Manganese Vs Zinc Phosphate Coating . Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. The coating tends to be smoother as the weight per square foot decreases. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese.

from www.mdpi.com

Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The coating tends to be smoother as the weight per square foot decreases.

Materials Free FullText Modified Manganese Phosphate Conversion Coating on LowCarbon Steel

Manganese Vs Zinc Phosphate Coating The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. The coating tends to be smoother as the weight per square foot decreases. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts.

From bansaltrading.com

Application and Properties of Zinc Phosphate Bansal Trading Company Manganese Vs Zinc Phosphate Coating Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts.. Manganese Vs Zinc Phosphate Coating.

From www.e-plating.com.tw

Zinc phosphate and Manganese phosphate coating Hsieh Shun Industrial Co.,Ltd. Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. The coating tends to be smoother as the weight per square foot decreases. Light to moderate zinc phosphates are. Manganese Vs Zinc Phosphate Coating.

From www.valencesurfacetech.com

Zinc Phosphate Coating Services Valence Surface Technologies Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection. Manganese Vs Zinc Phosphate Coating.

From dir.indiamart.com

Manganese Phosphating Services, Manganese Phosphate Coating Services in India Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Manganese and zinc are two of the. Manganese Vs Zinc Phosphate Coating.

From www.lightmetalscoloring.com

What Is Manganese Phosphate and What Is It Used For? Manganese Vs Zinc Phosphate Coating Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Manganese and. Manganese Vs Zinc Phosphate Coating.

From www.apollomachine.com

Zinc and Manganese Phosphate Chemical Plating Apollo Machine Manganese Vs Zinc Phosphate Coating Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Manganese and zinc are two of the. Manganese Vs Zinc Phosphate Coating.

From www.vishwashindustries.com

Vishwash Ceramic Industries Phosphate Cleaning Services Process of Auto Engine Parts and Machine Manganese Vs Zinc Phosphate Coating Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The coating tends to be smoother as the weight per square foot decreases. The main types of phosphate. Manganese Vs Zinc Phosphate Coating.

From www.calicocoatings.com

Manganese Phosphate Coatings Calico Coatings Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2.. Manganese Vs Zinc Phosphate Coating.

From www.phosphating.net

Manganese Phosphate Coating Manganese Phosphating Process Details Manganese Vs Zinc Phosphate Coating Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. The coating tends to be smoother as the. Manganese Vs Zinc Phosphate Coating.

From www.valencesurfacetech.com

Manganese Phosphate Manganese Vs Zinc Phosphate Coating Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Unlike zinc phosphate, the only. Manganese Vs Zinc Phosphate Coating.

From www.researchgate.net

(PDF) Double Substituted with Manganese and Strontium Tricalcium Phosphate Coatings on Zinc Manganese Vs Zinc Phosphate Coating The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Manganese and zinc are two of the. Manganese Vs Zinc Phosphate Coating.

From www.linkedin.com

Everything You Need To Know About Zinc Phosphate Coating Manganese Vs Zinc Phosphate Coating The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. The coating tends to be smoother as the weight per square foot decreases. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance,. Manganese Vs Zinc Phosphate Coating.

From patents.google.com

EP0439377A1 Method of applying a zincnickelmanganese phosphate coating. Google Patents Manganese Vs Zinc Phosphate Coating The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. The coating tends to be. Manganese Vs Zinc Phosphate Coating.

From asgkuber.com.au

MILP16232 F TYPE M Phosphate Coatings, Heavy, Manganese or Zinc Base Manganese Vs Zinc Phosphate Coating Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2.. Manganese Vs Zinc Phosphate Coating.

From customcoatinginc.com

Bonderite Lubrite 2 Manganese Phosphate Conversion Coating for Steel and Iron Custom Coating, Inc. Manganese Vs Zinc Phosphate Coating Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The coating tends to be smoother as the weight per square foot decreases. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. The main types of phosphate coatings are iron,. Manganese Vs Zinc Phosphate Coating.

From www.semanticscholar.org

Progress in Zinc Phosphate Conversion Coatings A Review Semantic Scholar Manganese Vs Zinc Phosphate Coating Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. The coating tends to be smoother as the weight per square foot decreases. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Unlike zinc phosphate, the only purpose of manganese phosphate. Manganese Vs Zinc Phosphate Coating.

From www.mdpi.com

Materials Free FullText Modified Manganese Phosphate Conversion Coating on LowCarbon Steel Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The coating. Manganese Vs Zinc Phosphate Coating.

From www.researchgate.net

The chemical composition of manganese phosphating treatment and process... Download Table Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Unlike zinc phosphate, the only purpose of manganese. Manganese Vs Zinc Phosphate Coating.

From apollomachine.com

Zinc and Manganese Phosphate Chemical Plating Apollo Machine Manganese Vs Zinc Phosphate Coating The coating tends to be smoother as the weight per square foot decreases. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for. Manganese Vs Zinc Phosphate Coating.

From bansaltrading.com

Application and Properties of Zinc Phosphate Bansal Trading Company Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. The coating tends to be. Manganese Vs Zinc Phosphate Coating.

From pubs.rsc.org

Characteristics and corrosion studies of zincmanganese phosphate coatings on magnesiumlithium Manganese Vs Zinc Phosphate Coating Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection. Manganese Vs Zinc Phosphate Coating.

From innovationfilter.com

Phosphating sludge separator 7 questions about zinc phosphating Manganese Vs Zinc Phosphate Coating The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The coating tends to be. Manganese Vs Zinc Phosphate Coating.

From www.mdpi.com

Materials Free FullText Modified Manganese Phosphate Conversion Coating on LowCarbon Steel Manganese Vs Zinc Phosphate Coating Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. The coating tends to be smoother as the weight per square foot decreases. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Manufacturers use manganese phosphate coatings primarily for improving. Manganese Vs Zinc Phosphate Coating.

From www.researchgate.net

(PDF) MANGANESE PHOSPHATE COATING Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection. Manganese Vs Zinc Phosphate Coating.

From www.workingsolutions.net

Do You Need A Iron, Zinc, Or Manganese Phosphate System? Working Solutions Has The Phosphate Manganese Vs Zinc Phosphate Coating Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The main. Manganese Vs Zinc Phosphate Coating.

From liccogroup.com

Phosphate Coating Licco Group Manganese Vs Zinc Phosphate Coating Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft. Manganese Vs Zinc Phosphate Coating.

From www.metalcheminc.com

Phosphate Coatings Zinc & Manganese Phosphate Metal Chem Inc. Manganese Vs Zinc Phosphate Coating Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft. Manganese Vs Zinc Phosphate Coating.

From pubs.rsc.org

Characteristics and corrosion studies of zincmanganese phosphate coatings on magnesiumlithium Manganese Vs Zinc Phosphate Coating The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Manganese and zinc are two of the most. Manganese Vs Zinc Phosphate Coating.

From www.researchgate.net

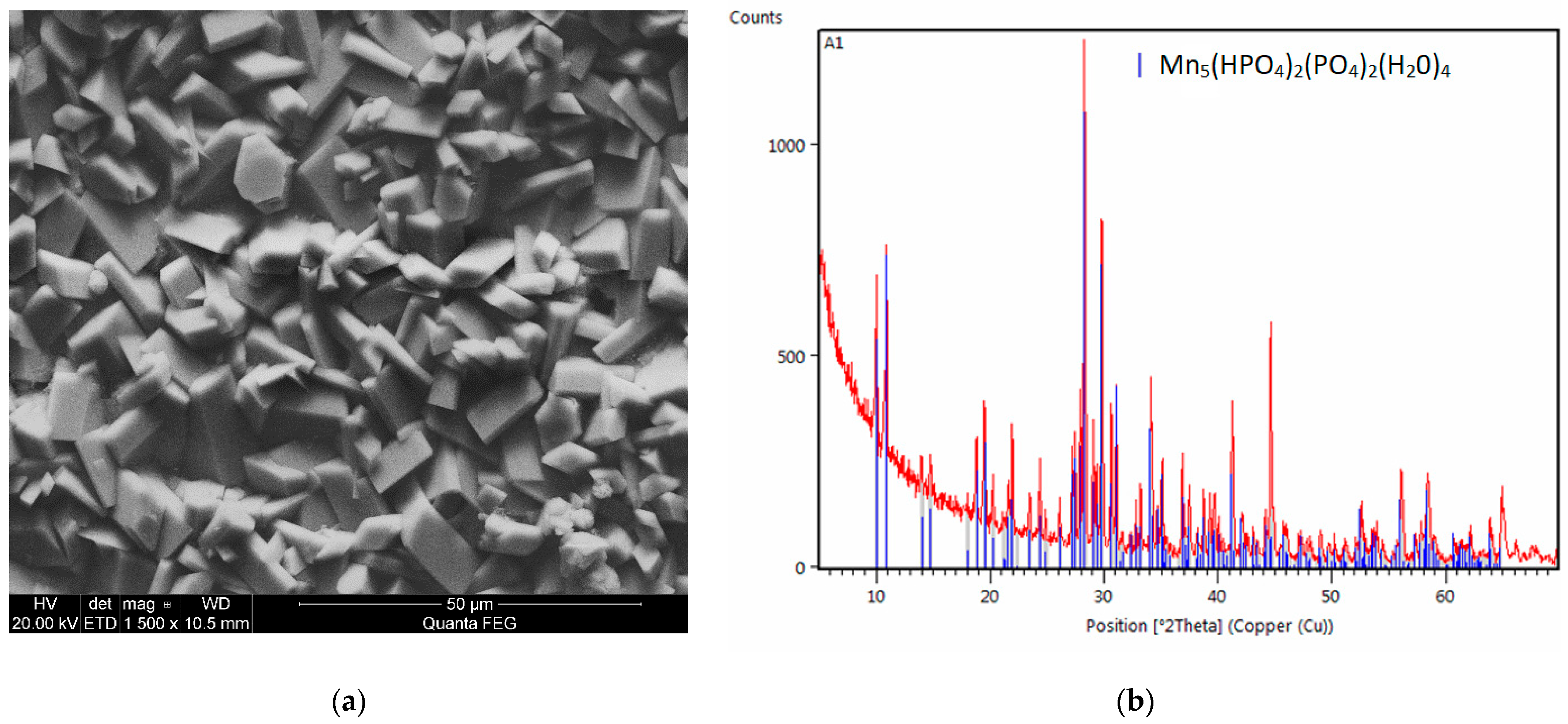

XRD patterns; (a) AISI 1045, (b) manganese phosphate coating. Download Scientific Diagram Manganese Vs Zinc Phosphate Coating Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated. Manganese Vs Zinc Phosphate Coating.

From www.argos-st.com

Phosphate Coating Manganese and Zinc Phosphating Treatments Argos ST Manganese Vs Zinc Phosphate Coating Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The coating tends to be smoother as the weight per square foot decreases. Unlike zinc phosphate, the only purpose. Manganese Vs Zinc Phosphate Coating.

From www.ilve.com.tr

Manganese Phosphate Coating Process Black Phosphating Manganese Vs Zinc Phosphate Coating Manganese and zinc are two of the most common phosphate coatings, but how do you decide which one is right for your. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. The coating tends to be smoother as the weight per square foot decreases. Light to moderate zinc phosphates are. Manganese Vs Zinc Phosphate Coating.

From www.semanticscholar.org

Figure 1 from A Zinc and Manganese Phosphate Coating on Automobile Iron Castings Semantic Scholar Manganese Vs Zinc Phosphate Coating The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Manganese and zinc are two of the. Manganese Vs Zinc Phosphate Coating.

From www.mdpi.com

Materials Free FullText Manganese Phosphatizing Coatings The Effects of Preparation Manganese Vs Zinc Phosphate Coating Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The coating tends to be smoother as the weight per square foot decreases. Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Light to moderate zinc phosphates are crystalline, developing. Manganese Vs Zinc Phosphate Coating.

From www.gruppogaser.com

Fosfatazione allo Zinco Fosfatazione al Manganese Gruppo Gaser Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. The main types of phosphate coatings are iron, zinc (light to heavy), and manganese. Manganese and zinc are two of the most. Manganese Vs Zinc Phosphate Coating.

From www.phosphating.net

Zinc Phosphate Coating Zinc Phosphating Process Details Manganese Vs Zinc Phosphate Coating Manufacturers use manganese phosphate coatings primarily for improving the wear resistance, corrosion resistance, and lubricity of the treated parts. Light to moderate zinc phosphates are crystalline, developing a range of coating weights from 500 to 3,000 mg/ft 2. Unlike zinc phosphate, the only purpose of manganese phosphate is for use with an oil coating for storage protection and. The coating. Manganese Vs Zinc Phosphate Coating.