Wire Terminal Crimping Standards . All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. The three key elements in the crimping process are the terminal, the wire, and the tooling. The most specific standard for wire. Terminal for most applications, it is not economically practical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical.

from forum.digikey.com

The three key elements in the crimping process are the terminal, the wire, and the tooling. Terminal for most applications, it is not economically practical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. The most specific standard for wire. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire.

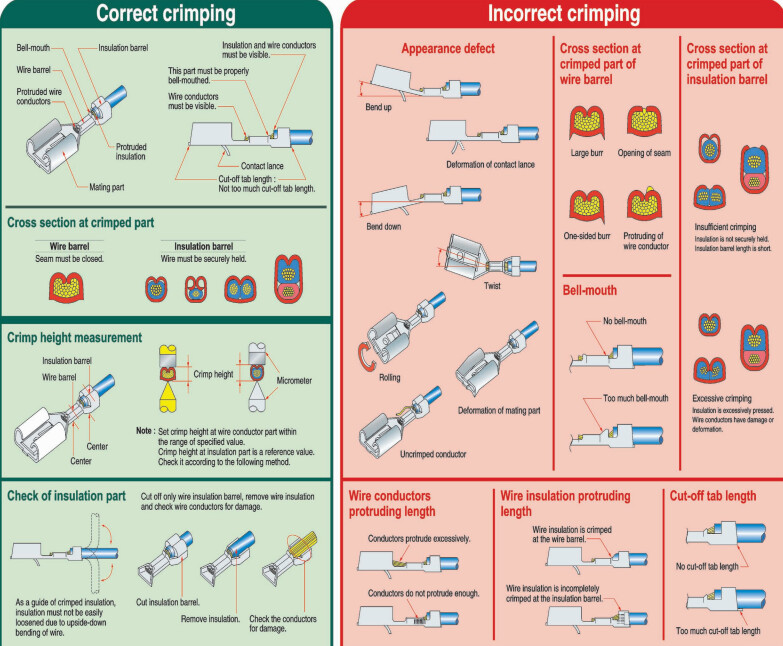

Crimping Identifying Correct Vs. Incorrect Crimps Support

Wire Terminal Crimping Standards Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. The three key elements in the crimping process are the terminal, the wire, and the tooling. The most specific standard for wire. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Terminal for most applications, it is not economically practical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical.

From www.desertcart.ae

Buy TUBTAP Pin Crimping Tool For Spade Bullet Connectors AWG 2216(0.5 Wire Terminal Crimping Standards All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Terminal for most applications, it is not economically practical. The three key elements in the crimping process are the terminal, the wire, and the tooling. Developed to replace the need to solder terminations, crimping technology provides a high quality. Wire Terminal Crimping Standards.

From www.automachines.cn

Pneumatic Terminal Crimping Tool Hexagonal Electric Hydraulic Crimping Wire Terminal Crimping Standards The most specific standard for wire. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Terminal for most applications, it is not economically practical. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. The. Wire Terminal Crimping Standards.

From www.amazon.com

Wire Terminals Crimping Tool, Qibaok Insulated Ratcheting Terminals Wire Terminal Crimping Standards The three key elements in the crimping process are the terminal, the wire, and the tooling. Terminal for most applications, it is not economically practical. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. The most specific standard for wire. Correct selection of wire, terminal and applicator for. Wire Terminal Crimping Standards.

From www.ubuy.co.in

650mm² Large Wire Terminal Crimping Tool Cable Lug Ubuy India Wire Terminal Crimping Standards All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Terminal for most applications, it is not economically practical. The most specific standard for wire. The three key elements in the crimping process are the terminal, the wire, and the tooling. Tool and terminal are carefully engineered to act. Wire Terminal Crimping Standards.

From www.ubuy.co.in

Buy Large Wire Terminal Crimping Tool 650mm² Cable Lug Crimper Cu/Al Wire Terminal Crimping Standards The three key elements in the crimping process are the terminal, the wire, and the tooling. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Terminal for most applications, it is not economically practical. The most specific standard for wire. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g.,. Wire Terminal Crimping Standards.

From hoster.pk

Online Wholesale Shop Fashion shopping style Crimping Tool Insulated Wire Terminal Crimping Standards Terminal for most applications, it is not economically practical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. All crimping needs to comply with the terminal manufacturer’s published requirements,. Wire Terminal Crimping Standards.

From www.homedepot.com

Gardner Bender Terminal and Crimping Tool KitGS67K The Home Depot Wire Terminal Crimping Standards Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Terminal for most applications, it is not economically practical. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. The three key elements in the crimping process are the terminal, the wire,. Wire Terminal Crimping Standards.

From www.ebay.com

Large Wire Terminal Crimping Tool 650mm² Cable Lug Crimper Cu/Al Wire Terminal Crimping Standards All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. The most specific standard for wire. The three key elements in the crimping process are the terminal, the wire, and the tooling.. Wire Terminal Crimping Standards.

From www.ebay.com

Wire Terminals Crimping Tool Interchangeable Jaw Insulated Ratcheting Wire Terminal Crimping Standards Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. The three key elements in the crimping process are the terminal, the wire, and the tooling. Tool and. Wire Terminal Crimping Standards.

From www.ebay.com

Engineer Inc PA20 Precise Universal Wire Terminal Crimping Tool eBay Wire Terminal Crimping Standards Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Terminal for most applications, it is not economically practical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. All crimping needs to comply with the. Wire Terminal Crimping Standards.

From www.amazon.ca

Wirefy Crimping Tool For Insulated Electrical Connectors Ratcheting Wire Terminal Crimping Standards The most specific standard for wire. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always. Wire Terminal Crimping Standards.

From www.aliexpress.com

Multi function Ratchet Type Saving Force Terminal Crimping Pliers Wire Wire Terminal Crimping Standards Terminal for most applications, it is not economically practical. The most specific standard for wire. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. The. Wire Terminal Crimping Standards.

From www.wireharnessetop.com

Crimping standard and defect Wire Terminal Crimping Standards The most specific standard for wire. The three key elements in the crimping process are the terminal, the wire, and the tooling. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Developed to replace the need to solder terminations, crimping technology provides a high quality connection. Wire Terminal Crimping Standards.

From www.amazon.com

Pneumatic Crimping Tool AM10 Pneumatic Air Powered Wire Terminal Wire Terminal Crimping Standards Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Terminal for most applications, it is not economically practical. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. The three key elements in the crimping process are the terminal, the wire,. Wire Terminal Crimping Standards.

From info.waytekwire.com

Wire Crimping Techniques & Tools by Molex® Wire Terminal Crimping Standards All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. The three key elements in the crimping process are the terminal, the wire, and the tooling. Terminal for. Wire Terminal Crimping Standards.

From www.desertcart.ae

Buy Insulated Wire Terminal Crimping Tool Kit, Preciva 0.56mm² Ratchet Wire Terminal Crimping Standards Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. The. Wire Terminal Crimping Standards.

From www.autooi.com

9299393 Terminal Crimping Tool YueQing Auto Electronic Co.,Ltd Wire Terminal Crimping Standards Terminal for most applications, it is not economically practical. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. The most specific standard for wire. All crimping needs to comply. Wire Terminal Crimping Standards.

From www.aliexpress.com

Wire Crimping Tool Terminal Lug Crimper M22520/701 For Wiring Harness Wire Terminal Crimping Standards Terminal for most applications, it is not economically practical. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Developed to replace the need to solder terminations, crimping technology provides. Wire Terminal Crimping Standards.

From www.youtube.com

015 CRIMPING STANDARD AVIATION WIRE TERMINALS USING SIMPLE CRIMPER Wire Terminal Crimping Standards Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. The most specific standard for wire. The three key elements in the crimping process are the. Wire Terminal Crimping Standards.

From www.mecalbystarn.com

Wire Harness Crimping Quality Mecal by Starn Wire Terminal Crimping Standards All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. The three key elements in the crimping process are the terminal, the wire, and the tooling.. Wire Terminal Crimping Standards.

From joiejoqvq.blob.core.windows.net

Electrical Wire Crimp Terminals at Teresa Dietz blog Wire Terminal Crimping Standards Terminal for most applications, it is not economically practical. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Correct selection of wire, terminal and applicator for double wire applications with different. Wire Terminal Crimping Standards.

From localrevive.com

How to crimp wire ferrule with and without ferrule crimping tool Wire Terminal Crimping Standards Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Terminal for most applications, it is not economically practical. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. All crimping needs to comply with the terminal manufacturer’s published requirements,. Wire Terminal Crimping Standards.

From www.pinterest.com

Car audio installation, Crimps, Wire Wire Terminal Crimping Standards The most specific standard for wire. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Terminal for most applications, it is not economically practical. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. All crimping needs to comply with the. Wire Terminal Crimping Standards.

From www.etopwireharness.com

Crimping standard and defect Wire Terminal Crimping Standards Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Terminal for most applications, it is not economically practical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. The most specific standard for wire. Developed to replace the need. Wire Terminal Crimping Standards.

From forum.digikey.com

Crimping Identifying Correct Vs. Incorrect Crimps Support Wire Terminal Crimping Standards Terminal for most applications, it is not economically practical. The three key elements in the crimping process are the terminal, the wire, and the tooling. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. The most specific standard for wire. Tool and terminal are carefully engineered to act. Wire Terminal Crimping Standards.

From www.ubuy.co.in

Wire Terminal Crimping Tool 650mm² Cable Lug Ubuy India Wire Terminal Crimping Standards The most specific standard for wire. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. The three key elements in the crimping process are the. Wire Terminal Crimping Standards.

From a9937b39fc1b22b7.en.made-in-china.com

Factory Supply Discount Price Insulated Wire Connectors Wire Crimp Wire Terminal Crimping Standards Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Correct. Wire Terminal Crimping Standards.

From dxosccrep.blob.core.windows.net

Cable Wire Ends at Craig Smith blog Wire Terminal Crimping Standards The most specific standard for wire. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Correct selection of wire, terminal and applicator for double wire applications with different size wires always. Wire Terminal Crimping Standards.

From dsshgjhmg.blogspot.com

Different Kinds Of Electrical Crimps Do You Use Wire Crimp Beanies Wire Terminal Crimping Standards The most specific standard for wire. All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Correct selection of wire, terminal and applicator for double wire applications with. Wire Terminal Crimping Standards.

From www.amazon.co.uk

Eventronic 1200 Electrical Terminals Crimp Connectors Electrical Crimp Wire Terminal Crimping Standards Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. The most specific standard for wire. The three key elements in the crimping process are the terminal, the wire, and the tooling. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical. Wire Terminal Crimping Standards.

From www.grelly.com

Large Wire Terminal Crimping Tool 650mm² Grelly USA Wire Terminal Crimping Standards Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. The three key elements in the crimping process are the terminal, the wire, and the tooling.. Wire Terminal Crimping Standards.

From www.hitshop.pk

1 MultiFunction Wire Terminal Crimping Tool With Accessories in Wire Terminal Crimping Standards Terminal for most applications, it is not economically practical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. All crimping needs to comply with the terminal manufacturer’s published requirements,. Wire Terminal Crimping Standards.

From www.temu.com

Wire Terminal Crimping Kits ² Clamp Crimping Tool With Four Temu Wire Terminal Crimping Standards Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire. The most specific standard for wire. The three key elements in the crimping process are the terminal, the wire, and the tooling.. Wire Terminal Crimping Standards.

From www.desertcart.in

Buy Wire Terminals Crimper Kit,Dechengbao 2 in 1 CrimpTool Wire Wire Terminal Crimping Standards All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter in. Terminal for most applications, it is not economically practical. Tool and terminal are carefully engineered to. Wire Terminal Crimping Standards.

From joibkcqtb.blob.core.windows.net

Wire Terminal Types at Eden Haskin blog Wire Terminal Crimping Standards All crimping needs to comply with the terminal manufacturer’s published requirements, e.g., crimp height, pull test, etc., without regard to the. Tool and terminal are carefully engineered to act in tandem, creating crimps that optimize electrical and mechanical. Correct selection of wire, terminal and applicator for double wire applications with different size wires always place wire with smallest outer diameter. Wire Terminal Crimping Standards.