Sanding Disc Vs Grinding Disc . in terms of function, ceramic sanding discs can do just about anything a flap disc can do. However, they can accomplish those jobs without risking overheating due to their ceramic construction. Hook and loop sanding discs are made up of abrasive coated cloth,. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. They are designed for grinding and shaping metals,. flap discs vs grinding wheels: They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. Grinding discs are perhaps the most widely used abrasive discs in various industries. Flap discs are capable of.

from www.nainc.org

They are designed for grinding and shaping metals,. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. However, they can accomplish those jobs without risking overheating due to their ceramic construction. Flap discs are capable of. Hook and loop sanding discs are made up of abrasive coated cloth,. flap discs vs grinding wheels: Grinding discs are perhaps the most widely used abrasive discs in various industries. in terms of function, ceramic sanding discs can do just about anything a flap disc can do. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits.

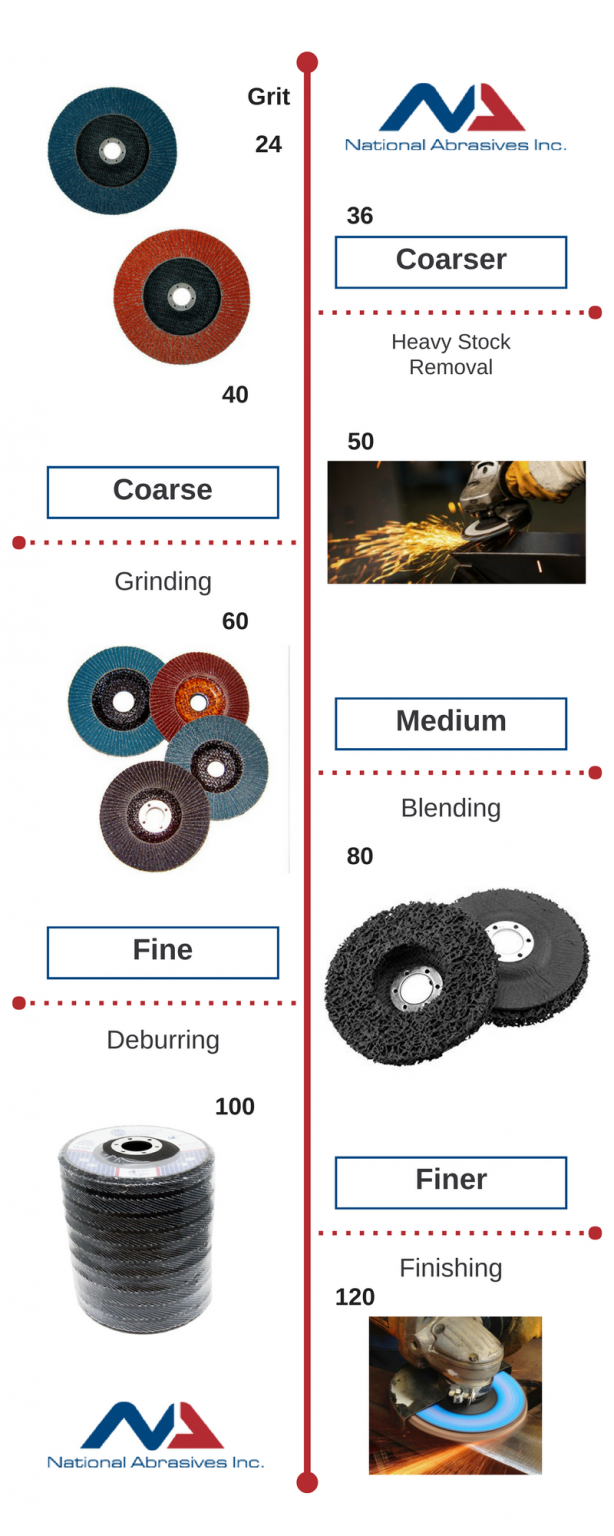

Sandpaper Grit Guide for Auto Body Work National Abrasives

Sanding Disc Vs Grinding Disc They are designed for grinding and shaping metals,. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. in terms of function, ceramic sanding discs can do just about anything a flap disc can do. Hook and loop sanding discs are made up of abrasive coated cloth,. They are designed for grinding and shaping metals,. Grinding discs are perhaps the most widely used abrasive discs in various industries. Flap discs are capable of. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. flap discs vs grinding wheels: flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. However, they can accomplish those jobs without risking overheating due to their ceramic construction.

From www.weem-abrasives.com

Resin Fiber Sanding Discs For Angle Grinder / Zirconia Aluminum Grain Sanding Disc Vs Grinding Disc Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. Hook and loop sanding discs are made up of abrasive coated cloth,. Flap discs are capable of. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are. Sanding Disc Vs Grinding Disc.

From www.ebay.com

100 DISC LOT 3M Roloc Abrasive Sanding Die Grinder Discs 2" 100 Grit w Sanding Disc Vs Grinding Disc They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. flap discs vs grinding wheels: However, they can accomplish those jobs without risking overheating due to their ceramic construction. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to. Sanding Disc Vs Grinding Disc.

From www.lazada.com.ph

BUILDMATE Hoyoma Sanding Disc Fiber Abrasive GRIT 24 240 Polishing Sanding Disc Vs Grinding Disc Flap discs are capable of. flap discs vs grinding wheels: However, they can accomplish those jobs without risking overheating due to their ceramic construction. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. Hook and loop sanding discs are made up of abrasive coated cloth,. They. Sanding Disc Vs Grinding Disc.

From www.youtube.com

Make a Disc Sander Attachment For Angle Grinder Angle Grinder Hack Sanding Disc Vs Grinding Disc Hook and loop sanding discs are made up of abrasive coated cloth,. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. They are designed for grinding and shaping metals,. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits.. Sanding Disc Vs Grinding Disc.

From exobkksky.blob.core.windows.net

Sander Disc Grit at Lillie Hansen blog Sanding Disc Vs Grinding Disc Flap discs are capable of. flap discs vs grinding wheels: Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. They are designed for grinding and shaping metals,. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around. Sanding Disc Vs Grinding Disc.

From www.amazon.co.uk

Bulnqyk 225mm Sanding Disc 6 Holes Hook and Loop Discs,30 Pcs P40/P60 Sanding Disc Vs Grinding Disc Flap discs are capable of. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. They are designed for grinding and shaping metals,. Grinding discs are perhaps the most widely used abrasive discs in various industries. grinding wheels are most commonly used for various grinding,. Sanding Disc Vs Grinding Disc.

From www.amazon.com

OEMTOOLS 24940 2” Twist Lock Surface Prep Discs, 25 Piece Medium Die Sanding Disc Vs Grinding Disc Hook and loop sanding discs are made up of abrasive coated cloth,. flap discs vs grinding wheels: flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. Better yet, many modern ceramic. Sanding Disc Vs Grinding Disc.

From www.youtube.com

How To Make Disc Sander Attachment For Angle Grinder YouTube Sanding Disc Vs Grinding Disc grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. Flap discs are capable of. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. However, they can accomplish those jobs without risking overheating due to their ceramic construction. Better. Sanding Disc Vs Grinding Disc.

From www.walmart.com

50Pcs Sanding Discs 115mm Fibre Sanding Grinding Discs Wheels 24120 Sanding Disc Vs Grinding Disc grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient. Sanding Disc Vs Grinding Disc.

From www.amazon.co.uk

25PCS 150mm Sanding Discs, JatilEr Grit 3000/4000/5000/7000/10000 Round Sanding Disc Vs Grinding Disc grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. Flap discs are capable of. flap discs vs grinding wheels: However, they can accomplish those jobs without risking overheating due to their ceramic construction. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than. Sanding Disc Vs Grinding Disc.

From engweld.co.uk

Flap Discs Guide Engweld Talk Sanding Disc Vs Grinding Disc However, they can accomplish those jobs without risking overheating due to their ceramic construction. Grinding discs are perhaps the most widely used abrasive discs in various industries. in terms of function, ceramic sanding discs can do just about anything a flap disc can do. Hook and loop sanding discs are made up of abrasive coated cloth,. Better yet, many. Sanding Disc Vs Grinding Disc.

From dxoevnvtz.blob.core.windows.net

Sanding Disc For Angle Grinder Toolstation at Virginia Davis blog Sanding Disc Vs Grinding Disc flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. However, they can accomplish those jobs without risking overheating due to their ceramic construction. flap discs vs grinding wheels: They are designed for grinding and shaping metals,. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining. Sanding Disc Vs Grinding Disc.

From abrasive-systems.co.uk

Flap Discs or Grinding Discs? Abrasive Finishing Systems Sanding Disc Vs Grinding Disc Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. in terms of function, ceramic sanding discs can do just about anything a flap disc can do. flap discs vs grinding wheels: Flap discs are capable of. grinding wheels are most commonly used. Sanding Disc Vs Grinding Disc.

From www.ebay.com

BlueSpot 11pc Polishing Sanding Flap Discs Set Angle Grinder 115mm 4.5 Sanding Disc Vs Grinding Disc flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. Flap discs are capable of. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one. Sanding Disc Vs Grinding Disc.

From www.aliexpress.com

10pcs100mmSandingDiscSandpaper80GritPolishingDiscGrinding Sanding Disc Vs Grinding Disc flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. They are designed for grinding and shaping metals,. However, they can accomplish those jobs without risking overheating due to their ceramic construction. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient. Sanding Disc Vs Grinding Disc.

From www.empireabrasives.com

Flap Discs vs Grinding Wheels A SidebySide Comparison for Better Sanding Disc Vs Grinding Disc They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. flap discs vs grinding wheels: Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. in terms of function, ceramic sanding discs can do just. Sanding Disc Vs Grinding Disc.

From www.walmart.com

4Inch x 5/8Inch Aluminum Oxide Resin Fiber Discs, Center Hole 36 Grit Sanding Disc Vs Grinding Disc Flap discs are capable of. They are designed for grinding and shaping metals,. Hook and loop sanding discs are made up of abrasive coated cloth,. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one. Sanding Disc Vs Grinding Disc.

From www.weem-abrasives.com

Grit P27 Angle Grinder Flap Discs , Zirconia Alumina Sanding Disc Sanding Disc Vs Grinding Disc Hook and loop sanding discs are made up of abrasive coated cloth,. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Flap discs are capable of. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. . Sanding Disc Vs Grinding Disc.

From www.jtape.com

How to Choose the Correct Sanding Disc JTAPE Sanding Disc Vs Grinding Disc They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. Flap discs are capable of. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Hook and loop sanding discs are made up of abrasive coated cloth,. flap discs vs grinding wheels:. Sanding Disc Vs Grinding Disc.

From www.penntoolco.com

TRUMAXX Aluminum Oxide QuickChange Sanding Discs, Type R, 3" Diameter Sanding Disc Vs Grinding Disc in terms of function, ceramic sanding discs can do just about anything a flap disc can do. Flap discs are capable of. Grinding discs are perhaps the most widely used abrasive discs in various industries. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. They are. Sanding Disc Vs Grinding Disc.

From www.nainc.org

Sandpaper Grit Guide for Auto Body Work National Abrasives Sanding Disc Vs Grinding Disc Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. in terms of function, ceramic sanding discs can do just about anything a flap disc can do. flap discs vs grinding wheels: They are designed for grinding and shaping metals,. Grinding discs are perhaps. Sanding Disc Vs Grinding Disc.

From www.aliexpress.com

50Pcs 2inch 50mm Sanding Roloc Grinding Discs 80 Grit Roll Lock Surface Sanding Disc Vs Grinding Disc Grinding discs are perhaps the most widely used abrasive discs in various industries. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. flap discs vs grinding wheels:. Sanding Disc Vs Grinding Disc.

From www.researchgate.net

Specification of abrasive cutting discs used during tests. Download Sanding Disc Vs Grinding Disc Hook and loop sanding discs are made up of abrasive coated cloth,. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. Better yet, many modern ceramic sanding discs carry a higher sanding. Sanding Disc Vs Grinding Disc.

From binictools.com

How To Select The Best Sanding Discs For Your Projects Binic Abrasive Sanding Disc Vs Grinding Disc Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. flap discs vs grinding wheels: Hook and loop sanding discs are made up of abrasive coated cloth,. They are designed for grinding and shaping metals,. flap discs are a cross between a grinding disc. Sanding Disc Vs Grinding Disc.

From www.cheefatt.com

7 Types of Abrasive Discs Abrasives Chee Fatt Singapore Sanding Disc Vs Grinding Disc Grinding discs are perhaps the most widely used abrasive discs in various industries. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. flap discs vs grinding wheels: However, they can accomplish those jobs without risking overheating due to their ceramic construction. in terms of function,. Sanding Disc Vs Grinding Disc.

From electriccounselor.com

Best 5 Angle Grinder Sanding Disc Electric Counselor Sanding Disc Vs Grinding Disc Flap discs are capable of. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them. Sanding Disc Vs Grinding Disc.

From sinoabrasives.en.made-in-china.com

4" Flap Sanding Discs Angle Grinder Wheel Orbital Sander Pad Tool Sanding Disc Vs Grinding Disc They are designed for grinding and shaping metals,. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. However, they can accomplish those jobs without risking overheating due to. Sanding Disc Vs Grinding Disc.

From www.youtube.com

ARA / Te Pukenga "How to" Change sanding and grinding discs on the Sanding Disc Vs Grinding Disc Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. They are designed for grinding and shaping metals,. Hook and loop sanding discs are made up of abrasive coated cloth,. However, they can accomplish those jobs without risking overheating due to their ceramic construction. They are. Sanding Disc Vs Grinding Disc.

From www.youtube.com

[23] angle grinder sanding discs DIY YouTube Sanding Disc Vs Grinding Disc flap discs vs grinding wheels: flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Hook and loop sanding discs are made up of abrasive coated cloth,. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. They are. Sanding Disc Vs Grinding Disc.

From www.junseng.com.my

SYK Bosch 4 Inch Fiber Sanding Disc Grinding Disc Mata Grinder Kertas Sanding Disc Vs Grinding Disc in terms of function, ceramic sanding discs can do just about anything a flap disc can do. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. Grinding discs are perhaps the most widely used abrasive discs in various industries. However, they can accomplish those. Sanding Disc Vs Grinding Disc.

From www.youtube.com

Make An Angle Grinder Sanding Disc Sanding Attachment YouTube Sanding Disc Vs Grinding Disc flap discs vs grinding wheels: However, they can accomplish those jobs without risking overheating due to their ceramic construction. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Flap discs are capable of. Hook and loop sanding discs are made up of abrasive coated cloth,. in terms of function,. Sanding Disc Vs Grinding Disc.

From mundakawg.com

Sanding Disc, Aluminum Oxide Flap Disc, Grinding Wheel 41/2" x 7/8" 6 Sanding Disc Vs Grinding Disc Flap discs are capable of. in terms of function, ceramic sanding discs can do just about anything a flap disc can do. flap discs vs grinding wheels: They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. grinding wheels are most commonly used for various grinding, abrasive cutting,. Sanding Disc Vs Grinding Disc.

From exoirnoqr.blob.core.windows.net

Sanding Discs Use at Lynn Barton blog Sanding Disc Vs Grinding Disc They are designed for grinding and shaping metals,. They are made by overlapping strips of coarse abrasive sandpaper (flaps) over one another, fanning out around the disc. Grinding discs are perhaps the most widely used abrasive discs in various industries. Flap discs are capable of. However, they can accomplish those jobs without risking overheating due to their ceramic construction. . Sanding Disc Vs Grinding Disc.

From www.empireabrasives.com

Choosing the Right Sanding Disc Empire Abrasives Sanding Disc Vs Grinding Disc However, they can accomplish those jobs without risking overheating due to their ceramic construction. They are designed for grinding and shaping metals,. Hook and loop sanding discs are made up of abrasive coated cloth,. grinding wheels are most commonly used for various grinding, abrasive cutting, and machining jobs, while flap discs are used to conform. in terms of. Sanding Disc Vs Grinding Disc.

From www.amazon.ae

KEILEOHO 90 PCS 2 Inch Sanding Discs Set, Die Grinder Sanding Disc with Sanding Disc Vs Grinding Disc They are designed for grinding and shaping metals,. Flap discs are capable of. flap discs are a cross between a grinding disc and a sanding disc with plenty of benefits. Better yet, many modern ceramic sanding discs carry a higher sanding capacity than their metal counterparts, making them as efficient as they are durable. They are made by overlapping. Sanding Disc Vs Grinding Disc.