Visual Inspection Tools In Welding . The role of a weld. Visual inspection or visual testing are carried. This guide contains information to assist in the visual examination of welds. It also explains the causes of. Visual inspection is a crucial method for evaluating the weld quality of a test subject. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. Included are sections on fundamentals, surface. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities.

from technoweld.com.au

It also explains the causes of. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. Included are sections on fundamentals, surface. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Visual inspection or visual testing are carried. The role of a weld. Visual inspection is a crucial method for evaluating the weld quality of a test subject. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. This guide contains information to assist in the visual examination of welds.

Visual Welding Inspection Benefits South Australia and NSW

Visual Inspection Tools In Welding It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. Visual inspection or visual testing are carried. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. Included are sections on fundamentals, surface. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. This guide contains information to assist in the visual examination of welds. It also explains the causes of. The role of a weld. Visual inspection is a crucial method for evaluating the weld quality of a test subject.

From www.youtube.com

Welding defects, their visual appearance, and identification for CSWIP Visual Inspection Tools In Welding This guide contains information to assist in the visual examination of welds. Visual inspection is a crucial method for evaluating the weld quality of a test subject. The role of a weld. It also explains the causes of. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. A visual inspector of welds. Visual Inspection Tools In Welding.

From www.youtube.com

Cara Visual Welding Inspection YouTube Visual Inspection Tools In Welding Visual inspection is a crucial method for evaluating the weld quality of a test subject. It also explains the causes of. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. Included are sections on fundamentals, surface. The role of a weld. It explains how techniques. Visual Inspection Tools In Welding.

From www.youtube.com

CSWIP Visual Inspection of Welds YouTube Visual Inspection Tools In Welding Visual inspection or visual testing are carried. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. Included are sections on fundamentals, surface. This guide contains information to assist in the visual examination of welds. It also explains the causes of. Visual inspection is a crucial method for. Visual Inspection Tools In Welding.

From www.sai.edu.my

Visual Welding Inspector Level 1 Skills Asia Visual Inspection Tools In Welding A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Visual inspection is a crucial method for evaluating the weld quality of a test subject. The role of a weld. Visual inspection or visual testing are carried. It also explains the causes of. This guide contains information to assist in the visual examination. Visual Inspection Tools In Welding.

From ndtvendor.com

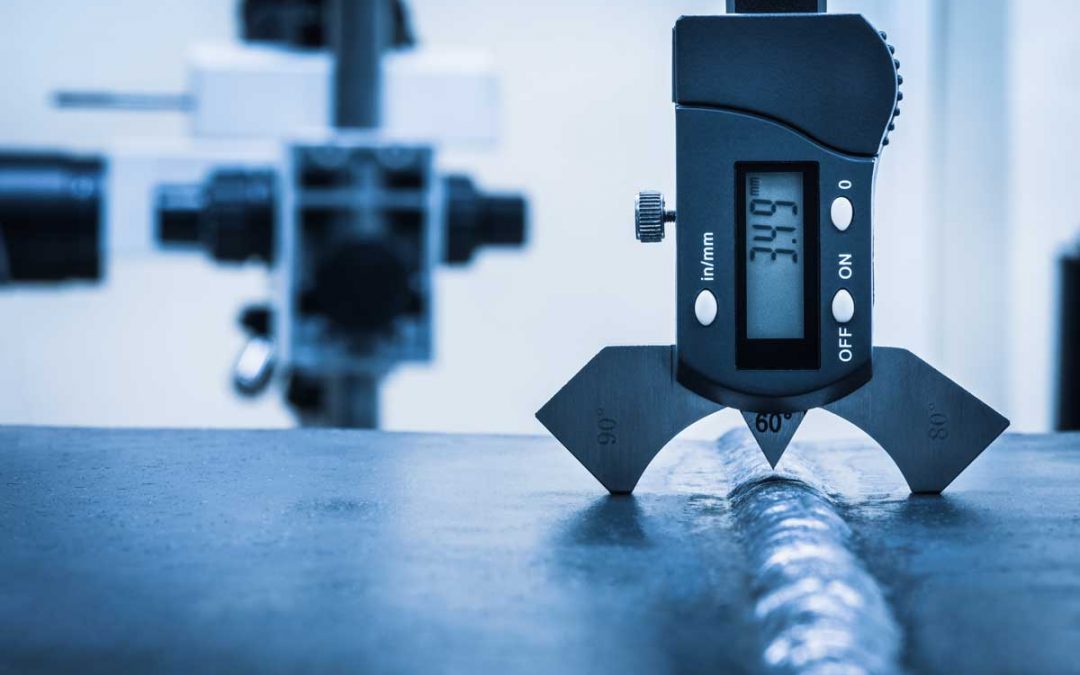

Extended weld inspection kit Weld Measuring Gauges Visual Inspection Tools In Welding Included are sections on fundamentals, surface. Visual inspection is a crucial method for evaluating the weld quality of a test subject. The role of a weld. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. It explains how techniques for weld inspection and testing are used to. Visual Inspection Tools In Welding.

From weldguru.com

Weld Quality Testing Visual, Physical & NDT Weld Guru Visual Inspection Tools In Welding This guide contains information to assist in the visual examination of welds. Visual inspection is a crucial method for evaluating the weld quality of a test subject. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. A lack of proper welding inspection offers the potential. Visual Inspection Tools In Welding.

From technoweld.com.au

Visual Welding Inspection Benefits South Australia and NSW Visual Inspection Tools In Welding Visual inspection or visual testing are carried. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. This guide contains information to assist in the visual examination of welds. The role of a weld. Included are sections on fundamentals, surface. Weld visual testing or vt is carried out using natural vision and also. Visual Inspection Tools In Welding.

From www.codeaweld.com

NonDestructive Weld Testing Advantages Of Thorough Testing London Visual Inspection Tools In Welding It also explains the causes of. This guide contains information to assist in the visual examination of welds. Visual inspection is a crucial method for evaluating the weld quality of a test subject. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. The role of a weld.. Visual Inspection Tools In Welding.

From mungfali.com

Visual Welding Inspection 2f6 Visual Inspection Tools In Welding It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. This guide contains information to assist in the visual examination of welds. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. The. Visual Inspection Tools In Welding.

From www.ndt.com.ua

Welds testing Visual Inspection Tools In Welding Visual inspection or visual testing are carried. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. Included are sections on fundamentals, surface. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. It also. Visual Inspection Tools In Welding.

From www.sik.ba

Inspection of Welded Parts SIK Mostar Visual Inspection Tools In Welding Included are sections on fundamentals, surface. Visual inspection is a crucial method for evaluating the weld quality of a test subject. The role of a weld. This guide contains information to assist in the visual examination of welds. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel. Visual Inspection Tools In Welding.

From www.newmantools.com

How to read welding inspection gauges, WG series gages Visual Inspection Tools In Welding It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. Visual inspection or visual testing are carried. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. It also explains the causes of. Weld visual. Visual Inspection Tools In Welding.

From www.researchgate.net

Process and Visual Welding Inspection Tasks (Continued) Download Visual Inspection Tools In Welding It also explains the causes of. This guide contains information to assist in the visual examination of welds. Visual inspection is a crucial method for evaluating the weld quality of a test subject. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. It explains how techniques for. Visual Inspection Tools In Welding.

From technoweld.com.au

What Types of Welding Inspections Should You Know About? Technoweld Visual Inspection Tools In Welding Visual inspection is a crucial method for evaluating the weld quality of a test subject. This guide contains information to assist in the visual examination of welds. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Included are sections on fundamentals, surface. A visual inspector of welds is trained and certified to. Visual Inspection Tools In Welding.

From trinityndt.com

Visual Testing VT Level 2 Welding training Institute in India Visual Inspection Tools In Welding It also explains the causes of. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. A lack of proper welding inspection offers the potential. Visual Inspection Tools In Welding.

From www.scribd.com

Visual Inspection of Weld Nondestructive Testing Welding Visual Inspection Tools In Welding A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. Visual inspection or visual testing are carried. Included are sections on fundamentals, surface. It also explains the causes of. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. The role. Visual Inspection Tools In Welding.

From www.dreamstime.com

Visual Inspection stock image. Image of dimensions, asme 40283979 Visual Inspection Tools In Welding The role of a weld. Included are sections on fundamentals, surface. This guide contains information to assist in the visual examination of welds. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. It explains how techniques for weld inspection and testing are used to identify and characterise. Visual Inspection Tools In Welding.

From 1streporting.com

The Welding Inspection Checklist For Your Business (For Powerful Visual Inspection Tools In Welding A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Visual inspection is a crucial method for evaluating the weld quality of a test subject. It explains how techniques for weld. Visual Inspection Tools In Welding.

From resources.arcmachines.com

Orbital Pipe Welding Visual Inspection Checklist Arc Machines Visual Inspection Tools In Welding Visual inspection is a crucial method for evaluating the weld quality of a test subject. This guide contains information to assist in the visual examination of welds. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Weld visual testing or vt is carried out using natural vision and also with aided tools. Visual Inspection Tools In Welding.

From barracuda-ss.com

Barracuda Specialty Service LLC provides a variety of VT visual Visual Inspection Tools In Welding A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Visual inspection or visual testing are carried. The role of a weld. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. It also explains the causes of. Included. Visual Inspection Tools In Welding.

From egac.co

Visual Inspection Test (Level I & II) VT Egyptian Academy Visual Inspection Tools In Welding Visual inspection or visual testing are carried. It also explains the causes of. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. This guide. Visual Inspection Tools In Welding.

From fortisweldinspection.co.nz

Our Services Fortis Weld Inspection Visual Inspection Tools In Welding Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. Included are sections on fundamentals, surface. Visual inspection is a crucial method for evaluating the weld quality of a test subject. Visual inspection or visual testing are carried. It also explains the causes of. The role. Visual Inspection Tools In Welding.

From ndtvendor.com

Extended weld inspection kit Weld Measuring Gauges Visual Inspection Tools In Welding It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. Visual inspection or visual testing are carried. It also explains the causes of. This guide contains information to assist in the visual examination of welds. A lack of proper welding inspection offers the potential for quality problems,. Visual Inspection Tools In Welding.

From www.youtube.com

Welding visual inspection procedure YouTube Visual Inspection Tools In Welding A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. It also explains the causes of. The role of a weld. Included are sections on fundamentals, surface. Visual inspection or visual testing are carried. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a. Visual Inspection Tools In Welding.

From weldingclarity.com

Visual Inspection in Weld Quality Testing How it Works? Visual Inspection Tools In Welding Included are sections on fundamentals, surface. Visual inspection is a crucial method for evaluating the weld quality of a test subject. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. This guide contains information to assist in the visual examination of welds. The role of. Visual Inspection Tools In Welding.

From blog.morganitech.com

New Product Line Hawkeye Remote Visual Inspection Tools Visual Inspection Tools In Welding Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance criteria. This guide contains information to assist in the visual examination of welds. Included are. Visual Inspection Tools In Welding.

From www.cruxweld.com

Quality Weld Inspection Nondestructive Testing cruxweld Visual Inspection Tools In Welding Visual inspection is a crucial method for evaluating the weld quality of a test subject. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. A visual inspector of welds is trained and certified to inspect a finished weld to ensure it meets the relevant acceptance. Visual Inspection Tools In Welding.

From www.aliexpress.com

Stainless Steel Welder Inspection Gauge Welding Measure Gauge Kits Visual Inspection Tools In Welding This guide contains information to assist in the visual examination of welds. Visual inspection is a crucial method for evaluating the weld quality of a test subject. Visual inspection or visual testing are carried. Included are sections on fundamentals, surface. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. It explains how. Visual Inspection Tools In Welding.

From toolsidee.co.uk

HBM 16 Piece Professional Welding Tools Set, Visual Weld Inspection Set Visual Inspection Tools In Welding Included are sections on fundamentals, surface. Visual inspection is a crucial method for evaluating the weld quality of a test subject. It also explains the causes of. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. This guide contains information to assist in the visual examination. Visual Inspection Tools In Welding.

From tagumdoctors.edu.ph

Welding Gauge Tool Kit Welding Measure Gauge Test Ulnar Welder Visual Inspection Tools In Welding Visual inspection or visual testing are carried. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. The role of a weld. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Included are sections on fundamentals, surface. It. Visual Inspection Tools In Welding.

From matec.ca

Visual Weld Inspection Matec Consulting Services Visual Inspection Tools In Welding Visual inspection is a crucial method for evaluating the weld quality of a test subject. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. This guide contains information to assist in the visual examination of welds. Visual inspection or visual testing are carried. A lack of. Visual Inspection Tools In Welding.

From resources.arcmachines.com

How to Do a Pipe Welding Visual Inspection Arc Machines Visual Inspection Tools In Welding It also explains the causes of. Visual inspection or visual testing are carried. Included are sections on fundamentals, surface. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel components. The role of a weld. A visual inspector of welds is trained and certified to inspect a finished. Visual Inspection Tools In Welding.

From awscwi.com

The Best Visual Weld Testing 10 Amazing Tools You Need Visual Inspection Tools In Welding A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. Included are sections on fundamentals, surface. Visual inspection or visual testing are carried. Weld visual testing or vt is carried out using natural vision and also with aided tools such as a torch, magnifying glass, and boroscope. It also explains the causes of.. Visual Inspection Tools In Welding.

From ewi.org

EWI Titanium Weld Color Inspection Kit Weld Inspection Solutions Visual Inspection Tools In Welding The role of a weld. Included are sections on fundamentals, surface. This guide contains information to assist in the visual examination of welds. Visual inspection is a crucial method for evaluating the weld quality of a test subject. It explains how techniques for weld inspection and testing are used to identify and characterise defects that can arise in structural steel. Visual Inspection Tools In Welding.

From www.ebindustries.com

Visual Weld Inspection 2019 NDT Weld Testing EB Industries Visual Inspection Tools In Welding Included are sections on fundamentals, surface. A lack of proper welding inspection offers the potential for quality problems, life safety issues and liabilities. This guide contains information to assist in the visual examination of welds. Visual inspection is a crucial method for evaluating the weld quality of a test subject. Weld visual testing or vt is carried out using natural. Visual Inspection Tools In Welding.