How To Chamfer Threaded Rod . Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. End of thread at undercut or recess should also be chamfered at 45°. Join our fastener specialist as he cuts. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. Looking for the most effective method on how to cut threaded rod? There should be from 1 1/2 to 4 threads sticking past the nut,. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. Exact angles can not be produced due to the displacement of the metal forming the thread. To perform this process we use a tool called the uniburr.

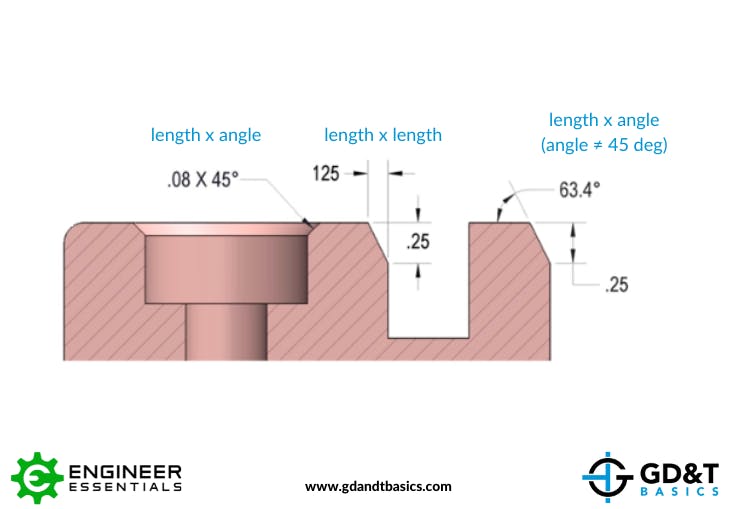

from www.gdandtbasics.com

Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. To perform this process we use a tool called the uniburr. Exact angles can not be produced due to the displacement of the metal forming the thread. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. There should be from 1 1/2 to 4 threads sticking past the nut,. Join our fastener specialist as he cuts. When threads are rolled, the angle on the first and last threads may approximate a 45° angle.

Chamfer Dimensioning GD&T Basics

How To Chamfer Threaded Rod Exact angles can not be produced due to the displacement of the metal forming the thread. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. Exact angles can not be produced due to the displacement of the metal forming the thread. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. End of thread at undercut or recess should also be chamfered at 45°. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. To perform this process we use a tool called the uniburr. Looking for the most effective method on how to cut threaded rod? Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. There should be from 1 1/2 to 4 threads sticking past the nut,. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Join our fastener specialist as he cuts.

From craftwithlathes.com

How to chamfer on a lathe Using Different Steps and Tools How To Chamfer Threaded Rod Join our fastener specialist as he cuts. Looking for the most effective method on how to cut threaded rod? To perform this process we use a tool called the uniburr. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. There should be from 1 1/2 to 4 threads. How To Chamfer Threaded Rod.

From www.youtube.com

Video 2 Testing Chamfer Tools on Construction Grade Threaded Rod How To Chamfer Threaded Rod There should be from 1 1/2 to 4 threads sticking past the nut,. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. To perform this process we use a tool called the uniburr. A uniburr is. How To Chamfer Threaded Rod.

From www.albanycountyfasteners.com

How To Properly Cut, Deburr and Chamfer Threaded Rod How To Chamfer Threaded Rod End of thread at undercut or recess should also be chamfered at 45°. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. Join our fastener specialist as he cuts.. How To Chamfer Threaded Rod.

From www.woodsmith.com

The Versatile Chamfer Woodsmith How To Chamfer Threaded Rod When threads are rolled, the angle on the first and last threads may approximate a 45° angle. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Looking for the most effective method on how to cut threaded rod? End of thread at undercut or recess. How To Chamfer Threaded Rod.

From www.albanycountyfasteners.com

What's A Chamfering Tool? Albany County Fasteners How To Chamfer Threaded Rod To perform this process we use a tool called the uniburr. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. Chamfering is done to clean up the start of threads so. How To Chamfer Threaded Rod.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics How To Chamfer Threaded Rod Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. There should be from 1 1/2 to 4 threads sticking past the nut,. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. In this. How To Chamfer Threaded Rod.

From www.youtube.com

Automatic rod chamfer raidus end machine,chamfering machine YouTube How To Chamfer Threaded Rod Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Join our fastener specialist as he cuts. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. Exact angles can not be produced due. How To Chamfer Threaded Rod.

From www.youtube.com

double end rod chamfer, rod chamfering machine 6mm YouTube How To Chamfer Threaded Rod Join our fastener specialist as he cuts. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. There should be from 1 1/2 to 4 threads sticking past the nut,. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without. How To Chamfer Threaded Rod.

From www.computeraideddesignguide.com

How to Make Threads in SolidWorks How To Chamfer Threaded Rod Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. Looking for the most effective method on how to cut threaded rod? Join our fastener specialist. How To Chamfer Threaded Rod.

From support.ptc.com

About Trimming Chamfer Geometry How To Chamfer Threaded Rod Looking for the most effective method on how to cut threaded rod? In this video i demonstrate how to add an appropriate sized chamfer for an external thread. There should be from 1 1/2 to 4 threads sticking past the nut,. Join our fastener specialist as he cuts. To perform this process we use a tool called the uniburr. Dive. How To Chamfer Threaded Rod.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics How To Chamfer Threaded Rod Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Chamfering is done to clean up the start of threads so a nut can. How To Chamfer Threaded Rod.

From www.youtube.com

How to Chamfer Threads in Fusion 360 YouTube How To Chamfer Threaded Rod End of thread at undercut or recess should also be chamfered at 45°. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. In this video i. How To Chamfer Threaded Rod.

From weldingrods.com

Chamfer Rod The Ultimate Gouging Electrode How To Chamfer Threaded Rod To perform this process we use a tool called the uniburr. There should be from 1 1/2 to 4 threads sticking past the nut,. End of thread at undercut or recess should also be chamfered at 45°. Join our fastener specialist as he cuts. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away. How To Chamfer Threaded Rod.

From www.toolking.com.au

Chamfer pro Bolt and threaded rod Deburring tool PROFESSIONAL 212mm How To Chamfer Threaded Rod When threads are rolled, the angle on the first and last threads may approximate a 45° angle. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. To perform this process we use a tool called the uniburr. There should be from 1 1/2 to 4 threads sticking past the. How To Chamfer Threaded Rod.

From www.pmpa.org

Designer’s Guide ThreadsThread Relief and Chamfers Precision How To Chamfer Threaded Rod A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. Join our. How To Chamfer Threaded Rod.

From www.youtube.com

Video 3 Testing Chamfer Tools on Grade 8 Threaded Rod YouTube How To Chamfer Threaded Rod Join our fastener specialist as he cuts. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. When threads are rolled, the angle on the first and last threads may approximate a 45°. How To Chamfer Threaded Rod.

From www.woodsmith.com

The Versatile Chamfer Woodsmith How To Chamfer Threaded Rod Join our fastener specialist as he cuts. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. There should be from 1 1/2 to 4 threads sticking past the nut,. Looking for the most effective method on. How To Chamfer Threaded Rod.

From www.youtube.com

Mastercam Tip Chamfer any angle with a 45° Chamfering Tool YouTube How To Chamfer Threaded Rod There should be from 1 1/2 to 4 threads sticking past the nut,. Join our fastener specialist as he cuts. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Exact angles can not be produced due to the displacement of the metal forming the thread.. How To Chamfer Threaded Rod.

From www.albanycountyfasteners.com

How To Properly Cut, Deburr and Chamfer Threaded Rod How To Chamfer Threaded Rod A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. Looking for the most effective method on how to cut threaded rod? Join our fastener specialist as he cuts a couple of threaded. How To Chamfer Threaded Rod.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist How To Chamfer Threaded Rod A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. There should be from 1 1/2 to 4 threads sticking past the nut,. Join our fastener specialist as he cuts. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without. How To Chamfer Threaded Rod.

From www.youtube.com

hand feeding chamfering machines to chamfer rod ends 20mm YouTube How To Chamfer Threaded Rod Join our fastener specialist as he cuts. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. End of thread at undercut or recess should also be chamfered at 45°. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with. How To Chamfer Threaded Rod.

From www.toolking.com.au

Chamfer pro Bolt and threaded rod Deburring tool Professional LARGE 10 How To Chamfer Threaded Rod Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. When threads are rolled, the angle on the first and last threads may approximate a 45° angle.. How To Chamfer Threaded Rod.

From www.youtube.com

Chamfering the Edge ToolsToday YouTube How To Chamfer Threaded Rod To perform this process we use a tool called the uniburr. End of thread at undercut or recess should also be chamfered at 45°. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Dive into our comprehensive guide and learn the best way to get. How To Chamfer Threaded Rod.

From toolnotes.com

Thread Terminology ToolNotes How To Chamfer Threaded Rod When threads are rolled, the angle on the first and last threads may approximate a 45° angle. End of thread at undercut or recess should also be chamfered at 45°. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. Looking for the most effective method on how. How To Chamfer Threaded Rod.

From www.youtube.com

Quick Clip How To Cut & Chamfer Threaded Rod Fasteners 101 YouTube How To Chamfer Threaded Rod Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. Exact angles can not be produced due to the displacement of the metal forming the thread. There should. How To Chamfer Threaded Rod.

From www.youtube.com

Adding a Chamfer Dimension YouTube How To Chamfer Threaded Rod Join our fastener specialist as he cuts. End of thread at undercut or recess should also be chamfered at 45°. To perform this process we use a tool called the uniburr. Looking for the most effective method on how to cut threaded rod? Dive into our comprehensive guide and learn the best way to get your threaded rod cut to. How To Chamfer Threaded Rod.

From www.youtube.com

threaded rod chamfering machine, chamfer screw, screw chamfering How To Chamfer Threaded Rod A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. In this video i demonstrate how to add an appropriate sized chamfer for an external thread. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. When threads are. How To Chamfer Threaded Rod.

From www.youtube.com

cnc programming how to make chamfer program chamfer with angle How To Chamfer Threaded Rod In this video i demonstrate how to add an appropriate sized chamfer for an external thread. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. Join our fastener specialist as he cuts. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging. How To Chamfer Threaded Rod.

From toolnotes.com

Thread Terminology ToolNotes How To Chamfer Threaded Rod Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging the threads. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. Exact angles can not be produced due to the displacement of the metal forming the thread. To perform. How To Chamfer Threaded Rod.

From www.albanycountyfasteners.com

How To Properly Cut, Deburr and Chamfer Threaded Rod How To Chamfer Threaded Rod End of thread at undercut or recess should also be chamfered at 45°. Looking for the most effective method on how to cut threaded rod? Exact angles can not be produced due to the displacement of the metal forming the thread. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the. How To Chamfer Threaded Rod.

From www.youtube.com

thread rod chamfer, threaded rod chamfering machine, hex bolt bevelling How To Chamfer Threaded Rod Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. There should be from 1 1/2 to 4 threads sticking past the nut,. Exact angles can. How To Chamfer Threaded Rod.

From www.youtube.com

Video 4 Testing Chamfer Tools on HRC 39 Threaded Rod YouTube How To Chamfer Threaded Rod Exact angles can not be produced due to the displacement of the metal forming the thread. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them with a uniburr plus 1816. Dive into our comprehensive guide and learn the best way to get your threaded rod cut to length without damaging. How To Chamfer Threaded Rod.

From www.mcgill.ca

Dimensioning threaded fasteners Engineering Design McGill University How To Chamfer Threaded Rod Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. A uniburr is a cone shaped tool that attaches to a drill and quickly chamfers away the edges of a fastener. Join our fastener specialist as he cuts a couple of threaded rod sticks down to size and chamfers them. How To Chamfer Threaded Rod.

From www.albanycountyfasteners.com

How To Properly Cut, Deburr and Chamfer Threaded Rod How To Chamfer Threaded Rod To perform this process we use a tool called the uniburr. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod. Looking for the most effective method on how to cut threaded rod?. How To Chamfer Threaded Rod.

From vibadirect.com

Dimension Guidelines ViBaDirect How To Chamfer Threaded Rod Join our fastener specialist as he cuts. When threads are rolled, the angle on the first and last threads may approximate a 45° angle. Exact angles can not be produced due to the displacement of the metal forming the thread. Chamfering is done to clean up the start of threads so a nut can be easily fastened to the rod.. How To Chamfer Threaded Rod.