Surface Plate Repeatability . Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Again, you have to consult the federal. Flatness denotes the difference between the lowest and highest point on the. The repeat measurement specification insures that errors in measurement due to surface variations are held.

from hill-engineering.com

Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Again, you have to consult the federal. Ensure that it falls within the repeatability specification of the plate of the size and the grade. The repeat measurement specification insures that errors in measurement due to surface variations are held. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Flatness denotes the difference between the lowest and highest point on the.

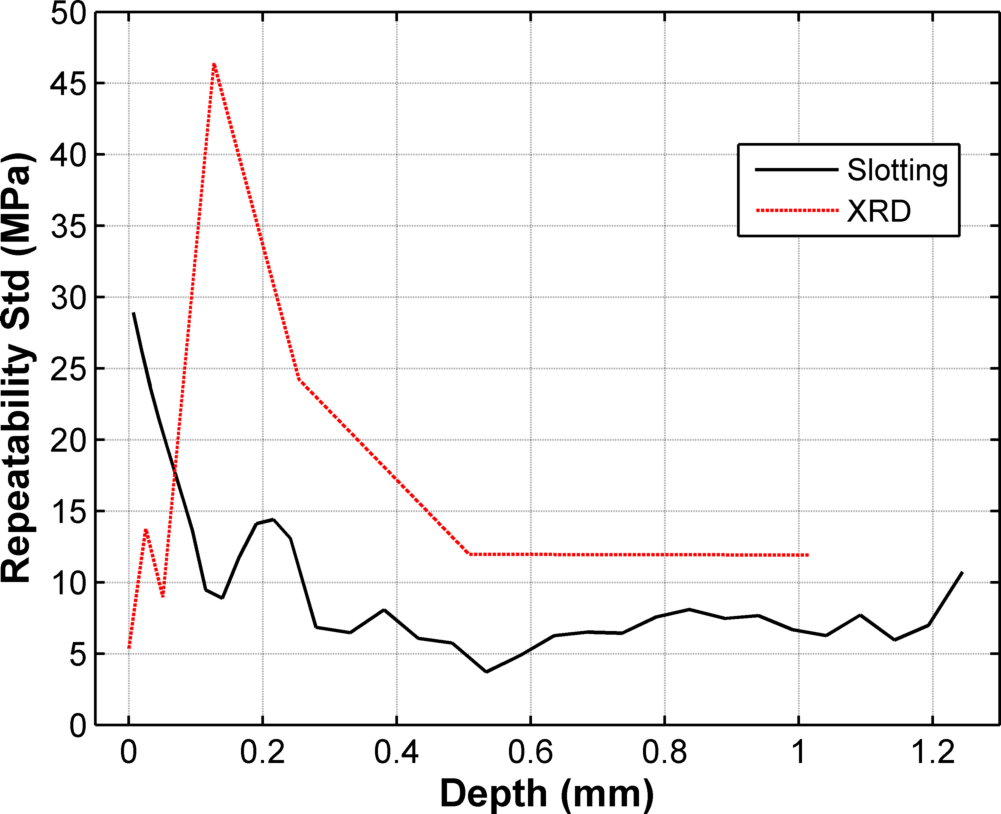

New Publication Near Surface Residual Stress Measurement Using

Surface Plate Repeatability Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Flatness denotes the difference between the lowest and highest point on the. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Again, you have to consult the federal. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. The repeat measurement specification insures that errors in measurement due to surface variations are held.

From checkout.starrett.com

Granite Surface Plates and Accessories RepeatOMeter Reading Gage Surface Plate Repeatability Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. The repeat measurement specification insures that errors in measurement due to surface variations are held. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Surface plates are solid flat plates. Surface Plate Repeatability.

From www.youtube.com

SURFACE PLATE CALIBRATION BY USING WYLER LEVEL AND CROSS CHECKING WITH Surface Plate Repeatability Ensure that it falls within the repeatability specification of the plate of the size and the grade. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a. Surface Plate Repeatability.

From www.scribd.com

33K64101 Rev 30 Jan 2017 SURFACE PLATES PDF Ret PDF Surface Plate Repeatability Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Ensure that it. Surface Plate Repeatability.

From www.dimensionalgauge.com

Discussion of proper surface plate repair and calibration Surface Plate Repeatability Again, you have to consult the federal. Flatness denotes the difference between the lowest and highest point on the. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. The repeat measurement specification insures that. Surface Plate Repeatability.

From www.taiwantrade.com

Surface Plate Repeat Checking Calibrator Taiwantrade Surface Plate Repeatability Flatness denotes the difference between the lowest and highest point on the. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Again, you have to consult the federal. Flatness and repeatability are both critical aspects for determining whether or not a plate. Surface Plate Repeatability.

From optimalcalibration.com

calibration and resurfacing service of granite surface plates Surface Plate Repeatability The repeat measurement specification insures that errors in measurement due to surface variations are held. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Again, you have to consult the federal. Flatness denotes the. Surface Plate Repeatability.

From gaugehow.com

Surface plate Grade system GaugeHow Mechanical Engineering Surface Plate Repeatability Ensure that it falls within the repeatability specification of the plate of the size and the grade. Flatness denotes the difference between the lowest and highest point on the. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. The repeat measurement specification insures that errors in measurement. Surface Plate Repeatability.

From hill-engineering.com

New Publication Near Surface Residual Stress Measurement Using Surface Plate Repeatability Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements. Surface Plate Repeatability.

From www.slideserve.com

PPT Squares and Surface Plates PowerPoint Presentation, free download Surface Plate Repeatability The repeat measurement specification insures that errors in measurement due to surface variations are held. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. To. Surface Plate Repeatability.

From hill-engineering.com

Case Study Contour Method Repeatability Hill Engineering Surface Plate Repeatability Flatness denotes the difference between the lowest and highest point on the. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Ensure that it falls. Surface Plate Repeatability.

From www.researchgate.net

Validation steps of the bixin determination method. (A) Image of plate Surface Plate Repeatability Flatness denotes the difference between the lowest and highest point on the. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Flatness and repeatability are. Surface Plate Repeatability.

From optimalcalibration.com

calibration and resurfacing service of granite surface plates Surface Plate Repeatability Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Again, you have to consult the federal. Ensure that it falls within the repeatability specification of the plate of the size and the grade. To consistently achieve accurate measurements, all surface plates must. Surface Plate Repeatability.

From www.dimensionalgauge.com

Surface Plate Calibration Surface Plate Repeatability To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Again, you have to consult the federal. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Flatness denotes the difference between the lowest and highest point on the. The repeat measurement specification insures that. Surface Plate Repeatability.

From optimalcalibration.com

calibration and resurfacing service of granite surface plates Surface Plate Repeatability Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Ensure that it falls within the repeatability specification of the plate of the size and the. Surface Plate Repeatability.

From www.precisiongageco.com

Why Granite Surface Plate Calibration is Important Precision Gage Co Surface Plate Repeatability Again, you have to consult the federal. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. The repeat measurement specification insures that errors in measurement due to surface variations are held. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Typical uses are precision inspection (for quality control,. Surface Plate Repeatability.

From gaugehow.com

Types of Surface plates GaugeHow Mechanical Engineering Surface Plate Repeatability Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Flatness denotes the difference between the lowest and highest point on the. To consistently achieve accurate. Surface Plate Repeatability.

From www.youtube.com

Surface plate use and applications YouTube Surface Plate Repeatability Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate. Surface Plate Repeatability.

From standridgegranite.com

Surface Plates Surface Plate Repeatability Flatness denotes the difference between the lowest and highest point on the. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. The repeat measurement specification insures that errors in measurement due to surface variations. Surface Plate Repeatability.

From www.jaking.com

Should You Calibrate Your Surface Plate? J. A. King Surface Plate Repeatability To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Again, you have to consult the federal. Flatness denotes the difference between the lowest and highest point on the. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. The repeat measurement specification insures that. Surface Plate Repeatability.

From eleymet.com

What are Surface Plates A Beginners Guide Eley Metrology Surface Plate Repeatability The repeat measurement specification insures that errors in measurement due to surface variations are held. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Ensure that it falls within the repeatability specification of the. Surface Plate Repeatability.

From optimalcalibration.com

calibration and resurfacing service of granite surface plates Surface Plate Repeatability Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Again, you have to consult the federal. Flatness denotes the difference between the lowest and highest point on the. The repeat. Surface Plate Repeatability.

From store.gaging.com

Surface Plate Calibration Systems Surface Plate Repeatability Ensure that it falls within the repeatability specification of the plate of the size and the grade. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. The repeat measurement specification insures that errors in measurement due to surface variations are held. Flatness and repeatability are both critical aspects for determining whether or not a plate provides. Surface Plate Repeatability.

From thermotemp.com

Calibration ThermoTemp, Inc. Surface Plate Repeatability To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. The repeat measurement specification insures that errors in measurement due to surface variations are held. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Flatness and repeatability are both. Surface Plate Repeatability.

From www.researchgate.net

Experimental repeatability analysis Download Scientific Diagram Surface Plate Repeatability To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. The repeat measurement specification insures that errors in measurement due to surface variations are held. Typical uses are precision inspection (for quality control, for example),. Surface Plate Repeatability.

From www.youtube.com

Repeat Reading Gauge and Checking Surface Plate Calibration YouTube Surface Plate Repeatability Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Flatness denotes the difference between the lowest and highest point on. Surface Plate Repeatability.

From www.mitutoyo.com

Surface Plates Accuracy and Calibration Mitutoyo Surface Plate Repeatability To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Flatness denotes the difference between the lowest and highest point on the. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Typical uses are precision inspection (for quality control, for example), marking out (putting. Surface Plate Repeatability.

From eleymet.com

Granite Surface Plate 1200 x 900 x 150 With Stand Grade 0 Eley Metrology Surface Plate Repeatability Again, you have to consult the federal. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Typical uses are precision. Surface Plate Repeatability.

From www.qualitymag.com

The Surface Plate Quality Magazine Surface Plate Repeatability The repeat measurement specification insures that errors in measurement due to surface variations are held. Again, you have to consult the federal. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to. Surface Plate Repeatability.

From www.researchgate.net

Reactive agility system with compliant surface plate. Download Surface Plate Repeatability Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top. Surface Plate Repeatability.

From www.slideserve.com

PPT PEB Plate repeatability PowerPoint Presentation, free download Surface Plate Repeatability Again, you have to consult the federal. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. The. Surface Plate Repeatability.

From www.docdroid.net

Surface Plate Calibration 2021 Complete Guide.pdf DocDroid Surface Plate Repeatability Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. The repeat measurement specification insures that errors in measurement due to surface variations are held. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface. Surface Plate Repeatability.

From maycongnghiep.net.vn

Surface Plate Repeat Checking Calibrator Metrology PLA9002, PLA9003 Surface Plate Repeatability Surface plates are solid flat plates used to mimic a perfect 2d plane as accurately as possible to facilitate other measurements being made on top that plane. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Ensure that it falls within the repeatability specification of the plate. Surface Plate Repeatability.

From www.slideserve.com

PPT PEB Plate repeatability PowerPoint Presentation, free download Surface Plate Repeatability The repeat measurement specification insures that errors in measurement due to surface variations are held. Flatness denotes the difference between the lowest and highest point on the. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a precise surface for obtaining accurate measurements. Again, you have to consult the federal. Typical uses are precision. Surface Plate Repeatability.

From eleymet.com

What are Surface Plates A Beginners Guide Eley Metrology Surface Plate Repeatability To consistently achieve accurate measurements, all surface plates must maintain flatness and repeatability. Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. Ensure that it falls within the repeatability specification of the plate of the size and the grade. Again, you have to consult the federal. Flatness. Surface Plate Repeatability.

From maycongnghiep.net.vn

Surface Plate Repeat Checking Calibrator Metrology PLA9002, PLA9003 Surface Plate Repeatability Typical uses are precision inspection (for quality control, for example), marking out (putting precise markings to guide machine work), and tooling setup. The repeat measurement specification insures that errors in measurement due to surface variations are held. Again, you have to consult the federal. Flatness and repeatability are both critical aspects for determining whether or not a plate provides a. Surface Plate Repeatability.