Brazing Flux Diy . Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. Because most brazing fluxes are corrosive, cleaning is essential. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. For using any kind of brazing flux, i have seen it done in 5 ways. Here is a simple and easy homemade rosin flux made from pine cones. If you have a welding supply just buy a can of flux. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for.

from www.lazada.co.id

Here is a simple and easy homemade rosin flux made from pine cones. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. If you have a welding supply just buy a can of flux. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. For using any kind of brazing flux, i have seen it done in 5 ways. Because most brazing fluxes are corrosive, cleaning is essential. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in.

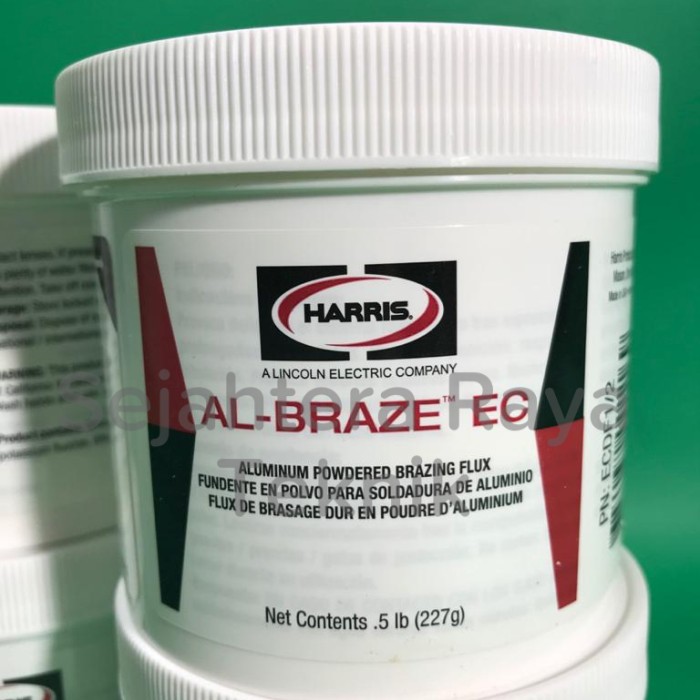

BRAZING FLUX ALUMINIUM merk HARRIS AL BRAZE FLUX KAWAT LAS PERAK ALUMI

Brazing Flux Diy Because most brazing fluxes are corrosive, cleaning is essential. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Because most brazing fluxes are corrosive, cleaning is essential. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. If you have a welding supply just buy a can of flux. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. For using any kind of brazing flux, i have seen it done in 5 ways. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Here is a simple and easy homemade rosin flux made from pine cones. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air.

From www.castolin.com

Paste flux for braze welding with Brazing Alloy 18. Brass/ Bronze flux Brazing Flux Diy For using any kind of brazing flux, i have seen it done in 5 ways. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. If you have a welding supply just buy a can of flux. Brazing aluminum is a quick and inexpensive option for repairing. Brazing Flux Diy.

From www.suppliesplustore.com

Harris AlBraze Flux Powdered Brazing Flux Supplies Plus Store Brazing Flux Diy Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. If you have a welding supply just buy a can of flux. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. Proper fluxing is important because the. Brazing Flux Diy.

From www.solderconnection.com

TENACITY 5 BRAZING FLUX POWDER Solder Connection Brazing Flux Diy It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Because most brazing fluxes are corrosive, cleaning is essential. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Head of solpro and master cutler, james tear takes us through. Brazing Flux Diy.

From www.youtube.com

Aluminum Brazing with Use of Flux YouTube Brazing Flux Diy 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes. Brazing Flux Diy.

From www.grainger.com

HARRIS Brazing Flux 5 lb, Jar, Paste, FB3C, StaySilv Black 54RY05 Brazing Flux Diy Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. Here is a simple and easy homemade rosin flux made from pine cones. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Because most brazing fluxes are corrosive,. Brazing Flux Diy.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Brazing Flux Diy Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Because most brazing fluxes are corrosive, cleaning is essential. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes. Brazing Flux Diy.

From www.indiamart.com

Aluminum Brazing Flux Paste at Rs 1200/kg Brazing Fluxes in Pune ID Brazing Flux Diy Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Because most brazing fluxes are corrosive, cleaning is essential. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air. Fluxes can be made from hydrochloric acid, zinc chloride or. Brazing Flux Diy.

From www.jewelrysupply.com

jewelry soldering tips and tricks KwikFlux Silver Brazing Flux Brazing Flux Diy For using any kind of brazing flux, i have seen it done in 5 ways. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Here is a simple and easy homemade rosin flux made from pine cones. 1)solid crystal, heat your rod, then touch the rod over the stone to. Brazing Flux Diy.

From blog.carbideprocessors.com

Brazing Flux » Carbide Processors Blog Brazing Flux Diy For using any kind of brazing flux, i have seen it done in 5 ways. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. It's in. Brazing Flux Diy.

From www.lazada.co.id

BRAZING FLUX ALUMINIUM merk HARRIS AL BRAZE FLUX KAWAT LAS PERAK ALUMI Brazing Flux Diy Because most brazing fluxes are corrosive, cleaning is essential. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Here is a simple and easy homemade rosin flux made from pine cones. For using any kind of brazing flux, i have seen. Brazing Flux Diy.

From www.youtube.com

brazing flux removal YouTube Brazing Flux Diy Because most brazing fluxes are corrosive, cleaning is essential. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Brazing Flux Diy.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Brazing Flux Diy For using any kind of brazing flux, i have seen it done in 5 ways. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air. If you have a. Brazing Flux Diy.

From dir.indiamart.com

Brass Brazing Fluxes at Best Price in India Brazing Flux Diy Here is a simple and easy homemade rosin flux made from pine cones. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. If you have a welding supply just buy a can of flux. Proper fluxing is important because the flux absorbs oxides formed during. Brazing Flux Diy.

From www.diytrade.com

Silver brazing flux paste FB102C11 TiBright (China Manufacturer Brazing Flux Diy Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for.. Brazing Flux Diy.

From www.youtube.com

Alu Braze Flux, Alusol dan Easy Flux dengan Temperature yang tepat Brazing Flux Diy If you have a welding supply just buy a can of flux. Because most brazing fluxes are corrosive, cleaning is essential. For using any kind of brazing flux, i have seen it done in 5 ways. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Head of solpro and master cutler,. Brazing Flux Diy.

From www.superiorflux.com

Superior Flux Home Page Superior Flux & Mfg. Co. Brazing Flux Diy It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. Here is a simple and easy homemade rosin flux made from pine cones. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. If you have a welding supply just buy a can of. Brazing Flux Diy.

From hansjuon.blogspot.com

Brazing Brass To Aluminum DIY Aluminum Brazing holes in canoe / boat Brazing Flux Diy It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Flux. Brazing Flux Diy.

From www.sarusilver.com

Silver Brazing Flux Low Temperature Brazing, Brazing Flux Brazing Flux Diy Here is a simple and easy homemade rosin flux made from pine cones. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler. Brazing Flux Diy.

From www.hobbyistgeek.com

What Is Brazing Flux And How To Use It? Brazing Flux Diy Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Here is a simple and easy homemade rosin flux made from pine cones. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler. Brazing Flux Diy.

From www.walmart.com

Brazing Flux Powder, 8Ounce Brazing Flux Diy Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Here is a simple and easy homemade rosin flux made from pine cones. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. Brazing aluminum is a. Brazing Flux Diy.

From www.indiamart.com

Brass Flux Brass Brazing Fluxes, Automation Grade Manual, Rs 600 Brazing Flux Diy Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air. If you have a welding supply just buy a can of flux. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the. Brazing Flux Diy.

From www.lazada.co.id

Ace Flux Cair / Silver Brazing Flux Lazada Indonesia Brazing Flux Diy For using any kind of brazing flux, i have seen it done in 5 ways. Here is a simple and easy homemade rosin flux made from pine cones. Because most brazing fluxes are corrosive, cleaning is essential. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. Flux is used in soldering to remove oxides from the contacts. Brazing Flux Diy.

From www.mitre10.com.au

Weldclass Brazing Rod Flux Coated Manganese Bronze 2.4mm Mitre 10 Brazing Flux Diy Here is a simple and easy homemade rosin flux made from pine cones. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. Fluxes can be made. Brazing Flux Diy.

From www.indiamart.com

Braze Flux Copper Alloy Brazing Fluxes at Rs 950/kilogram Brazing Brazing Flux Diy Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Because most brazing fluxes are corrosive, cleaning is essential. If you have a welding supply just buy a can of flux. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. For using any kind of brazing flux, i have. Brazing Flux Diy.

From weldtool.com

Brazing Flux SDS Sheet Weldtool Technologies Brazing Flux Diy Because most brazing fluxes are corrosive, cleaning is essential. For using any kind of brazing flux, i have seen it done in 5 ways. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. If you have a welding supply just buy a can of flux. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks,. Brazing Flux Diy.

From blog.thepipingmart.com

Brazing Flux vs Soldering Flux What's the Difference Brazing Flux Diy Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in.. Brazing Flux Diy.

From www.diytrade.com

Silver brazing flux paste FB102C11 TiBright (China Manufacturer Brazing Flux Diy If you have a welding supply just buy a can of flux. Here is a simple and easy homemade rosin flux made from pine cones. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler. Brazing Flux Diy.

From fyonidqbu.blob.core.windows.net

Best Flux For Brazing Copper at Joe Aviles blog Brazing Flux Diy Fluxes can be made from hydrochloric acid, zinc chloride or rosin. If you have a welding supply just buy a can of flux. 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. It's. Brazing Flux Diy.

From www.pinterest.com

Highquality Flux for Aluminum Brazing Brazing Flux Diy 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Because most brazing fluxes are corrosive, cleaning is essential. For using any kind of brazing flux, i have seen it done in 5 ways. It's. Brazing Flux Diy.

From www.takealot.com

MTS Brazing Flux 500g Shop Today. Get it Tomorrow! Brazing Flux Diy Fluxes can be made from hydrochloric acid, zinc chloride or rosin. It's in the torch welding area, with brazing, silver solder, nickle, aluminum,. Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Because most brazing fluxes are corrosive, cleaning is essential. If you have a welding supply just buy a can. Brazing Flux Diy.

From shopee.ph

Borax Brazing Flux 450g Shopee Philippines Brazing Flux Diy If you have a welding supply just buy a can of flux. Here is a simple and easy homemade rosin flux made from pine cones. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. Brazing aluminum is a quick and inexpensive option for repairing leaks,. Brazing Flux Diy.

From dokumen.tips

(PDF) How to Select a Brazing Flux · 2020. 1. 3. · per AWS Brazing Brazing Flux Diy Because most brazing fluxes are corrosive, cleaning is essential. For using any kind of brazing flux, i have seen it done in 5 ways. Fluxes can be made from hydrochloric acid, zinc chloride or rosin. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler metal. Brazing aluminum is a quick and. Brazing Flux Diy.

From dxozdsyqe.blob.core.windows.net

Can You Braze Without Flux at Gladys Johnson blog Brazing Flux Diy For using any kind of brazing flux, i have seen it done in 5 ways. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air. If you have a welding supply just buy a can of flux. Fluxes can be made from hydrochloric acid, zinc chloride or rosin.. Brazing Flux Diy.

From www.diydoctor.org.uk

How to Braze Metal in 6 Easy Steps DIY Doctor Brazing Flux Diy 1)solid crystal, heat your rod, then touch the rod over the stone to get it coated in. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air. If you have a welding supply just buy a can of flux. Here is a simple and easy homemade rosin flux. Brazing Flux Diy.

From www.thewelderswarehouse.com

500g Brazing Flux for most Grades of Brazing Alloys Brazing Flux Diy Flux is used in soldering to remove oxides from the contacts of the parts to be soldered together. Head of solpro and master cutler, james tear takes us through how to correctly mix flux powder for brazing and what to look for. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow of filler. Brazing Flux Diy.