Why Stainless Steel Pitting . Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Chlorine and chloride salts are responsible for metal pitting on stainless steel. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. But, adding oil to a.

from ptspl.com

They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. But, adding oil to a. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. Chlorine and chloride salts are responsible for metal pitting on stainless steel. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal.

Pitting Corrosion Test Professional Testing Services

Why Stainless Steel Pitting But, adding oil to a. When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. But, adding oil to a. Chlorine and chloride salts are responsible for metal pitting on stainless steel. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result.

From orbitkitchen.com

Are Pitted Stainless Steel Pots Safe To Use? Why Stainless Steel Pitting They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little. Why Stainless Steel Pitting.

From www.researchgate.net

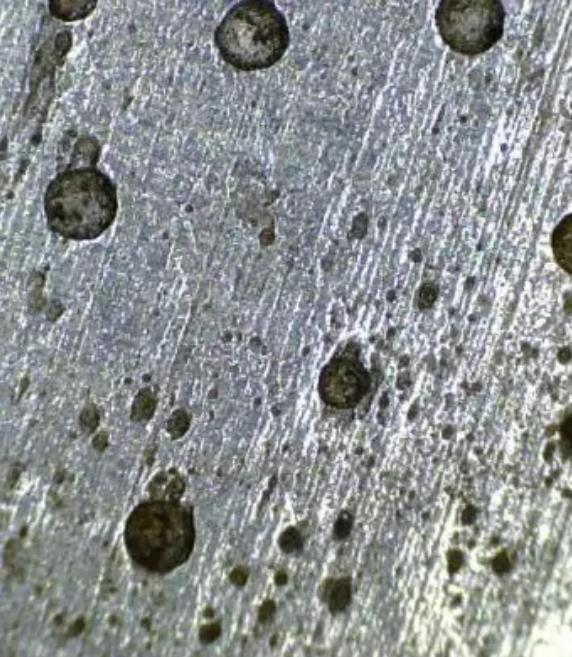

Pitting pattern at TiN sites of stainlesssteel samples exposure to... Download Scientific Diagram Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. But, adding oil to a. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting. Why Stainless Steel Pitting.

From amechieneer.com

Pitting Corrosion Of Stainless Steel The Mechanical Engineer Why Stainless Steel Pitting But, adding oil to a. When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on. Why Stainless Steel Pitting.

From orapiasia.com

Pitting Corrosion An InDepth Analysis ORAPI Asia Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil.. Why Stainless Steel Pitting.

From www.youtube.com

Pitting in stainless steel barrel YouTube Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. But, adding. Why Stainless Steel Pitting.

From ptspl.com

Pitting Corrosion Test Professional Testing Services Why Stainless Steel Pitting When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. They cause a. Why Stainless Steel Pitting.

From www.leigongtech.com

Common Corrosion Of Stainless Steel Pitting Corrosion Knowledge Tianjin Leigong Welding Why Stainless Steel Pitting They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Chlorine and chloride salts are responsible for metal pitting on stainless steel. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Pitting corrosion can be prevented or minimized by choosing. Why Stainless Steel Pitting.

From mungfali.com

Pitting Corrosion In Stainless Steel Why Stainless Steel Pitting Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. But, adding oil to a. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Chlorine and chloride salts are responsible for metal pitting on stainless steel. They cause a breakdown of the passive. Why Stainless Steel Pitting.

From www.researchgate.net

Schematic representation of pitting corrosion of austenitic stainless... Download Scientific Why Stainless Steel Pitting Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. When cooking with a stainless. Why Stainless Steel Pitting.

From www.assemblymag.com

Corrosion of Stainless Steel Test Methods and Proper Expectations 20171001 ASSEMBLY Why Stainless Steel Pitting But, adding oil to a. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. Pitting corrosion. Why Stainless Steel Pitting.

From www.researchgate.net

Schematics of pitting process on vertically positioned 304 stainless... Download Scientific Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Chlorine and. Why Stainless Steel Pitting.

From amechieneer.com

Pitting Corrosion Of Stainless Steel The Mechanical Engineer Why Stainless Steel Pitting Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the. Why Stainless Steel Pitting.

From klafbxnou.blob.core.windows.net

How To Remove Pitted Rust From Stainless Steel at Joey Nero blog Why Stainless Steel Pitting Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. But, adding oil to a. When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it. Why Stainless Steel Pitting.

From www.youtube.com

How to Remove Rust on Stainless Steel East Chem YouTube Why Stainless Steel Pitting They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. But, adding. Why Stainless Steel Pitting.

From www.youtube.com

How To Clean And Restore Pitted Chrome and Stainless Steel YouTube Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Chlorine and. Why Stainless Steel Pitting.

From www.researchgate.net

Visualization of pitting on stainless steel. Scanning electron... Download Scientific Diagram Why Stainless Steel Pitting Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Chlorine and chloride salts are responsible for metal pitting on stainless steel. Pitting on stainless steel pans is caused by the breakdown of the. Why Stainless Steel Pitting.

From blog.belzona.com

How to repair pitting corrosion Why Stainless Steel Pitting Chlorine and chloride salts are responsible for metal pitting on stainless steel. But, adding oil to a. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. When cooking with a stainless. Why Stainless Steel Pitting.

From www.corrosionalliance.com

Pitting of Stainless steel drinking water lines due to microbial influenced corrosion Why Stainless Steel Pitting Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Pitting on. Why Stainless Steel Pitting.

From www.hydrocarbonprocessing.com

Is coating required on stainlesssteel components? Why Stainless Steel Pitting Chlorine and chloride salts are responsible for metal pitting on stainless steel. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Keeping service temperatures below the critical pitting. Why Stainless Steel Pitting.

From www.ddcoatings.co.uk

What is Pitting Corrosion? How to detect and treat pitting corrosion? Why Stainless Steel Pitting Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. But, adding oil to a. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the. Why Stainless Steel Pitting.

From www.researchgate.net

(PDF) Pitting Corrosion Resistance on Annealing Treated Super Duplex Stainless Steel S32750 Why Stainless Steel Pitting But, adding oil to a. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Chlorine and chloride salts are responsible for metal pitting on stainless steel. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. Stainless steel typically shows. Why Stainless Steel Pitting.

From jpt.spe.org

Localized Pitting Corrosion of Superduplex Stainless Steel in a Seawater Application Why Stainless Steel Pitting When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. But, adding. Why Stainless Steel Pitting.

From www.alliagesunifies.com

What is A Pitting Resistance Equivalent Number (PREN)? Unified Alloys Why Stainless Steel Pitting Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. But, adding oil to a. When cooking. Why Stainless Steel Pitting.

From www.snglrtywatch.com

Corrosion Pitting, The Achilles Heel of Stainless Steel Watches Why Stainless Steel Pitting When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. But, adding oil to a. Keeping service temperatures below the critical pitting temperature of the chosen material. Why Stainless Steel Pitting.

From icolorex.htgetrid.com

Pitting how its prevention is manifested Why Stainless Steel Pitting When cooking with a stainless steel pan, it's important to wait until the pan is hot before adding oil. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result.. Why Stainless Steel Pitting.

From blog.inoxmare.com

How to Avoid Pitting Corrosion? Blog Inox mare En Why Stainless Steel Pitting Chlorine and chloride salts are responsible for metal pitting on stainless steel. But, adding oil to a. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. Stainless steel typically shows pitting. Why Stainless Steel Pitting.

From www.alliagesunifies.com

What is A Pitting Resistance Equivalent Number (PREN)? Unified Alloys Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Chlorine and chloride salts are responsible for metal pitting on stainless steel. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. Pitting on stainless steel pans. Why Stainless Steel Pitting.

From mavink.com

Pitting Corrosion Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. They cause a breakdown of the passive. Why Stainless Steel Pitting.

From www.finishing.com

Staining & Pitting of 304/304L Stainless Steel after cleaning Why Stainless Steel Pitting Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface,. Why Stainless Steel Pitting.

From www.iqsdirectory.com

Stainless Steel 316 What Is It? How Is It Made? Grades Why Stainless Steel Pitting Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm.. Why Stainless Steel Pitting.

From blog.thepipingmart.com

Pitted Surface Stainless Steel A Complete Guide Why Stainless Steel Pitting Chlorine and chloride salts are responsible for metal pitting on stainless steel. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. When cooking with a stainless steel pan,. Why Stainless Steel Pitting.

From www.slideserve.com

PPT ChlorideInduced Stress Corrosion Cracking of Austenitic Stainless Steel PowerPoint Why Stainless Steel Pitting They cause a breakdown of the passive chromium oxide layer on the metal, and once the pitting starts, it can spread rapidly. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. But, adding oil to a. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match. Why Stainless Steel Pitting.

From www.hometalk.com

How do I repair a pitted stainless steel table? Hometalk Why Stainless Steel Pitting Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. Chlorine and chloride salts are responsible for metal pitting on stainless steel. Pitting on stainless steel pans is caused by the breakdown of the passive chromium oxide layer on the metal. But, adding oil to a. Pitting on stainless steel pans. Why Stainless Steel Pitting.

From www.researchgate.net

(PDF) Initiation and propagation of stainless steel pitting corrosion under heat flux Why Stainless Steel Pitting Keeping service temperatures below the critical pitting temperature of the chosen material is also an important factor. But, adding oil to a. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Pitting corrosion can be prevented or minimized by choosing materials with high pitting resistance that match the service environment. When cooking. Why Stainless Steel Pitting.

From www.polytops.com

stainlesssteelpittingcorrosion POLYTOPS® Why Stainless Steel Pitting But, adding oil to a. Stainless steel typically shows pitting corrosion in a neutral aqueous solution containing as little as 1 mm. Pitting on stainless steel pans is caused by a breakdown of the chromium oxide layer on the metal's surface, which is usually the result. They cause a breakdown of the passive chromium oxide layer on the metal, and. Why Stainless Steel Pitting.