What Does Plastic Dip Coating Mean . Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater.

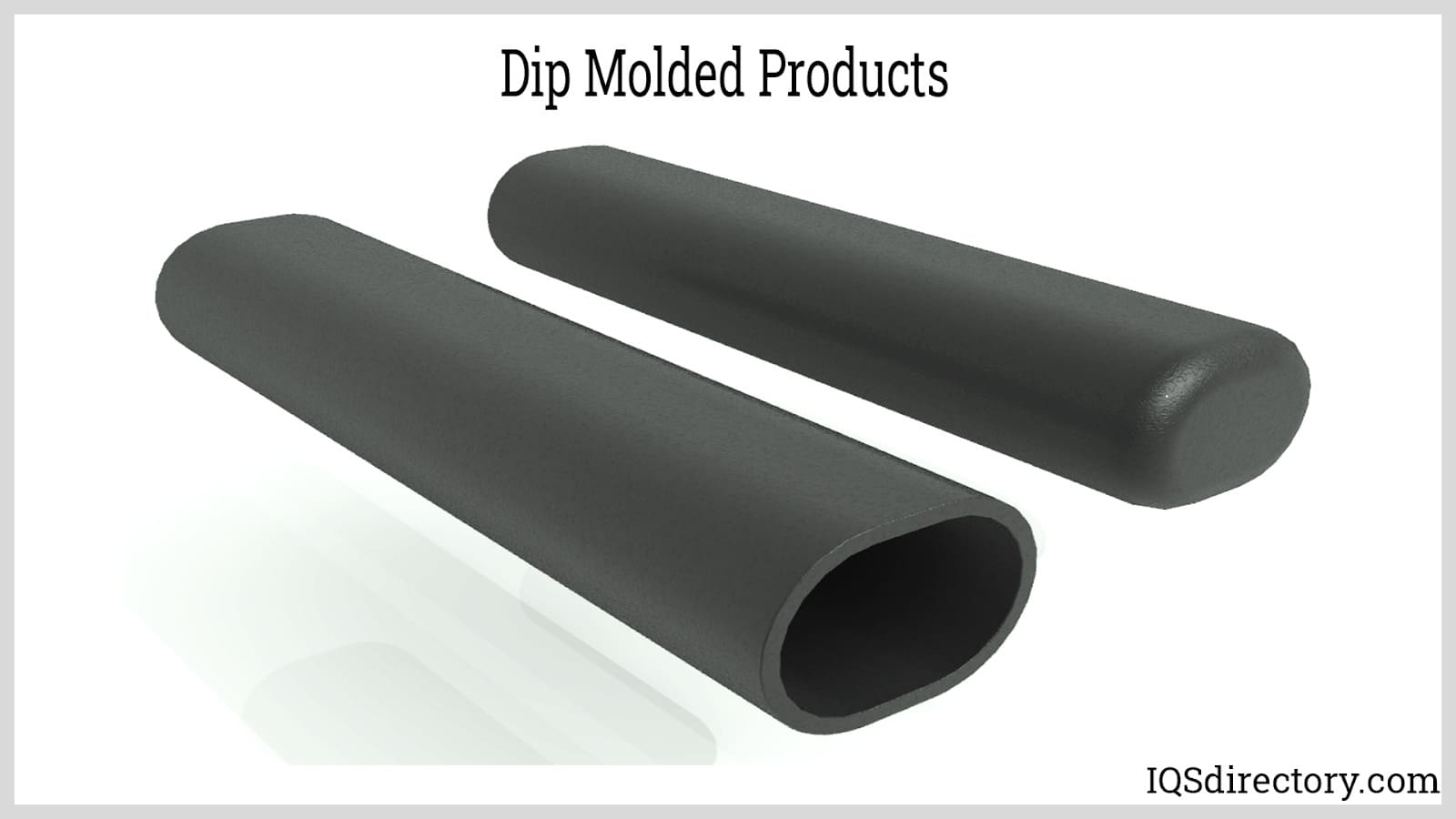

from www.iqsdirectory.com

It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its.

Plastic Coating What Is It? How Does It Work? Process

What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. The metal to be coated serves as a mold, allowing the plastic or polymer to. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at.

From www.dipmoldedplastics.com

Plastic Coatings Photo Gallery What Does Plastic Dip Coating Mean The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing. What Does Plastic Dip Coating Mean.

From www.homedepot.com

Plasti Dip 11 oz. Red Rubber Coating Spray 112016 The Home Depot What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. The metal to be coated serves as a mold, allowing. What Does Plastic Dip Coating Mean.

From www.youtube.com

What is dipcoating ? YouTube What Does Plastic Dip Coating Mean It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating is a powder coating process that involves immersing, or dipping, a substrate. What Does Plastic Dip Coating Mean.

From www.slideserve.com

PPT DIP COATING PowerPoint Presentation, free download ID618468 What Does Plastic Dip Coating Mean Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. Dip coating is an industrial coating process used to apply. What Does Plastic Dip Coating Mean.

From www.mdpi.com

Polymers Free FullText A Review of Electro Conductive Textiles What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. It involves dipping a substrate into a liquid coating, such as a paint or. What Does Plastic Dip Coating Mean.

From www.researchgate.net

Schematic illustration of the solutionbased (dipcoating) process with What Does Plastic Dip Coating Mean Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of. What Does Plastic Dip Coating Mean.

From www.piper-plastics.com

Dip Coating & Plastisol Coating Process Piper Plastics Corp. What Does Plastic Dip Coating Mean Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. The metal to be coated serves. What Does Plastic Dip Coating Mean.

From www.precisiondipcoating.com

The Process Of Plastic Dip Coating Precision Dip Coating What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip. What Does Plastic Dip Coating Mean.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. Dip coating involves the deposition of a liquid film via. What Does Plastic Dip Coating Mean.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process What Does Plastic Dip Coating Mean The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has. What Does Plastic Dip Coating Mean.

From www.desertcart.ae

Buy Plasti DipPerformix 12213 Black 22 oz. Dip Can Online at What Does Plastic Dip Coating Mean Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. It involves dipping a substrate into a liquid coating, such as a paint or. What Does Plastic Dip Coating Mean.

From www.researchgate.net

Schematic of dip coating [124] Download Scientific Diagram What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. Dip coating is a powder coating process that involves immersing,. What Does Plastic Dip Coating Mean.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process What Does Plastic Dip Coating Mean Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. Dip coating is a simple, reliable, and powerful option, capable. What Does Plastic Dip Coating Mean.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. Dip coating is a simple, reliable, and powerful option, capable. What Does Plastic Dip Coating Mean.

From www.ebay.com

New Cool Blue 14.5oz PLASTI DIP Plastic Multi Rubber Coating Handle What Does Plastic Dip Coating Mean Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material,. What Does Plastic Dip Coating Mean.

From mwrco.com

One of the First Plastic Manufacturing Methods Vacuum Forming What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. It involves dipping a substrate into a liquid coating, such. What Does Plastic Dip Coating Mean.

From www.youtube.com

Powder Dip Coating YouTube What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating involves. What Does Plastic Dip Coating Mean.

From www.precisiondipcoating.com

The Process Of Plastic Dip Coating What Does Plastic Dip Coating Mean The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in. What Does Plastic Dip Coating Mean.

From www.asseenontvlive.com

Dip and Grip Rubberized Coating As Seen On TV What Does Plastic Dip Coating Mean It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating is a simple, reliable, and powerful option, capable of coating almost any. What Does Plastic Dip Coating Mean.

From www.youtube.com

Rubber 1 How To Use Plasti Dip Liquid Plastic Coating YouTube What Does Plastic Dip Coating Mean It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material. What Does Plastic Dip Coating Mean.

From www.piper-plastics.com

The Advantages of Dip Molding Piper Plastics Corp. What Does Plastic Dip Coating Mean Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating is a simple, reliable, and powerful option, capable. What Does Plastic Dip Coating Mean.

From exoocexko.blob.core.windows.net

What Does Dip Finger Mean at Alice Mauriello blog What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in. What Does Plastic Dip Coating Mean.

From www.researchgate.net

The dipcoating process and the considerable electrostatic What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip. What Does Plastic Dip Coating Mean.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process What Does Plastic Dip Coating Mean Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. It involves dipping a substrate into a liquid coating, such as a paint or. What Does Plastic Dip Coating Mean.

From www.awarehousefull.com

Plasti Dip 5 gallon Rubber Coating AWarehouseFull What Does Plastic Dip Coating Mean The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has. What Does Plastic Dip Coating Mean.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process What Does Plastic Dip Coating Mean Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled rate. Dip coating is a simple, reliable,. What Does Plastic Dip Coating Mean.

From www.youtube.com

Plastic Dip Coating Services and Industry Information YouTube What Does Plastic Dip Coating Mean Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. It involves dipping a substrate into a liquid coating, such. What Does Plastic Dip Coating Mean.

From www.aftfasteners.com

Plasti Dip Sythetic Rubber Coating Clear AFT Fasteners What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves. What Does Plastic Dip Coating Mean.

From www.mdpi.com

Coatings Free FullText ThinFilm Coating Methods A Successful What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. The metal to be coated serves as a mold, allowing the plastic or polymer to. It involves dipping. What Does Plastic Dip Coating Mean.

From vehiclefreak.com

How Long Does Plasti Dip Take To Dry Before You Can Drive? What Does Plastic Dip Coating Mean The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip coater. Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material. What Does Plastic Dip Coating Mean.

From www.lowes.com

Plasti Dip 14.5fl oz Black Dip Rubberized Coating at What Does Plastic Dip Coating Mean Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in a variety of different industries. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of. What Does Plastic Dip Coating Mean.

From b2b.partcommunity.com

Plastic Dip Coated Hooks Precision Dip Coating LLC What Does Plastic Dip Coating Mean Dip coating is a powder coating process that involves immersing, or dipping, a substrate into a solution of coating material at. The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating involves the deposition of a liquid film via the precise and controlled withdrawal of a substrate from a solution using a dip. What Does Plastic Dip Coating Mean.

From www.slideserve.com

PPT Dip coating techniques PowerPoint Presentation, free download What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. The metal to be coated serves as a mold, allowing the plastic or polymer to. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled. What Does Plastic Dip Coating Mean.

From www.youtube.com

What is Dip Coating? YouTube What Does Plastic Dip Coating Mean Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. The metal to be coated serves as a mold, allowing the plastic or polymer to. It involves dipping a substrate into a liquid coating, such as a paint or polymer solution, and then slowly removing it at a controlled. What Does Plastic Dip Coating Mean.

From www.summitracing.com

Plasti Dip 12213 Plasti Dip Multipurpose Rubber Coatings Summit Racing What Does Plastic Dip Coating Mean The metal to be coated serves as a mold, allowing the plastic or polymer to. Dip coating is a simple, reliable, and powerful option, capable of coating almost any substrate material, but it also has its. Dip coating is an industrial coating process used to apply a thin, uniform coating to a substrate and is commonly used in manufacturing in. What Does Plastic Dip Coating Mean.