Chamfering On Lathe Machine . They are created for mainly for protecting the chamfered object as. The chamfer can be either a component feature or it can be just a. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. A chamfer is an angle on the edge of a workpiece. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. Many times, a chamfer is required before the parting off operation. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application.

from rsvautomotive.co.uk

Many times, a chamfer is required before the parting off operation. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. They are created for mainly for protecting the chamfered object as. A chamfer is an angle on the edge of a workpiece. The chamfer can be either a component feature or it can be just a.

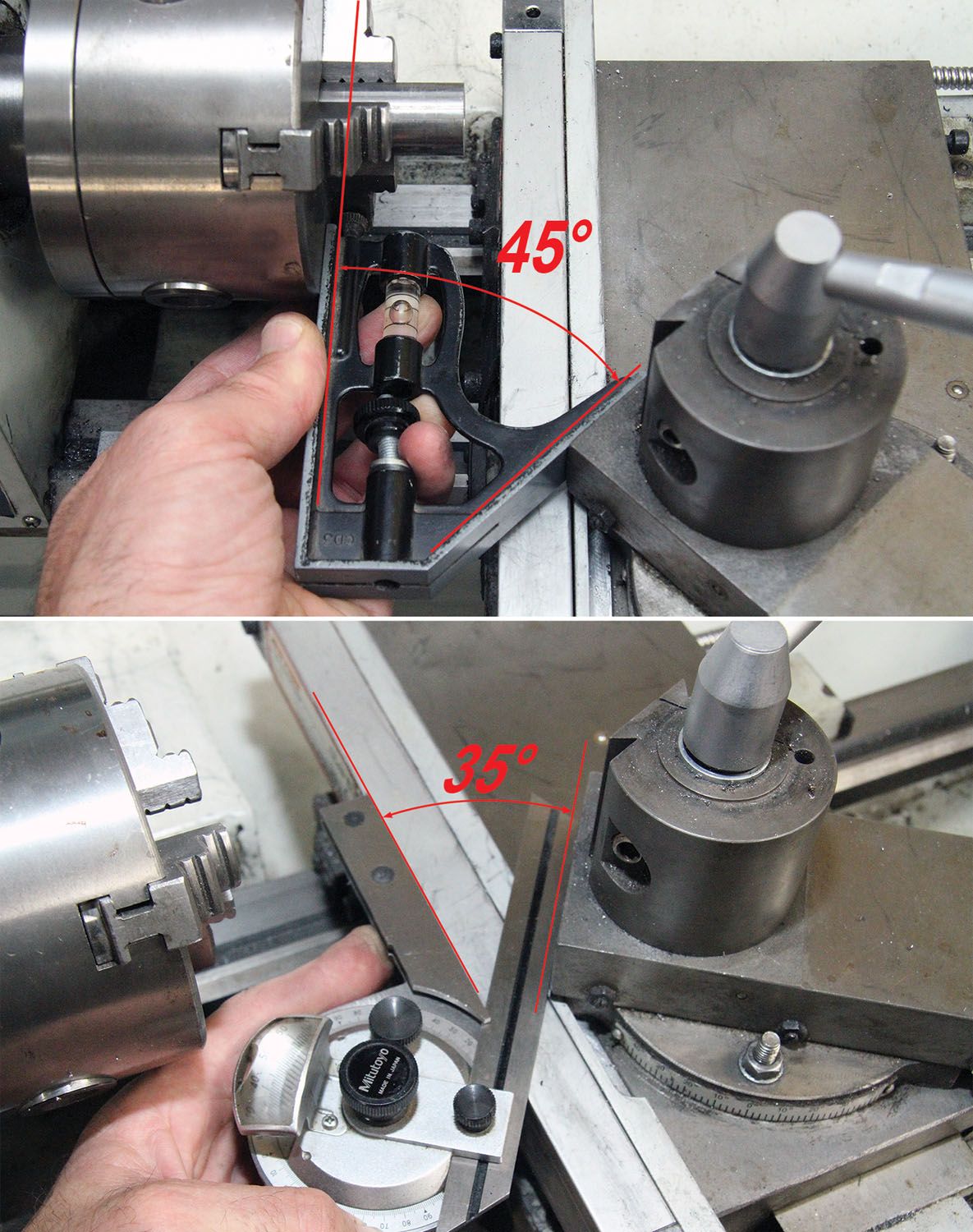

chamfering Tool makes It a Workhorse Facing New Lathe 45 Degree Turning

Chamfering On Lathe Machine Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. Many times, a chamfer is required before the parting off operation. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. They are created for mainly for protecting the chamfered object as. The chamfer can be either a component feature or it can be just a. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. A chamfer is an angle on the edge of a workpiece.

From www.aliexpress.com

Multifunctional chamfering machine GD 900H Table High speed compound Chamfering On Lathe Machine Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously,. Chamfering On Lathe Machine.

From fractory.com

CNC Milling a Complete Guide to Understand the Process Chamfering On Lathe Machine By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. The chamfer can be either. Chamfering On Lathe Machine.

From www.youtube.com

Lathe processes Chamfering YouTube Chamfering On Lathe Machine Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. They are created for mainly for protecting the chamfered object as. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Many times, a chamfer is. Chamfering On Lathe Machine.

From www.slideserve.com

PPT Machining PowerPoint Presentation, free download ID8895935 Chamfering On Lathe Machine They are created for mainly for protecting the chamfered object as. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Many times, a chamfer is required before the parting off operation. The chamfer can be either a component feature or it can be just a.. Chamfering On Lathe Machine.

From www.youtube.com

Introduction to Chamfering & Deburring Operations Using a Lathe Machine Chamfering On Lathe Machine Many times, a chamfer is required before the parting off operation. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer is an angle on the edge of a workpiece. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. By setting. Chamfering On Lathe Machine.

From www.engineeringchoice.com

Lathe Machine Operations and Lathe Cutting Tools Chamfering On Lathe Machine The chamfer can be either a component feature or it can be just a. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. They are created for mainly for protecting the chamfered object as. Chamfering is the process in developing that edge and what one. Chamfering On Lathe Machine.

From rsvautomotive.co.uk

chamfering Tool makes It a Workhorse Facing New Lathe 45 Degree Turning Chamfering On Lathe Machine The chamfer can be either a component feature or it can be just a. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. They are created for mainly for protecting the chamfered object as. A chamfer is an. Chamfering On Lathe Machine.

From rsvautomotive.co.uk

chamfering Tool makes It a Workhorse Facing New Lathe 45 Degree Turning Chamfering On Lathe Machine Many times, a chamfer is required before the parting off operation. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. They are created for mainly for protecting the chamfered object as. A chamfer is an angle on the edge of a workpiece. Chamfering refers to. Chamfering On Lathe Machine.

From www.homenish.com

14 Different Types of Lathe Tools Explained Homenish Chamfering On Lathe Machine Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer is an angle on the edge of a workpiece. The chamfer can be either a component feature or it can be just a. Chamfering is the process in developing that edge and what one could argue, a unique yet very common. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering Machine, C3A ChamferMate® Bar, Stud and Tube Chamfering Chamfering On Lathe Machine They are created for mainly for protecting the chamfered object as. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally.. Chamfering On Lathe Machine.

From www.youtube.com

OD & ID Chamfer Operation on CNC LATHE YouTube Chamfering On Lathe Machine Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Many times, a chamfer is required before the parting off. Chamfering On Lathe Machine.

From www.youtube.com

CNC tube cutting and Chamfering Auto lathe machine Chamfering On Lathe Machine Many times, a chamfer is required before the parting off operation. They are created for mainly for protecting the chamfered object as. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. By setting. Chamfering On Lathe Machine.

From www.youtube.com

Straight Turning with Chamfering in the Lathe Machine YouTube Chamfering On Lathe Machine Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. A chamfer edge improves visual properties, but it is also. Chamfering On Lathe Machine.

From www.youtube.com

To perform turning, facing and chamfering operation on a lathe YouTube Chamfering On Lathe Machine Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. They are created for mainly for protecting the chamfered object as. A chamfer is an angle on the edge of a workpiece. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves. Chamfering On Lathe Machine.

From klarqaqxa.blob.core.windows.net

What Is Chamfering Operation In Lathe Machine at Ryan Stewart blog Chamfering On Lathe Machine By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. The chamfer can be either a component feature or it can be just a. Chamfering plays a crucial. Chamfering On Lathe Machine.

From www.rapiddirect.com

Different Types of Lathe Tools You Can Use in CNC Turning RapidDirect Chamfering On Lathe Machine Many times, a chamfer is required before the parting off operation. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering Operation On Lathe Machine For Fitter Turner Machinist ITI Chamfering On Lathe Machine Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. The chamfer can be either a component feature or it can be just a. They are created for mainly for protecting the chamfered object as. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering Operation On Lathe Machine लेथ मशीन पे चांफेरिंग ऑपरेशन Chamfering On Lathe Machine A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering with the Taig Micro Lathe YouTube Chamfering On Lathe Machine By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. They are created for mainly for protecting the chamfered object as. Many times, a chamfer is required before the parting off operation. A chamfer edge improves visual properties, but it is also a practical option for. Chamfering On Lathe Machine.

From qhunt.blogspot.com

Various Types of Operations Performed on Lathe Machine Q Hunt Chamfering On Lathe Machine A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. They are created for mainly for protecting the chamfered object as. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Specifically, this involves removing sharp edges and. Chamfering On Lathe Machine.

From www.arrowmachinetools.org

Cutting And Chamfering Machine Rotary Drilling And Tapping SPM Chamfering On Lathe Machine They are created for mainly for protecting the chamfered object as. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Specifically, this involves removing sharp edges and. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering YouTube Chamfering On Lathe Machine Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Many times, a chamfer is required before the parting off operation. Chamfering is the process in developing that edge and what one could argue, a. Chamfering On Lathe Machine.

From www.youtube.com

lathe machine operation Facing Turning Grooving chamferingparting Chamfering On Lathe Machine The chamfer can be either a component feature or it can be just a. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Chamfering is the process. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering on the Lathe YouTube Chamfering On Lathe Machine Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. They are created for mainly for protecting the chamfered object as. Many times, a chamfer is required before the parting off operation. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Chamfering plays a. Chamfering On Lathe Machine.

From www.youtube.com

Taper Turning & Chamfering operation on Lathe Machine YouTube Chamfering On Lathe Machine Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. By setting up the. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering Tool Lathe YouTube Chamfering On Lathe Machine The chamfer can be either a component feature or it can be just a. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. Chamfering refers to a processing method in which the edges of materials such as metals. Chamfering On Lathe Machine.

From klarqaqxa.blob.core.windows.net

What Is Chamfering Operation In Lathe Machine at Ryan Stewart blog Chamfering On Lathe Machine Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. A chamfer is an angle on the edge of a workpiece. By setting up the machine correctly, choosing. Chamfering On Lathe Machine.

From learnmechanical.com

Lathe Machine Definition, Introduction, Parts, Types, Operations, and Chamfering On Lathe Machine A chamfer is an angle on the edge of a workpiece. They are created for mainly for protecting the chamfered object as. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering Machine YouTube Chamfering On Lathe Machine A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. A chamfer is an angle on the edge of a workpiece. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Chamfering plays a crucial role in lathe machine operations as it helps to remove. Chamfering On Lathe Machine.

From klarqaqxa.blob.core.windows.net

What Is Chamfering Operation In Lathe Machine at Ryan Stewart blog Chamfering On Lathe Machine They are created for mainly for protecting the chamfered object as. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances the overall. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Many. Chamfering On Lathe Machine.

From www.youtube.com

Chamfering operation on lathe machine with tool settings chamfering on Chamfering On Lathe Machine Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope.. Chamfering On Lathe Machine.

From www.youtube.com

All Lathe Machine Operations Turning, Facing, Taper Turning, Boring Chamfering On Lathe Machine Many times, a chamfer is required before the parting off operation. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. A chamfer edge improves visual. Chamfering On Lathe Machine.

From www.youtube.com

Setting the Lathe compound to precision angles YouTube Chamfering On Lathe Machine The chamfer can be either a component feature or it can be just a. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Chamfering plays a crucial role in lathe machine operations as it helps to remove burrs and sharp edges, improves the functionality and aesthetics of the finished product, and enhances. Chamfering On Lathe Machine.

From www.youtube.com

The Facing, boring chamfering and turning by Nine9 cutting tool on CNC Chamfering On Lathe Machine By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously, operators can ensure accurate chamfering operations. Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Chamfering refers to a processing method in which the edges of materials such as metals and resins. Chamfering On Lathe Machine.

From www.shutterstock.com

Cnc Lathe Machine Chamfering Cut Metal Stock Photo 2135070051 Chamfering On Lathe Machine Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. By setting up the machine correctly, choosing appropriate tooling, determining parameters accurately, and writing the program code meticulously,. Chamfering On Lathe Machine.