Welding Half Inch Steel . Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. It is similar to the v bevel but it's a u shape (see. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. How to mig weld steel for beginners: If we have prints that call out weld sizes. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld.

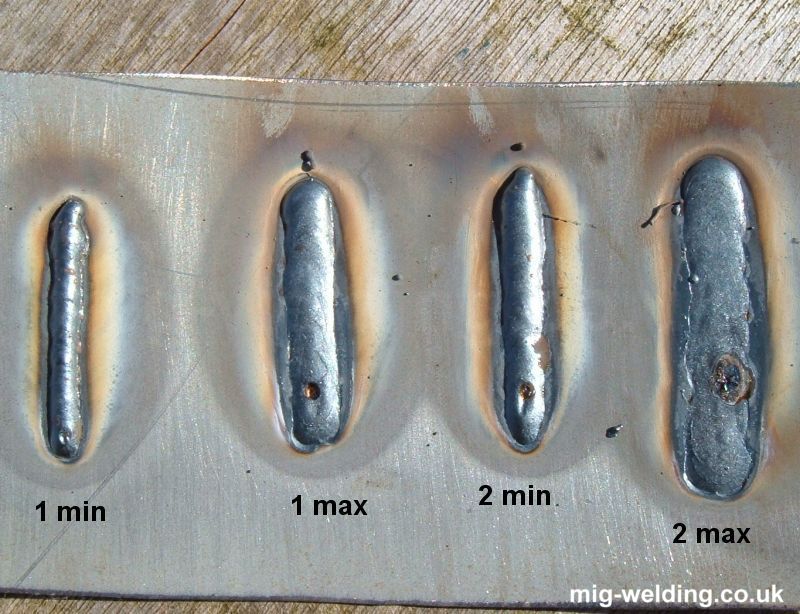

from www.mig-welding.co.uk

If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. It is similar to the v bevel but it's a u shape (see. How to mig weld steel for beginners: A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. If we have prints that call out weld sizes. Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld.

Welding thick metal

Welding Half Inch Steel If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. It is similar to the v bevel but it's a u shape (see. How to mig weld steel for beginners: If we have prints that call out weld sizes. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount.

From cartoondealer.com

CNC Robotic Mig Welding Of Half Inch Steel Parts Stock Image Welding Half Inch Steel How to mig weld steel for beginners: It is similar to the v bevel but it's a u shape (see. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. If we have prints that call out weld sizes. This post gives simple calculations for determining. Welding Half Inch Steel.

From weldguru.com

TIG Welding Stainless Steel A Beginners Guide Weld Guru Welding Half Inch Steel Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. How to mig weld steel for beginners: It is similar to the v bevel. Welding Half Inch Steel.

From catalog.wosupply.com

Steel 3000 lb Socket Weld Half Coupling Product Detail WO Welding Half Inch Steel When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. It is similar to the v bevel but it's a u shape (see. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses. Welding Half Inch Steel.

From pipefurniture.com.au

22mm (Half Inch) Threaded Black Steel Pipe Set Lengths Welding Half Inch Steel If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. It is similar to the v bevel but it's a u shape (see. Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and. Welding Half Inch Steel.

From www.bgstructuralengineering.com

Welding Intro Welding Half Inch Steel Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. If the print calls for a 3/16” fillet,. Welding Half Inch Steel.

From www.reddit.com

Struck welding half inch carbon steel. 6010 electrode with about 9 Welding Half Inch Steel When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. Mig welding is an arc welding process in. Welding Half Inch Steel.

From www.indiamart.com

2 inch Stainless Steel Socket Weld Half Coupling threaded, For Plumbing Welding Half Inch Steel When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. It is similar to the v bevel but. Welding Half Inch Steel.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Welding Half Inch Steel How to mig weld steel for beginners: Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. This post gives. Welding Half Inch Steel.

From steelfittings-flange.com

Socket Weld Half Coupling ESTAN PIPE FITTINGS CO., LTD Welding Half Inch Steel If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. How to mig weld steel for beginners: If we have prints that call out weld sizes. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use. Welding Half Inch Steel.

From www.alamy.com

Bright light and smoke from CNC robotic mig welding of half inch steel Welding Half Inch Steel If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. How to mig weld steel for beginners: A welder that excels in metal inert. Welding Half Inch Steel.

From www.youtube.com

JB Weld Joining 2 Pieces of Steel 2nd Try YouTube Welding Half Inch Steel A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. It is similar to the v bevel but it's a u shape (see. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. If we. Welding Half Inch Steel.

From www.indiamart.com

Mild Steel Half Threaded Welding Nipple, Rs 50 /piece Saitechs Welding Half Inch Steel If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. How to mig weld steel for beginners: A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. When welding steel plate that is anywhere from. Welding Half Inch Steel.

From www.reddit.com

Just started 2 weeks ago. One of my best so far TIG welds on 1/4 inch Welding Half Inch Steel A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. If we have prints that call out weld sizes. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. When welding steel plate that is. Welding Half Inch Steel.

From ritonmetalind.com

Buy Socket weld Half Coupling, Welded Socket weld Half Welding Half Inch Steel If we have prints that call out weld sizes. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. Mig welding is. Welding Half Inch Steel.

From www.youtube.com

Round Pipe Notching Techniques // Round Tube T Joint // Metal Pipe Welding Half Inch Steel How to mig weld steel for beginners: It is similar to the v bevel but it's a u shape (see. If we have prints that call out weld sizes. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. If you'd like to learn how to mig weld steel, then this. Welding Half Inch Steel.

From www.dreamstime.com

Acid Etch Test for Welding Depth in Half Inch Thick Steel Macro Stock Welding Half Inch Steel It is similar to the v bevel but it's a u shape (see. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to. Welding Half Inch Steel.

From primeweld.com

A Guide to Weld Joints PrimeWeld Welding Half Inch Steel If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. A welder that excels in metal inert gas (mig) welding. Welding Half Inch Steel.

From www.dragzine.com

MIGWelding Basics To Help You Correctly Melt Metal Welding Half Inch Steel When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. If we have prints that call out weld sizes. It is similar to. Welding Half Inch Steel.

From www.onestopndt.com

Fillet Weld Sizing Guidelines OnestopNDT Welding Half Inch Steel If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. How to mig weld steel for beginners: When welding steel. Welding Half Inch Steel.

From www.mig-welding.co.uk

Welding thick metal Welding Half Inch Steel Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. If we have prints that call out weld. Welding Half Inch Steel.

From milehidistilling.com

Half Inch Stainless Steel NPT Male Fitting Threaded Plug Mile Hi Welding Half Inch Steel This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. How to mig weld steel for beginners: A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. If we have prints that call out weld sizes. When welding steel. Welding Half Inch Steel.

From steelpipefittingsplus.com

Socket Weld Half Coupling Welding Half Inch Steel A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. It is similar to the v bevel but it's a u shape (see. If we have prints that call out weld sizes. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to. Welding Half Inch Steel.

From www.youtube.com

TIG Welding 11/2" Inch Thick Aluminum YouTube Welding Half Inch Steel If we have prints that call out weld sizes. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. If the print calls for a 3/16” fillet,. Welding Half Inch Steel.

From www.eng-tips.com

Fillet Weld Size Based On Plate Thick Structural engineering general Welding Half Inch Steel When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. How to mig weld steel for beginners: If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. Mig. Welding Half Inch Steel.

From www.walmart.com

Uxcell 304 Stainless Steel G1/2 Male Half Threaded Weldable Weld Welding Half Inch Steel This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. A welder that excels in metal inert gas (mig) welding offers the precision and. Welding Half Inch Steel.

From www.indiamart.com

2 inch Stainless Steel Socket Weld Half Coupling threaded, For Plumbing Welding Half Inch Steel It is similar to the v bevel but it's a u shape (see. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. When welding. Welding Half Inch Steel.

From millenniumalloys.ca

Common Methods Of Welding Stainless Steel Millennium Alloys Welding Half Inch Steel When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. Mig welding is an arc welding process in which a continuous solid wire. Welding Half Inch Steel.

From weldinghelmetgenius.com

Socket Weld A Comprehensive Guide (Updated March 2024) Welding Half Inch Steel If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. How to mig weld steel for beginners: This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. If you'd like to learn. Welding Half Inch Steel.

From www.alamy.com

Half inch steel being bent in degree press with vibration sensor Welding Half Inch Steel If we have prints that call out weld sizes. If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. A welder that excels in. Welding Half Inch Steel.

From www.indiamart.com

Carbon Steel Socket Weld Half Coupling, Size 1/4 To 4 Inch at Rs 25 Welding Half Inch Steel If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. If we have prints that call out weld sizes. It. Welding Half Inch Steel.

From www.welding.org

Welding Positions Wall Poster Hobart Institute of Welding Technology Welding Half Inch Steel If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times the required amount. Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. This post gives simple calculations for determining the minimum and. Welding Half Inch Steel.

From www.youtube.com

How to Weld a 3g Half inch plate with a 7018 Backing Strip Tulsa Welding Half Inch Steel If we have prints that call out weld sizes. How to mig weld steel for beginners: It is similar to the v bevel but it's a u shape (see. Mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld. If you'd like to learn how to. Welding Half Inch Steel.

From www.haihaopiping.com

Threaded Full/Half Carbon Steel Fittings ASTM A234 Welding Half Inch Steel If you'd like to learn how to mig weld steel, then this instructable will give you the keys to unlock your mig welding potential. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. Mig welding is an arc welding process in. Welding Half Inch Steel.

From coremaintenance.com

PIPE WELDING & INSTALLATION Core Industrial Maintenance Welding Half Inch Steel This post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. If we have prints that call out weld sizes. A welder that excels in metal inert gas (mig) welding offers the precision and power needed for such tasks. How to mig weld steel for beginners: If the print. Welding Half Inch Steel.

From blog.thepipingmart.com

Stainless Steel Pipe Welding Process A Complete Guide Welding Half Inch Steel If we have prints that call out weld sizes. When welding steel plate that is anywhere from ½ inch to ¾ of an inch you should use the u type bevel to properly prepare your metal joint. If the print calls for a 3/16” fillet, the 5/16” fillet weld you deposit would be overwelding by 177%, or almost three times. Welding Half Inch Steel.