Plate Grain Direction . This is because grain direction makes sheet metal stronger in some directions and weaker in others. How does grain direction affect sheet metal parts? When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. We need to find the grain direction on a small piece of ar450 2 thick plate. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. We need to bend it and. Grain direction in metal bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. All edges have been trimmed.

from www.mdpi.com

This is because grain direction makes sheet metal stronger in some directions and weaker in others. Grain direction in metal bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. We need to find the grain direction on a small piece of ar450 2 thick plate. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. We need to bend it and. How does grain direction affect sheet metal parts? All edges have been trimmed.

Metals Free FullText Effect of Heat Treatment on the InPlane

Plate Grain Direction We need to bend it and. This is because grain direction makes sheet metal stronger in some directions and weaker in others. All edges have been trimmed. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. We need to bend it and. How does grain direction affect sheet metal parts? Grain direction in metal bending. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. We need to find the grain direction on a small piece of ar450 2 thick plate. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to.

From www.youtube.com

Understanding Grain Direction and Runout Planing Downhill YouTube Plate Grain Direction When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. We need to bend it and. We need to find the grain direction on a small piece of ar450 2 thick plate. How does grain direction affect sheet metal parts? Applying this to metal bending, be it. Plate Grain Direction.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Plate Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. We need to find the grain direction on a small piece of ar450 2 thick plate. How does grain direction affect. Plate Grain Direction.

From www.youtube.com

Grain Direction in Paper What is Paper Grain How to Identify the Plate Grain Direction Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. This is because grain direction makes sheet metal stronger in some directions and weaker in others. How does grain direction affect sheet metal parts? We need to find the grain direction on a small piece of ar450. Plate Grain Direction.

From www.aaaairsupport.com

Metal Grain Direction What You Need To Know AAA Air Support Plate Grain Direction When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. All edges have been trimmed. When working with any steel, but in particular wear resistant steels, it. Plate Grain Direction.

From www.youtube.com

Video Tech Tip Master SOLIDWORKS Sheet Metal Grain Direction YouTube Plate Grain Direction We need to bend it and. Grain direction in metal bending. This is because grain direction makes sheet metal stronger in some directions and weaker in others. How does grain direction affect sheet metal parts? All edges have been trimmed. When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction. Plate Grain Direction.

From blog.papercraftpanda.com

Two Easy Ways to Find Grain Direction in Paper Bookbinding Basics Plate Grain Direction Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. This is because grain direction makes sheet metal stronger in some directions and weaker in others. We. Plate Grain Direction.

From starwaymfg.en.made-in-china.com

Metal Plate Bending Grain Direction in Sheet Metal Bending Custom Sheet Plate Grain Direction We need to find the grain direction on a small piece of ar450 2 thick plate. How does grain direction affect sheet metal parts? We need to bend it and. This is because grain direction makes sheet metal stronger in some directions and weaker in others. When working with plate, pay close attention to whether you are forming with (longitudinal). Plate Grain Direction.

From www.claravision.com

Grain size measurement for metallography Grani Claravision Plate Grain Direction When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Applying this to metal bending, be it plate bending, press braking. Plate Grain Direction.

From www.youtube.com

The Effect Of Grain Direction In Sheet Metal Bending YouTube Plate Grain Direction All edges have been trimmed. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. We need to find the grain direction on a small piece of ar450 2 thick plate. We need to bend it and. This is because grain direction makes sheet metal stronger in some directions and. Plate Grain Direction.

From www.youtube.com

How to detect grain direction and work with it. YouTube Plate Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. How does grain direction affect sheet metal parts? We need to. Plate Grain Direction.

From www.researchgate.net

Grain boundaries of the plates (a) pure tungsten, (b) W0.2 wt Plate Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. The. Plate Grain Direction.

From www.researchgate.net

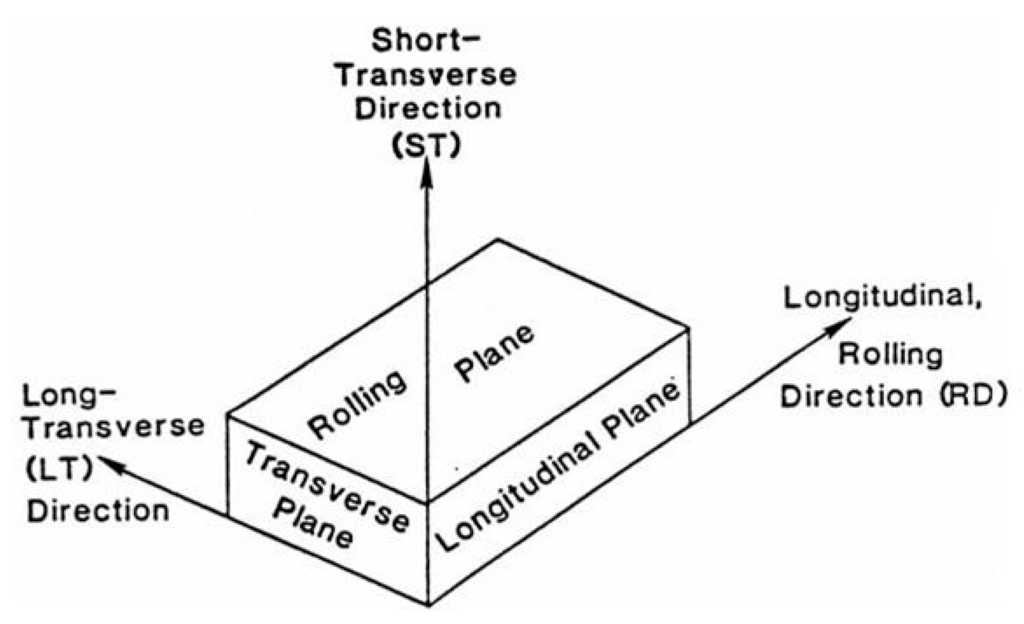

Schematic of a 7000 series aluminum alloy microstructure after rolling Plate Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. We need to bend it and. All edges have been trimmed. How does grain direction affect sheet metal parts? When working with plate, pay close attention to whether you are forming with (longitudinal) or. Plate Grain Direction.

From www.youtube.com

Grain/Coil Direction Annotation in SolidWorks YouTube Plate Grain Direction We need to find the grain direction on a small piece of ar450 2 thick plate. We need to bend it and. Grain direction in metal bending. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. All edges have been trimmed. This is. Plate Grain Direction.

From www.thefabricator.com

What sheet metal shops wish you knew Reasonable tolerances, grain Plate Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet metal stronger in some directions and weaker in others. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming,. Plate Grain Direction.

From www.stressebook.com

Generic MMPDS Mechanical Properties Table Plate Grain Direction When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. How does grain direction affect sheet metal parts? We need to bend it and. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and. Plate Grain Direction.

From www.es3.co.nz

The Importance of Grain Direction in Folding ES3 Plate Grain Direction We need to bend it and. All edges have been trimmed. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. The direction of the grain is. Plate Grain Direction.

From thesapientimages.blogspot.com

Sheet Metal Grain Direction Symbol Grain direction is usually Plate Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet metal stronger in some directions and weaker in others. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming,. Plate Grain Direction.

From www.thefabricator.com

Grain direction’s effect on sheet metal bending Plate Grain Direction We need to bend it and. We need to find the grain direction on a small piece of ar450 2 thick plate. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. How does grain direction affect sheet metal parts? All edges have been trimmed. The direction. Plate Grain Direction.

From www.stressebook.com

Generic MMPDS Mechanical Properties Table Plate Grain Direction We need to bend it and. How does grain direction affect sheet metal parts? The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. All edges have been trimmed. Applying this to metal bending, be it plate bending, press braking or any other type. Plate Grain Direction.

From aluminumplatehensei.blogspot.com

Aluminum Plate Grain Direction In Aluminum Plate Plate Grain Direction We need to find the grain direction on a small piece of ar450 2 thick plate. Grain direction in metal bending. We need to bend it and. All edges have been trimmed. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. How does grain direction affect sheet metal parts?. Plate Grain Direction.

From www.youtube.com

Basics on Bridge Plate Grain Direction YouTube Plate Grain Direction Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. This is because grain direction makes sheet metal stronger in some directions and weaker in others. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. When. Plate Grain Direction.

From thesapientimages.blogspot.com

Sheet Metal Grain Direction Symbol Grain direction is usually Plate Grain Direction Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. We need to find the grain direction on a small piece of ar450 2 thick plate. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending,. Plate Grain Direction.

From www.mdpi.com

Metals Free FullText Grain Structure Rearrangement by Means the Plate Grain Direction How does grain direction affect sheet metal parts? All edges have been trimmed. When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. We need to find the grain direction on a small piece of ar450 2 thick plate. Applying this to metal bending, be it plate. Plate Grain Direction.

From www.renaissancewoodworker.com

Grain Direction The Renaissance Woodworker Plate Grain Direction How does grain direction affect sheet metal parts? The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. This is because grain direction makes. Plate Grain Direction.

From www.researchgate.net

Grain structure of the rolled surface (on top) and in cross section Plate Grain Direction When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. How does grain direction affect sheet metal parts? Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. All edges have been trimmed. We. Plate Grain Direction.

From www.researchgate.net

Comparison grain direction (DP980HY) Download Scientific Diagram Plate Grain Direction We need to bend it and. All edges have been trimmed. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. We need to find the grain direction on a small piece of ar450 2 thick plate. How does grain direction affect sheet metal parts? Applying this to metal bending,. Plate Grain Direction.

From www.phase-trans.msm.cam.ac.uk

Metallography of Steels Plate Grain Direction How does grain direction affect sheet metal parts? Grain direction in metal bending. We need to find the grain direction on a small piece of ar450 2 thick plate. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. When working with plate, pay. Plate Grain Direction.

From www.researchgate.net

Recrystallization and growth of grains in metals. The new, strainfree Plate Grain Direction When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. We need to bend it and. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. All edges have been trimmed. We need to find the grain. Plate Grain Direction.

From www.popularwoodworking.com

Understanding Grain Direction Popular Woodworking Plate Grain Direction How does grain direction affect sheet metal parts? Grain direction in metal bending. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be. Plate Grain Direction.

From www.mdpi.com

Metals Free FullText Effect of Heat Treatment on the InPlane Plate Grain Direction How does grain direction affect sheet metal parts? When working with any steel, but in particular wear resistant steels, it is imperative that you know the grain direction of the plate. We need to bend it and. Grain direction in metal bending. This is because grain direction makes sheet metal stronger in some directions and weaker in others. The direction. Plate Grain Direction.

From agclassroom.org

Understanding MyPlate (Grades 35) National Agriculture in the Classroom Plate Grain Direction Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to. Grain direction in metal bending. How does grain direction affect sheet metal parts? We need to bend it and. All edges have been trimmed. We need to find the grain direction on a small piece of ar450. Plate Grain Direction.

From geologylearn.blogspot.com

Learning Geology The Basis of Rock Classification Plate Grain Direction Grain direction in metal bending. We need to find the grain direction on a small piece of ar450 2 thick plate. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction. All edges have been trimmed. When working with any steel, but in particular wear resistant steels, it is imperative. Plate Grain Direction.

From sites.psu.edu

So, what did your plate look like today? Penn State Dining Dietitians Plate Grain Direction We need to bend it and. This is because grain direction makes sheet metal stronger in some directions and weaker in others. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Grain direction in metal bending. All edges have been trimmed. When working. Plate Grain Direction.

From justaplate.com

The Plate Method How To Make Healthy Eating Simple Plate Grain Direction We need to find the grain direction on a small piece of ar450 2 thick plate. All edges have been trimmed. How does grain direction affect sheet metal parts? We need to bend it and. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation. Plate Grain Direction.

From www.researchgate.net

Schematic sketches illustrating grain refining during welding (a Plate Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. When working with any steel, but in particular wear resistant steels, it is imperative that you know the. Plate Grain Direction.