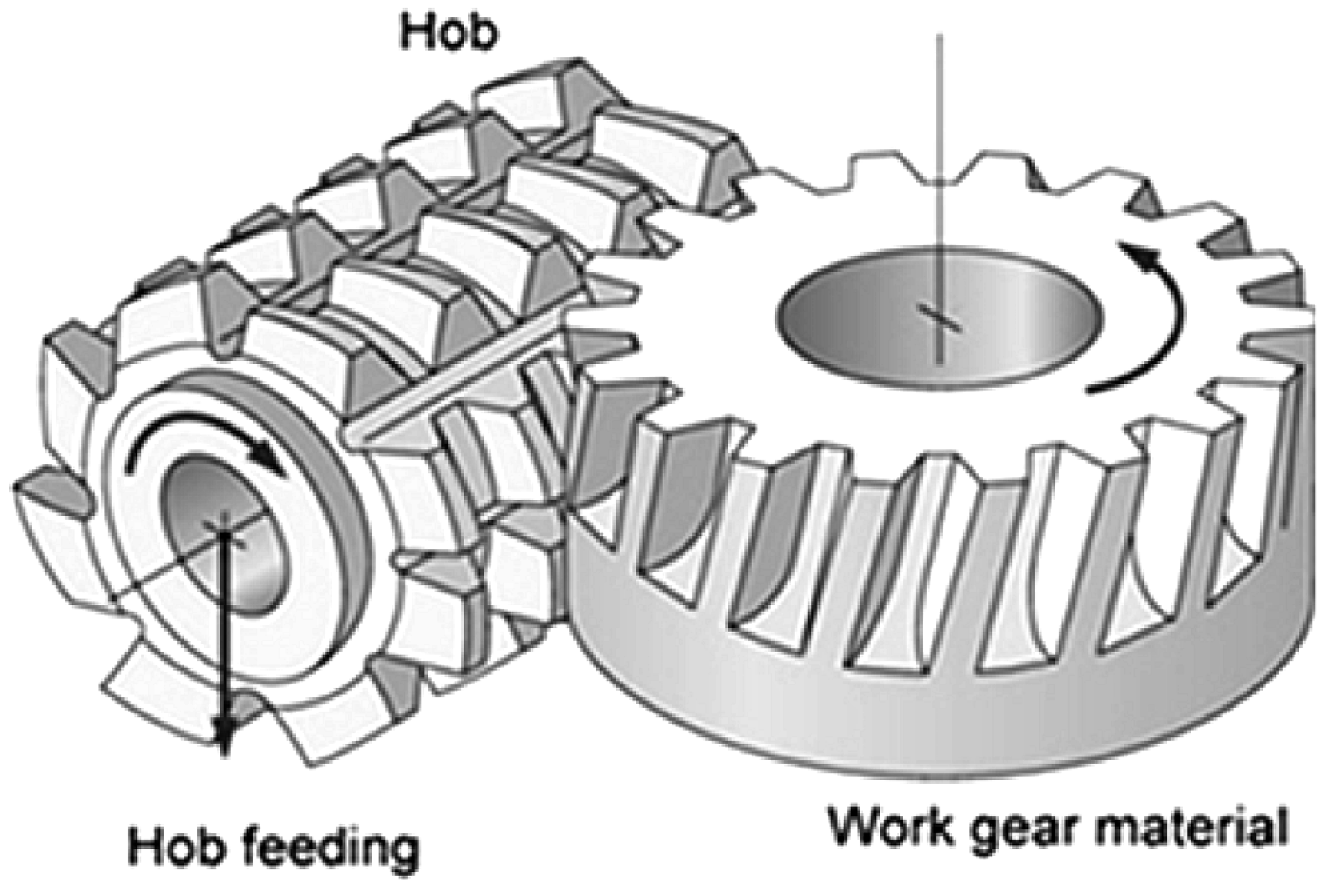

Helical Gear Hobbing Process . The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a worm, typically. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The hob and gear blank are rotated.

from www.mdpi.com

Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Each successive rack is shifted axially to create a worm, typically. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The hob is a series of racks positioned around the circumference of a cylindrical tool. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The hob and gear blank are rotated.

Energies Free FullText An Intelligent Deep Learning Technique for

Helical Gear Hobbing Process Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Each successive rack is shifted axially to create a worm, typically. The hob is a series of racks positioned around the circumference of a cylindrical tool. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The hob and gear blank are rotated. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing.

From www.youtube.com

Amazing Manufacturing Process of Helical Gear Gear Hobbing Operation Helical Gear Hobbing Process Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The gear hobbing process, including cutting. Helical Gear Hobbing Process.

From www.researchgate.net

Power curve of the complete helical gear hobbing process Download Helical Gear Hobbing Process The hob and gear blank are rotated. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a worm, typically. Gear hobbing is the process of generating gear teeth with a. Helical Gear Hobbing Process.

From mechanicalbasics.com

Gear Hobbing Machine With FAQs & Video Mechanical Basics Helical Gear Hobbing Process Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The hob is. Helical Gear Hobbing Process.

From www.semanticscholar.org

Figure 1 from CADBased Simulation of Gear hobbing Semantic Scholar Helical Gear Hobbing Process Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The hob and gear blank are rotated. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the. Helical Gear Hobbing Process.

From www.shutterstock.com

Process Cutting Helical Gear Modular Hob Stock Photo 2185831963 Helical Gear Hobbing Process Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The hob and gear blank are rotated. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank. Helical Gear Hobbing Process.

From www.shutterstock.com

Gear Hobbing Helical Gear Hobbing Process Stock Illustration 2210473649 Helical Gear Hobbing Process Each successive rack is shifted axially to create a worm, typically. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The hob is a series of racks positioned around the circumference of a cylindrical. Helical Gear Hobbing Process.

From www.researchgate.net

a Schematic diagram of the gear hobbing machine (source authors). b Helical Gear Hobbing Process Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Each successive rack is shifted axially. Helical Gear Hobbing Process.

From www.zhygear.com

Machining status of helical face gear ZHY Gear Helical Gear Hobbing Process Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Each successive rack is shifted axially to create a worm, typically. The hob is a series of racks positioned around the circumference of a cylindrical tool. The hob and gear blank are rotated. Gear hobbing is the process. Helical Gear Hobbing Process.

From www.slideserve.com

PPT THE INDEXING MECHANISM OF GEAR HOBBING MACHINE PowerPoint Helical Gear Hobbing Process Each successive rack is shifted axially to create a worm, typically. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the. Helical Gear Hobbing Process.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Helical Gear Hobbing Process The hob and gear blank are rotated. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is a process in which gear is cut by a generating process by rotating. Helical Gear Hobbing Process.

From www.fictiv.com

The 3 Essential Methods for Gear Machining Fictiv Helical Gear Hobbing Process The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The hob is a series of racks positioned around the circumference of a cylindrical tool. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Gear hobbing is a process in which. Helical Gear Hobbing Process.

From www.researchgate.net

Basic kinematics and essential parameters of gear hobbing Download Helical Gear Hobbing Process The hob and gear blank are rotated. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The hob is a series of racks positioned around the circumference of a cylindrical tool. Hobbing is a gear manufacturing process. Helical Gear Hobbing Process.

From www.shutterstock.com

Process Cutting Helical Gear Modular Hob Stock Photo 2164352875 Helical Gear Hobbing Process Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Each successive rack is shifted axially to create a worm, typically. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. Hobbing is a gear manufacturing process in which gear teeth are generated through a series. Helical Gear Hobbing Process.

From www.lampin.com

Hobbing and Gear Cutting Services by Lampin Co. Helical Gear Hobbing Process The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time. Helical Gear Hobbing Process.

From www.motorgearengineer.com

Gear Hobbing Service Introduction, Working, and Applications Helical Gear Hobbing Process Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The hob and gear blank are rotated. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing.. Helical Gear Hobbing Process.

From www.zhygear.com

Machining method of helical gear hobbing and shaping ZHY Gear Helical Gear Hobbing Process Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The hob and gear blank are rotated. The hob is a series of racks positioned around the circumference of a cylindrical tool. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is a process in. Helical Gear Hobbing Process.

From www.youtube.com

Hobbing a Helical Gear (Differential Method) YouTube Helical Gear Hobbing Process Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Each successive rack is shifted axially to create a worm, typically. The gear hobbing process, including cutting tools (hobs), generating process, equipment,. Helical Gear Hobbing Process.

From learnmech.com

Gear Hobbing Parts, Working, Diagram, Advantages, Disadvantages Helical Gear Hobbing Process The hob and gear blank are rotated. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The gear blank and hob rotate continuously until all gear teeth are cut into the. Helical Gear Hobbing Process.

From www.youtube.com

The process of Gear Hobbing. Engineer's Academy YouTube Helical Gear Hobbing Process Each successive rack is shifted axially to create a worm, typically. The hob and gear blank are rotated. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Hobbing is a gear manufacturing process in which. Helical Gear Hobbing Process.

From www.researchgate.net

The four possible cutting variations in hobbing of helical gears Helical Gear Hobbing Process Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The hob and gear blank are rotated. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with. Helical Gear Hobbing Process.

From dlxinxiang-machine.en.made-in-china.com

Gear Hobbing Machine Can Process Super Gear Helical Gear Ydq31400 Helical Gear Hobbing Process The hob and gear blank are rotated. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Each successive rack is shifted axially to create a worm, typically. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The gear hobbing process,. Helical Gear Hobbing Process.

From thors.com

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process Helical Gear Hobbing Process Each successive rack is shifted axially to create a worm, typically. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The hob is a series of racks positioned around the circumference of a cylindrical. Helical Gear Hobbing Process.

From www.alamy.com

Gear hobbing of helical gear Hobbing process to cut a helical gear with Helical Gear Hobbing Process Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The hob is a series of racks positioned around the circumference of a cylindrical tool. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds,. Helical Gear Hobbing Process.

From extrudergearbox.net

Hobbing The Gear Manufacturing Process Explained Helical Gear Hobbing Process Each successive rack is shifted axially to create a worm, typically. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing.. Helical Gear Hobbing Process.

From www.semanticscholar.org

A Review on Gear Hobbing Process Semantic Scholar Helical Gear Hobbing Process The hob and gear blank are rotated. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The hob. Helical Gear Hobbing Process.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Hobbing Process Each successive rack is shifted axially to create a worm, typically. The hob and gear blank are rotated. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Hobbing is a gear manufacturing process in which. Helical Gear Hobbing Process.

From www.zhygear.com

Hobbing of helical gear installation of hob ZHY Gear Helical Gear Hobbing Process Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. The gear blank and hob rotate continuously. Helical Gear Hobbing Process.

From www.shutterstock.com

Process Cutting Helical Gear Modular Hob Stock Photo 2163016191 Helical Gear Hobbing Process The hob and gear blank are rotated. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The hob is a series of racks positioned around the circumference of a cylindrical tool. Hobbing is a gear manufacturing process. Helical Gear Hobbing Process.

From thors.com

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process Helical Gear Hobbing Process Each successive rack is shifted axially to create a worm, typically. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Helical Gear Hobbing Process.

From www.istockphoto.com

Process Of Cutting Helical Gear With Modular Hob Cutter Stock Photo Helical Gear Hobbing Process The hob and gear blank are rotated. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The hob is a series of racks positioned around the circumference of a cylindrical tool. The gear hobbing process, including cutting. Helical Gear Hobbing Process.

From www.youtube.com

Gear Hobbing Process Compilation Kompilasi Proses Gear Hobbing Helical Gear Hobbing Process Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Each successive rack is shifted axially to. Helical Gear Hobbing Process.

From www.mdpi.com

Energies Free FullText An Intelligent Deep Learning Technique for Helical Gear Hobbing Process The hob is a series of racks positioned around the circumference of a cylindrical tool. The hob and gear blank are rotated. Each successive rack is shifted axially to create a worm, typically. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The gear hobbing process, including. Helical Gear Hobbing Process.

From www.youtube.com

How To Helical Gear Teeth Cutting On "HOBBING MACHINE" YouTube Helical Gear Hobbing Process Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The hob and gear blank are rotated. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a. Helical Gear Hobbing Process.

From engineeringlearn.com

Gear Hobbing Machine Definition, Types, Uses, Working & Construction Helical Gear Hobbing Process The hob and gear blank are rotated. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Each successive rack is shifted axially to create a worm, typically. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb vs conventional hobbing. Gear hobbing is a process in which gear. Helical Gear Hobbing Process.

From www.liebherr.com

Gear shaping of double helical gears Liebherr Liebherr Helical Gear Hobbing Process The hob and gear blank are rotated. Hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The gear hobbing process, including cutting tools (hobs), generating process, equipment, machinery, feeds, and climb. Helical Gear Hobbing Process.