Surface Roughness Measurement Standard . The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. The machining surface finish chart offers important guidelines for measuring standard surface. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. It defines key parameters such.

from www.mechanicaleducation.com

The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: It defines key parameters such. The machining surface finish chart offers important guidelines for measuring standard surface.

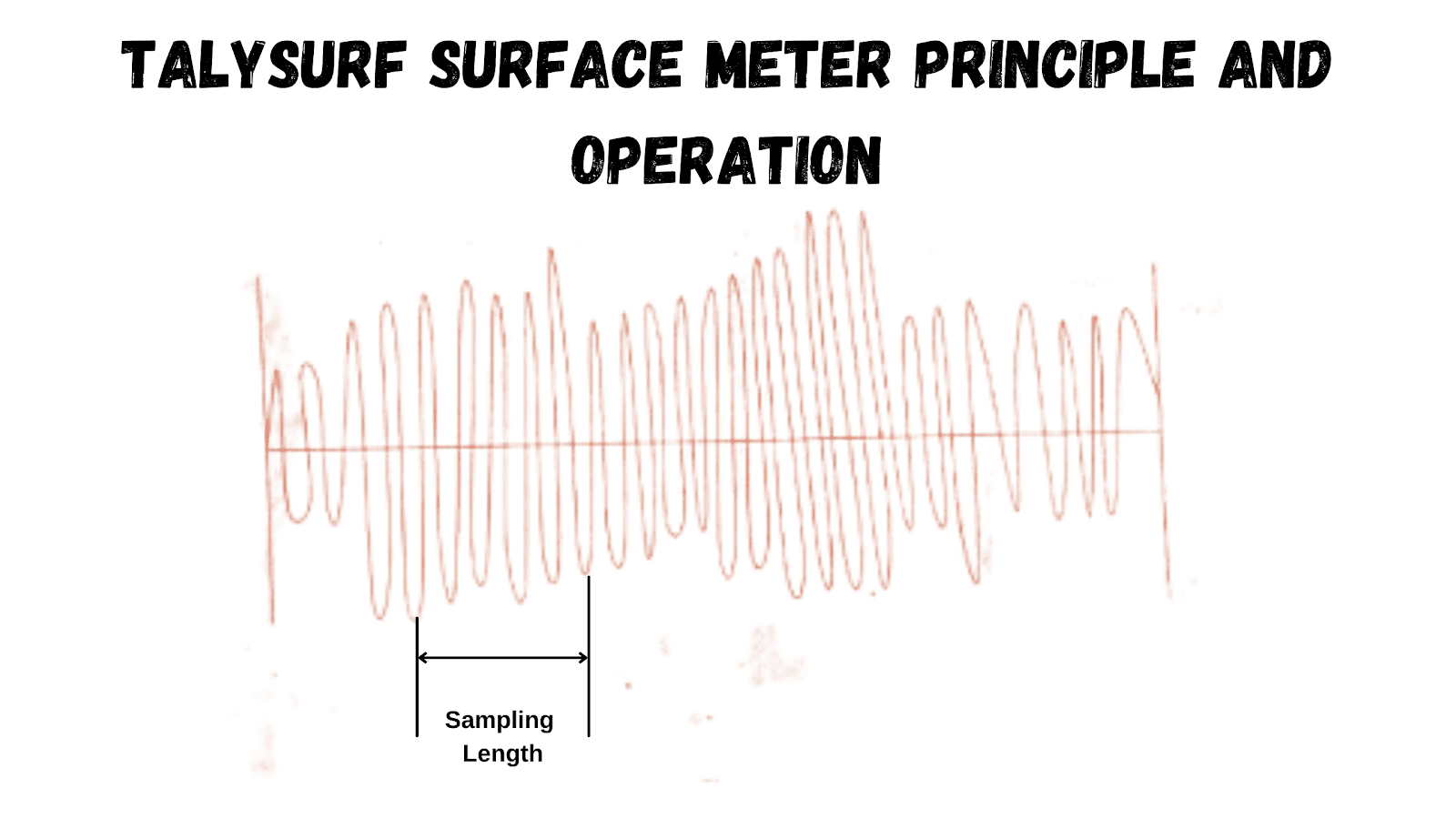

Sampling Length In Surface Roughness Measurement Mechanical Education

Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. The machining surface finish chart offers important guidelines for measuring standard surface. It defines key parameters such. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve.

From get-it-made.co.uk

Surface Roughness Explained Ra Roughness Chart Surface Roughness Measurement Standard It defines key parameters such. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the. Surface Roughness Measurement Standard.

From www.scribd.com

Surface Roughness Conversion Chart PDF Surface Roughness Measurement Standard Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. The machining surface finish chart offers important guidelines for measuring. Surface Roughness Measurement Standard.

From metrologicallyspeaking.com

Surface Roughness Measurement and Applications Everything About Metrology Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. It defines key parameters such. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. The din en iso 21920 provides clear guidelines for describing. Surface Roughness Measurement Standard.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Measurement Standard The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: Surface roughness measures the closely spaced irregularities or variations, such. Surface Roughness Measurement Standard.

From cncmachinecenter.en.made-in-china.com

Surface Roughness Measurement Tool High Precision CNC Accessories and Surface Roughness Measurement Standard Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. The machining surface finish chart offers important guidelines for measuring standard surface. All roughness parameters without the “max” suffix represent the mean value measured within the five. Surface Roughness Measurement Standard.

From oliverrandall.z13.web.core.windows.net

Rms Surface Roughness Chart Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: It defines key parameters such. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. The machining surface finish chart offers important guidelines for measuring standard surface. Explore the unique characteristics. Surface Roughness Measurement Standard.

From www.flexbar.com

Surface Roughness Standards Set 30 Specimens — Flexbar Machine Surface Roughness Measurement Standard Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. The. Surface Roughness Measurement Standard.

From www.engineeringchoice.com

What Is Surface Roughness? Unit, Chart, Measurement Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. The din en iso 21920 provides clear guidelines for describing and evaluating. Surface Roughness Measurement Standard.

From www.fowlerprecision.com

Fowler Surface Roughness Standards Surface Roughness Measurement Standard The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. It defines key parameters such. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. The machining surface finish chart offers important guidelines for measuring standard surface. All roughness parameters without. Surface Roughness Measurement Standard.

From www.researchgate.net

Types of surface roughness measurement Download Scientific Diagram Surface Roughness Measurement Standard Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. The machining surface finish chart offers important guidelines for measuring standard surface. The din en iso 21920 provides clear guidelines for describing. Surface Roughness Measurement Standard.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: It defines key parameters such. Surface roughness measures the closely spaced irregularities or variations, such as cutting. Surface Roughness Measurement Standard.

From www.youtube.com

Mitutoyo Metrology Class How to Measure Surface Roughness with the Surface Roughness Measurement Standard The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve.. Surface Roughness Measurement Standard.

From www.researchgate.net

Surface roughness measurement procedures Download Scientific Diagram Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface. Surface Roughness Measurement Standard.

From mungfali.com

Surface Roughness Standards Surface Roughness Measurement Standard It defines key parameters such. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. The machining surface finish chart offers important guidelines for measuring standard surface. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. The. Surface Roughness Measurement Standard.

From www.youtube.com

Surface Roughness Measurement 10 point Rz method YouTube Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. The din en iso 21920 provides clear guidelines for describing and evaluating. Surface Roughness Measurement Standard.

From inksterspartoftherock.blogspot.com

19 Images Surface Roughness Chart Surface Roughness Measurement Standard The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. The machining surface finish chart offers important guidelines for measuring standard surface. All roughness parameters without the. Surface Roughness Measurement Standard.

From measurementsupply.com

Mitutoyo 0.75mN Standard Type SJ210 Portable Surface Roughness Tester Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. It defines key parameters such. The machining surface finish chart offers important guidelines for measuring standard surface.. Surface Roughness Measurement Standard.

From www.mechanicaleducation.com

Sampling Length In Surface Roughness Measurement Mechanical Education Surface Roughness Measurement Standard It defines key parameters such. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Surface Roughness Measurement Standard.

From www.messmittel.tools

Surface roughness gauge standard set, Ra 0,05 12,5 µm Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. It defines key parameters such. The machining surface finish chart offers important guidelines for measuring standard surface. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths:. Surface Roughness Measurement Standard.

From www.slideserve.com

PPT Lab 5 Surface Roughness Test PowerPoint Presentation ID505423 Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and. Surface Roughness Measurement Standard.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: It defines key parameters such. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface.. Surface Roughness Measurement Standard.

From mavink.com

Surface Roughness Units Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. All. Surface Roughness Measurement Standard.

From www.onestopndt.com

Surface Roughness Measurement Tips OnestopNDT Surface Roughness Measurement Standard Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. It defines key parameters such. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. The din en iso. Surface Roughness Measurement Standard.

From www.yumpu.com

surface roughness measurement Mitutoyo America Corporation Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. Explore the unique characteristics of surface roughness, including its. Surface Roughness Measurement Standard.

From www.scribd.com

LC Surface Roughness Measurements Surface Roughness Measurement Standard Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. All roughness parameters without the “max” suffix represent the mean value measured. Surface Roughness Measurement Standard.

From www.aliexpress.com

30pcs Surface Roughness Comparator Standards Composite Set Model RUG Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. It defines key parameters such. The machining surface finish chart offers important guidelines for measuring standard surface. This section is based. Surface Roughness Measurement Standard.

From measurementsupply.com

Mitutoyo 4mN Standard Type SJ210 Portable Surface Roughness Tester 178 Surface Roughness Measurement Standard Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. It defines key parameters such. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface.. Surface Roughness Measurement Standard.

From gahess.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Measurement Standard The machining surface finish chart offers important guidelines for measuring standard surface. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. This section is based on proposals by iso technical. Surface Roughness Measurement Standard.

From www.vrogue.co

A Guide To Understanding Surface Roughness Measuremen vrogue.co Surface Roughness Measurement Standard Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. This section is based on proposals by iso technical. Surface Roughness Measurement Standard.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Surface Roughness Measurement Standard The din en iso 21920 provides clear guidelines for describing and evaluating the surface texture of components. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. It defines key parameters such. The machining surface finish chart offers important guidelines for measuring standard surface. All roughness parameters without. Surface Roughness Measurement Standard.

From www.china-machining.com

Understand the Surface Roughness Chart and Make Great Parts Surface Roughness Measurement Standard This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. Surface roughness measures the closely. Surface Roughness Measurement Standard.

From mavink.com

Surface Roughness Standards Surface Roughness Measurement Standard Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. This section is based on proposals by iso technical committee 57 to define the characteristics. Surface Roughness Measurement Standard.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree Surface Roughness Measurement Standard All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: The machining surface finish chart offers important guidelines for measuring standard surface. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. Explore the unique characteristics of surface roughness, including its. Surface Roughness Measurement Standard.

From michmet.com

Average Roughness basics Michigan Metrology Surface Roughness Measurement Standard Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and. This section is based on proposals by iso technical committee 57 to define the characteristics of instruments that directly measure surface profiles, which then can serve. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: It. Surface Roughness Measurement Standard.

From isofinishing.com

Surface Roughness Chart ISO Finishing Surface Roughness Measurement Standard Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface. All roughness parameters without the “max” suffix represent the mean value measured within the five sampling lengths: It defines key parameters such. This section is based on proposals by iso technical committee 57 to define the characteristics of. Surface Roughness Measurement Standard.