Oil Pump Bearing Lube . Oil rings interact with lubricant viscosities. Pumps using oil rings can suffer the following lubrication problems: When it comes to oil, there are also different lubrication methods. In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Slow ring rotation and insufficient lubrication from too high of an. The oil is contained in a sump in the. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Viscosity is by far the most important property of lubricants applied to process pump bearings. There are mainly two oil lubricants:

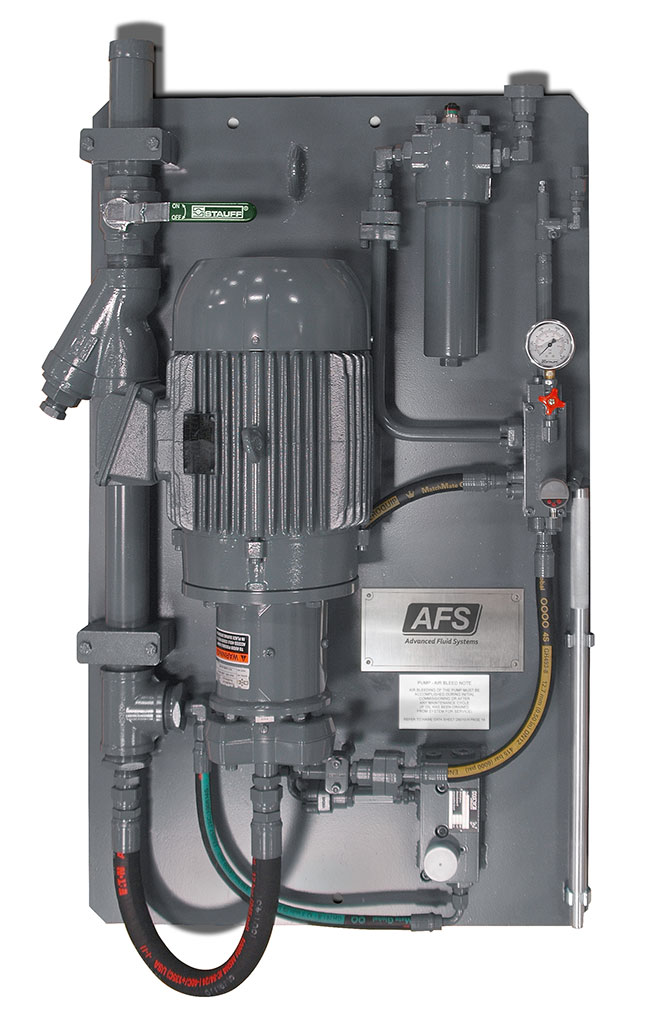

from advancedfluidsystems.com

In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Slow ring rotation and insufficient lubrication from too high of an. Pumps using oil rings can suffer the following lubrication problems: Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Oil rings interact with lubricant viscosities. When it comes to oil, there are also different lubrication methods. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Viscosity is by far the most important property of lubricants applied to process pump bearings. There are mainly two oil lubricants: The oil is contained in a sump in the.

Lubrication Unit Trunnion Bearing High Pressure

Oil Pump Bearing Lube Pumps using oil rings can suffer the following lubrication problems: Slow ring rotation and insufficient lubrication from too high of an. Pumps using oil rings can suffer the following lubrication problems: In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Viscosity is by far the most important property of lubricants applied to process pump bearings. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Oil rings interact with lubricant viscosities. When it comes to oil, there are also different lubrication methods. There are mainly two oil lubricants: The oil is contained in a sump in the. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant.

From www.dreamstime.com

Ball Bearing. Lubricating Oil Stock Photo Image of machinery Oil Pump Bearing Lube Viscosity is by far the most important property of lubricants applied to process pump bearings. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. When it comes to oil, there are also different lubrication methods. Pumps using oil rings can suffer the following lubrication problems: Oil rings interact with. Oil Pump Bearing Lube.

From www.plantservices.com

Fluid Handling Troubleshoot pump bearing failures Tips for efficient Oil Pump Bearing Lube When it comes to oil, there are also different lubrication methods. Viscosity is by far the most important property of lubricants applied to process pump bearings. There are mainly two oil lubricants: In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil splash lubrication can be achieved. Oil Pump Bearing Lube.

From wcmracing.com

Ultimate Bearing Lube WCM Racing Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Viscosity is by far the most important property of lubricants. Oil Pump Bearing Lube.

From cometkartsales.com

Xeramic Bearing Lube 400 ml Bearing Lubricants Chain Sprays Oil Pump Bearing Lube When it comes to oil, there are also different lubrication methods. In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil rings interact with lubricant viscosities. Slow ring rotation and insufficient lubrication from too high of an. Pumps using oil rings can suffer the following lubrication problems:. Oil Pump Bearing Lube.

From www.machinerylubrication.com

Selecting the Correct Lubricant for Bearing Applications Oil Pump Bearing Lube Slow ring rotation and insufficient lubrication from too high of an. The oil is contained in a sump in the. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil rings interact with lubricant viscosities. When it comes to oil, there are also different lubrication methods. There are. Oil Pump Bearing Lube.

From groove-ballbearing.com

Bearing Lubrication Oil and Grease Two Basic Types Oil Pump Bearing Lube In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. The oil is contained in a sump in the. Oil rings interact with lubricant viscosities. Oil splash. Oil Pump Bearing Lube.

From www.machinerylubrication.com

Rolling Bearing Lubrication for Critical Running Conditions Oil Pump Bearing Lube Pumps using oil rings can suffer the following lubrication problems: There are mainly two oil lubricants: Slow ring rotation and insufficient lubrication from too high of an. Oil rings interact with lubricant viscosities. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Oil splash lubrication can be achieved by. Oil Pump Bearing Lube.

From belgo-bearings.com

Bearing Lubrication Belgo Bearings Oil Pump Bearing Lube Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Viscosity is by far the most important property of lubricants applied to process pump bearings. Slow ring rotation and insufficient lubrication from too high of an. In this article, you will learn about optimal ways of lubricating the bearings in. Oil Pump Bearing Lube.

From www.practicalprods.com

Bostik® BEARING LUBRICANT® Practical Products Oil Pump Bearing Lube Pumps using oil rings can suffer the following lubrication problems: When it comes to oil, there are also different lubrication methods. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Oil splash lubrication can be achieved by the bearing. Oil Pump Bearing Lube.

From advancedfluidsystems.com

Lubrication Unit Trunnion Bearing High Pressure Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. In this article, you will learn about optimal ways. Oil Pump Bearing Lube.

From www.youtube.com

Pump bearing housing lubrication YouTube Oil Pump Bearing Lube When it comes to oil, there are also different lubrication methods. Pumps using oil rings can suffer the following lubrication problems: In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Slow ring rotation and insufficient lubrication from too high of an. Viscosity is by far the most. Oil Pump Bearing Lube.

From www.lubriplate.com

Wheel Bearing Grease Lubriplate Lubricants Co. Oil Pump Bearing Lube Pumps using oil rings can suffer the following lubrication problems: Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. When it comes to oil, there are also different lubrication methods. The oil is contained in a sump in the. Slow ring rotation and insufficient lubrication from too high of. Oil Pump Bearing Lube.

From savree.com

Bearing Lubrication Explained saVRee Oil Pump Bearing Lube Oil rings interact with lubricant viscosities. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Pumps using oil. Oil Pump Bearing Lube.

From www.pumpsandsystems.com

Back to Basics Pump Bearing Housing LubricationPart 2 Oil Pump Bearing Lube The oil is contained in a sump in the. There are mainly two oil lubricants: Slow ring rotation and insufficient lubrication from too high of an. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil splash lubrication can be achieved by the bearing being in direct contact. Oil Pump Bearing Lube.

From savree.com

Bearing Lubrication Explained saVRee Oil Pump Bearing Lube Oil rings interact with lubricant viscosities. There are mainly two oil lubricants: In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil splash lubrication may be. Oil Pump Bearing Lube.

From www.analogueseduction.net

ProJect LubeIT Bearing Oil Oil Pump Bearing Lube Slow ring rotation and insufficient lubrication from too high of an. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. The oil is contained in a sump in the. Viscosity is by far the most important property of lubricants applied to process pump bearings. Oil splash lubrication can be. Oil Pump Bearing Lube.

From www.youtube.com

Gear Pump Main Lube oil pump GE Frame5 Turbines Frame3 GasTurbine Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. When it comes to oil, there are also different lubrication methods. Viscosity is by far the most important property of lubricants applied to process pump bearings. The oil is contained. Oil Pump Bearing Lube.

From www.mechanical-knowledge.com

Bearings & Lubrication Oil Pump Bearing Lube In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Oil splash lubrication can be achieved by the. Oil Pump Bearing Lube.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Slow ring rotation and insufficient lubrication from too high of an. In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. There are mainly two oil lubricants:. Oil Pump Bearing Lube.

From www.youtube.com

How to Properly Lubricate a Plain Linear Bearing YouTube Oil Pump Bearing Lube The oil is contained in a sump in the. There are mainly two oil lubricants: Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil splash. Oil Pump Bearing Lube.

From www.pchemlabs.com

Edwards Stokes VLube Grade F Oil Lubricant, for Mechanical Piston Oil Pump Bearing Lube Pumps using oil rings can suffer the following lubrication problems: The oil is contained in a sump in the. Slow ring rotation and insufficient lubrication from too high of an. Viscosity is by far the most important property of lubricants applied to process pump bearings. Oil splash lubrication can be achieved by the bearing being in direct contact with the. Oil Pump Bearing Lube.

From lubchem.com

What is the Best Bearing Lubrication? Oil vs Grease Lubchem, Inc. Oil Pump Bearing Lube The oil is contained in a sump in the. When it comes to oil, there are also different lubrication methods. Viscosity is by far the most important property of lubricants applied to process pump bearings. There are mainly two oil lubricants: Pumps using oil rings can suffer the following lubrication problems: Oil splash lubrication can be achieved by the bearing. Oil Pump Bearing Lube.

From www.kodiaktrailerbrakes.com

Kodiak XL Pro Lube 8 oz Trailer Bearing Oil for Oil Bath Hub Kits Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Pumps using oil rings can suffer the following lubrication problems: When it comes to oil, there are also different. Oil Pump Bearing Lube.

From www.machinerylubrication.com

Boosting Pump Reliability Through Lubrication Best Practices Oil Pump Bearing Lube Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil rings interact with lubricant viscosities. Viscosity is by far the most important property of lubricants applied to process. Oil Pump Bearing Lube.

From mavink.com

Pump Bearing Lubrication Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Pumps using oil rings can suffer the following lubrication problems: Slow ring rotation and insufficient lubrication from too high of an. The oil is contained in a sump in the.. Oil Pump Bearing Lube.

From www.machinerylubrication.com

Sampling and Effluent Collection Options for Oil Mist Systems Oil Pump Bearing Lube Pumps using oil rings can suffer the following lubrication problems: Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or. Oil Pump Bearing Lube.

From www.youtube.com

How to Select the Best Bearing Lubricant YouTube Oil Pump Bearing Lube Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Pumps using oil rings can suffer the following lubrication problems: The oil is contained in a sump in the. When it comes to oil, there are also different lubrication methods. Oil splash lubrication can be achieved by the bearing being. Oil Pump Bearing Lube.

From www.parksupplyofamerica.com

Armstrong Pumps Oil Lube Bearing Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Slow ring rotation and insufficient lubrication from too high of an. Pumps using oil rings can suffer the following lubrication problems: The oil is contained in a sump in the. In this article, you will learn about optimal ways. Oil Pump Bearing Lube.

From www.oilandgaseng.com

Oil & Gas Engineering Understanding lubrication from the bearing’s Oil Pump Bearing Lube In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings. Oil Pump Bearing Lube.

From blog.slsbearings.com

The Importance of Lubrication in Bearings and Other Components Oil Pump Bearing Lube Oil rings interact with lubricant viscosities. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil splash lubrication may be the most common method of bearing lubrication for horizontal pumps from 5 to 250 bhp. Slow ring rotation and insufficient lubrication from too high of an. When it. Oil Pump Bearing Lube.

From www.pumpsandsystems.com

Optimizing Lube Oil Pumps for Rotating Machinery Pumps & Systems Oil Pump Bearing Lube There are mainly two oil lubricants: Pumps using oil rings can suffer the following lubrication problems: Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. Slow ring rotation and insufficient lubrication from too high of an. Oil splash lubrication. Oil Pump Bearing Lube.

From favpng.com

Oil Automatic Lubrication System Lubricant Bearing, PNG, 569x762px, Oil Oil Pump Bearing Lube Slow ring rotation and insufficient lubrication from too high of an. In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Oil rings interact with lubricant viscosities. Pumps using oil rings can suffer the following lubrication problems: Oil splash lubrication may be the most common method of bearing. Oil Pump Bearing Lube.

From baartgroup.com

Lubricate a Mounted Bearing A Howto Guide Baart Group Oil Pump Bearing Lube There are mainly two oil lubricants: The oil is contained in a sump in the. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant. Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it. Oil Pump Bearing Lube.

From www.youtube.com

Howto Lube Sealed Bearings YouTube Oil Pump Bearing Lube Oil splash lubrication can be achieved by the bearing being in direct contact with the oil, oil rings contacting the lubricant and splashing it throughout the bearing housing, or slinger. The oil is contained in a sump in the. Oil rings interact with lubricant viscosities. Slow ring rotation and insufficient lubrication from too high of an. In this article, you. Oil Pump Bearing Lube.

From www.sundyne.com

Genuine Pump & Compressor Parts Sundyne Oil Pump Bearing Lube In this article, you will learn about optimal ways of lubricating the bearings in api process pumps, including data on discs vs. Pumps using oil rings can suffer the following lubrication problems: When it comes to oil, there are also different lubrication methods. There are mainly two oil lubricants: The oil is contained in a sump in the. Oil splash. Oil Pump Bearing Lube.