Injection Machine Hydraulic System . Greater clamp force for large parts. High resistance to wear and tear. A hydraulic system or unit is crucial in plastic injection molding machines. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. This precision is key to ensuring. The system may be running continuously during production cycles. Slides, core pulls, ejection systems, and unscrewing cores. They provide precise control of process variables like pressure, flow, and position. Learn about the importance of hydraulics in injection moulding machines. Hydraulic actuators are used for various injection molding applications such as: A hydraulic system is a key feature in plastics injection molding machines. In injection molding machines, hydraulic systems serve multiple purposes:

from www.tupelohydraulics.com

They provide precise control of process variables like pressure, flow, and position. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. The system may be running continuously during production cycles. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Slides, core pulls, ejection systems, and unscrewing cores. High resistance to wear and tear. A hydraulic system is a key feature in plastics injection molding machines. A hydraulic system or unit is crucial in plastic injection molding machines. Learn about the importance of hydraulics in injection moulding machines. Hydraulic actuators are used for various injection molding applications such as:

Injection molding equipment and repairs offered by Tupelo Hydraulics.

Injection Machine Hydraulic System Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. This precision is key to ensuring. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Greater clamp force for large parts. Hydraulic actuators are used for various injection molding applications such as: Slides, core pulls, ejection systems, and unscrewing cores. A hydraulic system or unit is crucial in plastic injection molding machines. The system may be running continuously during production cycles. High resistance to wear and tear. A hydraulic system is a key feature in plastics injection molding machines. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. In injection molding machines, hydraulic systems serve multiple purposes: They provide precise control of process variables like pressure, flow, and position. Learn about the importance of hydraulics in injection moulding machines.

From www.researchgate.net

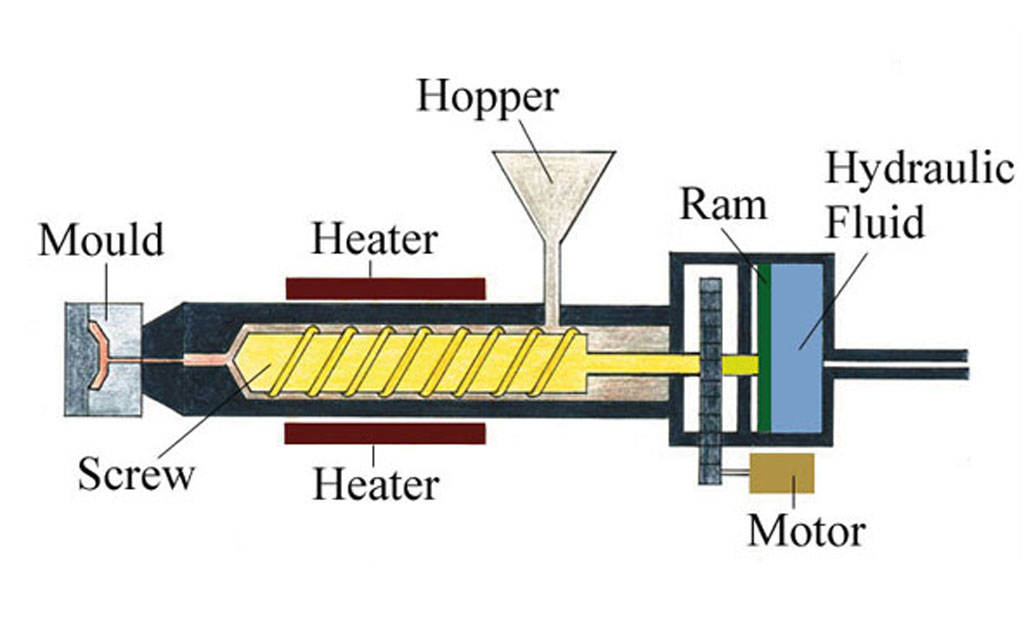

(a) Schematic illustration of the hydraulic injection system. (b Injection Machine Hydraulic System Learn about the importance of hydraulics in injection moulding machines. They provide precise control of process variables like pressure, flow, and position. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. This precision is key to ensuring. A hydraulic system is a key feature in plastics injection molding machines. A hydraulic. Injection Machine Hydraulic System.

From www.researchgate.net

(a) Schematic illustration of the hydraulic injection system. (b Injection Machine Hydraulic System A hydraulic system is a key feature in plastics injection molding machines. High resistance to wear and tear. Slides, core pulls, ejection systems, and unscrewing cores. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. This precision is key to ensuring. Greater clamp force for large parts. They provide precise control of process variables. Injection Machine Hydraulic System.

From tbtpiling.com.my

Hydraulic Injection Piling System TBT Piling (Sabah) Sdn Bhd Injection Machine Hydraulic System Learn about the importance of hydraulics in injection moulding machines. They provide precise control of process variables like pressure, flow, and position. A hydraulic system is a key feature in plastics injection molding machines. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Greater clamp force for large parts. Hydraulic actuators. Injection Machine Hydraulic System.

From www.siliconerubberinjectionmoldingmachine.com

2000 CC Injection Capacity Hydraulic Injection Machine Automotive Injection Machine Hydraulic System In injection molding machines, hydraulic systems serve multiple purposes: In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. A hydraulic system is a key feature in plastics injection molding machines. High resistance to wear and tear. This precision is key to ensuring. Slides, core pulls, ejection systems, and unscrewing cores. Hydraulic. Injection Machine Hydraulic System.

From learnmech.com

Basic Components and its Functions of a Hydraulic System Injection Machine Hydraulic System A hydraulic system is a key feature in plastics injection molding machines. In injection molding machines, hydraulic systems serve multiple purposes: High resistance to wear and tear. Greater clamp force for large parts. A hydraulic system or unit is crucial in plastic injection molding machines. Learn about the importance of hydraulics in injection moulding machines. They provide precise control of. Injection Machine Hydraulic System.

From www.basilius.com

Hydraulics Systems for Injection Molds Basilius Inc. Injection Machine Hydraulic System In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. In injection molding machines, hydraulic systems serve multiple purposes: Slides, core pulls, ejection systems, and unscrewing cores. They provide precise control of process variables like pressure, flow, and position. This precision is key to ensuring. Hydraulic actuators are used for various injection. Injection Machine Hydraulic System.

From www.youtube.com

PNEUMATIC & HYDRAULIC CYLINDER CALCULATION Injection Mould YouTube Injection Machine Hydraulic System Greater clamp force for large parts. In injection molding machines, hydraulic systems serve multiple purposes: A hydraulic system is a key feature in plastics injection molding machines. Slides, core pulls, ejection systems, and unscrewing cores. A hydraulic system or unit is crucial in plastic injection molding machines. The system may be running continuously during production cycles. Learn about the importance. Injection Machine Hydraulic System.

From ec546e2fd4119511.en.made-in-china.com

Efficient Professional Digital Hydraulic System for Injection Molding Injection Machine Hydraulic System This precision is key to ensuring. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. They provide precise control of process variables like pressure, flow, and position. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. A hydraulic system or unit is crucial in plastic. Injection Machine Hydraulic System.

From www.rg-group.com

Using Hydraulics in Injection Moulding Machines RG Group Injection Machine Hydraulic System This precision is key to ensuring. A hydraulic system is a key feature in plastics injection molding machines. The system may be running continuously during production cycles. Learn about the importance of hydraulics in injection moulding machines. Hydraulic actuators are used for various injection molding applications such as: Greater clamp force for large parts. Plastics injection molding machines feature a. Injection Machine Hydraulic System.

From www.rem-b.com

Hydraulic components plastic injection moulding machines REMB HYDRAULICS Injection Machine Hydraulic System A hydraulic system is a key feature in plastics injection molding machines. Hydraulic actuators are used for various injection molding applications such as: The system may be running continuously during production cycles. In injection molding machines, hydraulic systems serve multiple purposes: Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. Greater clamp force for. Injection Machine Hydraulic System.

From www.researchgate.net

Schematic of a typical hydraulic injection moulding machine. Download Injection Machine Hydraulic System Learn about the importance of hydraulics in injection moulding machines. In injection molding machines, hydraulic systems serve multiple purposes: Greater clamp force for large parts. A hydraulic system is a key feature in plastics injection molding machines. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. This precision is key to. Injection Machine Hydraulic System.

From www.google.com

Patent US6280170 Hydraulic control system for an injection molding Injection Machine Hydraulic System Learn about the importance of hydraulics in injection moulding machines. Slides, core pulls, ejection systems, and unscrewing cores. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Greater clamp force for large parts. In injection molding machines, hydraulic systems serve multiple purposes: A hydraulic system is a key feature in plastics. Injection Machine Hydraulic System.

From www.mdpi.com

Applied Sciences Free FullText Injection Molding Process Control Injection Machine Hydraulic System Learn about the importance of hydraulics in injection moulding machines. High resistance to wear and tear. Slides, core pulls, ejection systems, and unscrewing cores. They provide precise control of process variables like pressure, flow, and position. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. A hydraulic system or unit is crucial in plastic. Injection Machine Hydraulic System.

From alphadescaler.com

Injection Moulding & The Plastics Industry Injection Machine Hydraulic System This precision is key to ensuring. In injection molding machines, hydraulic systems serve multiple purposes: The system may be running continuously during production cycles. Slides, core pulls, ejection systems, and unscrewing cores. Learn about the importance of hydraulics in injection moulding machines. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. Greater clamp force. Injection Machine Hydraulic System.

From www.circuitdiagram.co

Hydraulic Circuit Diagram Of Injection Molding Machine Circuit Diagram Injection Machine Hydraulic System The system may be running continuously during production cycles. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. They provide precise control of process variables like pressure, flow, and position. Slides, core pulls, ejection systems, and unscrewing cores. High resistance to wear and tear. A hydraulic system or unit is crucial in plastic injection. Injection Machine Hydraulic System.

From www.mdpi.com

Energies Free FullText A Comprehensive Study of Energy Injection Machine Hydraulic System High resistance to wear and tear. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. The system may be running continuously during production cycles. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. A hydraulic system or unit is crucial in plastic injection molding machines.. Injection Machine Hydraulic System.

From www.allworldmachinery.com

Hydraulics for Injection Molding Machines All World Machinery Injection Machine Hydraulic System They provide precise control of process variables like pressure, flow, and position. A hydraulic system or unit is crucial in plastic injection molding machines. This precision is key to ensuring. The system may be running continuously during production cycles. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. Learn about the importance of hydraulics. Injection Machine Hydraulic System.

From soongiant.en.taiwantrade.com

Hydraulic Clamping Injection Molding Machine, Plastic Processing Injection Machine Hydraulic System Greater clamp force for large parts. Learn about the importance of hydraulics in injection moulding machines. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. A hydraulic system is a key feature in plastics injection molding machines. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through. Injection Machine Hydraulic System.

From www.youtube.com

New Hydraulic Injection Units Animation YouTube Injection Machine Hydraulic System Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. Greater clamp force for large parts. A hydraulic system or unit is crucial in plastic injection molding machines. Learn about the importance of hydraulics in injection moulding machines. Hydraulic actuators are used for various injection molding applications such as: They provide precise control of process. Injection Machine Hydraulic System.

From www.google.com

Patent US6280170 Hydraulic control system for an injection molding Injection Machine Hydraulic System Slides, core pulls, ejection systems, and unscrewing cores. In injection molding machines, hydraulic systems serve multiple purposes: Greater clamp force for large parts. A hydraulic system or unit is crucial in plastic injection molding machines. High resistance to wear and tear. This precision is key to ensuring. They provide precise control of process variables like pressure, flow, and position. In. Injection Machine Hydraulic System.

From www.negribossi.com

Servo Hydraulic Injection Molding Machines Negri Bossi Injection Machine Hydraulic System In injection molding machines, hydraulic systems serve multiple purposes: High resistance to wear and tear. Slides, core pulls, ejection systems, and unscrewing cores. A hydraulic system or unit is crucial in plastic injection molding machines. This precision is key to ensuring. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. In this article, we’ll. Injection Machine Hydraulic System.

From www.pinterest.com

High Precision plastic injection molding machine,Powerjet Machinery Injection Machine Hydraulic System A hydraulic system or unit is crucial in plastic injection molding machines. This precision is key to ensuring. Hydraulic actuators are used for various injection molding applications such as: Slides, core pulls, ejection systems, and unscrewing cores. They provide precise control of process variables like pressure, flow, and position. Learn about the importance of hydraulics in injection moulding machines. In. Injection Machine Hydraulic System.

From en.bole-machinery.com

Injection molding machine,plastic injection machine,plastic injection Injection Machine Hydraulic System Learn about the importance of hydraulics in injection moulding machines. Slides, core pulls, ejection systems, and unscrewing cores. Hydraulic actuators are used for various injection molding applications such as: They provide precise control of process variables like pressure, flow, and position. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Plastics. Injection Machine Hydraulic System.

From www.waxinjector.com

Hydraulic Wax injection Machine, Hydraulic Ceramic Injection machine Injection Machine Hydraulic System Learn about the importance of hydraulics in injection moulding machines. This precision is key to ensuring. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. The system may be running continuously during production cycles. In injection molding machines, hydraulic systems serve multiple purposes: A hydraulic system or unit is crucial in plastic injection molding. Injection Machine Hydraulic System.

From www.google.com

Patent US6280170 Hydraulic control system for an injection molding Injection Machine Hydraulic System Slides, core pulls, ejection systems, and unscrewing cores. A hydraulic system is a key feature in plastics injection molding machines. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. The system may be running continuously during production cycles. Hydraulic actuators are used for various injection molding applications such as: Greater clamp force for large. Injection Machine Hydraulic System.

From www.sz-changhong.com

A Guide on plastic injection molding with Hydraulic Machines Injection Machine Hydraulic System Hydraulic actuators are used for various injection molding applications such as: A hydraulic system or unit is crucial in plastic injection molding machines. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. In injection molding machines, hydraulic systems serve multiple purposes: High resistance to wear and tear. They provide precise control. Injection Machine Hydraulic System.

From www.researchgate.net

Hydraulic loop and injection system. Download Scientific Diagram Injection Machine Hydraulic System In injection molding machines, hydraulic systems serve multiple purposes: Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. Greater clamp force for large parts. The system may be running continuously during production cycles. Slides, core pulls, ejection systems, and unscrewing cores. Learn about the importance of hydraulics in injection moulding machines. Hydraulic actuators are. Injection Machine Hydraulic System.

From gioelpozo.blob.core.windows.net

Hydraulic System In Injection Moulding Machine at Garland Milton blog Injection Machine Hydraulic System The system may be running continuously during production cycles. Hydraulic actuators are used for various injection molding applications such as: They provide precise control of process variables like pressure, flow, and position. In injection molding machines, hydraulic systems serve multiple purposes: Slides, core pulls, ejection systems, and unscrewing cores. A hydraulic system is a key feature in plastics injection molding. Injection Machine Hydraulic System.

From www.dakumar.com

How To Maintain Injection Machine Hydraulic SystemDakumar Injection Machine Hydraulic System They provide precise control of process variables like pressure, flow, and position. A hydraulic system is a key feature in plastics injection molding machines. Slides, core pulls, ejection systems, and unscrewing cores. In injection molding machines, hydraulic systems serve multiple purposes: A hydraulic system or unit is crucial in plastic injection molding machines. The system may be running continuously during. Injection Machine Hydraulic System.

From guanxin-machinery.com

Causes and Treatment of Injection Molding Machine Hydraulic Leakage Injection Machine Hydraulic System Greater clamp force for large parts. They provide precise control of process variables like pressure, flow, and position. Hydraulic actuators are used for various injection molding applications such as: High resistance to wear and tear. The system may be running continuously during production cycles. Slides, core pulls, ejection systems, and unscrewing cores. Learn about the importance of hydraulics in injection. Injection Machine Hydraulic System.

From www.google.com

Patent EP0269204B1 Hydraulic system for a toggletype plastic Injection Machine Hydraulic System Greater clamp force for large parts. A hydraulic system is a key feature in plastics injection molding machines. A hydraulic system or unit is crucial in plastic injection molding machines. High resistance to wear and tear. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Hydraulic actuators are used for various. Injection Machine Hydraulic System.

From www.tupelohydraulics.com

Injection molding equipment and repairs offered by Tupelo Hydraulics. Injection Machine Hydraulic System This precision is key to ensuring. High resistance to wear and tear. Slides, core pulls, ejection systems, and unscrewing cores. Plastics injection molding machines feature a hydraulic system that must provide reliable performance through many. A hydraulic system or unit is crucial in plastic injection molding machines. In injection molding machines, hydraulic systems serve multiple purposes: In this article, we’ll. Injection Machine Hydraulic System.

From tbtpiling.com.my

Hydraulic Injection Piling System TBT Piling (Sabah) Sdn Bhd Injection Machine Hydraulic System Greater clamp force for large parts. The system may be running continuously during production cycles. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. A hydraulic system or unit is crucial in plastic injection molding machines. This precision is key to ensuring. A hydraulic system is a key feature in plastics. Injection Machine Hydraulic System.

From you-dent.com

Injection Machine,Hydraulic Injection Machine Hydraulic System In injection molding machines, hydraulic systems serve multiple purposes: Hydraulic actuators are used for various injection molding applications such as: In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. They provide precise control of process variables like pressure, flow, and position. A hydraulic system is a key feature in plastics injection. Injection Machine Hydraulic System.

From alleycho.com

Brief Introduce of Hydraulic System for Injection Molding Machines Injection Machine Hydraulic System This precision is key to ensuring. In this article, we’ll explain each one of those applications and show how we’ve used them at basilius. Slides, core pulls, ejection systems, and unscrewing cores. A hydraulic system or unit is crucial in plastic injection molding machines. In injection molding machines, hydraulic systems serve multiple purposes: High resistance to wear and tear. The. Injection Machine Hydraulic System.