Manufacturing Process Control Chart . If you’re looking to keep your processes on track, control charts are your best buddy. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. The complete guide for manufacturers. If you're a manufacturer looking to boost efficiency, a. These limits let you know when unusual variability occurs. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Picture them as the hall monitors of the.

from www.slideteam.net

By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. If you’re looking to keep your processes on track, control charts are your best buddy. These limits let you know when unusual variability occurs. The complete guide for manufacturers. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. Picture them as the hall monitors of the. If you're a manufacturer looking to boost efficiency, a. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process.

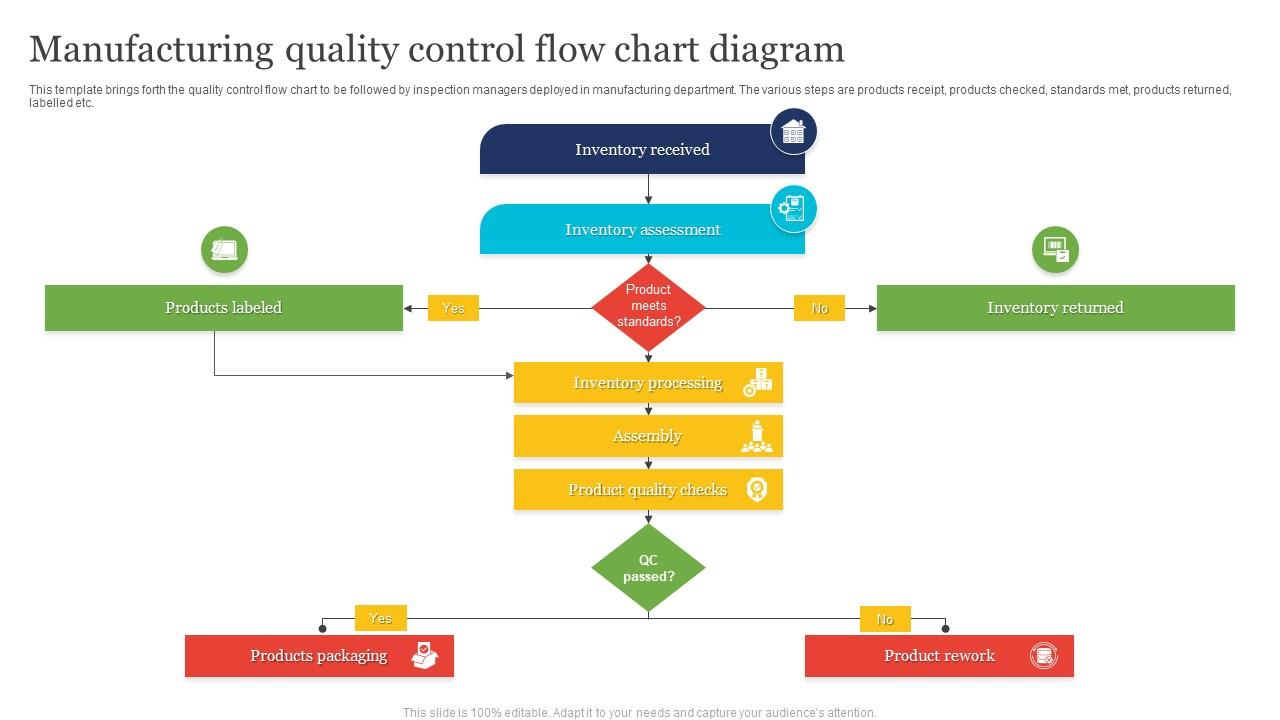

Manufacturing Quality Control Flow Chart Diagram PPT Sample

Manufacturing Process Control Chart Picture them as the hall monitors of the. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. These limits let you know when unusual variability occurs. If you're a manufacturer looking to boost efficiency, a. The complete guide for manufacturers. If you’re looking to keep your processes on track, control charts are your best buddy. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. Picture them as the hall monitors of the. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting.

From www.slideteam.net

Manufacturing Quality Control Flow Chart Diagram PPT Sample Manufacturing Process Control Chart Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. The complete guide for manufacturers. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. A control chart displays process data by time, along with upper. Manufacturing Process Control Chart.

From data1.skinnyms.com

Manufacturing Process Flow Chart Template Manufacturing Process Control Chart If you’re looking to keep your processes on track, control charts are your best buddy. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. The complete guide for manufacturers. These limits let you know when unusual variability occurs. Control charts stand as a pivotal. Manufacturing Process Control Chart.

From boardmix.com

Mastering Manufacturing Flow Charts A StepbyStep Guide Manufacturing Process Control Chart The complete guide for manufacturers. If you're a manufacturer looking to boost efficiency, a. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. By determining whether. Manufacturing Process Control Chart.

From www.researchgate.net

The five levels of process control and optimization in manufacturing Manufacturing Process Control Chart If you’re looking to keep your processes on track, control charts are your best buddy. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. The. Manufacturing Process Control Chart.

From mavink.com

Manufacturing Process Flow Diagram Template Manufacturing Process Control Chart If you’re looking to keep your processes on track, control charts are your best buddy. Picture them as the hall monitors of the. These limits let you know when unusual variability occurs. The complete guide for manufacturers. If you're a manufacturer looking to boost efficiency, a. Control charts are essential tools in the six sigma methodology, visually representing process performance. Manufacturing Process Control Chart.

From leanmanufacturing.online

Control Charts Enhancing Your Business Performance Manufacturing Process Control Chart A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. If you're a manufacturer looking to boost efficiency, a. The complete guide for manufacturers. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. If you’re looking. Manufacturing Process Control Chart.

From www.slideteam.net

Quality Control Process Flowchart For Manufacturing Company PPT Example Manufacturing Process Control Chart Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. The complete guide for manufacturers. These limits let you know when unusual variability occurs. If you're a manufacturer looking to boost efficiency, a. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select. Manufacturing Process Control Chart.

From www.template.net

FREE Quality Control Flowcharts Templates Download in Word, Google Manufacturing Process Control Chart If you're a manufacturer looking to boost efficiency, a. These limits let you know when unusual variability occurs. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and. Manufacturing Process Control Chart.

From technologystudent.com

Template Manufacturing Process Control Chart If you're a manufacturer looking to boost efficiency, a. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. These limits let you know when unusual variability occurs. The complete guide for manufacturers. Picture them as the hall monitors of the. If you’re looking to keep your processes on. Manufacturing Process Control Chart.

From works4space.blogspot.com

Works 4 Space Manufacturing Process/Flow Chart of Concrete Batching Plant Manufacturing Process Control Chart A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. If you’re looking to keep your processes on track, control charts are your best. Manufacturing Process Control Chart.

From flowchart.artourney.com

Quality Process Flow Chart Tqm Diagram — Professional Total Quality Manufacturing Process Control Chart A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. If you're a manufacturer looking to boost efficiency, a. The complete guide for manufacturers. These limits let you know when unusual variability occurs. Picture them as the hall monitors of the. Control charts are essential. Manufacturing Process Control Chart.

From www.edrawsoft.com

Understanding Manufacturing Process Flowcharts (With Examples) Manufacturing Process Control Chart Picture them as the hall monitors of the. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. The complete guide for manufacturers. A control chart displays process data. Manufacturing Process Control Chart.

From www.sampletemplatess.com

Process Control Chart Template SampleTemplatess SampleTemplatess Manufacturing Process Control Chart Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. If you're a manufacturer looking to boost efficiency, a. The complete guide for manufacturers. Picture them as the hall monitors of the. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help. Manufacturing Process Control Chart.

From mavink.com

Manufacturing Process Control Manufacturing Process Control Chart Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. The complete guide for manufacturers. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. A control chart displays process data by time, along with upper and lower control. Manufacturing Process Control Chart.

From courses.lumenlearning.com

The Control Process Principles of Management Manufacturing Process Control Chart Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. Picture them as the hall monitors of the. Control charts are essential tools in the six. Manufacturing Process Control Chart.

From www.projectmanager.com

How to Make a Production Flow Chart for Manufacturing (with Example) Manufacturing Process Control Chart A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. If you're a manufacturer looking to boost efficiency, a. If you’re looking to keep your processes on. Manufacturing Process Control Chart.

From manishflexipack.com

Manufacturing Process Manish Flexipack Pvt. Ltd. Manufacturing Process Control Chart If you're a manufacturer looking to boost efficiency, a. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. The complete guide for manufacturers. These limits let you know when unusual variability occurs. If you’re looking to keep your processes on track, control charts are your best buddy. Control. Manufacturing Process Control Chart.

From www.edrawsoft.com

Understanding Manufacturing Process Flowcharts (With Examples) Manufacturing Process Control Chart By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. These limits let you know when unusual variability occurs. Control charts are essential tools in the. Manufacturing Process Control Chart.

From blog.kainexus.com

An Introduction to Process Behavior Charts Manufacturing Process Control Chart The complete guide for manufacturers. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. If you're a manufacturer looking to boost efficiency, a. These limits let you know when unusual variability occurs. Picture them as the hall monitors of the. Control charts are essential. Manufacturing Process Control Chart.

From www.templateegg.com

Manufacturing Process Flow Chart PDF Manufacturing Process Control Chart The complete guide for manufacturers. Picture them as the hall monitors of the. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. If. Manufacturing Process Control Chart.

From www.pinterest.com

Pin on Examples Chart and Graph Templates Manufacturing Process Control Chart Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. If you're a manufacturer looking to boost efficiency, a. These limits let you know when unusual variability occurs. Picture them as the hall monitors of the. A control chart displays process data by time, along with upper and lower control limits that. Manufacturing Process Control Chart.

From robhosking.com

12+ Flow Chart Manufacturing Process Robhosking Diagram Manufacturing Process Control Chart Picture them as the hall monitors of the. The complete guide for manufacturers. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. If you’re looking to keep your. Manufacturing Process Control Chart.

From www.conceptdraw.com

ValueStream Mapping for Manufacturing Picture Graphs Lean Manufacturing Process Control Chart A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. These limits let you know when unusual variability occurs. Control charts are. Manufacturing Process Control Chart.

From mungfali.com

Statistical Process Control Charts Manufacturing Process Control Chart Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. These limits let you know when unusual variability occurs. The complete guide for manufacturers. Picture them as the hall monitors of the. If you're a manufacturer looking to boost efficiency, a. If you’re looking to keep your processes on track, control charts. Manufacturing Process Control Chart.

From www.slideteam.net

Process Flow Chart In Manufacturing Company PPT PowerPoint Manufacturing Process Control Chart If you're a manufacturer looking to boost efficiency, a. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. The complete guide for manufacturers. Picture them as the hall monitors of the. A control chart displays process data by time, along with upper and lower control limits that delineate. Manufacturing Process Control Chart.

From mavink.com

Ncmr Process Flow Chart Manufacturing Process Control Chart If you're a manufacturer looking to boost efficiency, a. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. If you’re looking to keep your processes on track, control charts are your best buddy. Control charts are essential tools in the six sigma methodology, visually representing process performance over. Manufacturing Process Control Chart.

From mungfali.com

Manufacturing Process Flow Chart Analysis Manufacturing Process Control Chart Picture them as the hall monitors of the. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. If you’re looking to keep your processes on track, control charts are your best buddy. If you're a manufacturer looking to boost efficiency, a. These limits let you know. Manufacturing Process Control Chart.

From www.slideserve.com

PPT Statistical Process Control PowerPoint Presentation, free Manufacturing Process Control Chart These limits let you know when unusual variability occurs. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. If you're a manufacturer looking to boost efficiency, a. Control charts stand. Manufacturing Process Control Chart.

From mavink.com

Manufacturing Process Control Manufacturing Process Control Chart By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. A control chart displays process data by time, along with upper and lower control limits that. Manufacturing Process Control Chart.

From mungfali.com

Manufacturing Process Flow Chart Analysis Manufacturing Process Control Chart A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma. Manufacturing Process Control Chart.

From www.slideteam.net

Process Flow Chart For Manufacturing Company Powerpoint Ppt Template Manufacturing Process Control Chart These limits let you know when unusual variability occurs. The complete guide for manufacturers. If you’re looking to keep your processes on track, control charts are your best buddy. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. Picture them as the hall monitors of the. A control chart displays process. Manufacturing Process Control Chart.

From www.presentationeze.com

Manufacturing Process Flow Chart PresentationEZE Manufacturing Process Control Chart If you're a manufacturer looking to boost efficiency, a. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. The complete guide for manufacturers. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. Picture them as the hall monitors of. Manufacturing Process Control Chart.

From techqualitypedia.com

Process flow chart in manufacturing Symbols for process flow chart Manufacturing Process Control Chart If you’re looking to keep your processes on track, control charts are your best buddy. The complete guide for manufacturers. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select appropriate improvement. Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. A. Manufacturing Process Control Chart.

From www.allbusinesstemplates.com

Manufacturing Process Flow Chart Templates at Manufacturing Process Control Chart Control charts are essential tools in the six sigma methodology, visually representing process performance over time and highlighting. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process. By determining whether the manufacturing process is stable or experiencing assignable causes, control charts help six sigma teams select. Manufacturing Process Control Chart.

From data1.skinnyms.com

Manufacturing Process Flow Chart Template Manufacturing Process Control Chart A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. These limits let you know when unusual variability occurs. If you’re looking to keep your processes on track, control charts are your best buddy. The complete guide for manufacturers. Control charts stand as a pivotal. Manufacturing Process Control Chart.