Membrane Filter Press Working Principle . working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. the first filter press was made by faure equipements in 1890. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. in the membrane filter press every second plate is equipped with an inflatable membrane. After the end of the filtration. A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. Filter presses are also used in chemical, sugar and brewery industries since a long. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. working principle of a filter press. working process of automatic membrane filter press. how does a membrane filter press work? Filtering procedure is the core process of filter press.

from www.etch2o.com

working process of automatic membrane filter press. After the end of the filtration. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. working principle of a filter press. the first filter press was made by faure equipements in 1890. A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. Filter presses are also used in chemical, sugar and brewery industries since a long. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. Filtering procedure is the core process of filter press.

Membrane Filter Press ETCH2O

Membrane Filter Press Working Principle the first filter press was made by faure equipements in 1890. in the membrane filter press every second plate is equipped with an inflatable membrane. Filter presses are also used in chemical, sugar and brewery industries since a long. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. After the end of the filtration. working process of automatic membrane filter press. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. the first filter press was made by faure equipements in 1890. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. how does a membrane filter press work? Filtering procedure is the core process of filter press. working principle of a filter press. A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. A membrane filter press is fed in the same way as a chamber filter press, however the filling level.

From www.etch2o.com

Membrane Filter Press ETCH2O Membrane Filter Press Working Principle in the membrane filter press every second plate is equipped with an inflatable membrane. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. how does a membrane filter press work? Filtering procedure is the core process of filter press. Filter presses are also used in chemical, sugar. Membrane Filter Press Working Principle.

From www.etch2o.com

Membrane Filter Press ETCH2O Membrane Filter Press Working Principle in the membrane filter press every second plate is equipped with an inflatable membrane. Filtering procedure is the core process of filter press. Filter presses are also used in chemical, sugar and brewery industries since a long. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. During discontinuous cake. Membrane Filter Press Working Principle.

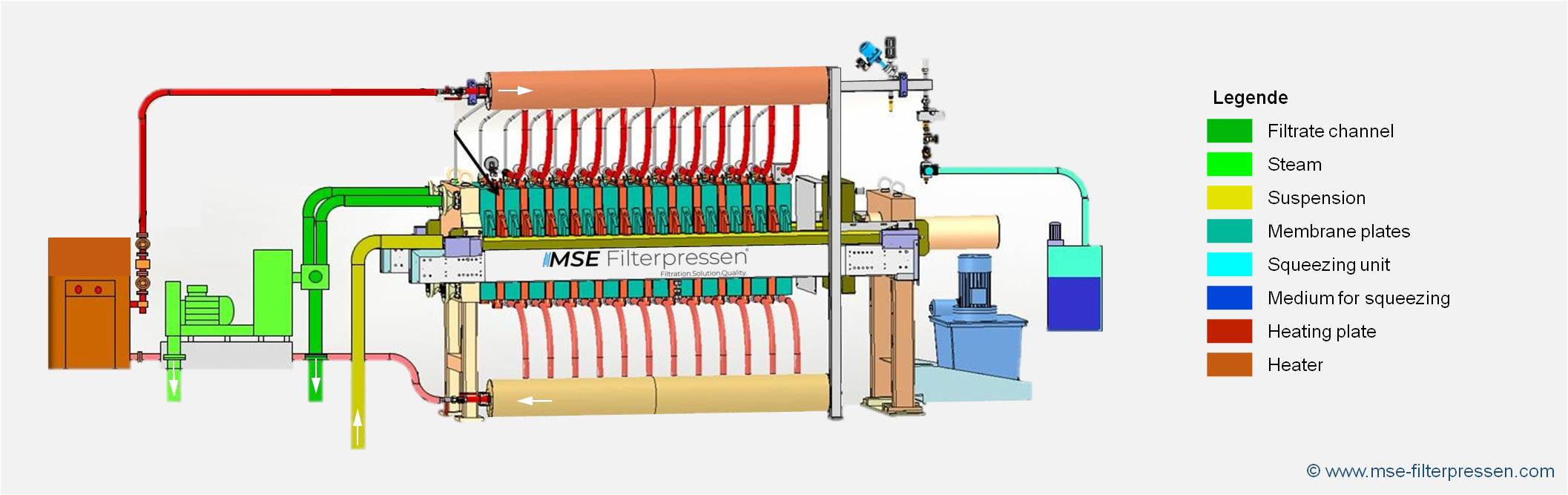

From mse-filterpressen.com

Filter press operation MSE Filterpressen® (filter press manufacturer) Membrane Filter Press Working Principle Filtering procedure is the core process of filter press. the first filter press was made by faure equipements in 1890. how does a membrane filter press work? in the membrane filter press every second plate is equipped with an inflatable membrane. After the end of the filtration. a membrane press is identical to a standard filter. Membrane Filter Press Working Principle.

From metchem.com

New Membrane Filter Press MetChem Membrane Filter Press Working Principle A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. working process of automatic membrane filter press. working principle of membrane filter press the operation of a. Membrane Filter Press Working Principle.

From www.filterpressmachine.com

Membrane Filter Press Plate Largest Filter Press Manufacturer Membrane Filter Press Working Principle After the end of the filtration. working process of automatic membrane filter press. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. in the membrane filter press every second plate is equipped with an inflatable membrane. the first filter press was made by faure. Membrane Filter Press Working Principle.

From www.youtube.com

M.W. Watermark Filter Press 101 How a Filter Press Works YouTube Membrane Filter Press Working Principle a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. working process of automatic membrane filter press. During discontinuous cake filtration with filter presses, the suspension to be. Membrane Filter Press Working Principle.

From eng.pengyusugar.com

PGB AUTOMATIC MEMBRANE FILTER PRESS Penglai Automation Factory Membrane Filter Press Working Principle Filter presses are also used in chemical, sugar and brewery industries since a long. the first filter press was made by faure equipements in 1890. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. working principle of membrane filter press the operation of a membrane. Membrane Filter Press Working Principle.

From mse-filterpressen.com

Membrane filter press MSE Filterpressen® (OEM) Membrane Filter Press Working Principle Filtering procedure is the core process of filter press. how does a membrane filter press work? Filter presses are also used in chemical, sugar and brewery industries since a long. After the end of the filtration. working principle of a filter press. A membrane filter press is fed in the same way as a chamber filter press, however. Membrane Filter Press Working Principle.

From hengdafilterpress.com

PP Membrane Filter Press hengda filter press Membrane Filter Press Working Principle working principle of a filter press. After the end of the filtration. A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. in the membrane filter press every second plate is equipped with an inflatable membrane. the first filter press was made by faure equipements in 1890. . Membrane Filter Press Working Principle.

From www.filterpressmachine.com

Membrane Filter Press Plate Largest Filter Press Manufacturer Membrane Filter Press Working Principle a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. Filtering procedure is the core process of filter press. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. A membrane filter press uses a thin layer of porous material, called a. Membrane Filter Press Working Principle.

From metchem.com

Membrane Filter Press MetChem What is a membrane Filter Press? Membrane Filter Press Working Principle a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. After the end of the filtration. the first filter press was made by faure equipements in 1890. working principle of. Membrane Filter Press Working Principle.

From mse-filterpressen.com

Membrane technology for filter presses MSE Filterpressen® Membrane Filter Press Working Principle After the end of the filtration. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. the first filter press was made by faure equipements in 1890. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. A membrane filter press. Membrane Filter Press Working Principle.

From www.slideserve.com

PPT Membrane Filter Presses PowerPoint Presentation, free download Membrane Filter Press Working Principle working process of automatic membrane filter press. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. the first filter press was made by faure equipements in 1890. how does a membrane filter press work? A membrane filter press uses a thin layer of porous material, called a membrane, to separate. Membrane Filter Press Working Principle.

From www.youtube.com

Filter Press Working Filter Press Operation How Filter Press Works Membrane Filter Press Working Principle working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. how does a membrane filter press work? Filter presses are also used in chemical, sugar and brewery industries since a long. After the end of the filtration. During discontinuous cake filtration with filter presses, the suspension to be filtered. Membrane Filter Press Working Principle.

From leofilterpress.en.made-in-china.com

Diaphragm Filter Press, Diaphragm Membrane Filter Press with Membrane Membrane Filter Press Working Principle A membrane filter press is fed in the same way as a chamber filter press, however the filling level. Filter presses are also used in chemical, sugar and brewery industries since a long. After the end of the filtration. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes. Membrane Filter Press Working Principle.

From penbelicangkeme.blogspot.com

Plate And Frame Filter Press Diagram / Frame Filter Press Qingdao Yimei Membrane Filter Press Working Principle Filtering procedure is the core process of filter press. how does a membrane filter press work? A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. the first filter. Membrane Filter Press Working Principle.

From www.getchemready.com

What is a Filter Press and How Does it Work? ChemREADY Membrane Filter Press Working Principle A membrane filter press is fed in the same way as a chamber filter press, however the filling level. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. Filter presses are also used in chemical, sugar and brewery industries since a long. in the membrane filter press every. Membrane Filter Press Working Principle.

From mse-filterpressen.com

Membrane filter press MSE Filterpressen® (OEM) Membrane Filter Press Working Principle working process of automatic membrane filter press. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. Filtering procedure is the core process of filter press. A membrane filter press uses a thin layer of porous material, called a membrane, to separate liquids and solids. a membrane press is. Membrane Filter Press Working Principle.

From www.youtube.com

How a Filter Press Works Animation YouTube Membrane Filter Press Working Principle Filtering procedure is the core process of filter press. working principle of a filter press. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. the first filter press was made by faure equipements in 1890. A membrane filter press uses a thin layer of porous. Membrane Filter Press Working Principle.

From www.dynnor.com

Automatic Membrane Filter PressDynNor Membrane Filter Press Working Principle Filter presses are also used in chemical, sugar and brewery industries since a long. working process of automatic membrane filter press. in the membrane filter press every second plate is equipped with an inflatable membrane. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. During discontinuous cake filtration. Membrane Filter Press Working Principle.

From www.cem-int.com.au

Filter Press Chemical Plant & Engineering (CPE) Membrane Filter Press Working Principle After the end of the filtration. working principle of a filter press. how does a membrane filter press work? working process of automatic membrane filter press. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. Filter presses are also used in chemical, sugar and brewery industries since a long. A. Membrane Filter Press Working Principle.

From www.filterpress.tech

Leo Filter Press Rubber Membrane Filter Press Working Principle and Membrane Filter Press Working Principle Filter presses are also used in chemical, sugar and brewery industries since a long. in the membrane filter press every second plate is equipped with an inflatable membrane. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. working process of automatic membrane filter press. working principle of. Membrane Filter Press Working Principle.

From www.youtube.com

Operation of Automatic Membrane Filter Press 3D Animated Video YouTube Membrane Filter Press Working Principle After the end of the filtration. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. in the membrane filter press every second plate is equipped with an inflatable membrane. working process of automatic membrane filter press. A membrane filter press uses a thin layer of porous material, called. Membrane Filter Press Working Principle.

From www.filterpress.org

Automatic Membrane Filter Press for Squeeze Filtration Membrane Filter Press Working Principle Filter presses are also used in chemical, sugar and brewery industries since a long. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. how does a membrane filter press work? in the membrane filter press every second plate is equipped with an inflatable membrane. working process of. Membrane Filter Press Working Principle.

From www.leofilter.com

Membrane Filter Press Working PrincipleMembrane Filter Press Operation Membrane Filter Press Working Principle how does a membrane filter press work? in the membrane filter press every second plate is equipped with an inflatable membrane. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. working principle of membrane filter press the operation of a membrane filter press involves a series of. Membrane Filter Press Working Principle.

From dewaterfilterpress.com

Membrane Filter Press Dewater Filter Press Membrane Filter Press Working Principle working principle of a filter press. working process of automatic membrane filter press. how does a membrane filter press work? After the end of the filtration. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. Filter presses are also used in chemical, sugar and brewery industries. Membrane Filter Press Working Principle.

From leofilterpress.en.made-in-china.com

Membrane Filter Press, Membrane Squeezing Automatic Working Membrane Membrane Filter Press Working Principle During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. A membrane filter press is fed in the same way as a chamber filter press, however the filling level. in the membrane filter. Membrane Filter Press Working Principle.

From www.leofilter.com

Membrane Filter Press Working PrincipleMembrane Filter Press Operation Membrane Filter Press Working Principle in the membrane filter press every second plate is equipped with an inflatable membrane. working process of automatic membrane filter press. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes. Membrane Filter Press Working Principle.

From c-cemg.org

Working principle of plate and frame filter press ccemg mechanical blog Membrane Filter Press Working Principle working principle of a filter press. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. the first filter press was made by faure equipements in 1890. in the membrane filter press every second plate is equipped with an inflatable membrane. During discontinuous cake filtration with filter. Membrane Filter Press Working Principle.

From leofilterpress.en.made-in-china.com

Membrane Filter Press, Plate and Frame Chamber Recessed Membrane Filter Membrane Filter Press Working Principle working process of automatic membrane filter press. working principle of a filter press. in the membrane filter press every second plate is equipped with an inflatable membrane. After the end of the filtration. Filter presses are also used in chemical, sugar and brewery industries since a long. working principle of membrane filter press the operation of. Membrane Filter Press Working Principle.

From www.youtube.com

Membrane filter press principle YouTube Membrane Filter Press Working Principle the first filter press was made by faure equipements in 1890. how does a membrane filter press work? a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. working principle of membrane filter press the operation of a membrane filter press involves a series of. Membrane Filter Press Working Principle.

From www.sinofilterpresses.com

Automatic Membrane Filter Press Manufacturers and Factory China Membrane Filter Press Working Principle a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. working process of automatic membrane filter press. in the membrane filter press every second plate is equipped with an inflatable membrane. Filtering procedure is the core process of filter press. A membrane filter press uses a. Membrane Filter Press Working Principle.

From www.leofilter.com

Membrane Filter Press Working PrincipleMembrane Filter Press Operation Membrane Filter Press Working Principle a membrane press is identical to a standard filter press except that the chambers (area between the plates) have membranes to. During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. After the end of the filtration. working principle of membrane filter press the operation of a membrane filter press involves a. Membrane Filter Press Working Principle.

From www.youtube.com

ANDRITZ membrane sidebar filter press with cloth washing device Membrane Filter Press Working Principle how does a membrane filter press work? A membrane filter press is fed in the same way as a chamber filter press, however the filling level. Filtering procedure is the core process of filter press. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. the first filter. Membrane Filter Press Working Principle.

From electricalworkbook.com

What is Plate and Frame Filter? Working Principle, Construction Membrane Filter Press Working Principle During discontinuous cake filtration with filter presses, the suspension to be filtered is pumped and concentrated. how does a membrane filter press work? working process of automatic membrane filter press. working principle of membrane filter press the operation of a membrane filter press involves a series of sequential steps. After the end of the filtration. A membrane. Membrane Filter Press Working Principle.