copper Pipe Size Chart Pdf at Darcy Day blog Hydraulic Tube Flow Chart The recommended flow diameter for the required flow rate and type of line can be determined by using. Calculate hydraulic diameter for pipes and ducts. These include the inner diameter. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: The table is based on the following. Use the following “recommended flow diameters” table (table 1). Use tables u13 and. Hydraulic Tube Flow Chart.

From aidanfreeman.z13.web.core.windows.net

Din Hydraulic Fittings Chart Hydraulic Tube Flow Chart The recommended flow diameter for the required flow rate and type of line can be determined by using. The first step in choosing the correct tube size is to determine required flow diameter. Use the following “recommended flow diameters” table (table 1). And flow calculations 35 chapter 5: The table is based on the following. Straight pipe, curved pipe, and.. Hydraulic Tube Flow Chart.

From quoteimg.com

steel pipe size flow chart Quotes Hydraulic Tube Flow Chart The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. The table is based on the following. Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. Use the following “recommended flow diameters” table (table 1). Step 1 determine required flow diameter. Straight. Hydraulic Tube Flow Chart.

From animalia-life.club

Hydraulic Flow Meter Hydraulic Tube Flow Chart Use the following “recommended flow diameters” table (table 1). Step 1 determine required flow diameter. The first step in choosing the correct tube size is to determine required flow diameter. In order to choose the right hydraulic tube, you need to understand their basic specifications. The inside diameter must be large enough to provide the flow area needed to assure. Hydraulic Tube Flow Chart.

From www.scribd.com

Pitot Pressure Flow Chart Pressure Nature Hydraulic Tube Flow Chart Step 1 determine required flow diameter. Straight pipe, curved pipe, and. Tubing must meet two requirements: The recommended flow diameter for the required flow rate and type of line can be determined by using. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. The table is based on the following. The. Hydraulic Tube Flow Chart.

From techblog.ctgclean.com

Reducing Flow vs. Reducing Pressure Which is it? CTG Hydraulic Tube Flow Chart The table is based on the following. In order to choose the right hydraulic tube, you need to understand their basic specifications. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. Straight pipe, curved pipe, and. The recommended flow diameter. Hydraulic Tube Flow Chart.

From mavink.com

Hydraulic Hose Flow Chart Hydraulic Tube Flow Chart Piping and pipeline pressure thickness integrity calculations 57 chapter 6: The recommended flow diameter for the required flow rate and type of line can be determined by using. Use the following “recommended flow diameters” table (table 1). Step 1 determine required flow diameter. Straight pipe, curved pipe, and. In order to choose the right hydraulic tube, you need to understand. Hydraulic Tube Flow Chart.

From www.academia.edu

(PDF) Hydraulic Flow Diagram of 75 m³/hr Effluent Treatment Plant (ETP Hydraulic Tube Flow Chart Use the following “recommended flow diameters” table (table 1). Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. The table is based on the following. And flow calculations 35 chapter 5: These. Hydraulic Tube Flow Chart.

From mavink.com

Hydraulic Tubing Flow Chart Hydraulic Tube Flow Chart Use the following “recommended flow diameters” table (table 1). The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. Calculate hydraulic diameter for pipes and ducts. These include the inner diameter. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: Use tables u13 and u14 to determine recommended flow diameter for. Hydraulic Tube Flow Chart.

From www.kurthydraulics.com

Flow and Velocity Kurt Hydraulics Hydraulic Tube Flow Chart The recommended flow diameter for the required flow rate and type of line can be determined by using. Calculate hydraulic diameter for pipes and ducts. These include the inner diameter. The first step in choosing the correct tube size is to determine required flow diameter. Use the following “recommended flow diameters” table (table 1). In order to choose the right. Hydraulic Tube Flow Chart.

From mavink.com

Hydraulic Hose Flow Chart Hydraulic Tube Flow Chart The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. Tubing must meet two requirements: Straight pipe, curved pipe, and. The recommended flow diameter for the required flow rate and type of line can be determined by using. Use the following “recommended flow diameters” table (table 1). Calculate hydraulic diameter for pipes. Hydraulic Tube Flow Chart.

From www.nipponsteel.com

Manufacturing Process Pipes and Tubes Products Nippon Steel Hydraulic Tube Flow Chart Piping and pipeline pressure thickness integrity calculations 57 chapter 6: Straight pipe, curved pipe, and. These include the inner diameter. Step 1 determine required flow diameter. The first step in choosing the correct tube size is to determine required flow diameter. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. And. Hydraulic Tube Flow Chart.

From imagefreehd.com

Hydraulic Tube Sizes images Hydraulic Tube Flow Chart The first step in choosing the correct tube size is to determine required flow diameter. In order to choose the right hydraulic tube, you need to understand their basic specifications. And flow calculations 35 chapter 5: Tubing must meet two requirements: Piping and pipeline pressure thickness integrity calculations 57 chapter 6: The table is based on the following. Calculate hydraulic. Hydraulic Tube Flow Chart.

From www.pugetsoundhydraulics.com

Puget Sound Hydraulics Tube & Pipe Chart Hydraulic Tube Flow Chart The recommended flow diameter for the required flow rate and type of line can be determined by using. Use the following “recommended flow diameters” table (table 1). These include the inner diameter. The table is based on the following. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. Tubing must meet. Hydraulic Tube Flow Chart.

From tubingchina.com

Cold Finished Stainless Steel Tube Technology Flow Chart Tubing China Hydraulic Tube Flow Chart The first step in choosing the correct tube size is to determine required flow diameter. Step 1 determine required flow diameter. Straight pipe, curved pipe, and. And flow calculations 35 chapter 5: In order to choose the right hydraulic tube, you need to understand their basic specifications. The inside diameter must be large enough to provide the flow area needed. Hydraulic Tube Flow Chart.

From www.hoseandfittings.com

Tube Pressure Chart Hose and Fittings Source Hydraulic Tube Flow Chart Use the following “recommended flow diameters” table (table 1). Calculate hydraulic diameter for pipes and ducts. Step 1 determine required flow diameter. The recommended flow diameter for the required flow rate and type of line can be determined by using. Tubing must meet two requirements: And flow calculations 35 chapter 5: In order to choose the right hydraulic tube, you. Hydraulic Tube Flow Chart.

From www.instpedia.com

Flow Hydraulic Tube Flow Chart In order to choose the right hydraulic tube, you need to understand their basic specifications. The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. Step 1 determine required flow diameter. Straight pipe, curved pipe, and. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: And flow calculations 35 chapter 5:. Hydraulic Tube Flow Chart.

From www.jiayuanfitting.com

BSP hydraulic fittings dimensions Knowledge Yuyao Jiayuan Hydraulic Hydraulic Tube Flow Chart These include the inner diameter. The recommended flow diameter for the required flow rate and type of line can be determined by using. And flow calculations 35 chapter 5: The first step in choosing the correct tube size is to determine required flow diameter. The table is based on the following. Use the following “recommended flow diameters” table (table 1).. Hydraulic Tube Flow Chart.

From www.titanfittings.com

Stainless Steel Tube Pressure Rating Charts Titan Fittings Hydraulic Tube Flow Chart Tubing must meet two requirements: Straight pipe, curved pipe, and. And flow calculations 35 chapter 5: Piping and pipeline pressure thickness integrity calculations 57 chapter 6: These include the inner diameter. Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. The recommended flow diameter for the required flow rate and. Hydraulic Tube Flow Chart.

From elchoroukhost.net

Pipe Dimensions Table Excel Elcho Table Hydraulic Tube Flow Chart The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. These include the inner diameter. And flow calculations 35 chapter 5: The table is based on the following. The first step in choosing the correct tube size is to determine required flow diameter. Piping and pipeline pressure thickness integrity calculations 57 chapter. Hydraulic Tube Flow Chart.

From inksterspartoftherock.blogspot.com

21 Best Pipe Flow Chart Gpm Hydraulic Tube Flow Chart Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. The first step in choosing the correct tube size is to determine required flow diameter. And flow calculations 35 chapter 5: Use the following “recommended flow diameters” table (table 1). In order to choose the right hydraulic tube, you need to. Hydraulic Tube Flow Chart.

From www.engineeringtoolbox.com

Pitot Tubes Hydraulic Tube Flow Chart Use the following “recommended flow diameters” table (table 1). Tubing must meet two requirements: Piping and pipeline pressure thickness integrity calculations 57 chapter 6: The table is based on the following. These include the inner diameter. Calculate hydraulic diameter for pipes and ducts. And flow calculations 35 chapter 5: Step 1 determine required flow diameter. In order to choose the. Hydraulic Tube Flow Chart.

From successimg.com

hydraulic fittings thread sizes chart Success Hydraulic Tube Flow Chart The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. The table is based on the following. Step 1 determine required flow diameter. The recommended flow diameter for the required flow rate and type of line can be determined by using. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: And. Hydraulic Tube Flow Chart.

From www.gridgit.com

6 Best Images of Hydraulic Fitting Size Chart Parker Hydraulic Hydraulic Tube Flow Chart Tubing must meet two requirements: The recommended flow diameter for the required flow rate and type of line can be determined by using. In order to choose the right hydraulic tube, you need to understand their basic specifications. These include the inner diameter. Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type. Hydraulic Tube Flow Chart.

From energy-models.com

Pipe Sizing Charts Tables Hydraulic Tube Flow Chart In order to choose the right hydraulic tube, you need to understand their basic specifications. Use the following “recommended flow diameters” table (table 1). Calculate hydraulic diameter for pipes and ducts. Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. The table is based on the following. Tubing must meet. Hydraulic Tube Flow Chart.

From www.jetech.com

FlowOrifice Charts Jetech International LLC Hydraulic Tube Flow Chart Use tables u13 and u14 to determine recommended flow diameter for the required flow rate and type of line. Step 1 determine required flow diameter. Piping and pipeline pressure thickness integrity calculations 57 chapter 6: The inside diameter must be large enough to provide the flow area needed to assure that fluid velocity. In order to choose the right hydraulic. Hydraulic Tube Flow Chart.

From www.fascinatewithzea.com

Calculate Flow Rate Of Garden Hose Fasci Garden Hydraulic Tube Flow Chart Tubing must meet two requirements: Calculate hydraulic diameter for pipes and ducts. The first step in choosing the correct tube size is to determine required flow diameter. The recommended flow diameter for the required flow rate and type of line can be determined by using. The inside diameter must be large enough to provide the flow area needed to assure. Hydraulic Tube Flow Chart.

From maryrosemurrell.blogspot.com

metric hydraulic fittings near me Maryrose Murrell Hydraulic Tube Flow Chart Straight pipe, curved pipe, and. Use the following “recommended flow diameters” table (table 1). And flow calculations 35 chapter 5: These include the inner diameter. The first step in choosing the correct tube size is to determine required flow diameter. Tubing must meet two requirements: Piping and pipeline pressure thickness integrity calculations 57 chapter 6: Calculate hydraulic diameter for pipes. Hydraulic Tube Flow Chart.