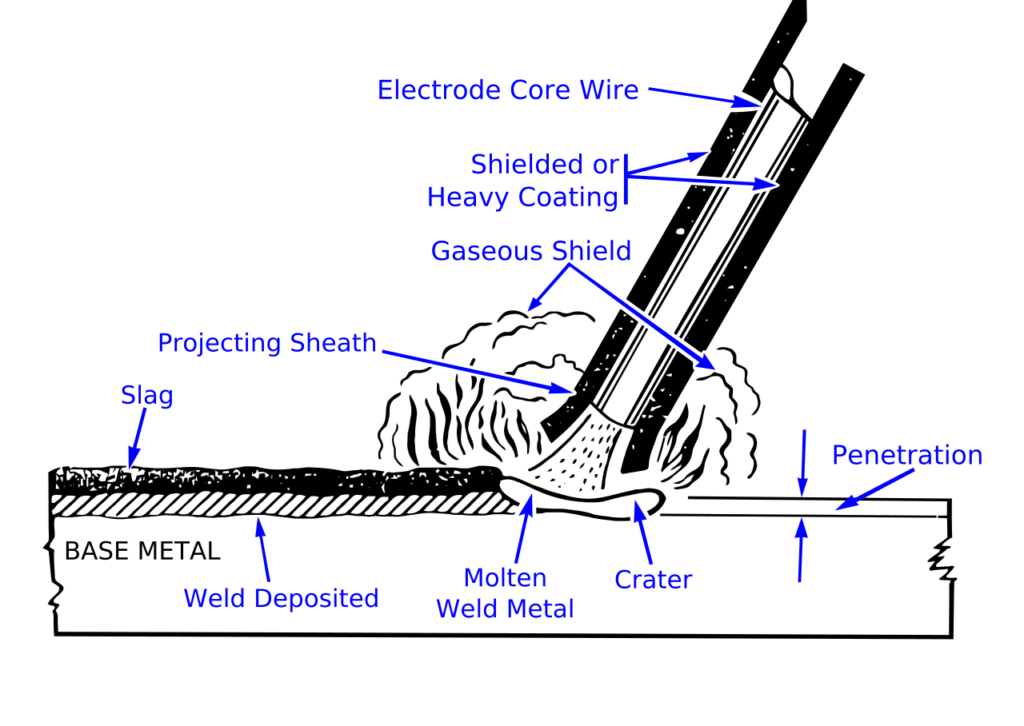

Stick Welding Carbon . Unlike wire welding where you basically point and shoot, stick. The most popular welding rods for hobbyists are 3/32” rods. The flux material provides the shielding gases and the protective slag. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. You need to consider many parameters to. It is suitable for indoor and. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. Stick welding is the most common form of arc welding, but creating a good weld may not be easy for the beginner. What are common stick welding rod sizes. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under arc heat. Stick welding electrode selection can be troublesome for beginners and home welders. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. The wire acts as both the electrode and the filler metal for the process. Arc stability through elements such as sodium and potassium. 1/8” and 5/32” are also very common.

from www.kingsofwelding.com

What are common stick welding rod sizes. Stick welding electrode selection can be troublesome for beginners and home welders. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. The flux material provides the shielding gases and the protective slag. You need to consider many parameters to. Unlike wire welding where you basically point and shoot, stick. The wire acts as both the electrode and the filler metal for the process. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. 1/8” and 5/32” are also very common. Arc stability through elements such as sodium and potassium.

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding

Stick Welding Carbon You need to consider many parameters to. Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron, and more. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. What are common stick welding rod sizes. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under arc heat. You need to consider many parameters to. 1/8” and 5/32” are also very common. The wire acts as both the electrode and the filler metal for the process. Stick welding is the most common form of arc welding, but creating a good weld may not be easy for the beginner. The most popular welding rods for hobbyists are 3/32” rods. It is suitable for indoor and. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. The flux material provides the shielding gases and the protective slag. Unlike wire welding where you basically point and shoot, stick. Stick welding electrode selection can be troublesome for beginners and home welders.

From blog.thepipingmart.com

How to Stick Weld Thin Metal An Overview Stick Welding Carbon Arc stability through elements such as sodium and potassium. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. The wire acts as both the. Stick Welding Carbon.

From www.weldingcity.com

3/32" x 12" WeldingCity® E6013 Carbon Steel Stick Welding Electrode Rods Stick Welding Carbon Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron, and more. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. Arc stability through elements such as sodium and potassium. What are common. Stick Welding Carbon.

From www.weldingtipsandtricks.com

Stick Welding Carbon Steel 1/4" 3f tee 7018 1/8" stringer root Stick Welding Carbon Arc stability through elements such as sodium and potassium. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under arc heat. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. Stick welding can be used to weld various materials,. Stick Welding Carbon.

From www.alibaba.com

Abyat E308 E308l Stainless Welding Stick Welding Electrode Carbon Steel Stick Welding Carbon The most popular welding rods for hobbyists are 3/32” rods. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. The wire acts as both the electrode and the filler metal for the process. 1/8” and 5/32” are also very. Stick Welding Carbon.

From weldguru.com

What Is SMAW (Stick Welding) & How Does It Work? Stick Welding Carbon 1/8” and 5/32” are also very common. Stick welding is the most common form of arc welding, but creating a good weld may not be easy for the beginner. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. The wire acts as both the electrode and the. Stick Welding Carbon.

From www.amazon.com

E4303 Carbon Steel Welding Rods 1/8" x14", Cast Iron Welding Rods, Arc Stick Welding Carbon Stick welding electrode selection can be troublesome for beginners and home welders. You need to consider many parameters to. Unlike wire welding where you basically point and shoot, stick. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Larger diameter welding rods are only really needed for welding. Stick Welding Carbon.

From weldingpros.net

Stick Welding Rod Charts and Calculator Amps, Sizes, Types Stick Welding Carbon Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron, and more. Stick welding electrode selection can be troublesome for beginners and home welders. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. Stick welding electrodes are consumable composite short. Stick Welding Carbon.

From www.amazon.com

Welding Rods Welding Sticks 5Pcs Air Carbon Arc Gouging Stick Welding Carbon Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. What are common stick welding rod sizes. Unlike wire welding where you basically point and shoot, stick. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc. Stick Welding Carbon.

From www.weldingtipsandtricks.com

Stick Welding Carbon Steel Pipe 3/8" wall 12 inch Downhill 7010 3/16" Stick Welding Carbon Stick welding is the most common form of arc welding, but creating a good weld may not be easy for the beginner. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The primary source of the slag system, which supports the weld puddle and helps remove impurities from. Stick Welding Carbon.

From weldgears.com

6 Advantages and 4 Limitations of Stick Welding Weld Gears Stick Welding Carbon Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. The wire acts as both the electrode and. Stick Welding Carbon.

From www.corrosionpedia.com

Stick Welding A Comprehensive Guide Stick Welding Carbon The flux material provides the shielding gases and the protective slag. The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under arc heat. Manual metal arc (mma) or ‘stick’ welding. Stick Welding Carbon.

From www.indiamart.com

Carbon Steel Welding Stick Electrode at Rs 1800/kg in Pune ID Stick Welding Carbon You need to consider many parameters to. 1/8” and 5/32” are also very common. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. Unlike wire welding where you basically point and shoot, stick. Larger diameter welding rods are only. Stick Welding Carbon.

From www.kingsofwelding.com

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding Stick Welding Carbon Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Stick welding electrode selection can be troublesome for beginners and home welders. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. Arc stability through elements. Stick Welding Carbon.

From www.youtube.com

🔥 Tips for Stick Welding Carbon Steel to Stainless Steel YouTube Stick Welding Carbon Unlike wire welding where you basically point and shoot, stick. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The most popular welding rods for hobbyists are 3/32” rods. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under arc. Stick Welding Carbon.

From www.weldingtipsandtricks.com

TIG Welding Training Exercise for 11 ga carbon steel Stick Welding Carbon Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under arc heat. Arc stability through elements such as sodium and potassium. It is suitable for indoor and. Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron, and more. You need to consider many parameters to.. Stick Welding Carbon.

From www.weldingtipsandtricks.com

Stick Welding carbon steel open root plate 6010 downhill Stick Welding Carbon 1/8” and 5/32” are also very common. It is suitable for indoor and. The wire acts as both the electrode and the filler metal for the process. Unlike wire welding where you basically point and shoot, stick. Stick welding electrode selection can be troublesome for beginners and home welders. Stick welding can be used to weld various materials, including carbon. Stick Welding Carbon.

From pandaconstruction.en.made-in-china.com

High Quality Welding Stick Low Carbon Steel Mild Steel Welding Rod Aws Stick Welding Carbon The flux material provides the shielding gases and the protective slag. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. It is suitable for indoor and. The most popular welding rods for hobbyists are 3/32” rods. The wire acts. Stick Welding Carbon.

From weldingpros.net

Carbon Arc Welding (CAW) Process Stick Welding Carbon What are common stick welding rod sizes. Unlike wire welding where you basically point and shoot, stick. Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron, and more. Stick welding is the most common form of arc welding, but creating a good weld may not be easy for the beginner. The primary source. Stick Welding Carbon.

From www.thefabricator.com

Classifying popular stick electrodes helps welders with decision making Stick Welding Carbon The flux material provides the shielding gases and the protective slag. The wire acts as both the electrode and the filler metal for the process. Stick welding is the most common form of arc welding, but creating a good weld may not be easy for the beginner. Arc stability through elements such as sodium and potassium. What are common stick. Stick Welding Carbon.

From www.youtube.com

STICK WELDING 101 Getting Started With SMAW YouTube Stick Welding Carbon You need to consider many parameters to. What are common stick welding rod sizes. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under arc heat. Stick welding is the most common form of arc welding, but creating a good weld may not be easy for the beginner. Manual metal arc (mma). Stick Welding Carbon.

From www.weldingcity.com

3/32" x 12" WeldingCity® E7018 LowHydrogen Carbon Steel Stick Welding Stick Welding Carbon It is suitable for indoor and. 1/8” and 5/32” are also very common. The flux material provides the shielding gases and the protective slag. Arc stability through elements such as sodium and potassium. You need to consider many parameters to. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an. Stick Welding Carbon.

From weldguru.com

How To Stick Weld (SMAW) Stainless Steel A Beginners’ Guide Stick Welding Carbon The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. Unlike wire welding where you basically point and shoot, stick. Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron, and more. Stick welding electrodes are consumable composite short rods with a. Stick Welding Carbon.

From www.youtube.com

Welder Qualification Tutorial SMAW 1G Butt Welding Training with 6013 Stick Welding Carbon Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The wire acts as both the electrode and the filler metal for the process. The most popular welding rods for hobbyists are 3/32” rods. Stick welding electrode selection can be troublesome for beginners and home welders. It is suitable. Stick Welding Carbon.

From www.youtube.com

1G Plate Stick Welding SMAW YouTube Stick Welding Carbon Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. The wire acts as both the electrode and the filler metal for the process. Stick welding. Stick Welding Carbon.

From www.weldingcity.com

3/32" x 12" WeldingCity® E6013 Carbon Steel Stick Welding Electrode Rods Stick Welding Carbon Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. Unlike wire welding where you basically point and shoot, stick. Arc stability through elements such as sodium and potassium. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co 2 under. Stick Welding Carbon.

From bridge-welding.en.made-in-china.com

Aws E7018 Welding Electrode Mild Steel Welding Stick Electrode Low Stick Welding Carbon The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. It is suitable for indoor and. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. 1/8” and. Stick Welding Carbon.

From www.waylanderwelding.com

Stick Welding A Beginner’s Guide Stick Welding Carbon What are common stick welding rod sizes. You need to consider many parameters to. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron,. Stick Welding Carbon.

From weldingpros.net

Carbon Arc Welding (CAW) Process Stick Welding Carbon What are common stick welding rod sizes. Stick welding can be used to weld various materials, including carbon steel, stainless steel, cast iron, and more. The flux material provides the shielding gases and the protective slag. Stick welding electrode selection can be troublesome for beginners and home welders. It is suitable for indoor and. 1/8” and 5/32” are also very. Stick Welding Carbon.

From www.topwellwelders.com

ARC600HD Heavy Duty Stick Welding and Carbon Arc Gouging Stick Stick Welding Carbon Unlike wire welding where you basically point and shoot, stick. What are common stick welding rod sizes. It is suitable for indoor and. The wire acts as both the electrode and the filler metal for the process. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between. Stick Welding Carbon.

From www.youtube.com

309 Stainless Steel to Carbon Stick Welding 1G PLATE YouTube Stick Welding Carbon It is suitable for indoor and. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered electrode and the workpiece. You need to consider many parameters to. 1/8” and 5/32” are also very common. What are common stick welding rod sizes. The wire acts. Stick Welding Carbon.

From weldingclarity.com

Stick Welding Cast Iron 4 Simple Steps for Flawless Results Stick Welding Carbon Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. The flux material provides the shielding gases and the protective slag. The most popular welding rods for hobbyists are 3/32” rods. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to cao and co. Stick Welding Carbon.

From sea.itwwelding.com

ITW Welding Singapore Carbon Steel Stick Electrode Basics Stick Welding Carbon The primary source of the slag system, which supports the weld puddle and helps remove impurities from the molten metal weld deposit. Arc stability through elements such as sodium and potassium. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. Stick welding electrodes are consumable composite. Stick Welding Carbon.

From www.youtube.com

The fastest way to learn stick welding with a new trick YouTube Stick Welding Carbon It is suitable for indoor and. 1/8” and 5/32” are also very common. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an electric arc between a flux covered. Stick Welding Carbon.

From hunanxianggong.en.made-in-china.com

Carbon Steel Welding Stick Welding Rod Welding Electrode J421 J422 Stick Welding Carbon It is suitable for indoor and. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. The flux material provides the shielding gases and the protective slag. Manual metal arc (mma) or ‘stick’ welding is the process in which a power source is used to create an. Stick Welding Carbon.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) Stick Welding Carbon Unlike wire welding where you basically point and shoot, stick. Stick welding electrode selection can be troublesome for beginners and home welders. The flux material provides the shielding gases and the protective slag. What are common stick welding rod sizes. 1/8” and 5/32” are also very common. Arc shielding when the calcium carbonate (caco 3) in the coating decomposes to. Stick Welding Carbon.