Gearbox Design Requirements . 141 rows wind energy generation systems — part 4: Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. This webinar covers how to design gearboxes (gear drives) that last longer & perform better: Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Design requirements for wind turbine gearboxes The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. From application factors & gear type selection to calculations & agma ratings.

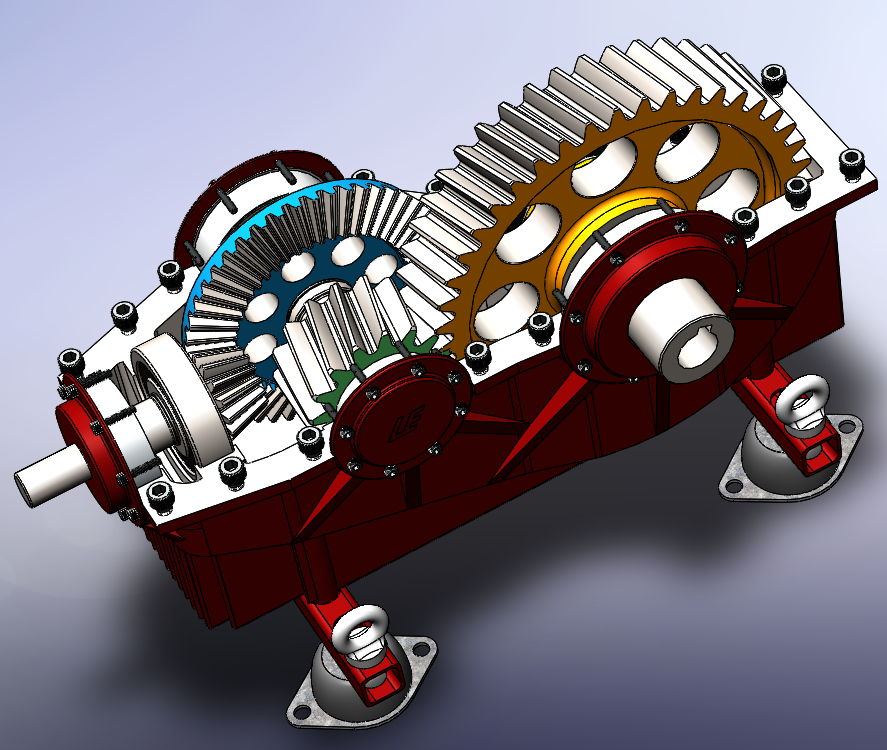

from lannix3d.com.au

Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. 141 rows wind energy generation systems — part 4: Design requirements for wind turbine gearboxes The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. This webinar covers how to design gearboxes (gear drives) that last longer & perform better: Devising an optimal design is often considered as the most important stage in the development of a new gearbox. From application factors & gear type selection to calculations & agma ratings. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset.

Industrial Gearbox Design Lannix 3D

Gearbox Design Requirements Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. From application factors & gear type selection to calculations & agma ratings. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Design requirements for wind turbine gearboxes Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. 141 rows wind energy generation systems — part 4: This webinar covers how to design gearboxes (gear drives) that last longer & perform better:

From darkmaster1814.github.io

Gearbox Design Project Gearbox Design Requirements 141 rows wind energy generation systems — part 4: Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. There are many different gear rating methods in use today, and they can give substantially different results for any. Gearbox Design Requirements.

From reidmphillips.blogspot.com

Reid's Trunk Gearbox design Gearbox Design Requirements Design requirements for wind turbine gearboxes The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission.. Gearbox Design Requirements.

From innovationdiscoveries.space

What are the Main Components of the Gear Box? Gearbox Design Requirements The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. 141 rows wind energy generation systems — part 4: Devising an optimal design is often considered as the most important stage in the development of a new gearbox. Design requirements for wind turbine gearboxes Firstly,. Gearbox Design Requirements.

From www.wisegeek.org

What is a Gearbox? (with pictures) Gearbox Design Requirements Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. From application factors & gear type selection to calculations & agma ratings. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. 141 rows wind energy generation systems —. Gearbox Design Requirements.

From www.chegg.com

Solved Project 1 Design of a Gearbox Design the gearbox Gearbox Design Requirements This webinar covers how to design gearboxes (gear drives) that last longer & perform better: From application factors & gear type selection to calculations & agma ratings. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. There are many different gear rating methods in. Gearbox Design Requirements.

From www.researchgate.net

Torque Distribution Gearbox. All the parts of the proposed design can Gearbox Design Requirements There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. 141 rows wind energy generation systems — part 4: Devising. Gearbox Design Requirements.

From www.youtube.com

How to Design Single Stage Reduction Helical Gear Box 344 Gearbox Design Requirements From application factors & gear type selection to calculations & agma ratings. 141 rows wind energy generation systems — part 4: Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. Design requirements for wind turbine gearboxes Devising an optimal design is often considered as the most important stage in the development of a. Gearbox Design Requirements.

From www.youtube.com

Multi Stage Gearbox Design Club Mechanical YouTube Gearbox Design Requirements There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in. Gearbox Design Requirements.

From maisonrcm.com

Precision plastic gears gear train design experts Gearbox Design Requirements 141 rows wind energy generation systems — part 4: Devising an optimal design is often considered as the most important stage in the development of a new gearbox. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. Design requirements for wind turbine gearboxes The life of gear depends on multiple factors such as. Gearbox Design Requirements.

From www.youtube.com

How to design a Gearbox ? Progressive and Geometric Gearbox YouTube Gearbox Design Requirements Devising an optimal design is often considered as the most important stage in the development of a new gearbox. Design requirements for wind turbine gearboxes 141 rows wind energy generation systems — part 4: Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. This webinar covers how to design gearboxes (gear drives) that. Gearbox Design Requirements.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Gearbox Design Requirements Design requirements for wind turbine gearboxes 141 rows wind energy generation systems — part 4: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. From. Gearbox Design Requirements.

From www.biopelletmachines.com

Industrial GearboxMain features and applications Gearbox Design Requirements Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. Design requirements for. Gearbox Design Requirements.

From www.youtube.com

How to design a Vertical Reduction Helical Gear Box Ratio = 12 360 Gearbox Design Requirements Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. 141 rows wind energy generation systems — part 4: From application factors & gear type selection to calculations & agma ratings. Devising an. Gearbox Design Requirements.

From www.howacarworks.com

How manual gearboxes work How a Car Works Gearbox Design Requirements 141 rows wind energy generation systems — part 4: This webinar covers how to design gearboxes (gear drives) that last longer & perform better: Devising an optimal design is often considered as the most important stage in the development of a new gearbox. Design requirements for wind turbine gearboxes Discover the steps of gearbox design—from analysis to manufacturing and quality. Gearbox Design Requirements.

From jiga.io

Design for Assembly Principles, Application and Guidelines Gearbox Design Requirements Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. 141 rows wind energy generation systems — part 4: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine,. Gearbox Design Requirements.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Gearbox Design Requirements This webinar covers how to design gearboxes (gear drives) that last longer & perform better: Design requirements for wind turbine gearboxes Devising an optimal design is often considered as the most important stage in the development of a new gearbox. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in. Gearbox Design Requirements.

From nevonprojects.com

3 Speed Gearbox Mechanism Nevon Projects Gearbox Design Requirements From application factors & gear type selection to calculations & agma ratings. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. 141 rows wind energy generation systems — part 4: There are many different gear rating methods in use today, and they can give substantially different results for any given. Gearbox Design Requirements.

From www.powertransmissionworld.com

Design optimization of gearbox and driveline systems Power Gearbox Design Requirements From application factors & gear type selection to calculations & agma ratings. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Design requirements for wind turbine gearboxes 141 rows wind energy generation systems — part 4: Firstly, engineers define operational needs like torque, speed, power transmission, and environmental. Gearbox Design Requirements.

From omarhusain.co

Gear Box Mechanical Design Omar Husain Gearbox Design Requirements From application factors & gear type selection to calculations & agma ratings. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. The life of gear depends on multiple factors such as lubrication,. Gearbox Design Requirements.

From tyocomlibe.weebly.com

Gearboxdesignprojectppt Gearbox Design Requirements Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. This webinar covers how. Gearbox Design Requirements.

From www.instructables.com

Understanding Motor and Gearbox Design 10 Steps (with Pictures Gearbox Design Requirements This webinar covers how to design gearboxes (gear drives) that last longer & perform better: Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. 141 rows wind energy generation systems — part 4: From application factors & gear type selection to calculations & agma ratings. Firstly, engineers define operational needs like torque, speed,. Gearbox Design Requirements.

From www.youtube.com

Sliding mesh gearbox How Gearbox works Construction and Operation Gearbox Design Requirements There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Design requirements for wind turbine gearboxes Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. This webinar covers how to design gearboxes (gear drives) that last longer & perform better: From application factors & gear. Gearbox Design Requirements.

From www.scribd.com

GearBox Design PDF Gear Transmission (Mechanics) Gearbox Design Requirements This webinar covers how to design gearboxes (gear drives) that last longer & perform better: Design requirements for wind turbine gearboxes Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. There. Gearbox Design Requirements.

From engineeringlearn.com

5 Types of Gearbox and Their Components Guide] Engineering Gearbox Design Requirements There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. From application factors & gear type selection to calculations & agma ratings. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear. Gearbox Design Requirements.

From www.researchgate.net

Main requirements of the demonstration gearbox design problem Gearbox Design Requirements Devising an optimal design is often considered as the most important stage in the development of a new gearbox. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. 141 rows wind energy generation systems — part 4: There are many different gear rating methods. Gearbox Design Requirements.

From www.researchgate.net

3D model of automotive gearbox and its components used for load Gearbox Design Requirements 141 rows wind energy generation systems — part 4: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. From application factors & gear type selection to calculations & agma ratings. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical. Gearbox Design Requirements.

From www.youtube.com

How to Design a Single Stage Gearbox 342 DesignWithAjay Gearbox Design Requirements From application factors & gear type selection to calculations & agma ratings. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. 141 rows. Gearbox Design Requirements.

From www.slideshare.net

Design of Gear Box Gearbox Design Requirements Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. 141 rows wind energy generation systems — part 4: The life of. Gearbox Design Requirements.

From www.researchgate.net

Schematic of the gearbox in the construction equipment Gearbox Design Requirements Devising an optimal design is often considered as the most important stage in the development of a new gearbox. From application factors & gear type selection to calculations & agma ratings. This webinar covers how to design gearboxes (gear drives) that last longer & perform better: Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical. Gearbox Design Requirements.

From www.chiefdelphi.com

Designing a 2 Speed Gearbox Technical Chief Delphi Gearbox Design Requirements 141 rows wind energy generation systems — part 4: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Design requirements for wind turbine gearboxes Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. Devising an optimal design is often considered. Gearbox Design Requirements.

From mechanicaljungle.com

Gearbox Introduction What Is a Gearbox? Types of Gearboxes Gearbox Design Requirements Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. 141 rows wind energy generation systems — part 4: There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. The. Gearbox Design Requirements.

From www.semanticscholar.org

Figure 5 from Design And Analysis Of 9 Speed Gearbox Semantic Scholar Gearbox Design Requirements Design requirements for wind turbine gearboxes 141 rows wind energy generation systems — part 4: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Devising an optimal design is often considered as the most important stage in the development of a new gearbox. Firstly,. Gearbox Design Requirements.

From joihjgngk.blob.core.windows.net

Gearbox Design Pdf at Michael Omeara blog Gearbox Design Requirements Firstly, engineers define operational needs like torque, speed, power transmission, and environmental conditions. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Design requirements for wind turbine gearboxes From application factors & gear type selection to calculations & agma ratings. There are many different. Gearbox Design Requirements.

From www.youtube.com

Gearbox Design Part 3 Design of Key, Assembly of Shaft and Bearing Gearbox Design Requirements Discover the steps of gearbox design—from analysis to manufacturing and quality assurance—to optimize mechanical power transmission. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. 141 rows wind energy generation systems — part 4: From application factors & gear type selection to calculations & agma ratings. Firstly, engineers. Gearbox Design Requirements.

From lannix3d.com.au

Industrial Gearbox Design Lannix 3D Gearbox Design Requirements Devising an optimal design is often considered as the most important stage in the development of a new gearbox. There are many different gear rating methods in use today, and they can give substantially different results for any given gearset. From application factors & gear type selection to calculations & agma ratings. The life of gear depends on multiple factors. Gearbox Design Requirements.