Atc Tool Change Position . Determine the sequence for an automatic tool change: When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. 6) verify the orientation sensor. 7) check the atc home sensor and verify that. You must install the power. The tool magazine and spindle relative motion realize tool change. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. In the process of tool changing must send the used tool back to tool. Example atc tool changer operation for a cnc. 5) move the atc turret to the tool position of the tool in the spindle. Axes moves to tool change. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®.

from www.gizin-atc.com

5) move the atc turret to the tool position of the tool in the spindle. You must install the power. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. 7) check the atc home sensor and verify that. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. In the process of tool changing must send the used tool back to tool. Determine the sequence for an automatic tool change: Axes moves to tool change. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. The tool magazine and spindle relative motion realize tool change.

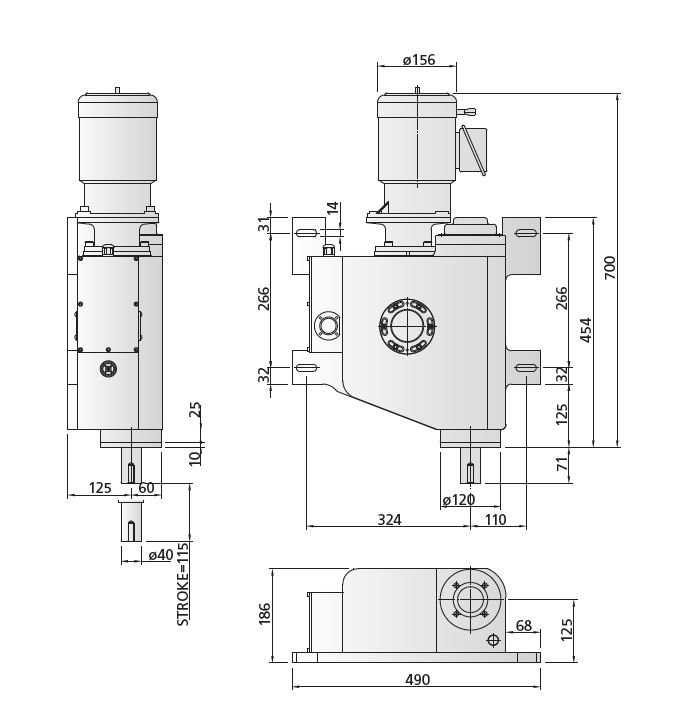

40 Vertical Automatic Tool Changer GE40 A02 Cambox|Automatic Tool

Atc Tool Change Position Determine the sequence for an automatic tool change: This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. 5) move the atc turret to the tool position of the tool in the spindle. You must install the power. The tool magazine and spindle relative motion realize tool change. In the process of tool changing must send the used tool back to tool. Example atc tool changer operation for a cnc. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. Determine the sequence for an automatic tool change: 6) verify the orientation sensor. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. Axes moves to tool change. 7) check the atc home sensor and verify that.

From www.ebay.co.uk

Automatic ATC Tool Changer 20/16/12/8 Position ISO30/ BT30 CNC Milling Atc Tool Change Position You must install the power. 5) move the atc turret to the tool position of the tool in the spindle. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. In the process of tool changing must send the used tool back to tool. Axes moves to tool change. 6) verify the orientation sensor.. Atc Tool Change Position.

From portlandcnc.com

New Modular ATC Tool Holder Pedestals — Portland CNC Atc Tool Change Position Determine the sequence for an automatic tool change: Axes moves to tool change. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. In the process of tool changing must send the used tool back to tool. This document gives instructions to install and use an. Atc Tool Change Position.

From www.gizin-atc.com

Automatic Tool Changers Types, Working, Advantages, and Applications Atc Tool Change Position You must install the power. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. The tool magazine and spindle relative motion realize tool change. In the process. Atc Tool Change Position.

From www.sspm.com.tw

Machine Tools Changer UnitAutomatic ToolChanging Mechanism Series Atc Tool Change Position Axes moves to tool change. Determine the sequence for an automatic tool change: Example atc tool changer operation for a cnc. In the process of tool changing must send the used tool back to tool. You must install the power. The tool magazine and spindle relative motion realize tool change. This document gives instructions to install and use an automatic. Atc Tool Change Position.

From cncmachinecenter.en.made-in-china.com

Taiwan Okada Atc Tool Changer CNC Machine Tools for Metal Cutting Atc Tool Change Position The tool magazine and spindle relative motion realize tool change. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. In the process of tool changing must send the used tool back to tool. You must install the power. 5) move the atc turret to the tool position of the tool in the spindle.. Atc Tool Change Position.

From www.youtube.com

A CNC Automatic Tool Changer (ATC) use Grbl_ESP32 YouTube Atc Tool Change Position The tool magazine and spindle relative motion realize tool change. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. Determine the sequence for an automatic tool change: You must install the power. 6) verify the orientation sensor. 5) move the atc turret to the tool position of the tool in the spindle. When. Atc Tool Change Position.

From www.youtube.com

Tech Tip How to Perform Automatic Tool Changer (ATC) Recovery YouTube Atc Tool Change Position 7) check the atc home sensor and verify that. Example atc tool changer operation for a cnc. You must install the power. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. 6) verify the orientation sensor. Axes moves to tool change. When a tool change. Atc Tool Change Position.

From signsofthetimes.com

Tormach's Automatic Tool Changer Atc Tool Change Position In the process of tool changing must send the used tool back to tool. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.”. Atc Tool Change Position.

From www.youtube.com

2022 Best Automatic Tool Changer CNC Router, ATC CNC Router, Atc Tool Change Position Determine the sequence for an automatic tool change: 6) verify the orientation sensor. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. You must install the power. Axes moves to tool change. Example atc tool changer operation for a cnc. In the process. Atc Tool Change Position.

From toolstoday.com

Automatic Tool Changer for STEPCRAFT MM1000 Spindle Atc Tool Change Position You must install the power. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. Determine the sequence for an automatic tool change: The tool magazine and spindle relative motion realize tool change. 5) move the atc turret to the tool position of the tool in. Atc Tool Change Position.

From www.doosanrobotics.com

Mate KOSMEK LTD. Robotic Hand Changer (ATC Automatic tool changer) Atc Tool Change Position You must install the power. In the process of tool changing must send the used tool back to tool. 5) move the atc turret to the tool position of the tool in the spindle. Example atc tool changer operation for a cnc. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for. Atc Tool Change Position.

From www.youtube.com

Arm type ATC CNC tool changer part 2/2 YouTube Atc Tool Change Position 7) check the atc home sensor and verify that. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. Axes moves to tool change. Determine the sequence for an automatic tool change: The tool magazine and spindle relative motion realize tool change. When a tool change. Atc Tool Change Position.

From www.aliexpress.com

22KWATCSpindle3HPISO2024000RPMAC220V800Hz80MMAutomaticTool Atc Tool Change Position 7) check the atc home sensor and verify that. The tool magazine and spindle relative motion realize tool change. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. Determine the sequence for an automatic tool change: This document gives instructions to install and. Atc Tool Change Position.

From www.youtube.com

Automatic tool changer (ATC) in HMC machine l how can replace puss road Atc Tool Change Position 7) check the atc home sensor and verify that. In the process of tool changing must send the used tool back to tool. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. 6) verify the orientation sensor. This makes for faster, more efficient tool changes which require the controller to record the dynamic. Atc Tool Change Position.

From www.meetyoucarbide.com

What is ATC(Auto Tool Changer)? Meetyou Carbide Atc Tool Change Position This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. 7) check the atc home sensor and verify that. 5) move the atc turret to the tool position of the tool in the spindle. Example atc tool changer operation for a cnc. In the process of. Atc Tool Change Position.

From www.gizin-atc.com

40 Vertical Automatic Tool Changer GE40 A02 Cambox|Automatic Tool Atc Tool Change Position This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. You must install the power. The tool magazine and spindle relative motion realize tool change. 6) verify the orientation sensor. In the process of tool changing must send the used tool back to tool. 7) check. Atc Tool Change Position.

From stoneycnc.co.uk

What is an automatic Tool Changer? • Stoney CNC Atc Tool Change Position Axes moves to tool change. 7) check the atc home sensor and verify that. In the process of tool changing must send the used tool back to tool. 5) move the atc turret to the tool position of the tool in the spindle. You must install the power. Determine the sequence for an automatic tool change: The tool magazine and. Atc Tool Change Position.

From www.fltechnical.com

Evaluating Your Rotary Toolholders for Wear F&L TECHNICAL SALES INC. Atc Tool Change Position Axes moves to tool change. 6) verify the orientation sensor. The tool magazine and spindle relative motion realize tool change. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. 7) check the atc home sensor and verify that. 5) move the atc turret. Atc Tool Change Position.

From www.youtube.com

CNC Build Ep 5 How to Setup an Automatic Tool Changer (ATC) on an Avid Atc Tool Change Position The tool magazine and spindle relative motion realize tool change. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. Example atc tool changer operation for a cnc. 5) move the atc turret to the tool position of the tool in the spindle. 6) verify the orientation sensor. Axes moves to tool change. You. Atc Tool Change Position.

From www.youtube.com

CNC ATC Tool Changer for the Taig CNC mill Final revision YouTube Atc Tool Change Position Determine the sequence for an automatic tool change: When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. Example atc tool changer operation for a cnc. Axes moves to tool change. In the process of tool changing must send the used tool back to. Atc Tool Change Position.

From www.wilatooling.com

Automatic Tool Change WILA Atc Tool Change Position 7) check the atc home sensor and verify that. In the process of tool changing must send the used tool back to tool. Determine the sequence for an automatic tool change: 6) verify the orientation sensor. You must install the power. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. 5) move the. Atc Tool Change Position.

From www.youtube.com

EMS800 EMS600 Tool Probing Ballscrew Auto Tool Changer ATC Mach3 Tool Atc Tool Change Position 6) verify the orientation sensor. You must install the power. The tool magazine and spindle relative motion realize tool change. Determine the sequence for an automatic tool change: Example atc tool changer operation for a cnc. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc. Atc Tool Change Position.

From www.youtube.com

Automatic Tool Changer YouTube Atc Tool Change Position 7) check the atc home sensor and verify that. The tool magazine and spindle relative motion realize tool change. You must install the power. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool. Atc Tool Change Position.

From www.youtube.com

CNC ATC Tool Changer for the Taig CNC mill YouTube Atc Tool Change Position Example atc tool changer operation for a cnc. 6) verify the orientation sensor. 7) check the atc home sensor and verify that. Axes moves to tool change. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. The tool magazine and spindle relative motion realize tool change. Determine the sequence for an automatic tool. Atc Tool Change Position.

From www.corbinstreehouse.com

Video How to Make an ATC Tool Rack Corbin's Treehouse Atc Tool Change Position Axes moves to tool change. The tool magazine and spindle relative motion realize tool change. 7) check the atc home sensor and verify that. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. You must install the power. When a tool change command is received, the tool to be changed is in a. Atc Tool Change Position.

From www.lvcnc.com

What Is An Automatic Tool Changer And The 4 Common Types TAICNC Atc Tool Change Position Axes moves to tool change. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. In the process of tool changing must send the used tool back to tool. 7) check the atc home sensor and verify that. This makes for faster, more efficient tool changes which require the controller to record the dynamic. Atc Tool Change Position.

From www.youtube.com

Denford Novamill ATC tool change with the Mach3 controll YouTube Atc Tool Change Position Axes moves to tool change. 5) move the atc turret to the tool position of the tool in the spindle. 7) check the atc home sensor and verify that. You must install the power. 6) verify the orientation sensor. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change. Atc Tool Change Position.

From www.techpro-cnc.com

Linear ATC CNC Router with Auto Tool Changer TECHPRO® Atc Tool Change Position The tool magazine and spindle relative motion realize tool change. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. 7) check the atc home sensor and verify that. When a tool change command is received, the tool to be changed is in a fixed position,. Atc Tool Change Position.

From planet-cnc.com

How to use tool change with ATC? CNC Atc Tool Change Position 7) check the atc home sensor and verify that. Axes moves to tool change. Example atc tool changer operation for a cnc. 5) move the atc turret to the tool position of the tool in the spindle. 6) verify the orientation sensor. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for. Atc Tool Change Position.

From www.dreamstime.com

The Automatic Tool Change ATC Operation with Swing Arm Stock Image Atc Tool Change Position In the process of tool changing must send the used tool back to tool. 6) verify the orientation sensor. Example atc tool changer operation for a cnc. Axes moves to tool change. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. 5) move the atc turret to the tool position of the tool. Atc Tool Change Position.

From www.youtube.com

Automatic Tool Changer (ATC) Mechanisms used in the CNC machines and Atc Tool Change Position Example atc tool changer operation for a cnc. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. 7) check the atc home sensor and verify that. You. Atc Tool Change Position.

From www.youtube.com

Automatic Tool Changer ATC Tormach 1100M YouTube Atc Tool Change Position You must install the power. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. Determine the sequence for an automatic tool change: In the process of tool changing must. Atc Tool Change Position.

From www.meetyoucarbide.com

¿Qué es ATC (cambiador automático de herramientas)? Meetyou Carburo Atc Tool Change Position Determine the sequence for an automatic tool change: This makes for faster, more efficient tool changes which require the controller to record the dynamic locations for every tool in the controller’s tool. The tool magazine and spindle relative motion realize tool change. You must install the power. This document gives instructions to install and use an automatic tool changer (atc). Atc Tool Change Position.

From circuitlistbilly.z13.web.core.windows.net

Haas Manual Tool Change Atc Tool Change Position 6) verify the orientation sensor. 7) check the atc home sensor and verify that. 5) move the atc turret to the tool position of the tool in the spindle. You must install the power. This document gives instructions to install and use an automatic tool changer (atc) on a 1100m®. The tool magazine and spindle relative motion realize tool change.. Atc Tool Change Position.

From portlandcnc.com

Modular ISO30 ATC Pedestals for Flexibility in CNC Router Builds Atc Tool Change Position 6) verify the orientation sensor. When a tool change command is received, the tool to be changed is in a fixed position, called the „tool change position.” the atc arm reaches. Example atc tool changer operation for a cnc. 7) check the atc home sensor and verify that. In the process of tool changing must send the used tool back. Atc Tool Change Position.