Valve Metals Definition . Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. One is “martensitic” steel and the other is “austenitic” steel. There are essentially two basic types of steel used to make valves. Other alloying elements, such as nickel (ni),. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,.

from hardhatengineer.com

Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Other alloying elements, such as nickel (ni),. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. One is “martensitic” steel and the other is “austenitic” steel. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. There are essentially two basic types of steel used to make valves. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under.

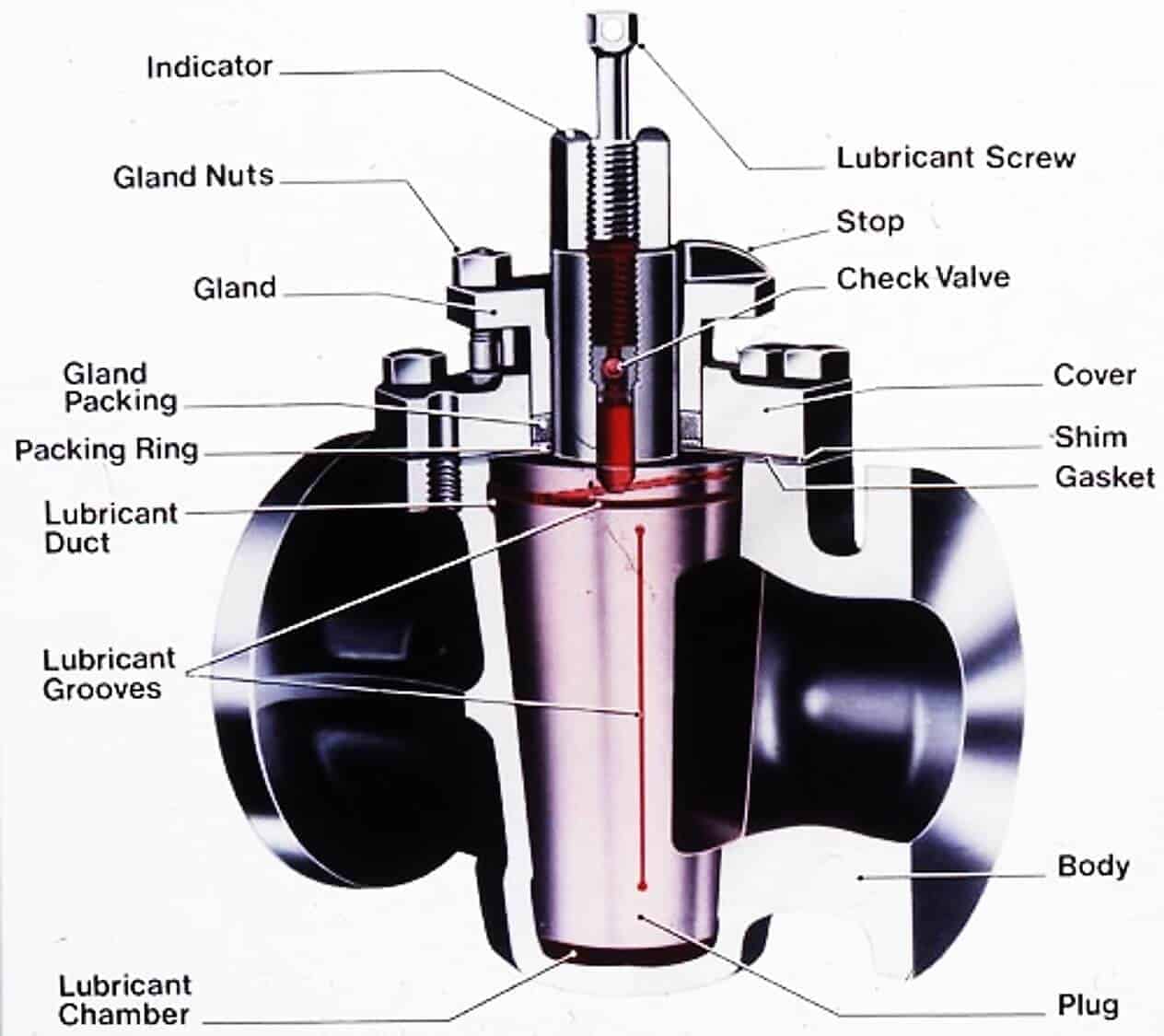

What is Plug Valve? A Complete Guide for Engineer

Valve Metals Definition Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. Other alloying elements, such as nickel (ni),. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. One is “martensitic” steel and the other is “austenitic” steel. There are essentially two basic types of steel used to make valves. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis.

From www.scribd.com

NRVModel Valve Metals Valve Metals Definition There are essentially two basic types of steel used to make valves. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Other alloying elements, such as nickel (ni),. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is. Valve Metals Definition.

From noelachampiono.blob.core.windows.net

Define Valve In Science Terms at noelachampiono blog Valve Metals Definition Other alloying elements, such as nickel (ni),. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. There are essentially two basic types of steel used to make valves. One is “martensitic” steel and the other is “austenitic” steel. Actually, while the industry is certainly formidable, its products are. Valve Metals Definition.

From hardhatengineer.com

Valve Trim and Parts Including API Trim Charts Valve Metals Definition There are essentially two basic types of steel used to make valves. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. One is “martensitic” steel and the other is “austenitic” steel. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of. Valve Metals Definition.

From www.watersvalve.com

Resilient Seated Gate Valve VS Metal Seated Gate Valve Watersvalve Valve Metals Definition Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. One is “martensitic” steel and the other is “austenitic” steel. There are essentially two. Valve Metals Definition.

From www.researchgate.net

Notes (A) Mechanism of oxide formation on valve metals. (B) Various Valve Metals Definition Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. There are essentially two basic types of steel used to make valves. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Other. Valve Metals Definition.

From www.superlokworld.com

Ball Valves vs. Needle Valves in Flow Control Superlok Blog Mako Valve Metals Definition Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. There are essentially two basic types of steel used to make valves. One is “martensitic” steel and the other. Valve Metals Definition.

From dizz.com

What are Needle Valves? Definition, Parts, Types, FAQ's [PDF] Design Valve Metals Definition Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Other alloying elements, such as nickel (ni),. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used. Valve Metals Definition.

From engineeringlearner.com

Flow Control Valve Definition, Types, Components & Working Principle Valve Metals Definition There are essentially two basic types of steel used to make valves. Other alloying elements, such as nickel (ni),. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals. Valve Metals Definition.

From qrcvalves.com

Gate Valve Components QRC Valves Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Actually, while the industry is certainly formidable, its products. Valve Metals Definition.

From constructionmechanical-engineering.blogspot.com

Ball Valves DefinitionConstruction Mechanical Engineering Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. There are essentially two basic types of steel used to make valves. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Other alloying elements, such as nickel (ni),.. Valve Metals Definition.

From pipefittingandvalve.com

Metal Seated Gate Valve ductile iron pipe fitting and valvefactory Valve Metals Definition Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Other alloying elements, such as nickel (ni),. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel. Valve Metals Definition.

From blog.thepipingmart.com

9 Types of Valves and Their Applications Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. There are essentially two basic types of steel used to make valves. Other alloying elements, such as nickel (ni),. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. Stainless steel, carbon steel, brass, and bronze are widely used for. Valve Metals Definition.

From engineeringlearn.com

Jacketed Valves Definition, Types, Construction, Materials Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct. Valve Metals Definition.

From bhansalimetalloysinc.com

Popular Metal Types used in Industrial Valves Bhansali Metalloys Inc Valve Metals Definition Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. There are essentially two basic types of steel used to make valves. One is “martensitic” steel and the other is “austenitic” steel. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high. Valve Metals Definition.

From blog.eaglegroupmanufacturers.com

Anatomy of Industrial Valves Valve Metals Definition Other alloying elements, such as nickel (ni),. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. There are essentially two basic types of steel used to make valves. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under.. Valve Metals Definition.

From onlyexcels.blogspot.com

MEP Skills Type Of Valves Used In Piping Valve Metals Definition Other alloying elements, such as nickel (ni),. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. One is “martensitic” steel and the other is “austenitic” steel. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling. Valve Metals Definition.

From blog.thepipingmart.com

What are Control Valves? Selection and Types of Control Valves Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Other alloying elements, such as nickel (ni),. There are essentially two basic types of steel used to make valves. Globe valve a valve whose closure element is a flat. Valve Metals Definition.

From www.artofit.org

Introduction to gate valve Artofit Valve Metals Definition Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. Stainless steel, carbon steel, brass, and bronze are widely. Valve Metals Definition.

From www.avkvalves.eu

Gate valve Learn about gate valves AVK International Valve Metals Definition Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Strength in a valve is its ability to. Valve Metals Definition.

From engineeringlearner.com

Flush Bottom Valve Definition, Types, Components, Working, Application Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Other alloying elements, such as nickel (ni),. Stainless steel, carbon steel, brass, and bronze are widely used for their. Valve Metals Definition.

From www.pinterest.com

What is a valve?14Types Of Valves And Their Working Principle Valve Metals Definition Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Other alloying elements, such as nickel (ni),. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. There are essentially two basic types of. Valve Metals Definition.

From globalflowcontrol.com

Metal Seated Ball Valves Global Flow Control Valve Metals Definition Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. Other alloying elements, such as nickel (ni),. There are essentially two basic types of steel used to make valves.. Valve Metals Definition.

From forumautomation.com

What is a Piston Valve? Valves Industrial Automation, PLC Valve Metals Definition Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Other alloying elements, such as nickel (ni),. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Actually, while the industry is certainly. Valve Metals Definition.

From www.valveking.com

6" Cast Iron Gate Valve Metal Seated, Rising Stem ValveKing Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Actually, while the industry. Valve Metals Definition.

From engineeringlearn.com

Flow Control Valve Definition, Types, Components & Working Principle Valve Metals Definition There are essentially two basic types of steel used to make valves. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. One is “martensitic” steel and the other is “austenitic” steel. Other alloying elements, such as nickel (ni),. Globe valve a valve whose closure element is a flat disc. Valve Metals Definition.

From engineeringlearn.com

Flow Control Valve Definition, Types, Components & Working Principle Valve Metals Definition Other alloying elements, such as nickel (ni),. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel. Valve Metals Definition.

From hardhatengineer.com

What is Plug Valve? A Complete Guide for Engineer Valve Metals Definition Other alloying elements, such as nickel (ni),. There are essentially two basic types of steel used to make valves. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals. Valve Metals Definition.

From www.saferack.com

Solenoid Valves SafeRack's Industrial Index Valve Metals Definition Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. There are essentially two basic types of steel used. Valve Metals Definition.

From www.pinterest.com

Types of Valves List of Valves Names of Valves Mechanical Valve Metals Definition Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Strength in a valve is its ability to withstand the internal stresses generated by containing and controlling the fluid under. Stainless steel, carbon steel, brass, and bronze are widely. Valve Metals Definition.

From www.iqsdirectory.com

Ball Valve What Is It? How Does It Work? Types Of, Uses Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. There are essentially two basic types of steel used to make valves. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Other alloying elements, such as nickel (ni),. Strength in a valve is. Valve Metals Definition.

From qrcvalves.com

Valve Types, Leakages, and Repair QRC Valves Valve Metals Definition Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. One is “martensitic” steel and the other is “austenitic” steel. There are essentially two basic types of steel used to make valves. Stainless steel, carbon steel, brass, and bronze. Valve Metals Definition.

From www.xhval.com

Valve Markings, Ratings & Standards A Full Guide XHVAL Valve Metals Definition Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures and pressures. Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. Globe valve a valve whose closure element is. Valve Metals Definition.

From www.electricalvolt.com

Control Valves Leakage Classifications Electrical Volt Valve Metals Definition Actually, while the industry is certainly formidable, its products are made of steel, iron and a host of other metals and alloys, all of which are used to construct valves, actuators,. One is “martensitic” steel and the other is “austenitic” steel. Stainless steel, carbon steel, brass, and bronze are widely used for their strength, durability, and resistance to high temperatures. Valve Metals Definition.

From www.americanwatercollege.org

American Water College Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Other alloying elements, such as nickel (ni),. There are essentially two basic types of steel used to make valves. Stainless steel, carbon steel, brass,. Valve Metals Definition.

From engineeringlearn.com

Needle Valve Definition, Types, Function & Application Engineering Learn Valve Metals Definition One is “martensitic” steel and the other is “austenitic” steel. There are essentially two basic types of steel used to make valves. Other alloying elements, such as nickel (ni),. Globe valve a valve whose closure element is a flat disc or conical plug sealing on a seat which is usually parallel to the flow axis. Strength in a valve is. Valve Metals Definition.