Etching Equipment Semiconductor . Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Introducing the product lineup of dry etch systems. Introducing the product lineup of conductor etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). An etch system is used. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some.

from kremesti.com

Introducing the product lineup of dry etch systems. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Introducing the product lineup of conductor etch systems. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some.

The Semiconductor Chip Manufacturing Process

Etching Equipment Semiconductor Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Introducing the product lineup of conductor etch systems. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Introducing the product lineup of dry etch systems.

From princetonscientific.com

Plasma Etching Etching Equipment Semiconductor An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Introducing the product lineup of conductor etch systems. In semiconductor device fabrication, etching refers to. Etching Equipment Semiconductor.

From www.alamy.com

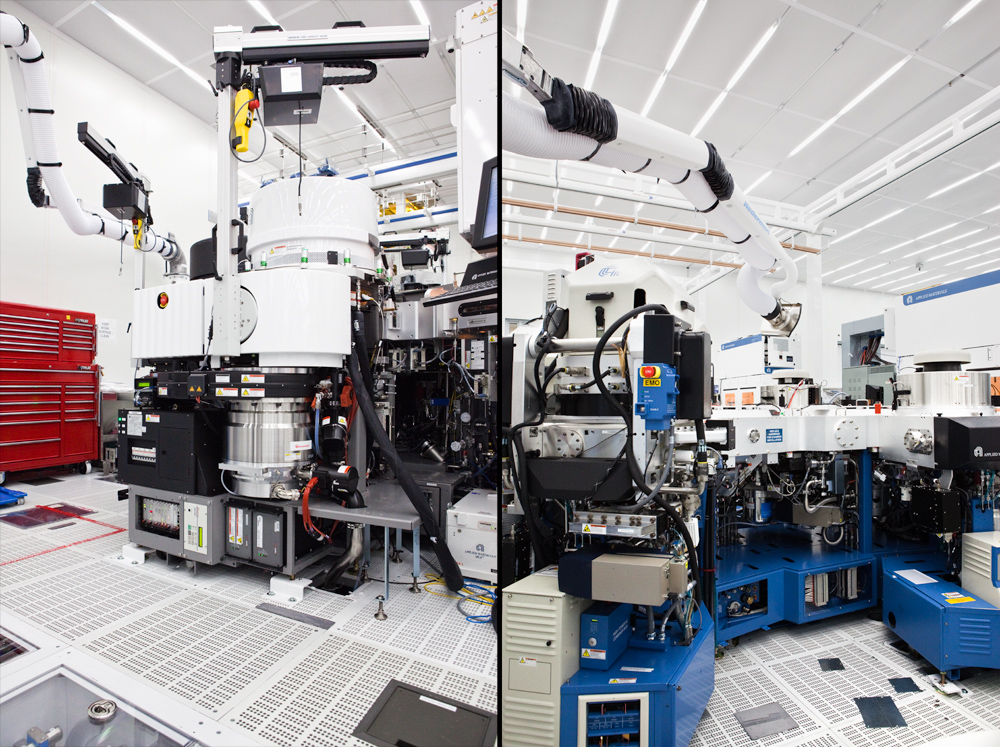

Chip manufacture. Etching equipment used in the production of Etching Equipment Semiconductor Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most. Etching Equipment Semiconductor.

From www.dalton.co.jp

Etching (cleaning) equipment Archives Semiconductor Equipments Etching Equipment Semiconductor An etch system is used. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Introducing the product lineup of dry etch systems. Introducing the product lineup of conductor etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on. Etching Equipment Semiconductor.

From www.ibuildwow.com

Semiconductor Dielectric Etching Equipment Market 2023, Size, Share Etching Equipment Semiconductor An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Introducing the product lineup of conductor etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on. Etching Equipment Semiconductor.

From www.hitachi.com

Semiconductor Manufacturing & Inspection Equipment Electronic Systems Etching Equipment Semiconductor An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. An etch system is used. Introducing the product lineup of conductor etch systems. Describes the types and plasma generation mechanism. Etching Equipment Semiconductor.

From www.acmrcsh.com

Semiconductor wet etching systems from ACM Research Etching Equipment Semiconductor In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Introducing the product lineup of dry etch systems. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching. Etching Equipment Semiconductor.

From www.dalton.co.jp

Spin etching (cleaning) equipment Semiconductor Equipments Etching Equipment Semiconductor An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from. Etching Equipment Semiconductor.

From www.linkedin.com

Semiconductor Etching Equipment Market, Global Outlook and Forecast Etching Equipment Semiconductor Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from. Etching Equipment Semiconductor.

From www.beswick.com

Semiconductor Beswick Engineering Etching Equipment Semiconductor Introducing the product lineup of dry etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. Reactive ion etching remains the core technology. Etching Equipment Semiconductor.

From www.eurotherm.com

Semiconductor Fabrication Dry Etch Processing Solution Eurotherm Limited Etching Equipment Semiconductor An etch system is used. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. Introducing the product lineup of dry etch systems. Introducing the product lineup of conductor etch systems. Describes the types. Etching Equipment Semiconductor.

From www.mdpi.com

Coatings Free FullText Spectroscopic Analysis of CF4/O2 Plasma Etching Equipment Semiconductor Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron. Etching Equipment Semiconductor.

From www.hi-mecha.co.jp

Semiconductor manufacturing equipment HiMECHA CORPORATION Etching Equipment Semiconductor Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to. Etching Equipment Semiconductor.

From www.horiba.com

Semiconductor Processing Etch Etching Equipment Semiconductor Introducing the product lineup of dry etch systems. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases. Etching Equipment Semiconductor.

From www.semiconductor-digest.com

Samco Unveils New Plasma Etching Cluster Tool for Compound Etching Equipment Semiconductor In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Introducing the product lineup of conductor etch systems. An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance. Etching Equipment Semiconductor.

From www.semistarcorp.com

Branson IPC L3200 Plasma etching semiconductor equipment SemiStar Etching Equipment Semiconductor Introducing the product lineup of dry etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Describes the types. Etching Equipment Semiconductor.

From suireng.ie

Semiconductor Wafer Fabrication Facility Suir Engineering Etching Equipment Semiconductor An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. Introducing the product lineup of conductor etch systems. Introducing the product lineup of dry etch systems. In semiconductor device. Etching Equipment Semiconductor.

From www.azom.com

PlasmaPro 100 Cobra to Achieve Fast Etching and Deposition Rates Etching Equipment Semiconductor An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Introducing the product lineup of dry etch systems. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Describes the types and plasma generation mechanism of etching equipment which are. Etching Equipment Semiconductor.

From www.researchgate.net

1 Semiconductor etching process of surface micromachine [2.1 Etching Equipment Semiconductor An etch system is used. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. Describes the types and plasma generation mechanism of etching equipment. Etching Equipment Semiconductor.

From www.thierry-corp.com

HF Etching Etching Equipment Semiconductor Introducing the product lineup of conductor etch systems. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. In semiconductor device fabrication, etching refers to. Etching Equipment Semiconductor.

From www.samcointl.com

Compound Semiconductor Etching Samco Inc. Etching Equipment Semiconductor Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Introducing the product lineup of dry etch systems. Introducing the product lineup of conductor etch. Etching Equipment Semiconductor.

From byteclicks.com

可实现扇出型晶圆级封装的铜电镀技术 字节点击 Etching Equipment Semiconductor In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Introducing the product lineup of conductor etch systems. Introducing the product lineup of dry etch systems. An etch system is used. Reactive ion etching remains the core technology for the semiconductor. Etching Equipment Semiconductor.

From kremesti.com

The Semiconductor Chip Manufacturing Process Etching Equipment Semiconductor An etch system is used. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Introducing the product lineup of conductor. Etching Equipment Semiconductor.

From newsletter.iimbaa.com

How to lay the solid foundation for semiconductor fabrication in India Etching Equipment Semiconductor An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Introducing the product lineup of conductor etch systems. Introducing the product lineup of dry etch systems. An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for. Etching Equipment Semiconductor.

From japaneseclass.jp

Images of ジャパンセミコンダクター大分ラグビー部 JapaneseClass.jp Etching Equipment Semiconductor Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Introducing the product lineup of dry etch systems. An etch system shapes the thin film. Etching Equipment Semiconductor.

From www.dalton.co.jp

Etching (cleaning) equipment Archives Semiconductor Equipments Etching Equipment Semiconductor Introducing the product lineup of conductor etch systems. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor. Etching Equipment Semiconductor.

From www.kedsemi.com

Single wafer Spin EtcherKED tech Etching Equipment Semiconductor Introducing the product lineup of dry etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Plasma etching is. Etching Equipment Semiconductor.

From www.mdpi.com

Applied Sciences Free FullText Factor Design for the Oxide Etching Etching Equipment Semiconductor An etch system is used. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Introducing the product lineup of conductor. Etching Equipment Semiconductor.

From news.mynavi.jp

Lam Research、GAA構造デバイスに対応する3種類の高選択エッチング装置を発表 TECH+(テックプラス) Etching Equipment Semiconductor Introducing the product lineup of dry etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. An etch system is used. Reactive ion. Etching Equipment Semiconductor.

From www.azom.com

Reactive Ion Etching (RIE) — PlasmaPro 100 RIE Quote, RFQ, Price and Buy Etching Equipment Semiconductor Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Introducing the product lineup of dry etch systems. Introducing the product lineup of conductor etch systems. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. An etch system. Etching Equipment Semiconductor.

From www.azom.com

Etch Technology Used in Semiconductor Manufacturing Etching Equipment Semiconductor An etch system is used. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching remains the core. Etching Equipment Semiconductor.

From www.mdpi.com

Applied Sciences Free FullText Factor Design for the Oxide Etching Etching Equipment Semiconductor An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used. Introducing the product lineup of conductor etch systems. In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on. Etching Equipment Semiconductor.

From www.emphysys.com

Large silicon wafer etching machine Emphysys Technology Solutions Etching Equipment Semiconductor An etch system is used. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Introducing the product lineup of dry etch systems. Plasma etching. Etching Equipment Semiconductor.

From auwiichiller.en.made-in-china.com

Industrial Chiller for Semiconductor Dry Etching Equipment China Etching Equipment Semiconductor An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Introducing the product lineup of conductor etch systems. Introducing the product lineup of dry etch systems. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron. Etching Equipment Semiconductor.

From www.alibaba.com

Plasma Etching Machine Semiconductor Vacuum Plasma Cleaner Equipment Etching Equipment Semiconductor Introducing the product lineup of conductor etch systems. Plasma etching is perhaps the most essential process in semiconductor manufacturing, and possibly the most complex. Reactive ion etching remains the core technology for the semiconductor industry, and is likely to retain its dominance for some. An etch system is used. Introducing the product lineup of dry etch systems. Describes the types. Etching Equipment Semiconductor.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Etching Equipment Semiconductor In semiconductor device fabrication, etching refers to any technology that will selectively remove material from a thin film on a substrate (with or without prior structures on its surface). An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching remains the core technology for the semiconductor industry,. Etching Equipment Semiconductor.