Rockwell Hardness R . 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. Both methods measure the resistance of the plastic toward. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. The rockwell test measures the depth of. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load.

from ktcasting.com

Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. Both methods measure the resistance of the plastic toward. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The rockwell test measures the depth of. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material.

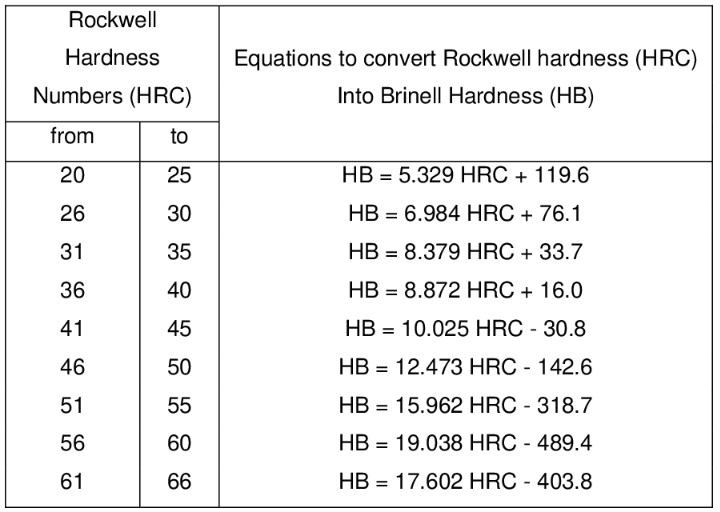

Conversion of Rockwell Hardness to Brinell Hardness Everything You

Rockwell Hardness R The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell test measures the depth of. Both methods measure the resistance of the plastic toward. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load.

From www.gordonengland.co.uk

Hardness Scale Conversion Chart for Hard Materials Rockwell Hardness R The rockwell test measures the depth of. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Both methods measure the resistance of the plastic toward. Rockwell hardness testing is a useful and efficient way. Rockwell Hardness R.

From www.auto-met.com

Rockwell Hardness Scale Indentor Load Chart Rockwell Hardness R 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The rockwell hardness of the test piece. Rockwell Hardness R.

From www.hardnessgauge.com

What is the Rockwell Scale? Hardness Tester Rockwell Hardness R 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. Both methods measure the resistance of the plastic toward. Rockwell hardness refers to a method of measuring the hardness of materials, particularly. Rockwell Hardness R.

From www.scribd.com

Dial type Manual Rockwell hardness testing machine (tester) R150M Rockwell Hardness R Both methods measure the resistance of the plastic toward. The rockwell test measures the depth of. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. 21 rows the rockwell scale is a. Rockwell Hardness R.

From www.jewelry-secrets.com

ROCKWELL SCALE VS THE MOH’S SCALE Jewelry Secrets Rockwell Hardness R The rockwell test measures the depth of. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness. Rockwell Hardness R.

From ktcasting.com

Conversion of Rockwell Hardness to Brinell Hardness Everything You Rockwell Hardness R 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Both methods measure the resistance of the plastic toward. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The rockwell test measures the depth of. Rockwell hardness testing is a useful and efficient way. Rockwell Hardness R.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell Hardness R The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. The rockwell hardness of the test piece is calculated by subtracting the second load from the first. Rockwell Hardness R.

From materiallibbeckenbauer.z19.web.core.windows.net

Rockwell R Hardness Conversion Chart Rockwell Hardness R Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. Both methods measure the resistance of the plastic toward. The hardness testing of plastics is most often. Rockwell Hardness R.

From ar.inspiredpencil.com

Rockwell Hardness Chart Rockwell Hardness R The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. It. Rockwell Hardness R.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained Rockwell Hardness R Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Rockwell hardness testing is a useful and efficient way to determine the hardness of a. Rockwell Hardness R.

From www.marlbo.net

Analog Rockwell Hardness Tester Marlbo Trading Company Rockwell Hardness R Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell test measures the depth. Rockwell Hardness R.

From pdfslide.net

BrinellRockwell Hardness Chart JP CHART Visit us at http/ Brinell Rockwell Hardness R It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the. Rockwell Hardness R.

From metallography-matters.buehler.com

Material Thickness When Choosing a Rockwell Scale Metallography Matters Rockwell Hardness R The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. Both methods measure the resistance of the plastic toward. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. It measures the depth of penetration of an indenter on the material being. Rockwell Hardness R.

From www.youtube.com

ROCKWELL HARDNESS TEST HOW TO PERFORM ROCKWELL HARDNESS TEST Rockwell Hardness R 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Both methods measure the resistance of the plastic toward. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using. Rockwell Hardness R.

From www.researchgate.net

A comparison of Rockwell C hardness with Vickers hardness per ASTM E140 Rockwell Hardness R The rockwell test measures the depth of. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Both methods measure the resistance of the plastic toward. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell hardness of. Rockwell Hardness R.

From amesportablehardnesstesters.com

Hardness Testing in Rockwell Scales Rockwell Hardness R Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness. Rockwell Hardness R.

From www.brystartools.com

Hardness Conversion Chart Rockwell "C" Hardness Range Rockwell Hardness R The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness. Rockwell Hardness R.

From www.yorksaw.com

Rockwell Hardness Guide What it is, How to Measure, & More Rockwell Hardness R It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Both methods measure the resistance of the plastic toward. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The hardness testing of plastics is most often measured by the. Rockwell Hardness R.

From brokeasshome.com

stainless steel hardness table Rockwell Hardness R It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer). Rockwell Hardness R.

From payscalechart.z28.web.core.windows.net

rockwell scale conversion chart Rockwell hardness chart metals brinell Rockwell Hardness R Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. Both. Rockwell Hardness R.

From www.researchgate.net

Rockwell Hardness Test (HRC) by using varying charcoal composition Rockwell Hardness R The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Both methods measure the resistance of the plastic toward. 21 rows the rockwell scale. Rockwell Hardness R.

From tillyclark.z13.web.core.windows.net

Rockwell Hardness Conversion Chart Rockwell Hardness R The rockwell test measures the depth of. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying. Rockwell Hardness R.

From classhirsch.z21.web.core.windows.net

Steel Rockwell Hardness Chart For Metals Rockwell Hardness R Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. Both methods measure the resistance of the plastic toward. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. Rockwell hardness refers to a method of measuring the hardness of materials, particularly. Rockwell Hardness R.

From www.scribd.com

Hardness Conversion Table Approximate Equivalents of Rockwell B Rockwell Hardness R The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. It. Rockwell Hardness R.

From hardnesstester.en.made-in-china.com

Digital Rockwell Hardness Testing Machine R150t Rockwell Hardness Rockwell Hardness R It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. The rockwell hardness of the test piece is calculated by subtracting the second load from. Rockwell Hardness R.

From brokeasshome.com

rockwell hardness table metals Rockwell Hardness R 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. Both methods measure the resistance of. Rockwell Hardness R.

From www.scribd.com

Rockwell Hardness Test Rockwell Hardness R Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. The rockwell test measures the depth of. The hardness testing of plastics is most often. Rockwell Hardness R.

From whatispiping.com

Rockwell Hardness Scale for Hardness Test What Is Piping Rockwell Hardness R Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and. Rockwell Hardness R.

From dokumen.tips

Hardness Conversion Table Hardness Conversion Table Leeb Vickers Rockwell Hardness R Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and. Rockwell Hardness R.

From www.youtube.com

Rockwell Hardness test to find the BHN(Rockwell hardness number) of Rockwell Hardness R Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The rockwell test measures the depth of. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying. Rockwell Hardness R.

From www.freelin-wade.com

Plastic Tubing Durometer Chart Shore A, D, Rockwell R Rockwell Hardness R The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. The rockwell test measures the depth of. Both methods measure the resistance of the plastic toward. 17 rows rockwell. Rockwell Hardness R.

From www.yorksaw.com

Rockwell Hardness Guide What it is, How to Measure, & More Rockwell Hardness R Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load. The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. It measures the depth of penetration of an indenter on the material being tested, making it possible. Rockwell Hardness R.

From mavink.com

Rockwell Hardness Scale Metals Chart Rockwell Hardness R Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. Both methods measure the resistance of the plastic toward. 17 rows rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used. The hardness testing of plastics is most often measured by the rockwell hardness test or shore. Rockwell Hardness R.

From amlinstruments.co.uk

Rockwell Hardness Tester UK MINOR R & MINOR S AML Instruments Rockwell Hardness R The rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the rockwell formula. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. 21 rows the. Rockwell Hardness R.

From www.slideshare.net

Rockwell Hardness Tester by ACMAS Technologies Pvt Ltd. Rockwell Hardness R The hardness testing of plastics is most often measured by the rockwell hardness test or shore (durometer) hardness test. Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. Both methods measure the resistance of the plastic toward. Rockwell hardness refers to a method of measuring the hardness of materials, particularly metals and alloys,. Rockwell Hardness R.