Roasting Furnace Definition . Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Seslike roasting, smelting, converting and refining require large amount of thermal ener. Similar to a rotary kiln, used for ore processing and other metallurgical operations. Smelting occurs at high temperatures while roasting involves a lower temperature. Smelting and roasting are two methods used in the process of metal extraction. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles

from mavink.com

Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Smelting and roasting are two methods used in the process of metal extraction. Similar to a rotary kiln, used for ore processing and other metallurgical operations. Smelting occurs at high temperatures while roasting involves a lower temperature. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles Seslike roasting, smelting, converting and refining require large amount of thermal ener.

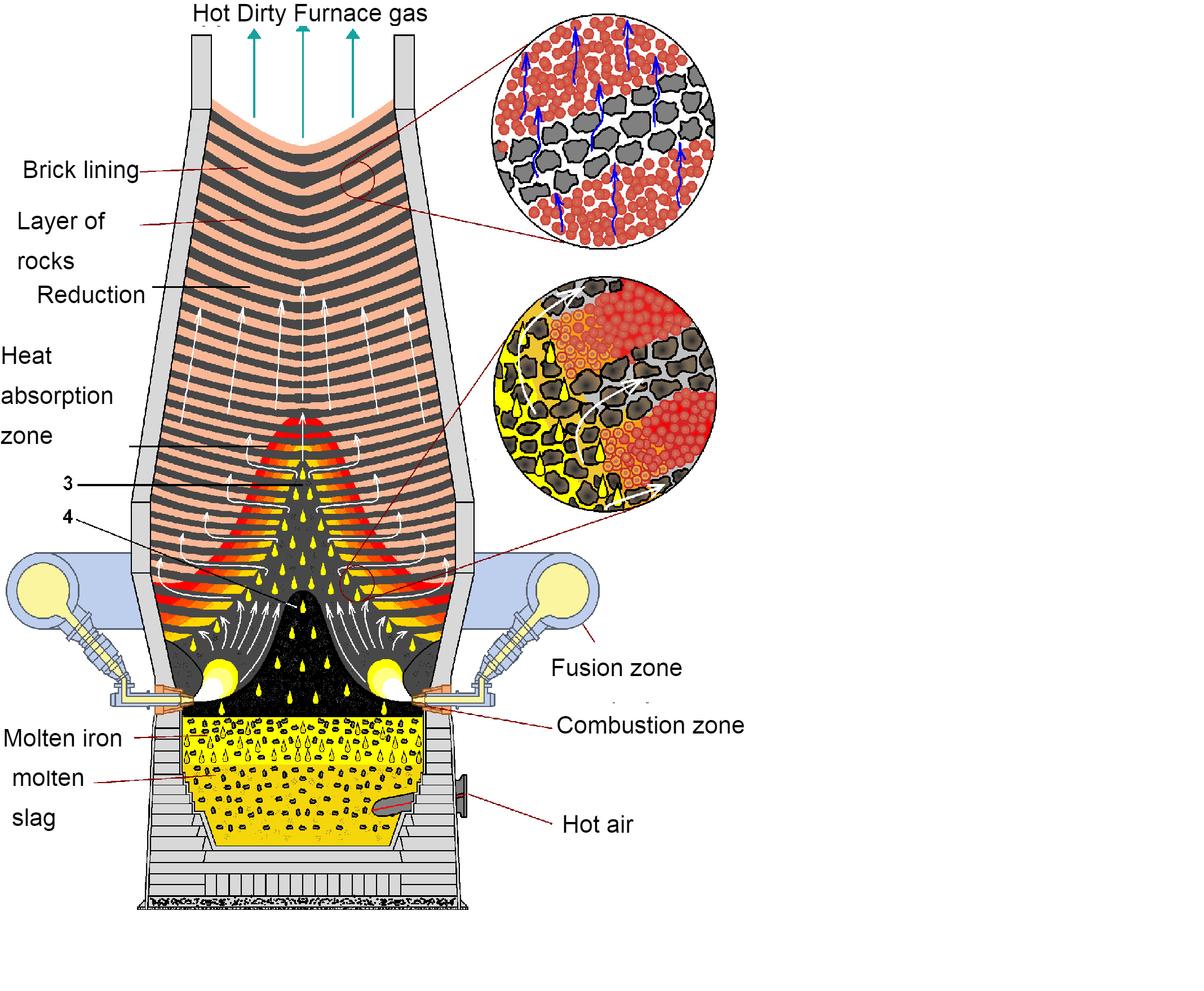

Blast Furnace Schematic

Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Smelting and roasting are two methods used in the process of metal extraction. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Smelting occurs at high temperatures while roasting involves a lower temperature. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles Similar to a rotary kiln, used for ore processing and other metallurgical operations. Seslike roasting, smelting, converting and refining require large amount of thermal ener.

From www.iqsdirectory.com

Furnaces What Is It? How Does It Work? Types, Uses, Fueling Roasting Furnace Definition Smelting occurs at high temperatures while roasting involves a lower temperature. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Seslike roasting, smelting, converting and refining require large amount of thermal ener. A sintered or pelletized feed consisting of coke (for fuel),. Roasting Furnace Definition.

From www.alamy.com

Faber du Faur Roasting retort furnace Stock Photo Alamy Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Smelting and roasting are two methods used in the process of metal extraction. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to. Roasting Furnace Definition.

From hengjumachine.en.made-in-china.com

Activated Carbon Furnace for Roasting and Activation of External Roasting Furnace Definition Similar to a rotary kiln, used for ore processing and other metallurgical operations. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Smelting occurs at high temperatures while roasting involves a lower temperature. Therefore, the main difference between roasting and calcination is that roasting involves the heating. Roasting Furnace Definition.

From www.911metallurgist.com

Roasting Furnace Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. Smelting occurs at high temperatures while roasting involves a lower temperature. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Similar to a rotary kiln, used for ore processing. Roasting Furnace Definition.

From www.heatwhiz.com

Short Explanation on How Does a Furnace Work Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. Similar to a rotary kiln, used for ore processing and other metallurgical operations. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. A sintered or pelletized feed consisting of coke (for fuel), limestone (as. Roasting Furnace Definition.

From www.researchgate.net

Process and material flows diagram of shaft furnace roasting process Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Seslike roasting, smelting, converting and refining require large amount of thermal. Roasting Furnace Definition.

From www.advancedhvac.ca

The Benefits of a HighEfficiency Furnace Advanced HVAC Roasting Furnace Definition Similar to a rotary kiln, used for ore processing and other metallurgical operations. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles The equipment used in. Roasting Furnace Definition.

From www.slideshare.net

Tutorial on roasting furnaces final Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or. Roasting Furnace Definition.

From stock.adobe.com

Roasting furnace. Industrial process of production of cement clinker or Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. Smelting occurs at high temperatures while roasting involves a lower temperature. Similar to a rotary kiln, used for ore processing and other metallurgical operations. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into. Roasting Furnace Definition.

From www.britannica.com

Copper processing Roasting, Smelting, Converting Britannica Roasting Furnace Definition The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air. Roasting Furnace Definition.

From www.youtube.com

Reverberatory furnace calcination, Roasting, Reduction carbon reduction Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Similar to a rotary kiln, used for ore processing and other metallurgical operations. A sintered or pelletized feed consisting of coke (for fuel), limestone (as. Roasting Furnace Definition.

From pixels.com

COPPER REFINING FURNACE AND ROASTING FURNACE l1 Photograph by Historic Roasting Furnace Definition Similar to a rotary kiln, used for ore processing and other metallurgical operations. Seslike roasting, smelting, converting and refining require large amount of thermal ener. Smelting occurs at high temperatures while roasting involves a lower temperature. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the. Roasting Furnace Definition.

From www.dreamstime.com

Vintage Diagram of a Merton Reverberatory Roasting Furnace Editorial Roasting Furnace Definition A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid. Roasting Furnace Definition.

From fractory.com

Annealing Explained Definition, Process and Benefits Fractory Roasting Furnace Definition A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in. Roasting Furnace Definition.

From www.shutterstock.com

2,430 Roasting Furnace Images, Stock Photos & Vectors Shutterstock Roasting Furnace Definition Smelting occurs at high temperatures while roasting involves a lower temperature. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Similar to a rotary kiln, used for ore processing and other metallurgical operations. The equipment used in the roasting process can be. Roasting Furnace Definition.

From enon-casting.en.made-in-china.com

Precision Casting Sodium Silicate Mold Shell Roasting Furnace China Roasting Furnace Definition A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in. Roasting Furnace Definition.

From www.alamy.com

Roasting copper furnace Black and White Stock Photos & Images Alamy Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. Seslike roasting, smelting, converting and refining require large amount of thermal ener. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. A sintered or pelletized feed consisting of coke. Roasting Furnace Definition.

From enon-casting.en.made-in-china.com

Burning Shell Mold Roasting Furnace Industry Furnace (single door Roasting Furnace Definition The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Seslike roasting, smelting, converting and refining require large amount of thermal ener. Similar to a rotary kiln, used for ore processing and other metallurgical operations. Smelting occurs at high temperatures while roasting involves a lower temperature. Smelting and. Roasting Furnace Definition.

From exotulqfy.blob.core.windows.net

Furnace Definition Chemistry at William Dunklin blog Roasting Furnace Definition Smelting occurs at high temperatures while roasting involves a lower temperature. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Similar to a rotary kiln, used for ore processing and other metallurgical operations. A sintered or pelletized feed consisting of coke (for. Roasting Furnace Definition.

From www.youtube.com

Calcination Roasting and blast furnace and ellingham diagram YouTube Roasting Furnace Definition Similar to a rotary kiln, used for ore processing and other metallurgical operations. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Smelting occurs at high temperatures while roasting involves a lower temperature. A sintered or pelletized feed consisting of coke (for. Roasting Furnace Definition.

From www.directindustry.com

Heat treatment furnace FP11001200P SOLO Swiss & BOREL Swiss Roasting Furnace Definition Seslike roasting, smelting, converting and refining require large amount of thermal ener. Smelting occurs at high temperatures while roasting involves a lower temperature. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. The equipment used in the roasting process can be divided. Roasting Furnace Definition.

From mavink.com

Blast Furnace Schematic Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or. Roasting Furnace Definition.

From www.javatpoint.com

Difference Between Calcination and Roasting javatpoint Roasting Furnace Definition A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles Similar to a rotary kiln, used for ore processing and other metallurgical operations. The equipment used in. Roasting Furnace Definition.

From www.youtube.com

Reverberatory furnace సులభంగా పఠం గీసే విధానం YouTube Roasting Furnace Definition Similar to a rotary kiln, used for ore processing and other metallurgical operations. Seslike roasting, smelting, converting and refining require large amount of thermal ener. Smelting occurs at high temperatures while roasting involves a lower temperature. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Therefore, the. Roasting Furnace Definition.

From www.alamy.com

Interior blast furnace hires stock photography and images Alamy Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Smelting and roasting are two methods used in the process of metal extraction. Smelting occurs at high temperatures while roasting involves a lower temperature. Seslike roasting, smelting, converting and refining require large amount. Roasting Furnace Definition.

From www.dreamstime.com

Rotating Furnace for Limestone Roasting at Industrial Plant Stock Photo Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Smelting occurs at high temperatures while roasting involves a lower temperature. Similar to a rotary kiln, used for ore processing and other metallurgical operations. Seslike roasting, smelting, converting and refining require large amount. Roasting Furnace Definition.

From www.911metallurgist.com

Retort Furnace, Retorting Pot & Condensing Pipe Roasting Furnace Definition A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top of the furnace through a double bell or rotating chute, and heated air is blown in through nozzles Smelting and roasting are two methods used in the process of metal extraction. Similar to a rotary. Roasting Furnace Definition.

From www.911metallurgist.com

Roasting Furnace Roasting Furnace Definition Similar to a rotary kiln, used for ore processing and other metallurgical operations. Smelting and roasting are two methods used in the process of metal extraction. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. The equipment used in the roasting process. Roasting Furnace Definition.

From www.dreamstime.com

Rotating Furnace for Limestone Roasting at Industrial Plant Stock Photo Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Seslike roasting, smelting, converting and refining require large amount of thermal ener. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is. Roasting Furnace Definition.

From www.britannica.com

Blast furnace Definition, Temperature, Diagrams, & Facts Britannica Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to. Roasting Furnace Definition.

From www.dreamstime.com

Rotating Furnace for Limestone Roasting at Plant in Evening Stock Image Roasting Furnace Definition Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Smelting and roasting are two methods used in the process of metal extraction. Seslike roasting, smelting, converting and refining require large amount of thermal ener. Smelting occurs at high temperatures while roasting involves. Roasting Furnace Definition.

From hxeniujtt.blob.core.windows.net

Duct Furnace Definition at Jerry Burge blog Roasting Furnace Definition Seslike roasting, smelting, converting and refining require large amount of thermal ener. Smelting and roasting are two methods used in the process of metal extraction. Similar to a rotary kiln, used for ore processing and other metallurgical operations. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air. Roasting Furnace Definition.

From exogkvpnj.blob.core.windows.net

Pot Furnace Definition at Ruby Williams blog Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. Therefore, the main difference between roasting and calcination is that roasting involves the heating of ore in the presence of excess air or oxygen whereas calcination involves. Seslike roasting, smelting, converting and refining require large amount of thermal ener. The equipment used in the roasting process can. Roasting Furnace Definition.

From www.dreamstime.com

Part of Giant Rotating Furnace for Limestone Roasting Stock Image Roasting Furnace Definition The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. Similar to a rotary kiln, used for ore processing and other metallurgical operations. Smelting and roasting are two methods used in the process of metal extraction. Therefore, the main difference between roasting and calcination is that roasting involves. Roasting Furnace Definition.

From www.alamy.com

Rotating furnace for limestone roasting at industrial plant Stock Photo Roasting Furnace Definition Smelting and roasting are two methods used in the process of metal extraction. The equipment used in the roasting process can be divided into fixed bed, moving bed, and fluid bed according to the movement. A sintered or pelletized feed consisting of coke (for fuel), limestone (as a flux for slag making), and iron oxide is charged into the top. Roasting Furnace Definition.