Heat Exchanger Natural Gas Processing . Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Building on decades of lng. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac.

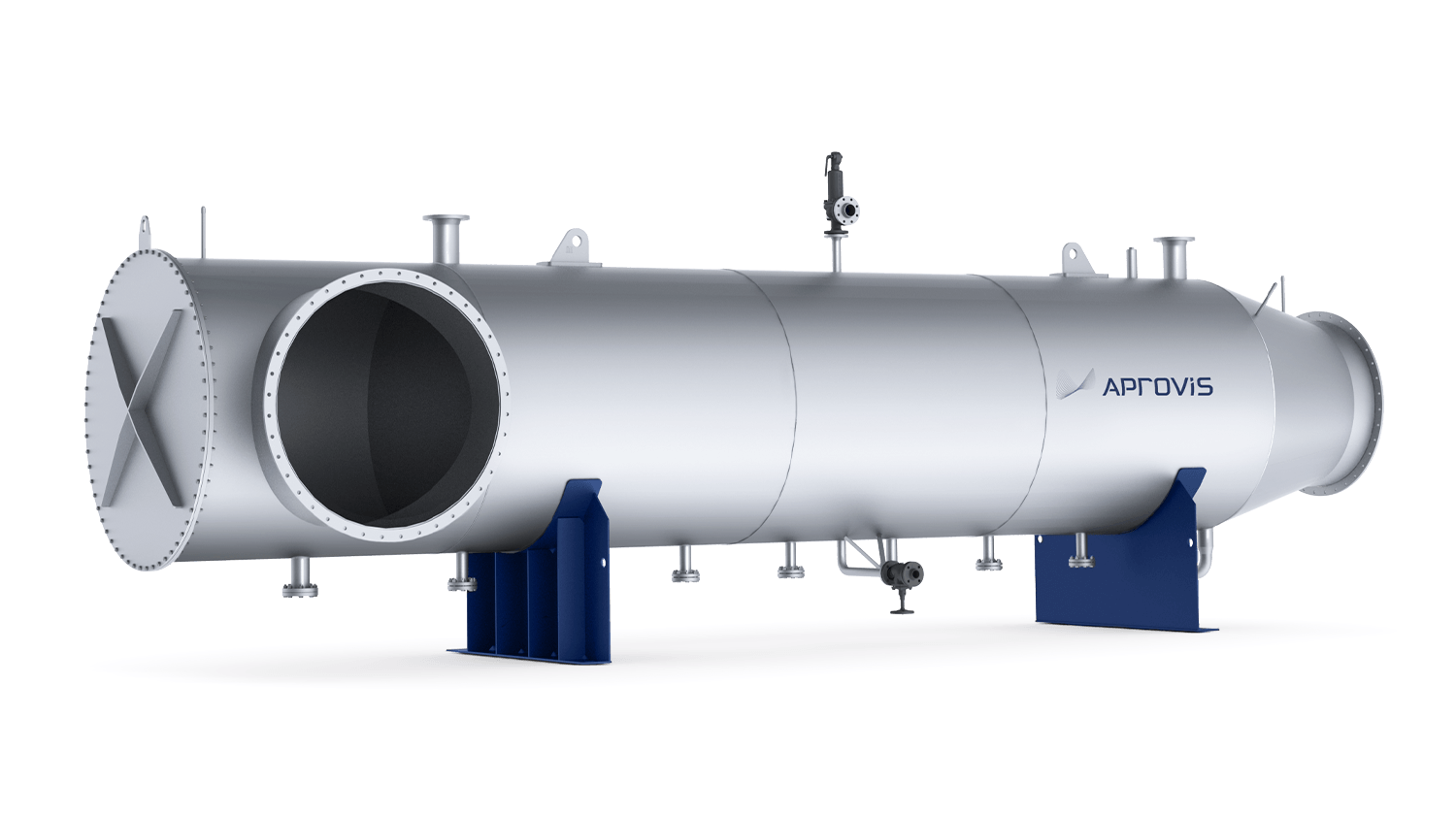

from www.aprovis.com

In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Building on decades of lng. Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream.

Exhaust gas heat exchangers APROVIS Better Performance Energy Systems

Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Building on decades of lng. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream.

From dairyprocessinghandbook.tetrapak.com

Heat exchangers Dairy Processing Handbook Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Heat exchangers are among the most important components determining. Heat Exchanger Natural Gas Processing.

From www.titanmf.com

Oil Heat Exchangers Gas Heat Exchangers Heat Exchanger Natural Gas Processing Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and. Heat Exchanger Natural Gas Processing.

From www.sigmathermal.com

Process Heating for the Gas Processing Industry Sigma Thermal Heat Exchanger Natural Gas Processing In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas. Heat Exchanger Natural Gas Processing.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Heat Exchanger Natural Gas Processing In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency. Heat Exchanger Natural Gas Processing.

From www.torq-n-seal.com

How Do Shell And Tube Heat Exchangers Work? Torq N' Seal® Heat Exchanger Natural Gas Processing The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Building on decades of lng. In fuel. Heat Exchanger Natural Gas Processing.

From www.geurtsheatexchangers.com

GasGas Shell & tube heat exchanger Geurts Heat Exchangers Heat Exchanger Natural Gas Processing Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Building on decades. Heat Exchanger Natural Gas Processing.

From www.thomasnet.com

Understanding Heat Exchangers Heat Exchanger Natural Gas Processing The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Wildly used in a. Heat Exchanger Natural Gas Processing.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Heat Exchanger Natural Gas Processing Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Building on decades of lng. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. In fuel. Heat Exchanger Natural Gas Processing.

From www.tonex.com

Fundamentals of Natural Gas Processing Tonex Training Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Wildly used in a plethora of industrial applications. Heat Exchanger Natural Gas Processing.

From www.filsonfilters.com

Gas Heat Exchanger Manufacturer and Supplier in China Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can. Heat Exchanger Natural Gas Processing.

From www.dreamstime.com

Gas Cooler at Oil and Gas Central Processing Platform, Heat Exchanger Heat Exchanger Natural Gas Processing Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Wildly used in. Heat Exchanger Natural Gas Processing.

From www.dreamstime.com

Fin and Tube Heat Exchanger on Oil and Gas Central Processing Platform Heat Exchanger Natural Gas Processing The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Heat exchangers are among. Heat Exchanger Natural Gas Processing.

From flashsplash.org

Heat Exchangers Unveiled The Masters of Thermal Transformation Heat Exchanger Natural Gas Processing Building on decades of lng. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a. Heat Exchanger Natural Gas Processing.

From brainrack.co

Everything You Need To Know About Heat Exchangers Brainrack.Co Heat Exchanger Natural Gas Processing Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Building on decades of lng. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Wildly used in a plethora of industrial applications such as. Heat Exchanger Natural Gas Processing.

From www.titanmf.com

Oil Heat Exchangers Gas Heat Exchangers Heat Exchanger Natural Gas Processing Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Heat exchangers are an essential unit operation in the design of. Heat Exchanger Natural Gas Processing.

From www.titanmf.com

Oil Heat Exchangers Gas Heat Exchangers Heat Exchanger Natural Gas Processing Building on decades of lng. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of. Heat Exchanger Natural Gas Processing.

From engineeringlearn.com

5 Types of Heat Exchanger Definition, Parts and Application Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Wildly used in a plethora of industrial applications such. Heat Exchanger Natural Gas Processing.

From hzwkpche.com

LNG heat exchanger Natural gas FGSS, BOG cooler, offshore Heat Exchanger Natural Gas Processing Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such. Heat Exchanger Natural Gas Processing.

From www.andersonprocess.com

A Closer Look at Heat Exchangers Anderson Process Heat Exchanger Natural Gas Processing Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Heat exchangers are an. Heat Exchanger Natural Gas Processing.

From www.hofmann-heatexchanger.com

Plate Heat Exchanger For Oil & Gas Heat Exchanger Natural Gas Processing Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. In fuel gas supply systems (fgss), heatric. Heat Exchanger Natural Gas Processing.

From multitex-group.com

Pressure Vessels & Heat Exchanger Division Multitex Group Heat Exchanger Natural Gas Processing Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Building on decades of lng. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Wildly used in a plethora of industrial applications such as oil and gas,. Heat Exchanger Natural Gas Processing.

From www.aprovis.com

Exhaust gas heat exchangers APROVIS Better Performance Energy Systems Heat Exchanger Natural Gas Processing Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach. Heat Exchanger Natural Gas Processing.

From www.geurtsheatexchangers.com

Gas Gas heat exchanger Geurts Heat Exchangers Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility.. Heat Exchanger Natural Gas Processing.

From brandfuge.com

What is a Tube Heat Exchanger and How Does it Work? BrandFuge Heat Exchanger Natural Gas Processing Building on decades of lng. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Heat exchangers are an essential unit operation in the design of chemical processes, usually. Heat Exchanger Natural Gas Processing.

From www.pickhvac.com

Everything You Need To Know About Heat Exchanger Heat Exchanger Natural Gas Processing Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity. Heat Exchanger Natural Gas Processing.

From energas.co.za

Heating of Natural Gas Heat Exchangers Energas Technologies Heat Exchanger Natural Gas Processing Building on decades of lng. Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility.. Heat Exchanger Natural Gas Processing.

From www.titanmf.com

Oil Heat Exchangers Gas Heat Exchangers Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Heat exchangers. Heat Exchanger Natural Gas Processing.

From www.youtube.com

HEAT EXCHANGERS QUESTION& ANSWERS OIL & GAS PROFESSIONAL YouTube Heat Exchanger Natural Gas Processing Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia,. Heat Exchanger Natural Gas Processing.

From www.hofmann-heatexchanger.com

LNG Heat Exchanger HFM Plate Heat Exchanger for LNG Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers. Heat Exchanger Natural Gas Processing.

From norenthermal.com

The Role of Heat Exchangers in Oil & Gas Processing Noren Thermal, Inc. Heat Exchanger Natural Gas Processing The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. Building on decades of lng. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Wildly used in a plethora of. Heat Exchanger Natural Gas Processing.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Heat Exchanger Natural Gas Processing Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Building on decades of lng. Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a. Heat Exchanger Natural Gas Processing.

From www.sigatech.pl

Gas multistream heat exchanger SigaTech Heat Exchanger Natural Gas Processing Our cwhes act as the main cryogenic heat exchanger (mche) or precooler in numerous lng plants worldwide. Building on decades of lng. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. In fuel gas supply. Heat Exchanger Natural Gas Processing.

From www.alaquainc.com

Transform Oil and Gas Processing by Advanced Heat Exchanger Heat Exchanger Natural Gas Processing Natural gas processing plants use physical and chemical processes to separate and recover valuable hydrocarbon fluids from a gas stream. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are among the most important components determining the energy efficiency of cryogenic systems. Our cwhes act as the main. Heat Exchanger Natural Gas Processing.

From blog.softinway.com

Detailed Simulation of Heat Exchangers Turbomachinery blog Heat Exchanger Natural Gas Processing Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. In fuel gas supply systems (fgss), heatric pches are supporting the growth of cleaner engine fuels such as methane and ammonia, replacing. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food. Heat Exchanger Natural Gas Processing.

From sdwintech.en.made-in-china.com

Gas Condenser Heat Transfer Cooling Block Heat Exchanger for Petroleum Heat Exchanger Natural Gas Processing Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. The designed heat exchanger can efficiently cool oil and gas from 40 °c to 30 °c, and the oil and gas processing capacity can reach 870 m 3 /h, which is conducive to realizing. In fuel gas supply systems (fgss), heatric. Heat Exchanger Natural Gas Processing.