Robot Joint Drawing . They are used to restrict the relative motion between the two components at a joint o they result in the decrease of the. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning This both allows standard parts to be used, and permits standard, well. It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go.

from ymt-lab.com

Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning This both allows standard parts to be used, and permits standard, well. We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. They are used to restrict the relative motion between the two components at a joint o they result in the decrease of the. It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools.

YMT Lab 3Dプリンタで作るロボットジョイント

Robot Joint Drawing We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning They are used to restrict the relative motion between the two components at a joint o they result in the decrease of the. This both allows standard parts to be used, and permits standard, well. Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them.

From www.pinterest.co.uk

scott robertson spaceship Google Search Robot design sketch, Robot Robot Joint Drawing These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. They are used to restrict the relative motion between the two components at a. Robot Joint Drawing.

From atelier-yuwa.ciao.jp

A Guide To Robot Joint Design atelieryuwa.ciao.jp Robot Joint Drawing These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. It is common in robot design to construct complex joints. Robot Joint Drawing.

From www.researchgate.net

The mechanical assembly of our robot and its joint configuration. The Robot Joint Drawing This both allows standard parts to be used, and permits standard, well. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. If you. Robot Joint Drawing.

From www.youtube.com

Designing Robotic Joints For Concept Artists YouTube Robot Joint Drawing It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and. Robot Joint Drawing.

From ymt-lab.com

YMT Lab 3Dプリンタで作るロボットジョイント Robot Joint Drawing If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. Robot joints refer to the movable components of the robot that result. Robot Joint Drawing.

From hackaday.io

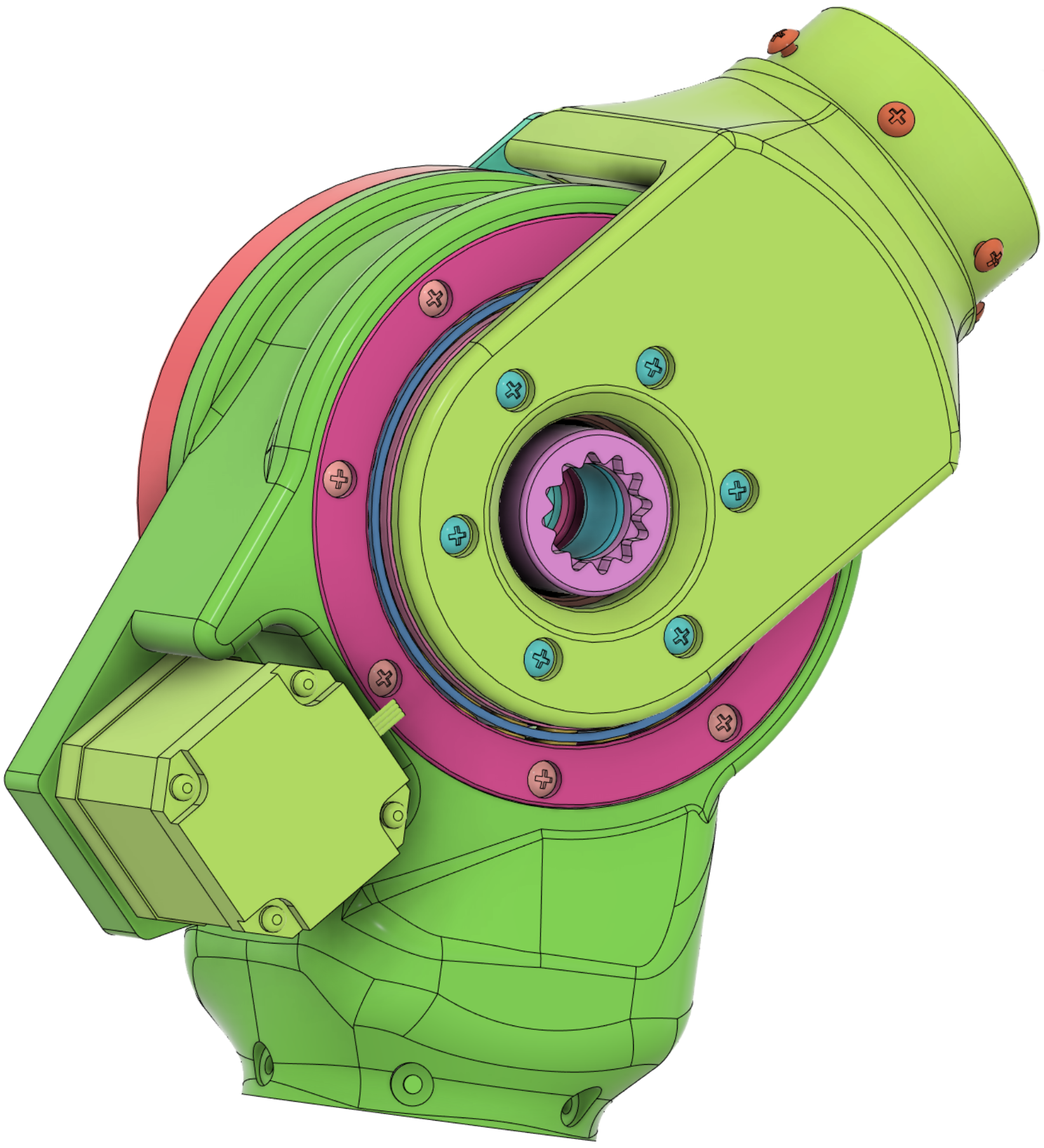

3D Printed Robot Joint with Active Compliance Hackaday.io Robot Joint Drawing These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. In this context, links are used to refer to the rigid members connecting the joints. Robot Joint Drawing.

From www.pinterest.com.au

Mech Joints Поиск в Google Cyberpunk, Design Reference, Art Reference Robot Joint Drawing In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. In this context, links are used to refer to the rigid members connecting the. Robot Joint Drawing.

From www.youtube.com

Robot Joints YouTube Robot Joint Drawing If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. They are used to restrict the relative motion between the two components at a joint o they result in the decrease of the. Robot joints refer to the movable components. Robot Joint Drawing.

From www.youtube.com

Drawing mech joints YouTube Robot Joint Drawing If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning These joints are typically equipped with actuators, sensors, and mechanical. Robot Joint Drawing.

From www.researchgate.net

Lightweight robot with 6 rotational joints [1]. Download Scientific Robot Joint Drawing They are used to restrict the relative motion between the two components at a joint o they result in the decrease of the. It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints. Robot Joint Drawing.

From peerj.com

Wholebody kinematic and dynamic modeling for quadruped robot under Robot Joint Drawing If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. They are used to restrict the relative motion between the two components at a joint o they result in the decrease of the. This both allows standard parts to be. Robot Joint Drawing.

From www.engineersgarage.com

What are the components of robotic arms and industrial robots? Robot Joint Drawing Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their. Robot Joint Drawing.

From www.researchgate.net

Original robotic joint configurations. Download Scientific Diagram Robot Joint Drawing In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. They are used to restrict. Robot Joint Drawing.

From in.pinterest.com

Diagram of a sixaxis industrial robotic arm. Robot arm, Robot design Robot Joint Drawing Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. This both allows standard parts to be used, and permits standard, well.. Robot Joint Drawing.

From myrobotlab.org

Interesting Robotic Joint design MyRobotLab Robot Joint Drawing This both allows standard parts to be used, and permits standard, well. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. Through a comprehensive. Robot Joint Drawing.

From gramaziokohler.github.io

compas_fab Kinematic model Robot Joint Drawing In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. These joints. Robot Joint Drawing.

From howtodrawcurlyhairsideprofile.blogspot.com

how to draw robot legs howtodrawcurlyhairsideprofile Robot Joint Drawing In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. Through a comprehensive analysis, we aim to provide a detailed understanding of how these. Robot Joint Drawing.

From robodk.com

Robot Joint Types The Essential Introduction RoboDK blog Robot Joint Drawing These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you. Robot Joint Drawing.

From westsideelectronics.com

2 Revolute Joint Robotic Arm Robot Joint Drawing Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. It is common in robot design to construct complex joints by combining. Robot Joint Drawing.

From www.reddit.com

Some robotic arms and mechanical parts sketches r/drawing Robot Joint Drawing In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. Robot joints come in many forms, including rotational. Robot Joint Drawing.

From www.haascnc.com

Haas Robot Troubleshooting Guide Robot Joint Drawing If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out. Robot Joint Drawing.

From www.pinterest.com

ArtStation Robotic Joint Design, Edon Guraziu Design, Robot, Robots Robot Joint Drawing Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. Robot joints refer to the movable components of the robot that result. Robot Joint Drawing.

From www.google.com

Patent US20110167945 Robot joint driving apparatus, robot having the Robot Joint Drawing It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. They are used to restrict the relative motion between the two components at a joint o they result in the decrease of the. Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. In this. Robot Joint Drawing.

From www.mdpi.com

Applied Sciences Free FullText Method for Robot Manipulator Joint Robot Joint Drawing Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. In this context, links are used to refer to the rigid members connecting. Robot Joint Drawing.

From www.pinterest.com

ArtStation Robotic Joint Design, Edon Guraziu Robot design, Design Robot Joint Drawing Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. They are used to restrict the relative motion between the two components at a joint o they result in the decrease of. Robot Joint Drawing.

From newatlas.com

Changing instructions to make robot joints more energy efficient Robot Joint Drawing It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. This both allows standard parts to be used, and permits standard, well. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. They are used to restrict the relative motion between the two components at. Robot Joint Drawing.

From mavink.com

Robotic Arm Diagram Robot Joint Drawing We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning It is common in robot design to construct. Robot Joint Drawing.

From www.researchgate.net

Joint structures and link frames of the robot and the human skeleton Robot Joint Drawing It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components. Robot Joint Drawing.

From www.mdpi.com

Energies Free FullText Design of the Joint Motor for an Robot Joint Drawing It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. These joints are typically equipped with actuators, sensors, and mechanical components. Robot Joint Drawing.

From hackaday.io

Project 3D Printed Robot Joint with Active Compliance Hackaday.io Robot Joint Drawing Robot joints refer to the movable components of the robot that result in relative motions between adjacent links. It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning We are going to look. Robot Joint Drawing.

From www.youtube.com

Robotic arm joint , solidworks, design, robot, robotics, Robot Joint Drawing In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. Robot joints refer to the. Robot Joint Drawing.

From www.pinterest.com

infinitedoodles Mech Joints Study Mechanical design, Robots concept Robot Joint Drawing It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. These joints are typically equipped with actuators, sensors, and mechanical components to facilitate controlled movement and precise positioning. In this context, links are used to refer to the rigid members connecting the joints for clear and adequate functioning Through a comprehensive analysis, we. Robot Joint Drawing.

From www.pinterest.se

mechanical joints mechanical studies from some gundam booksfocused on Robot Joint Drawing Robot joints come in many forms, including rotational joints like those in arms and legs, as well as sliding joints found in robotic grippers and other tools. It is common in robot design to construct complex joints by combining simple rotational and prismatic elements. In this article, we explore the anatomy, types, and physics of robotic joints, delving into their. Robot Joint Drawing.

From www.pinterest.com

Pin on TYPES OF JOINTS FOR MECH DESIGN Robot Joint Drawing In this article, we explore the anatomy, types, and physics of robotic joints, delving into their control systems and discussing the challenges encountered in their design and operation. Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. These joints are typically equipped with actuators, sensors, and mechanical components to. Robot Joint Drawing.

From www.researchgate.net

6axis industrial robot Stäubli TX200 robot Download Scientific Diagram Robot Joint Drawing Through a comprehensive analysis, we aim to provide a detailed understanding of how these fundamental components are engineered and controlled. If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go. Robot joints refer to the movable components of the robot. Robot Joint Drawing.