Output Shaft Bearing And Seal . And it's not a weep. It's basically leaking past the seal (bearing and shaft seal) while cold. My car has the same diff type with the. Expect fixings to be troublesome. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. The nut had been staked twice and had gasket sealant on it, further proof the. If you measure at the flange hole you will need. It's a leak, implying a relatively large gap. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). No heat, pressure or motion from operation. Use penetrating oil and repeatedly tighten them then loosen off.

from axleaddict.com

My car has the same diff type with the. Expect fixings to be troublesome. It's basically leaking past the seal (bearing and shaft seal) while cold. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). No heat, pressure or motion from operation. The nut had been staked twice and had gasket sealant on it, further proof the. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. Use penetrating oil and repeatedly tighten them then loosen off. If you measure at the flange hole you will need.

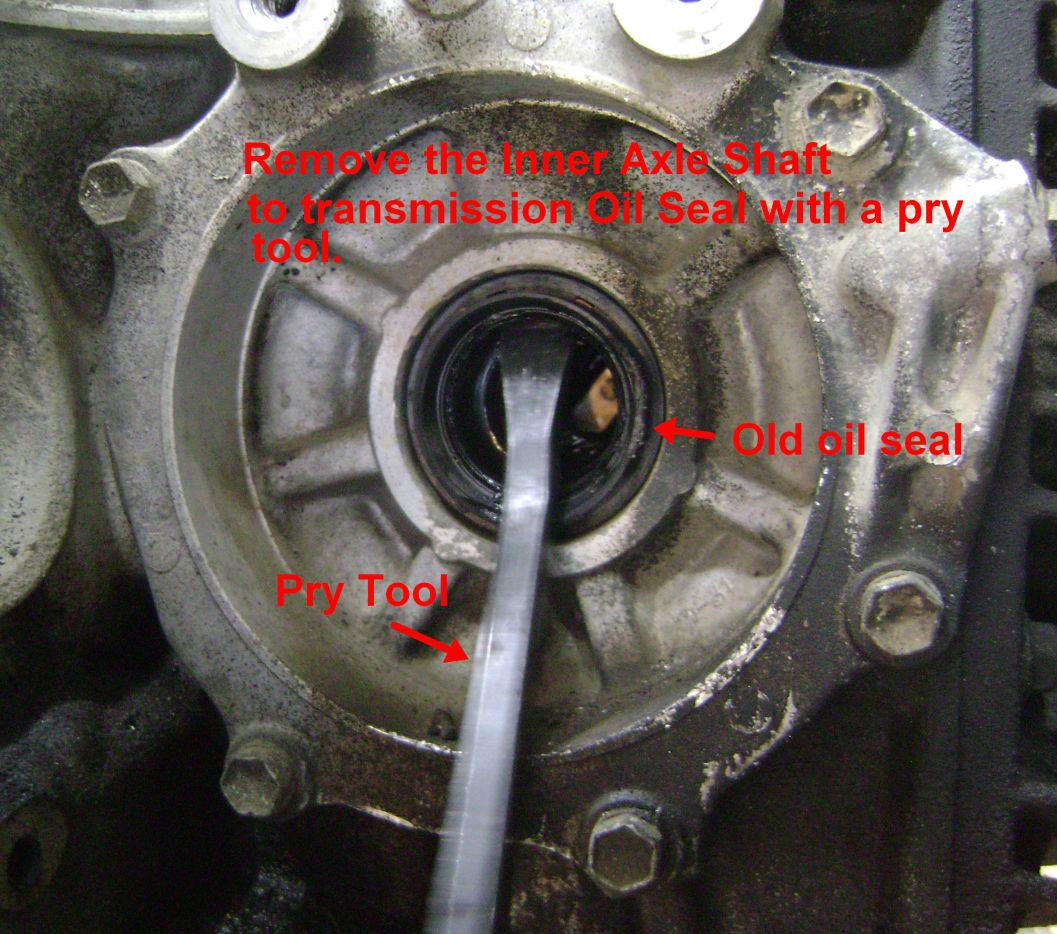

Replacing the CV Axle Shaft and Output Shaft Seal, or Replacing a CV

Output Shaft Bearing And Seal Expect fixings to be troublesome. My car has the same diff type with the. And it's not a weep. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. No heat, pressure or motion from operation. Use penetrating oil and repeatedly tighten them then loosen off. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). It's basically leaking past the seal (bearing and shaft seal) while cold. If you measure at the flange hole you will need. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. The nut had been staked twice and had gasket sealant on it, further proof the. It's a leak, implying a relatively large gap. Expect fixings to be troublesome.

From alltimediesel.com.au

Gearbox output shaft bearing 5556503 All Time Diesel Output Shaft Bearing And Seal If you measure at the flange hole you will need. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. It's. Output Shaft Bearing And Seal.

From www.riversidegear.com

Image Gallery > Front Output Shaft Seal Installation Tool GM 136 236 Output Shaft Bearing And Seal Use penetrating oil and repeatedly tighten them then loosen off. No heat, pressure or motion from operation. And it's not a weep. It's basically leaking past the seal (bearing and shaft seal) while cold. The nut had been staked twice and had gasket sealant on it, further proof the. Expect fixings to be troublesome. It's a leak, implying a relatively. Output Shaft Bearing And Seal.

From advanced-emc.com

PTFE Rotary Shaft Seals Polymer Bearings Rotary PTFE Lip Seals Output Shaft Bearing And Seal It's basically leaking past the seal (bearing and shaft seal) while cold. No heat, pressure or motion from operation. It's a leak, implying a relatively large gap. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. Use penetrating oil and repeatedly tighten them then loosen off. Expect fixings to. Output Shaft Bearing And Seal.

From www.carid.com

SKF® Chevy Silverado 1500 2002 Manual Transmission Output Shaft Seal Output Shaft Bearing And Seal Expect fixings to be troublesome. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. It's a leak, implying a relatively large gap. It's basically leaking past the seal (bearing and shaft seal) while cold. If you measure at the flange hole you will need. No heat, pressure or motion. Output Shaft Bearing And Seal.

From www.partsnext.com

Toyota 9031148022 SEAL, OIL (FOR OUTPUT SHAFT BEARING FRONT RETAINER) Output Shaft Bearing And Seal If you measure at the flange hole you will need. It's a leak, implying a relatively large gap. It's basically leaking past the seal (bearing and shaft seal) while cold. The nut had been staked twice and had gasket sealant on it, further proof the. Expect fixings to be troublesome. My car has the same diff type with the. Use. Output Shaft Bearing And Seal.

From forums.jag-lovers.com

How do the output shafts seal? ('71 S3) EType Jaglovers Forums Output Shaft Bearing And Seal And it's not a weep. It's a leak, implying a relatively large gap. If you measure at the flange hole you will need. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). My seal puller worked great as you can lever. Output Shaft Bearing And Seal.

From www.holden.co.uk

Differential Output Shaft Bearing Sealed bearing supplied with two Output Shaft Bearing And Seal And it's not a weep. No heat, pressure or motion from operation. If you measure at the flange hole you will need. Expect fixings to be troublesome. It's basically leaking past the seal (bearing and shaft seal) while cold. It's a leak, implying a relatively large gap. Use penetrating oil and repeatedly tighten them then loosen off. When it has. Output Shaft Bearing And Seal.

From www.alltranz.com.au

99480 BEARING OUTPUT SHAFT (6HP26/8HP45) Transmissions Output Shaft Bearing And Seal My car has the same diff type with the. Use penetrating oil and repeatedly tighten them then loosen off. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. Expect fixings to be troublesome. When it has just bit of play measure the force/torque required to turn the shaft, cause. Output Shaft Bearing And Seal.

From www.youtube.com

4 Wheels Drive Transmission Output Shaft Seal Replacement 4l80e YouTube Output Shaft Bearing And Seal My car has the same diff type with the. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). It's a leak, implying a relatively large gap. My seal puller worked great as you can lever off the output shaft spline, came. Output Shaft Bearing And Seal.

From www.sixityauto.com

19992017 Chevrolet Silverado 1500 4.3L 5.3L V6 V8 SKF Transfer Case Output Shaft Bearing And Seal My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. And it's not a weep. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. No heat, pressure or motion from operation. My car has the same diff type. Output Shaft Bearing And Seal.

From www.onlinegearboxparts.com

LT230 Output Shaft Bearing (STC1130) Online Gearbox Parts Shop Output Shaft Bearing And Seal My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. It's a leak, implying a relatively large gap. My car has the same diff type with the. And it's not a weep. Expect fixings to be troublesome. It's basically leaking past the seal (bearing and shaft seal) while cold. No. Output Shaft Bearing And Seal.

From www.johncraddockltd.co.uk

217490 Output Shaft Bearing Rear. Output Shaft Bearing And Seal My car has the same diff type with the. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. And it's not a weep. Use penetrating oil and repeatedly tighten them then loosen off. No heat, pressure or motion from operation. It's basically leaking past the seal (bearing and. Output Shaft Bearing And Seal.

From www.carid.com

National® 710138 Automatic Transmission Output Shaft Seal Output Shaft Bearing And Seal Use penetrating oil and repeatedly tighten them then loosen off. Expect fixings to be troublesome. It's a leak, implying a relatively large gap. My car has the same diff type with the. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. If you measure at the flange hole you. Output Shaft Bearing And Seal.

From forums.jag-lovers.com

How do the output shafts seal? ('71 S3) EType Jaglovers Forums Output Shaft Bearing And Seal It's a leak, implying a relatively large gap. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. My car has the same diff type with the. It's basically leaking past the seal (bearing and shaft seal) while cold. And it's not a weep. The nut had been staked twice. Output Shaft Bearing And Seal.

From www.justanswer.com

Q&A Front Output Shaft Bearing & Seal Replacement JustAnswer Output Shaft Bearing And Seal If you measure at the flange hole you will need. Expect fixings to be troublesome. My car has the same diff type with the. And it's not a weep. It's basically leaking past the seal (bearing and shaft seal) while cold. The nut had been staked twice and had gasket sealant on it, further proof the. Use penetrating oil and. Output Shaft Bearing And Seal.

From www.carid.com

National® 5206 Manual Transmission Output Shaft Seal Kit Output Shaft Bearing And Seal The nut had been staked twice and had gasket sealant on it, further proof the. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). It's basically leaking past the seal (bearing and shaft seal) while cold. I am in the process. Output Shaft Bearing And Seal.

From www.pumppartsdirect.com

AFI L27L35 Output Shaft Bearing Seal Kit Output Shaft Bearing And Seal If you measure at the flange hole you will need. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. And it's not a weep. The nut had been staked twice and had gasket sealant on it, further proof the. When it has just bit of play measure the. Output Shaft Bearing And Seal.

From www.veetwo.com

Seal Output Shaft Inner Seals Bearings, Seals and O'Rings Vee Output Shaft Bearing And Seal I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. Use penetrating oil and repeatedly tighten them then loosen off. My car has the same diff type with the. If you measure at the flange hole you will need. And it's not a weep. When it has just bit. Output Shaft Bearing And Seal.

From www.youtube.com

How to Replace CV Axle and CV Axle Seal (Output Shaft Seal) YouTube Output Shaft Bearing And Seal I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. The nut had been staked twice and had gasket sealant on it, further proof the. If you measure at the flange hole you will need. Expect fixings to be troublesome. It's basically leaking past the seal (bearing and shaft. Output Shaft Bearing And Seal.

From axleaddict.com

Replacing the CV Axle Shaft and Output Shaft Seal, or Replacing a CV Output Shaft Bearing And Seal It's a leak, implying a relatively large gap. Use penetrating oil and repeatedly tighten them then loosen off. And it's not a weep. If you measure at the flange hole you will need. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. I am in the process of replacing. Output Shaft Bearing And Seal.

From www.carid.com

National® Ford Taurus 2015 Automatic Transmission Output Shaft Seal Output Shaft Bearing And Seal Expect fixings to be troublesome. If you measure at the flange hole you will need. No heat, pressure or motion from operation. Use penetrating oil and repeatedly tighten them then loosen off. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. It's basically leaking past the seal (bearing. Output Shaft Bearing And Seal.

From jennifers68jag.blogspot.com

Jennifer's Jaguar Replacing the output shaft seals and bearings Output Shaft Bearing And Seal My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. If you measure at the flange hole you will need. Use penetrating oil and repeatedly tighten them then loosen off. It's basically leaking past the seal (bearing and shaft seal) while cold. I am in the process of replacing the. Output Shaft Bearing And Seal.

From www.carid.com

Genuine® 9L8Z 1177G Automatic Transmission Output Shaft Seal Output Shaft Bearing And Seal If you measure at the flange hole you will need. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). The nut had been staked twice and had gasket sealant on it, further proof the. Use penetrating oil and repeatedly tighten them. Output Shaft Bearing And Seal.

From www.clubfrontier.org

Transfer Case Output Shaft Front Seal Front Replacement Info Nissan Output Shaft Bearing And Seal If you measure at the flange hole you will need. Expect fixings to be troublesome. Use penetrating oil and repeatedly tighten them then loosen off. It's a leak, implying a relatively large gap. And it's not a weep. My car has the same diff type with the. My seal puller worked great as you can lever off the output shaft. Output Shaft Bearing And Seal.

From www.carid.com

National® 710502 Front Driver Side Axle Output Shaft Seal Output Shaft Bearing And Seal No heat, pressure or motion from operation. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. And it's not a weep. Expect fixings to be troublesome. The nut had been staked twice and had gasket sealant on it, further proof the. Use penetrating oil and repeatedly tighten them then. Output Shaft Bearing And Seal.

From www.autozone.com

Repair Guides Transfer Case Front Or Rear Output Shaft Seal Output Shaft Bearing And Seal It's a leak, implying a relatively large gap. If you measure at the flange hole you will need. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. Expect fixings to be troublesome. My car has the same diff type with the. It's basically leaking past the seal (bearing and. Output Shaft Bearing And Seal.

From www.carid.com

National® 5202 Manual Transmission Output Shaft Seal Kit Output Shaft Bearing And Seal It's a leak, implying a relatively large gap. My car has the same diff type with the. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). Expect fixings to be troublesome. My seal puller worked great as you can lever off. Output Shaft Bearing And Seal.

From www.autopartskart.com

2007 Chevrolet Cobalt Automatic Transmission Output Shaft Seal Kit Output Shaft Bearing And Seal My car has the same diff type with the. If you measure at the flange hole you will need. I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure.. Output Shaft Bearing And Seal.

From jandgtransmissions.com

How to Tell if Your Transfer Case Output Shaft Seal is Going Bad J Output Shaft Bearing And Seal When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). It's a leak, implying a relatively large gap. Use penetrating oil and repeatedly tighten them then loosen off. The nut had been staked twice and had gasket sealant on it, further proof. Output Shaft Bearing And Seal.

From www.alltranz.com.au

137480K OUTPUT SHAFT BEARING KIT (FW6AEL) Transmissions Output Shaft Bearing And Seal The nut had been staked twice and had gasket sealant on it, further proof the. It's basically leaking past the seal (bearing and shaft seal) while cold. If you measure at the flange hole you will need. It's a leak, implying a relatively large gap. I am in the process of replacing the diff output shaft oil seals on my. Output Shaft Bearing And Seal.

From shop.montehospital.com

Clutch and Drive Train Differential Output Shaft Seals, set The Output Shaft Bearing And Seal I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. It's a leak, implying a relatively large gap. It's basically leaking past the seal (bearing and shaft seal) while cold. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction. Output Shaft Bearing And Seal.

From www.carid.com

SKF® Kia Rio / Rio5 Automatic Transmission 2006 Automatic Output Shaft Bearing And Seal I am in the process of replacing the diff output shaft oil seals on my '65 ser1 due to a leak. When it has just bit of play measure the force/torque required to turn the shaft, cause of the friction of the seal (what i called the seal torque). It's a leak, implying a relatively large gap. If you measure. Output Shaft Bearing And Seal.

From klaewhbto.blob.core.windows.net

Output Shaft Seal Fix at Maria Mukai blog Output Shaft Bearing And Seal If you measure at the flange hole you will need. No heat, pressure or motion from operation. My car has the same diff type with the. My seal puller worked great as you can lever off the output shaft spline, came out with very little pressure. I am in the process of replacing the diff output shaft oil seals on. Output Shaft Bearing And Seal.